News

SpaceX’s BFR Mars rocket tooling makes rare appearance in LA Port tent

After nearly ten weeks hidden inside the company’s Port of Los Angeles tent, SpaceX’s main BFR manufacturing tooling made another brief appearance on July 1, showing off a new support structure and equipment that enables the entire device to spin and easily lay down layers of carbon fiber to construct the first Mars rocket prototype propellant tanks.

Based on photos taken of the large composite production equipment – known as a mandrel – in April 2018, as well as a photo released by CEO Elon Musk around the same time, it appears either that major modifications were made in the past two months or that an entirely new tool has been delivered to the dockside tent over the same period of time. Given that the shipment of the first hardware and its arrival at Port LA itself managed to slip beneath the eyes of local observers, there certainly is no reason that the same thing couldn’t be repeated. The mandrels and other production tooling SpaceX has acquired from Ascent Aerospace are likely shipped to their final destination disassembled.

- SpaceX’s first major BFR and BFS fabrication tooling, likely being stored temporarily in a tent at Port of San Pedro. Note the tent framework at the top. (Elon Musk)

- Images corroborated the location of the giant mandrel tool inside the Port of San Pedro tent, April 2018. (Pauline Acalin)

- SpaceX may well already be fabricating propellant tanks and structural components for the first Mars spaceship prototype in a giant tent at Port of San Pedro. July 1st. (Pauline Acalin)

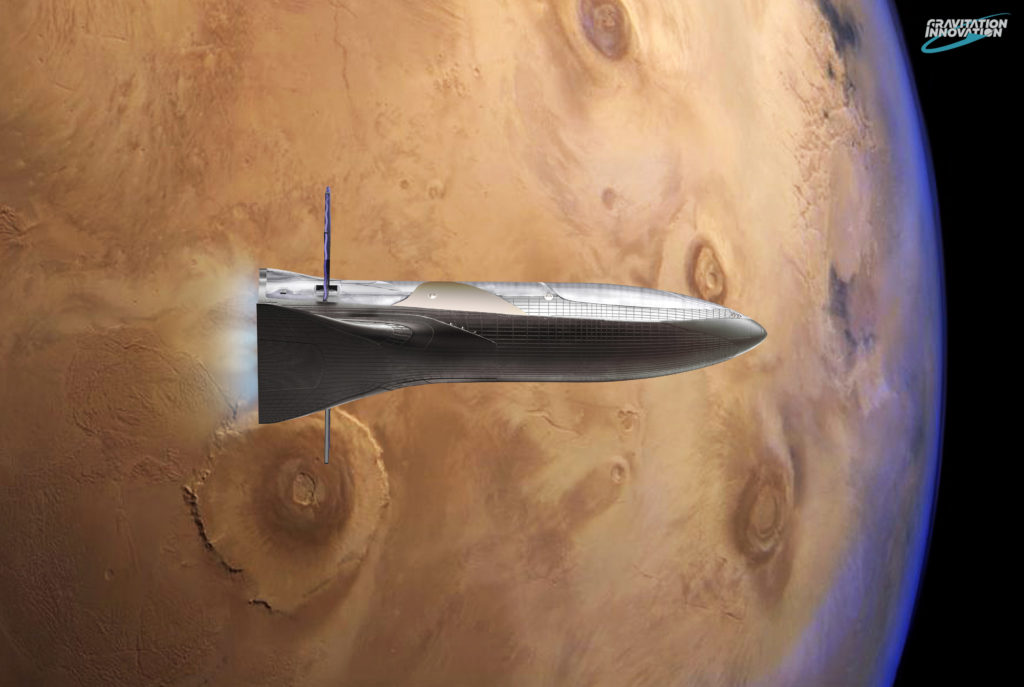

- BFR prepares for launch as the sun sets over the upgraded LC-39A, built off a concept of the future modifications included in SpaceX’s 2016 and 2017 video updates. At the request of a friend, artist David Romax put together a truly jaw-dropping collection of concept art featuring SpaceX’s BFR rocket and its Cargo and Crew spaceships. (Gravitation Innovation/David Romax)

- At the request of a friend, artist David Romax put together a truly jaw-dropping collection of concept art featuring SpaceX’s BFR rocket and its Cargo and Crew spaceships. (Gravitation Innovation/David Romax)

More relevant, however, is the probability that SpaceX will need more than a single mandrel to produce BFR ship and booster prototypes on anything faster than geological timescales. In fact, if (very) rough size estimates produced from Musk’s shared photo are correct, two (or even three) 16-meter long mandrels would almost perfectly mesh to create the Spaceship’s own massive 48-meter length, although the reality would be far more complex than a simple feat of 1+1+1 thanks to the complex front and rear shapes of the BFR upper stage.

Two mandrels would also ensure that SpaceX is able to rapidly prototype, test, and re-prototype BFR hardware while the company refines designs and moves into full-scale flight hardware production and flight testing, at least at the prototype phase. Recently, several BFR and Mars rocket-focused job postings were spotted with specific requirements related to composite-composite and composite-metal joining, a young but rapidly advancing subset of skills necessary to efficiently and economically produce massive structures primarily made up of composite materials.

- Tons of industrial equipment is now installed outside the tent, ranging from HVAC, power, and unknown fluid hookups, as well as an aerospace-grade Quincy air compressor. July 1. (Pauline Acalin)

- Unidentified tooling stored outside of the BFR tent, May 2018. These are most likely stands for completed composite parts and mold structures for composite production. (Pauline Acalin)

- April 2018. (Pauline Acalin)

Boeing’s 787 program, composed of 50% composites, is a strong example with each fuselage broken into a number of smaller segments that are later joined together with tolerances on the order of 1/5000 of an inch to avoid damage to the composite sandwich structures within. Long-lived, reliable, and resilient segmented composite structures are thus well-established as a viable solution, although Boeing is one of precious few entities able to lay claim to such mass-production successes. Ultimately, SpaceX does not need to start from scratch (even if they could, or still may) in order to successfully build the ultra-reusable Mars rocket they aspire to.

- Shown is the forward fuselage of the 787 on a mandrel for composite weaving and layup.(Boeing)

- Artist David Romax’s jaw-dropping rendition of a BFR burning to Mars orbit. The craft’s various curves and hull complexities will likely rely on cutting-edge composite joining tech to function. (Gravitation Innovation)

Follow us for live updates, peeks behind the scenes, and photos from Teslarati’s East and West Coast photographers.

Teslarati – Instagram – Twitter

Tom Cross – Twitter

Pauline Acalin – Twitter

Eric Ralph – Twitter

Elon Musk

Tesla Full Self-Driving set to get an awesome new feature, Elon Musk says

Tesla Full Self-Driving is set to get an awesome new feature in the near future, CEO Elon Musk confirmed on X.

Full Self-Driving is the company’s semi-autonomous driving program, which is among the best available to the general public. It still relies on the driver to ultimately remain in control and pay attention, but it truly does make traveling less stressful and easier.

However, Tesla still continuously refines the software through Over-the-Air updates, which are meant to resolve shortcomings in the performance of the FSD suite. Generally, Tesla does a great job of this, but some updates are definitely regressions, at least with some of the features.

Tesla Cybertruck owner credits FSD for saving life after freeway medical emergency

Tesla and Musk are always trying to improve the suite’s performance by fixing features that are presently available, but they also try to add new things that would be beneficial to owners. One of those things, which is coming soon, is giving the driver the ability to prompt FSD with voice demands.

For example, asking the car to park close to the front door of your destination, or further away in an empty portion of the parking lot, would be an extremely beneficial feature. Adjusting navigation is possible through Grok integration, but it is not always effective.

Musk confirmed that voice prompts for FSD would be possible:

Coming

— Elon Musk (@elonmusk) February 21, 2026

Tesla Full Self-Driving is a really great thing, but it definitely has its shortcomings. Navigation is among the biggest complaints that owners have, and it is easily my biggest frustration with using it. Some of the routes it chooses to take are truly mind-boggling.

Another thing it has had issues with is being situated in the correct lane at confusing intersections or even managing to properly navigate through local traffic signs. For example, in Pennsylvania, there are a lot of stop signs with “Except Right Turn” signs directly under.

This gives those turning right at a stop sign the opportunity to travel through it. FSD has had issues with this on several occasions.

Parking preferences would be highly beneficial and something that could be resolved with this voice prompt program. Grocery stores are full of carts not taken back by customers, and many people choose to park far away. Advising FSD of this preference would be a great advantage to owners.

Cybertruck

Elon Musk clarifies Tesla Cybertruck ’10 day’ comment, fans respond

Some are arguing that the decision to confirm a price hike in ten days is sort of counterproductive, especially considering it is based on demand. Giving consumers a timeline of just ten days to make a big purchase like a pickup truck for $60,000, and basically stating the price will go up, will only push people to make a reservation.

Elon Musk has clarified what he meant by his comment on X yesterday that seemed to indicate that Tesla would either do away with the new All-Wheel-Drive configuration of the Cybertruck or adjust the price.

The response was cryptic as nobody truly knew what Musk’s plans were for the newest Tesla Cybertruck trim level. We now have that answer, and fans of the company are responding in a polarizing fashion.

On Thursday night, Tesla launched the Cybertruck All-Wheel-Drive, priced competitively at $59,990. It was a vast improvement from the Rear-Wheel-Drive configuration Tesla launched last year at a similar price point, which was eventually cancelled just a few months later due to low demand.

Tesla launches new Cybertruck trim with more features than ever for a low price

However, Musk said early on Friday, “just for 10 days,” the truck would either be available or priced at $59,990. We can now confirm Tesla will adjust the price based on more recent comments from the CEO.

Musk said the price will fluctuate, but it “depends on how much demand we see at this price level.”

Depends on how much demand we see at this price level

— Elon Musk (@elonmusk) February 20, 2026

Some are defending the decision, stating that it is simply logical to see how the Cybertruck sells at this price and adjust accordingly.

Case 1: You don’t like it -> don’t buy it

Case 2 (me): You like it, it’s fits your situation and needs -> you buy it.

Case 3: Complain endlessly for no reason, you weren’t going to get one anyway, but you want people to know you’re mad, for some reason.Silly netizens.

— Ryan Scanlan 👥 (@Xenius) February 21, 2026

Others, not so much.

Alright I’m obviously not the one successful enough to be calling the shots at Tesla and worth almost a trillion dollars

But people were excited about the awesome Cybertruck news and then it got taken away, that’s why people are annoyed. The wording felt more like a threat.… pic.twitter.com/NWVNklcXoJ

— Dirty Tesla (@DirtyTesLa) February 21, 2026

No but fr wtf you doing dude???????

— Greggertruck (@greggertruck) February 20, 2026

It’s how it was communicated.

If it had been stated clearly on the website for everyone to see, everyone would be fine.— KiTT_2020 (@kitt_2020) February 20, 2026

Some are arguing that the decision to confirm a price hike in ten days is sort of counterproductive, especially considering it is based on demand. Giving consumers a timeline of just ten days to make a big purchase like a pickup truck for $60,000, and basically stating the price will go up, will only push people to make a reservation.

Demand will look strong because people want to lock in this price. The price will inevitably go up, and demand for the trim will likely fall a bit because of the increased cost.

Many are arguing Musk should have kept this detail internal, but transparency is a good policy to have. It is a polarizing move to confirm a price increase in just a week-and-a-half, but the community is obviously split on how to feel.

Cybertruck

Tesla Cybertruck’s newest trim will undergo massive change in ten days, Musk says

It appears as if the new All-Wheel-Drive trim of Cybertruck won’t be around for too long, however. Elon Musk revealed this morning that it will be around “only for the next 10 days.”

Tesla’s new Cybertruck trim has already gotten the axe from CEO Elon Musk, who said the All-Wheel-Drive configuration of the all-electric pickup will only be available “for the next ten days.”

Musk could mean the price, which is $59,990, or the availability of the trim altogether.

Last night, Tesla launched the All-Wheel-Drive configuration of the Cybertruck, a pickup that comes in at less than $60,000 and features a competitive range and features that are not far off from the offerings of the premium trim.

Tesla launches new Cybertruck trim with more features than ever for a low price

It was a nice surprise from Tesla, considering that last year, it offered a Rear-Wheel-Drive trim of the Cybertruck that only lasted a few months. It had extremely underwhelming demand because it was only $10,000 cheaper than the next trim level up, and it was missing a significant number of premium features.

Simply put, it was not worth the money. Tesla killed the RWD Cybertruck just a few months after offering it.

With the news that Tesla was offering this All-Wheel-Drive configuration of the Cybertruck, many fans and consumers were encouraged. The Cybertruck has been an underwhelming seller, and this seemed to be a lot of truck for the price when looking at its features:

- Dual Motor AWD w/ est. 325 mi of range

- Powered tonneau cover

- Bed outlets (2x 120V + 1x 240V) & Powershare capability

- Coil springs w/ adaptive damping

- Heated first-row seats w/ textile material that is easy to clean

- Steer-by-wire & Four Wheel Steering

- 6’ x 4’ composite bed

- Towing capacity of up to 7,500 lbs

- Powered frunk

It appears as if this trim of Cybertruck won’t be around for too long, however. Musk revealed this morning that it will be around “only for the next 10 days.”

Only for the next 10 days https://t.co/82JnvZQGh2

— Elon Musk (@elonmusk) February 20, 2026

Musk could mean the price of the truck and not necessarily the ability to order it. However, most are taking it as a cancellation.

If it is, in fact, a short-term availability decision, it is baffling, especially as Tesla fans and analysts claim that metrics like quarterly deliveries are no longer important. This seems like a way to boost sales short-term, and if so many people are encouraged about this offering, why would it be kept around for such a short period of time?

Some are even considering the potential that Tesla axes the Cybertruck program as a whole. Although Musk said during the recent Q4 Earnings Call that Cybertruck would still be produced, the end of the Model S and Model X programs indicates Tesla might be prepared to do away with any low-volume vehicles that do not contribute to the company’s future visions of autonomy.

The decision to axe the car just ten days after making it available seems like a true head-scratcher.