News

Tesla tinkering with Speed Profiles on FSD v14.2.1 has gone too far

Tesla recently released Full Self-Driving (FSD) v14.2.1, its latest version, but the tinkering with Speed Profiles has perhaps gone too far.

We try to keep it as real as possible with Full Self-Driving operation, and we are well aware that with the new versions, some things get better, but others get worse. It is all part of the process with FSD, and refinements are usually available within a week or so.

However, the latest v14.2.1 update has brought out some major complaints with Speed Profiles, at least on my end. It seems the adjustments have gone a tad too far, and there is a sizeable gap between Profiles that are next to one another.

Tesla FSD v14.2.1 first impressions:

✅ Smooth, stress-free highway operation

✅ Speed Profiles are refined — Hurry seems to be limited to 10 MPH over on highways. Switching from Mad Max to Hurry results in an abrupt braking pattern. Nothing of concern but do feel as if Speed…— TESLARATI (@Teslarati) November 29, 2025

The gap is so large that changing between them presents a bit of an unwelcome and drastic reduction in speed, which is perhaps a tad too fast for my liking. Additionally, Speed Profiles seem to have a set Speed Limit offset, which makes it less functional in live traffic situations.

Before I go any further, I’d like to remind everyone reading this that what I am about to write is purely my opinion; it is not right or wrong, or how everyone might feel. I am well aware that driving behaviors are widely subjective; what is acceptable to one might be unacceptable to another.

Speed Profiles are ‘Set’ to a Speed

From what I’ve experienced on v14.2.1, Tesla has chosen to go with somewhat of a preset max speed for each Speed Profile. With ‘Hurry,’ it appears to be 10 MPH over the speed limit, and it will not go even a single MPH faster than that. In a 55 MPH zone, it will only travel 65 MPH. Meanwhile, ‘Standard’ seems to be fixed at between 4-5 MPH over.

This is sort of a tough thing to have fixed, in my opinion. The speed at which the car travels should not be fixed; it should be more dependent on how traffic around it is traveling.

It almost seems as if the Speed Profile chosen should be more of a Behavior Profile. Standard should perform passes only to traffic that is slower than the traffic. If traffic is traveling at 75 MPH in a 65 MPH zone, the car should travel at 75 MPH. It should pass traffic that travels slower than this.

Hurry should be more willing to overtake cars, travel more than 10 MPH over the limit, and act as if someone is in a hurry to get somewhere, hence the name. Setting strict limits on how fast it will travel seems to be a real damper on its capabilities. It did much better in previous versions.

Some Speed Profiles are Too Distant from Others

This is specifically about Hurry and Mad Max, which are neighbors in the Speed Profiles menu. Hurry will only go 10 MPH over the limit, but Mad Max will travel similarly to traffic around it. I’ve seen some people say Mad Max is too slow, but I have not had that opinion when using it.

In a 55 MPH zone during Black Friday and Small Business Saturday, it is not unusual for traffic around me to travel in the low to mid-80s. Mad Max was very suitable for some traffic situations yesterday, especially as cars were traveling very fast. However, sometimes it required me to “gear down” into Hurry, especially as, at times, it would try to pass slower traffic in the right lane, a move I’m not super fond of.

We had some readers also mention this to us:

The abrupt speed reduction when switching to a slower speed profile is definitely an issue that should be improved upon.

— David Klem (@daklem) November 29, 2025

After switching from Mad Max to Hurry, there is a very abrupt drop in speed. It is not violent by any means, but it does shift your body forward, and it seems as if it is a tad drastic and could be refined further.

News

Tesla Cybercab spotted with interesting charging solution, stimulating discussion

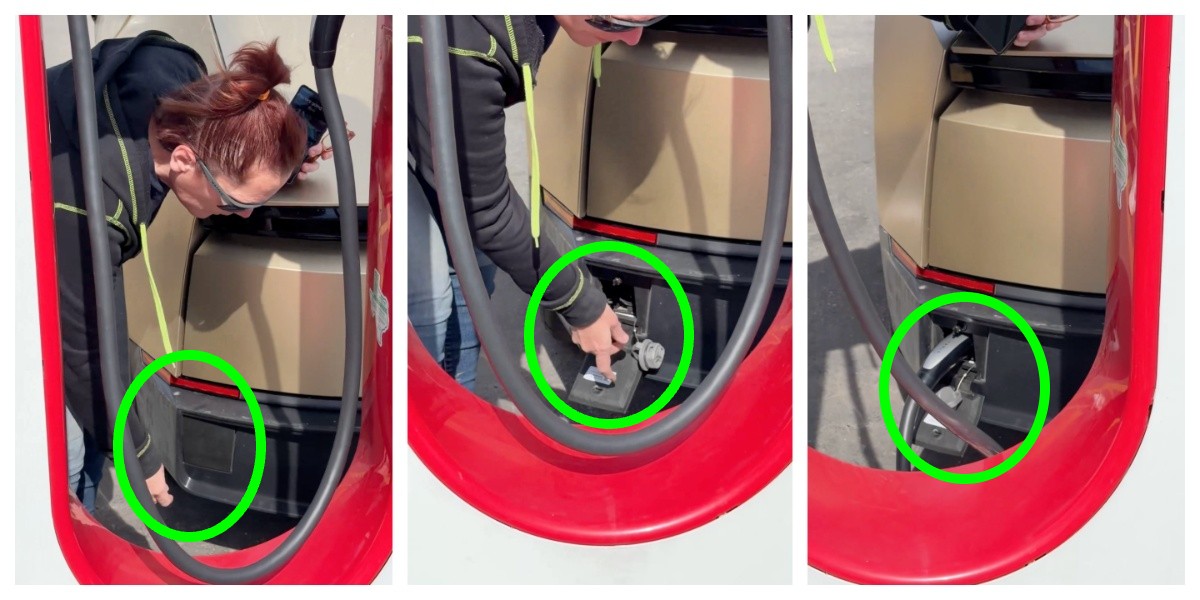

The port is located in the rear of the vehicle and features a manual door and latch for plug-in, and the video shows an employee connecting to a Tesla Supercharger.

Tesla Cybercab units are being tested publicly on roads throughout various areas of the United States, and a recent sighting of the vehicle’s charging port has certainly stimulated some discussions throughout the community.

The Cybercab is geared toward being a fully-autonomous vehicle, void of a steering wheel or pedals, only operating with the use of the Full Self-Driving suite. Everything from the driving itself to the charging to the cleaning is intended to be operated autonomously.

But a recent sighting of the vehicle has incited some speculation as to whether the vehicle might have some manual features, which would make sense, but let’s take a look:

🚨 Tesla Cybercab charging port is in the rear of the vehicle!

Here’s a great look at plugging it in!!

— TESLARATI (@Teslarati) January 29, 2026

The port is located in the rear of the vehicle and features a manual door and latch for plug-in, and the video shows an employee connecting to a Tesla Supercharger.

Now, it is important to remember these are prototype vehicles, and not the final product. Additionally, Tesla has said it plans to introduce wireless induction charging in the future, but it is not currently available, so these units need to have some ability to charge.

However, there are some arguments for a charging system like this, especially as the operation of the Cybercab begins after production starts, which is scheduled for April.

Wireless for Operation, Wired for Downtime

It seems ideal to use induction charging when the Cybercab is in operation. As it is for most Tesla owners taking roadtrips, Supercharging stops are only a few minutes long for the most part.

The Cybercab would benefit from more frequent Supercharging stops in between rides while it is operating a ride-sharing program.

Tesla wireless charging patent revealed ahead of Robotaxi unveiling event

However, when the vehicle rolls back to its hub for cleaning and maintenance, standard charging, where it is plugged into a charger of some kind, seems more ideal.

In the 45-minutes that the car is being cleaned and is having maintenance, it could be fully charged and ready for another full shift of rides, grabbing a few miles of range with induction charging when it’s out and about.

Induction Charging Challenges

Induction charging is still something that presents many challenges for companies that use it for anything, including things as trivial as charging cell phones.

While it is convenient, a lot of the charge is lost during heat transfer, which is something that is common with wireless charging solutions. Even in Teslas, the wireless charging mat present in its vehicles has been a common complaint among owners, so much so that the company recently included a feature to turn them off.

Production Timing and Potential Challenges

With Tesla planning to begin Cybercab production in April, the real challenge with the induction charging is whether the company can develop an effective wireless apparatus in that short time frame.

It has been in development for several years, but solving the issue with heat and energy loss is something that is not an easy task.

In the short-term, Tesla could utilize this port for normal Supercharging operation on the Cybercab. Eventually, it could be phased out as induction charging proves to be a more effective and convenient option.

News

Tesla confirms that it finally solved its 4680 battery’s dry cathode process

The suggests the company has finally resolved one of the most challenging aspects of its next-generation battery cells.

Tesla has confirmed that it is now producing both the anode and cathode of its 4680 battery cells using a dry-electrode process, marking a key breakthrough in a technology the company has been working to industrialize for years.

The update, disclosed in Tesla’s Q4 and FY 2025 update letter, suggests the company has finally resolved one of the most challenging aspects of its next-generation battery cells.

Dry cathode 4680 cells

In its Q4 and FY 2025 update letter, Tesla stated that it is now producing 4680 cells whose anode and cathode were produced during the dry electrode process. The confirmation addresses long-standing questions around whether Tesla could bring its dry cathode process into sustained production.

The disclosure was highlighted on X by Bonne Eggleston, Tesla’s Vice President of 4680 batteries, who wrote that “both electrodes use our dry process.”

Tesla first introduced the dry-electrode concept during its Battery Day presentation in 2020, pitching it as a way to simplify production, reduce factory footprint, lower costs, and improve energy density. While Tesla has been producing 4680 cells for some time, the company had previously relied on more conventional approaches for parts of the process, leading to questions about whether a full dry-electrode process could even be achieved.

4680 packs for Model Y

Tesla also revealed in its Q4 and FY 2025 Update Letter that it has begun producing battery packs for certain Model Y vehicles using its in-house 4680 cells. As per Tesla:

“We have begun to produce battery packs for certain Model Ys with our 4680 cells, unlocking an additional vector of supply to help navigate increasingly complex supply chain challenges caused by trade barriers and tariff risks.”

The timing is notable. With Tesla preparing to wind down Model S and Model X production, the Model Y and Model 3 are expected to account for an even larger share of the company’s vehicle output. Ensuring that the Model Y can be equipped with domestically produced 4680 battery packs gives Tesla greater flexibility to maintain production volumes in the United States, even as global battery supply chains face increasing complexity.

Elon Musk

Tesla Giga Texas to feature massive Optimus V4 production line

This suggests that while the first Optimus line will be set up in the Fremont Factory, the real ramp of Optimus’ production will happen in Giga Texas.

Tesla will build Optimus 4 in Giga Texas, and its production line will be massive. This was, at least, as per recent comments by CEO Elon Musk on social media platform X.

Optimus 4 production

In response to a post on X which expressed surprise that Optimus will be produced in California, Musk stated that “Optimus 4 will be built in Texas at much higher volume.” This suggests that while the first Optimus line will be set up in the Fremont Factory, and while the line itself will be capable of producing 1 million humanoid robots per year, the real ramp of Optimus’ production will happen in Giga Texas.

This was not the first time that Elon Musk shared his plans for Optimus’ production at Gigafactory Texas. During the 2025 Annual Shareholder Meeting, he stated that Giga Texas’ Optimus line will produce 10 million units of the humanoid robot per year. He did not, however, state at the time that Giga Texas would produce Optimus V4.

“So we’re going to launch on the fastest production ramp of any product of any large complex manufactured product ever, starting with building a one-million-unit production line in Fremont. And that’s Line one. And then a ten million unit per year production line here,” Musk stated.

How big Optimus could become

During Tesla’s Q4 and FY 2025 earnings call, Musk offered additional context on the potential of Optimus. While he stated that the ramp of Optimus’ production will be deliberate at first, the humanoid robot itself will have the potential to change the world.

“Optimus really will be a general-purpose robot that can learn by observing human behavior. You can demonstrate a task or verbally describe a task or show it a task. Even show it a video, it will be able to do that task. It’s going to be a very capable robot. I think long-term Optimus will have a very significant impact on the US GDP.

“It will actually move the needle on US GDP significantly. In conclusion, there are still many who doubt our ambitions for creating amazing abundance. We are confident it can be done, and we are making the right moves technologically to ensure that it does. Tesla, Inc. has never been a company to shy away from solving the hardest problems,” Musk stated.