News

Tesla Model 3 modules are comparable to F-35 flight controller, says expert

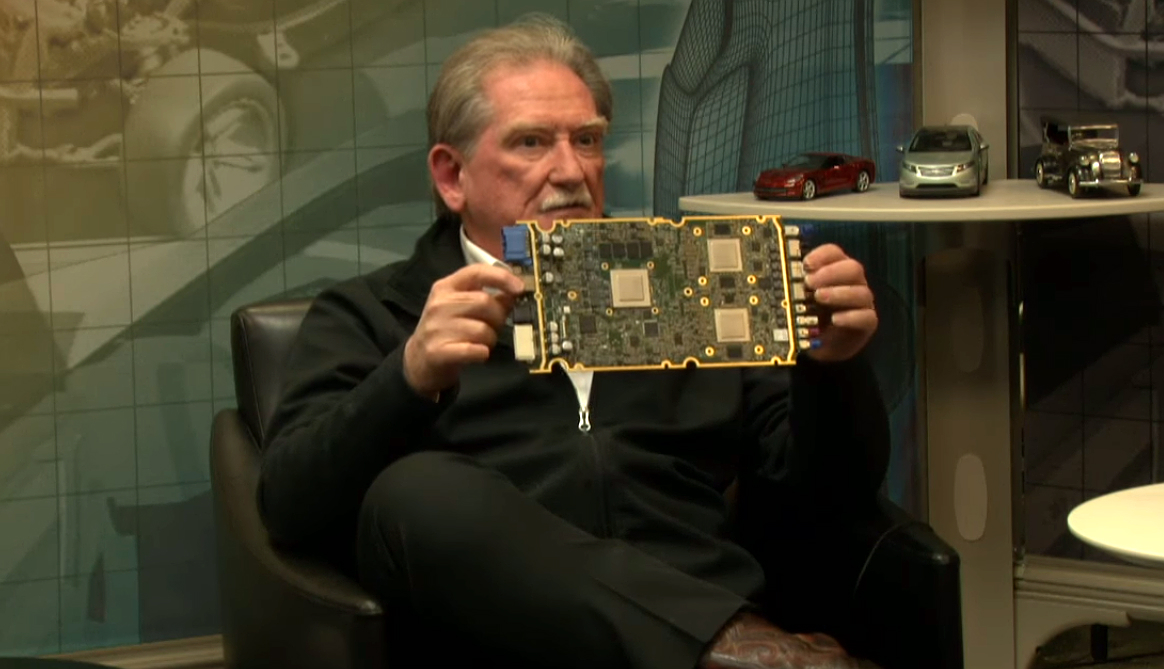

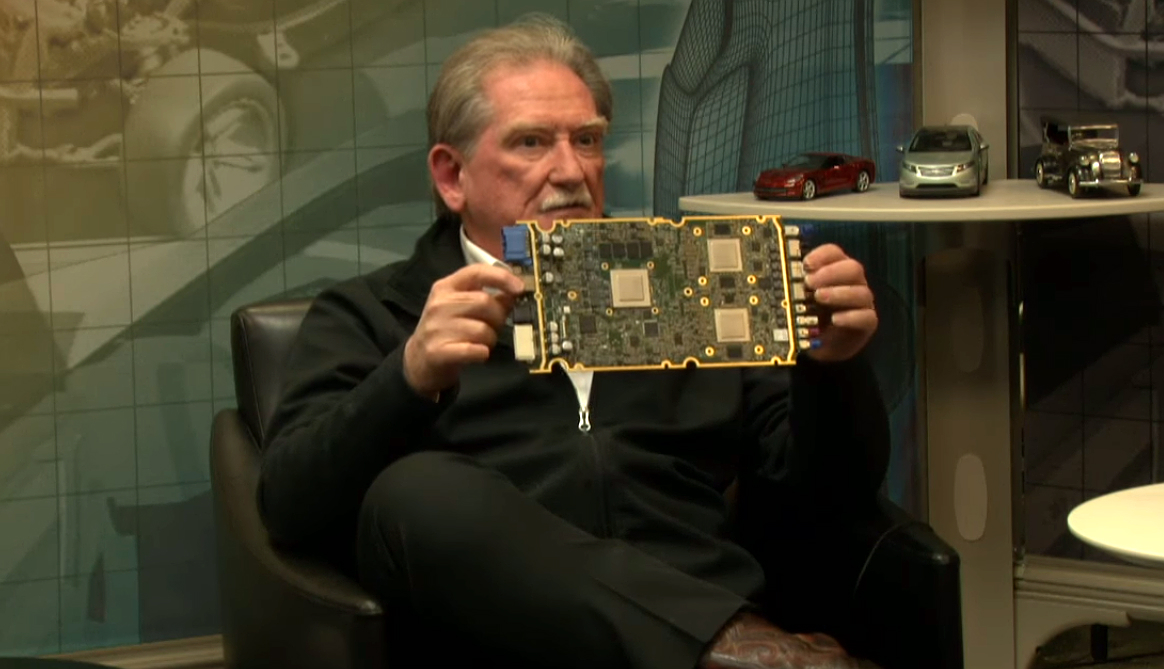

Tesla Model 3 critic and Detroit veteran Sandy Munro discussed much of the results of his company’s teardown of the electric car in a recent episode of Autoline After Hours. In a lengthy discussion with the network’s panel, Munro explained what he liked about electric car, even gushing at one point and saying that the Model 3 electronics are comparable to a flight controller found on the Lockheed Martin F-35 Lightning II stealth multirole fighter.

In his most recent Autoline interview, Munro noted that his team is almost finished with its analysis and teardown of the electric car. While the Detroit veteran still maintained that he doesn’t have much good to say about the vehicle’s mechanical components, the Model 3’s electronics, battery, and suspension are a completely different matter.

According to Munro, the Model 3’s Automatic Drive Modules are a class above the industry, featuring a design architecture that is usually found on high-end electronics and government-grade machines. Munro even compared the Model 3’s drive module to the flight controller of the F-35, which he is familiar with due to his company’s work for the US military.

“If you look at this thing, this is cellphone technology. This is the technology we would see in really high-end computers, normally for the government. When you look at this, you’re looking at the same kind of technology you’d see on a flight controller for an F-35, and we kind of know a little bit about that too. We do work for the military. Everything here smacks of cellphone technology and defense technology,” Munro said.

The Detroit veteran further stated that Tesla could very well be the leader in battery tech today. According to Munro, prior to tearing down the Model 3, he believed that LG’s battery modules used in the Chevy Bolt EV are the best in the industry. Tesla’s batteries, however, are on a completely new level. Munro was particularly impressed with the differential between each one of the Model 3’s battery blocks.

“We went through there, and the difference was .2 milliamps. Holy, nobody can balance batteries that close. Nobody. Nobody’s ever done that,” Munro said.

Apart from the Model 3’s battery and its electronics, Munro also noted that the suspension for the Model 3 was excellent. The teardown specialist went so far as to state that the person who designed the car’s suspension could easily be an “F1 prince.”

A close-up of the Automatic Drive Module of the Tesla Model 3. [Credit: Autoline Network/YouTube]

“Dr. Jekyll and Mr. Hyde, that’s where they are. And that’s the good thing for the auto industry because if it would have just been a normal car from the mechanical side, from, like I say, the dinosaur technologies; if it came out decent with all the other stuff, they’d mop the floor with everybody,” he said.

Overall, Munro ultimately concluded that the Model 3 is a car that the industry should not dismiss, and that anyone in the automotive business who chooses to ignore Tesla’s progress is doing so at their own peril.

“Anybody that doesn’t look at the electronics on the Tesla (Model) 3 is out of his mind. They’re in peril. This is not some Mickey Mouse outfit that you can just dismiss. Anybody that’s in the car industry that ignores this car is doing it at their own peril,” Munro said.

“This is big stuff. This is not inching up. This is revolutionary, and everybody else is sitting there twiddling their thumbs.”

Sandy Munro is the CEO of Munro & Associates, a company specializing in vehicle teardowns and analysis. Previously featured in two of Autoline’s YouTube segments about the Model 3, Munro took a very critical stance on the electric car’s build quality, calling the Model 3 a “miserable job” and admitting that he “hated” some of the vehicle’s design elements. In a later video about the Model 3’s ride and drive, however, Munro admitted that while the vehicle’s fit and finish were horrible, its handling and performance were great.

Watch Autoline After Hours’ episode featuring Sandy Munro and the general results of his company’s Model 3 teardown in the video below.

News

Tesla Megapacks arrive for massive battery replacing coal plant

Tesla Megapacks have started arriving on-site to the Stanwell Battery Project, just as Queensland prepares to wind down the Stanwell coal plant.

The first of over 300 Tesla Megapacks have arrived to the site of a massive battery energy storage system (BESS) being built in Australia, dubbed the Stanwell Battery Project after a coal plant it’s set to replace.

In a press release last week, the Stanwell Battery Project announced that the first Tesla Megapack 2XL units had arrived to the site, which is located outside of Rockhampton in Queensland, Australia. The project will eventually feature 324 Megapack units, set to arrive in the coming months, in order to support the 300MW/1,200MWh battery project.

“The Stanwell Battery is part of the diversification of our portfolio, to include cleaner and more flexible energy solutions,” said Angie Zahra, Stanwell Central Generation General Manager. “It is just one part of the 800 MW of battery energy storage capacity we have in our pipeline.

“Capable of discharging 300 MW of energy for up to four hours (1,200 MWh), our mega battery will be one of the largest in Queensland.”

Credit: Stanwell

Did you know Tesla’s Lathrop facility churns out a Megapack every 68 minutes? That’s enough energy to power 3,600 homes for an hour per unit! ⚡️ pic.twitter.com/bG6fpHkB9O

— TESLARATI (@Teslarati) June 11, 2025

READ MORE ON TESLA MEGAPACKS: Tesla Lathrop Megafactory celebrates massive Megapack battery milestone

The state is working with government-owned company Yurika to facilitate construction, and the process is expected to create roughly 80 jobs. The project is expected to come fully online in May 2027, with initial commissioning of the Megapacks aiming for November 2025.

The Stanwell Battery is set to replace the nearby Stanwell coal generation plant, which the government is planning to wind down starting in 2026 as part of efforts to reach an 80 percent renewable energy generation ratio by 2035. Meanwhile, the government is also set to begin winding down the Tarong and Callide coal plants, while several other Megapack projects are being built or coming online. o ya

Tesla currently has two Megapack production facilities, located in Lathrop, California, in the U.S. and another that came online earlier this year in Shanghai, China. The Shanghai Megafactory shipped its first units to Australia in March, while both factories are expected to be capable of producing 10,000 Megapack units per year upon reaching volume production.

News

The Tesla Diner is basically finished—here’s what it looks like

The company first broke ground on the Diner, Drive-in, and Supercharger location in September 2023. Now, it has served one of its first internal customers.

Tesla has finally completed the construction of its highly anticipated Diner, Drive-in, and Supercharger in Los Angeles, and recent photos of the interior’s “retro-futuristic” style are making their way around the internet.

X user Brad Goldberg shared photos from the Tesla Diner site last Tuesday, depicting some of the Supercharger stalls, indoor and outdoor seating areas, multiple neon lights, and even an Optimus robot. Goldberg also noted that there had been a “flurry of activity on site” while he was snapping the photos last week, suggesting that the restaurant location could be getting close to opening.

The Tesla Diner also served one of its first internal customers in the past few days, as Elon Musk posted on X on early Monday morning that he had just finished up eating a meal at the site:

I just had dinner at the retro-futuristic Tesla diner and Supercharger.

Team did great work making it one of the coolest spots in LA!

The photos also show that the site is pretty much done, with some of them even showing vehicles charging at the charging stalls.

You can see some of the latest photos of the Tesla Diner below.

Credit: BradGoldbergMD | X

Credit: BradGoldbergMD | X

Credit: BradGoldbergMD | X

Credit: BradGoldbergMD | X

Credit: TeslaKing420 | X

Credit: TeslaKing420 | X

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

READ MORE ON TESLA’S LA DINER: Tesla readies Drive-In Diner Supercharger for launch with app inclusion

When will the Tesla Diner open to external customers?

While it’s still not open to external customers yet, the news again suggests that the company could be close to an official opening date. Tesla first broke ground on the Diner in September 2023, after receiving a wave of building permit approvals throughout that year. Teslarati also covered much of the construction progress throughout last year, including when crews installed the first and second drive-in screens.

Located at 7001 West Santa Monica Boulevard, the idea was first discussed in 2018 by Musk and a few others on Twitter, featuring 1950s rock and roll, waiters on roller skates, and drive-in movie theater screens playing clips from some of history’s best movies. Notably, the photos of the front doors also show that the site will be open 24 hours a day, 7 days a week, whenever it does end up opening.

Tesla’s progress on Supercharger with diner, drive-in seen in aerial footage

Elon Musk

Tesla updates Robotaxi app with several big changes, including wider service area

Tesla’s Robotaxi app has gotten another update, and this time it offers a wider service area, but there are a lot of other changes, too.

Tesla is rolling out its second update to its Robotaxi app after it launched the driverless ride-hailing service less than a month ago in Austin.

Among the changes, Tesla has expanded its service area, added walking directions to both the pickup and dropoff areas, added closing times for dropoff destinations, and allowed editing of your destination after booking a ride.

The new app version, Robotaxi 25.7.5, was rolled out on Monday morning. The biggest change is the near doubling of the service area, as Tesla expanded the possible travel region by a significant margin:

Tesla’s Robotaxi geofence in Austin grows, and its shape is hard to ignore

It’s no surprise Tesla decided to push the envelope with a new, interesting shape to the geofenced area that is hard to ignore.

The new region includes notable points of interest in Austin, most notably is the University of Texas at Austin. Tesla included the school, which has over 53,000 students, in this expansion, and it could be pushing the app and service to some of them in the coming weeks.

It’s a great addition as it is a highly concentrated area of the city, full of students and visitors.

Robotaxi app changes outside of new service area

Tesla has also added a handful of new changes. With its first update of the Robotaxi app, Tesla addressed several highly requested changes, including the ability to adjust the pickup location instead of being fixed to a default spot.

Walking Directions to Pickup and Destination

In congested and large metro areas, ride-sharing pickups are sometimes confusing to navigate to. When it comes to dropoff at your destination, exiting the vehicle at the front door is not always possible (many in Austin noticed this at Terry Black’s BBQ).

Tesla Robotaxi’s biggest challenge seems to be this one thing

Now, the app will guide you on how to reach your Robotaxi and your destination when pickup and dropoff are not available at the entrances of the establishments you’re visiting.

Search Results now show closing times

If you’re going to arrive at an establishment close to its closing time, the Robotaxi app will now warn you that you could arrive with only a few minutes to spare, or you could miss it altogether.

This is a nice touch because there’s nothing worse than craving some ice cream at 10 p.m., only to arrive and see the doors are locked and the lights are off.

Many navigation apps have this integrated to eliminate any confusion about closing times.

Destination editing after booking

This feature could go hand-in-hand with the closing times. As a business might close shortly after your arrival, you might find it advantageous to visit another establishment that has more time to serve you.

You can now pivot your destination after you have entered your Roobtaxi.

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News2 days ago

News2 days agoTesla debuts hands-free Grok AI with update 2025.26: What you need to know

-

Elon Musk4 days ago

Elon Musk4 days agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

Elon Musk6 days ago

Elon Musk6 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News1 week ago

News1 week agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI’s Memphis data center receives air permit despite community criticism

-

News4 days ago

News4 days agoTesla begins Robotaxi certification push in Arizona: report

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla scrambles after Musk sidekick exit, CEO takes over sales