News

Ex-SpaceX engineer leads Stratolaunch to major rocket engine test milestone

Led by rocket propulsion expert Jeff Thornburg, Stratolaunch – famous for owning the largest fixed-wing aircraft ever built – has completed the first hot-fire test of a full-scale rocket engine component known as the preburner, a major milestone in the development of any launch vehicle or propulsion system.

Despite the significant size and power of the component, destined to support an engine that will generate 200,000 pounds (~900 kN) of thrust, Thornburg and his team of engineers and technicians have managed to go from designing the preburner to successfully hot-firing a full-scale test article, an extraordinary achievement by any measure.

The team made amazing progress this week! Check out the #PGAEngine preburner’s first hot-fire test at @NASAStennis. #NewUSEngine pic.twitter.com/kKTnf0bj1S

— Stratolaunch (@Stratolaunch) November 6, 2018

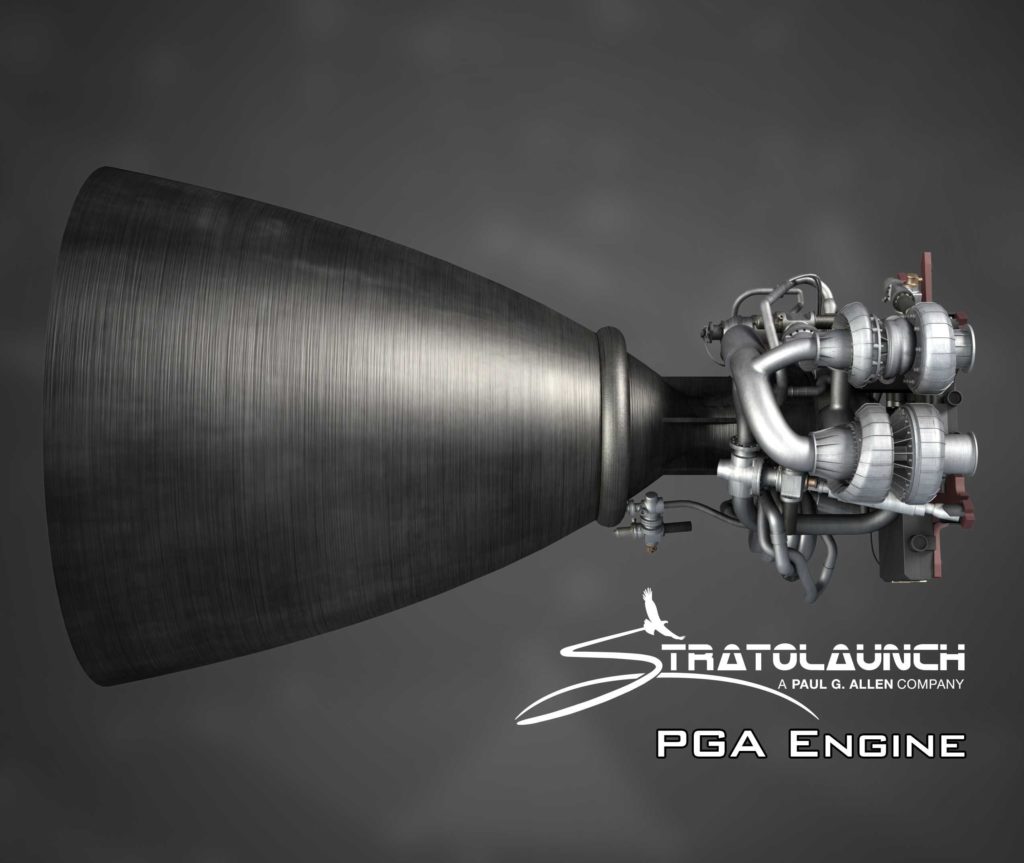

Aside from SpaceX, Blue Origin, and Aerojet-Rocketdyne, Stratolaunch is the only private entity developing – let alone testing full-scale parts for – a liquid-fueled rocket engine as large as PGA. Shorthand for the Stratolaunch’s late founder and bankroller Paul G. Allen, PGA is a fuel-rich staged combustion cycle engine that uses liquid hydrogen and oxygen (hydrolox) fuel and oxidizer, typically resulting in high efficiency. In terms of scale and thrust, PGA is very closely comparable to SpaceX’s Merlin 1D engine, which uses kerosene instead of hydrogen but produces roughly 190,000 lbf (850 kN) of thrust and stands 4 feet (1.2m) wide and ~10 feet (~3m) tall.

Another major difference between PGA and Merlin 1D is the fact Merlin 1D’s nozzle is largely optimized for sea level while PGA is being built for a rocket that will be “launched” from a massive plane flying around 35,000 feet (~10.5 km), ultimately resulting in a nozzle that is much wider and longer, featuring nearly the same proportions as fully vacuum-optimized engines like SpaceX’s MVac. By widening the nozzle relative to the rest of the engine, rocket engines are able to operate far more efficiently at higher altitudes, where Earth’s atmosphere thins and exerts less pressure on the escaping exhaust gases. This is visualized well by the visible expansion of rocket exhausts during launches, morphing from a straight cylinder to a massive teardrop-shaped plume. At lower altitudes (and thus higher atmospheric pressures), wider nozzles can produce extreme turbulence and will ultimately shake themselves to destruction, preventing their usage on ground-launched rocket boosters.

Judging from official renders of the engine, PGA’s in-atmosphere variant appears to utilize a form of regenerative nozzle cooling very similar to that used on M1D, where liquid propellant flows through thin capillaries sandwiched between two or more layers of metal to cool the nozzle much like cold water chills the skin of an uninsulated water bottle.

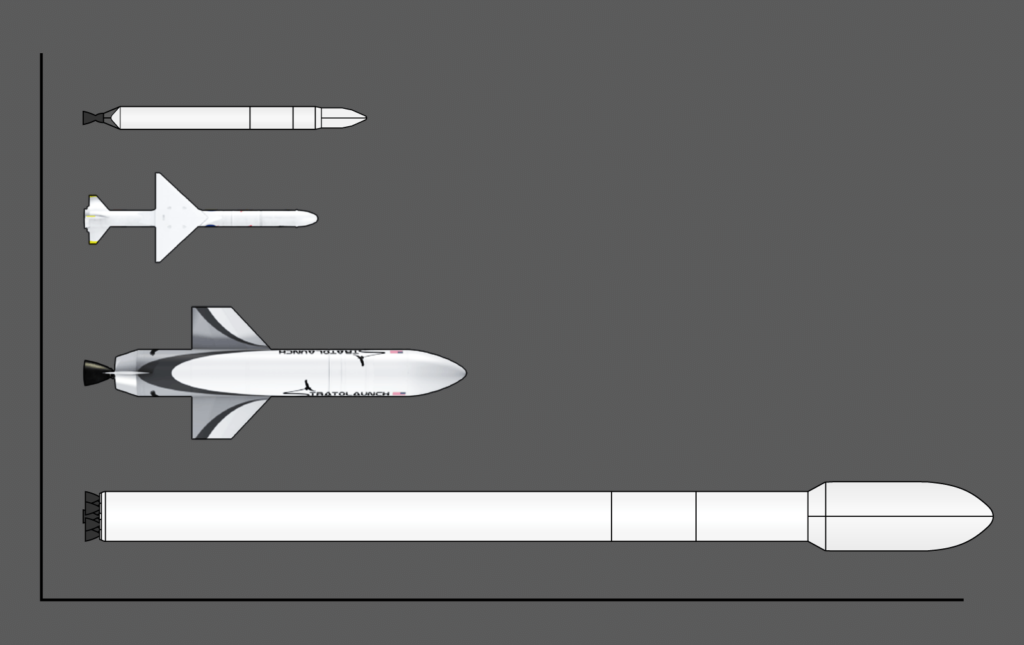

- A to-scale comparison of Falcon 1, Pegasus XL, MLV, and Falcon 9. (Teslarati/Stratolaunch/Wikipedia)

- A render of Stratolaunch’s impressive PGA engine. Note the giant nozzle relative to the throat. (Stratolaunch)

Testing rocket engine preburners

In the case of staged combustion cycle hydrolox rocket engines, a small portion of liquid oxygen and all of the liquid hydrogen (hence “fuel-rich”) are mixed and combusted to generate hot gas that then spools up the engine’s primary turbopump(s), ultimately drawing fuel and oxidizer into the combustion quickly enough to ignite the engine and generate sustained thrust. The components that get those main turbopumps started are known collectively as the preburner, which is what Stratolaunch successfully tested – at full-scale – for the first time ever last week. For any liquid rocket engine that cannot solely rely on propellant tank pressure to deliver fuel to the combustion chamber, full-scale tests of preburners or gas-generators effectively mark the moment that engines truly become real.

“This is the first step in proving the performance and highly efficient design of the PGA engine. The hot-fire test is an incredible milestone for both the propulsion team and Stratolaunch.” – Jeff Thornburg, VP of Propulsion, Stratolaunch

Stratolaunch’s propulsion team will continue to test the preburner for longer durations and at higher power levels over the next several months, likely optimizing operations and tweaking or upgrading the preburner’s hardware as real tests produce valuable lessons-learned. Built entirely with additive manufacturing (3D printing), the team should be able to rapidly iterate on the physical design of the engine, a rarity in a field where traditional fabrication methods can take weeks or months to produce complex turbomachinery components with mercilessly strict tolerances.

According to Thornburg, the ultimate goal is to continue that additive-manufacturing-only strategy throughout the development of this rocket engine, theoretically enabling unprecedented design flexibility while also slashing production time throughout. PGA will ultimately power the creatively-named Medium Launch Vehicle (MLV), a small-ish air-launched rocket designed to place a respectable 3400 kg into low Earth orbit (LEO) as early as 2022, as well as a Heavy version of MLV and, potentially, a reusable spaceplane somewhere down the line.

- PGA’s first full-scale preburner seen during assembly. (Stratolaunch)

- PGA’s first full-scale preburner seen during assembly. (Stratolaunch)

- Jeff Thornburg stands in front of Stratolaunch’s NASA Stennis Space Center test stand. (Stratolaunch)

- The PGA preburner seen after installation at Stennis. (Stratolaunch)

- The control center. (Stratolaunch)

- MLV is released from Stratolauncher. (Stratolaunch)

- A concept video produced by Stratolaunch shows the Roc launching a Kraken rocket. (Stratolaunch, via Wired)

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!

News

Tesla China January wholesale sales rise 9% year-on-year

Tesla reported January wholesale sales of 69,129 China-made vehicles, as per data released by the China Passenger Car Association.

Tesla China reported January wholesale sales of 69,129 Giga Shanghai-made vehicles, as per data released by the China Passenger Car Association (CPCA). The figure includes both domestic sales and exports from Gigafactory Shanghai.

The total represented a 9.32% increase from January last year but a 28.86% decline from December’s 97,171 units.

China EV market trends

The CPCA estimated that China’s passenger new energy vehicle wholesale volume reached about 900,000 units in January, up 1% year-on-year but down 42% from December. Demand has been pressured by the start-of-year slow season, a 5% additional purchase tax cost, and uncertainty around the transition of vehicle trade-in subsidies, as noted in a report from CNEV Post.

Market leader BYD sold 210,051 NEVs in January, down 30.11% year-on-year and 50.04% month-on-month, as per data released on February 1. Tesla China’s year-over-year growth then is quite interesting, as the company’s vehicles seem to be selling very well despite headwinds in the market.

Tesla China’s strategies

To counter weaker seasonal demand, Tesla China launched a low-interest financing program on January 6, offering up to seven-year terms on select produced vehicles. The move marked the first time an automaker offered financing of that length in the Chinese market.

Several rivals, including Xiaomi, Li Auto, XPeng, and NIO, later introduced similar incentives. Tesla China then further increased promotions on January 26 by reinstating insurance subsidies for the Model 3 sedan. The CPCA is expected to release Tesla’s China retail sales and export breakdown later this month.

News

Tesla’s Apple CarPlay ambitions are not dead, they’re still in the works

For what it’s worth, as a Tesla owner, I don’t particularly see the need for CarPlay, as I have found the in-car system that the company has developed to be superior. However, many people are in love with CarPlay simply because, when it’s in a car that is capable, it is really great.

Tesla’s Apple CarPlay ambitions appeared to be dead in the water after a large amount of speculation late last year that the company would add the user interface seemed to cool down after several weeks of reports.

However, it appears that CarPlay might make its way to Tesla vehicles after all, as a recent report seems to indicate that it is still being worked on by software teams for the company.

The real question is whether it is truly needed or if it is just a want by so many owners that Tesla is listening and deciding to proceed with its development.

Back in November, Bloomberg reported that Tesla was in the process of testing Apple CarPlay within its vehicles, which was a major development considering the company had resisted adopting UIs outside of its own for many years.

Nearly one-third of car buyers considered the lack of CarPlay as a deal-breaker when buying their cars, a study from McKinsey & Co. outlined. This could be a driving decision in Tesla’s inability to abandon the development of CarPlay in its vehicles, especially as it lost a major advantage that appealed to consumers last year: the $7,500 EV tax credit.

Tesla owners propose interesting theory about Apple CarPlay and EV tax credit

Although we saw little to no movement on it since the November speculation, Tesla is now reportedly in the process of still developing the user interface. Mark Gurman, a Bloomberg writer with a weekly newsletter, stated that CarPlay is “still in the works” at Tesla and that more concrete information will be available “soon” regarding its development.

While Tesla already has a very capable and widely accepted user interface, CarPlay would still be an advantage, considering many people have used it in their vehicles for years. Just like smartphones, many people get comfortable with an operating system or style and are resistant to using a new one. This could be a big reason for Tesla attempting to get it in their own cars.

Tesla gets updated “Apple CarPlay” hack that can work on new models

For what it’s worth, as a Tesla owner, I don’t particularly see the need for CarPlay, as I have found the in-car system that the company has developed to be superior. However, many people are in love with CarPlay simply because, when it’s in a car that is capable, it is really great.

It holds one distinct advantage over Tesla’s UI in my opinion, and that’s the ability to read and respond to text messages, which is something that is available within a Tesla, but is not as user-friendly.

With that being said, I would still give CarPlay a shot in my Tesla. I didn’t particularly enjoy it in my Bronco Sport, but that was because Ford’s software was a bit laggy with it. If it were as smooth as Tesla’s UI, which I think it would be, it could be a really great addition to the vehicle.

News

Tesla brings closure to Model Y moniker with launch of new trim level

With the launch of a new trim level for the Model Y last night, something almost went unnoticed — the loss of a moniker that Tesla just recently added to a couple of its variants of the all-electric crossover.

Tesla launched the Model Y All-Wheel-Drive last night, competitively priced at $41,990, but void of the luxurious features that are available within the Premium trims.

Upon examination of the car, one thing was missing, and it was noticeable: Tesla dropped the use of the “Standard” moniker to identify its entry-level offerings of the Model Y.

The Standard Model Y vehicles were introduced late last year, primarily to lower the entry price after the U.S. EV tax credit changes were made. Tesla stripped some features like the panoramic glass roof, premium audio, ambient lighting, acoustic-lined glass, and some of the storage.

Last night, it simply switched the configurations away from “Standard” and simply as the Model Y Rear-Wheel-Drive and Model Y All-Wheel-Drive.

There are three plausible reasons for this move, and while it is minor, there must be an answer for why Tesla chose to abandon the name, yet keep the “Premium” in its upper-level offerings.

“Standard” carried a negative connotation in marketing

Words like “Standard” can subtly imply “basic,” “bare-bones,” or “cheap” to consumers, especially when directly contrasted with “Premium” on the configurator or website. Dropping it avoids making the entry-level Model Y feel inferior or low-end, even though it’s designed for affordability.

Tesla likely wanted the base trim to sound neutral and spec-focused (e.g., just “RWD” highlights drivetrain rather than feature level), while “Premium” continues to signal desirable upgrades, encouraging upsells to higher-margin variants.

Simplifying the overall naming structure for less confusion

The initial “Standard vs. Premium” split (plus Performance) created a somewhat clunky hierarchy, especially as Tesla added more variants like Standard Long Range in some markets or the new AWD base.

Removing “Standard” streamlines things to a more straightforward progression (RWD → AWD → Premium RWD/AWD → Performance), making the lineup easier to understand at a glance. This aligns with Tesla’s history of iterative naming tweaks to reduce buyer hesitation.

Elevating brand perception and protecting perceived value

Keeping “Premium” reinforces that the bulk of the Model Y lineup (especially the popular Long Range models) remains a premium product with desirable features like better noise insulation, upgraded interiors, and tech.

Eliminating “Standard” prevents any dilution of the Tesla brand’s upscale image—particularly important in a competitive EV market—while the entry-level variants can quietly exist as accessible “RWD/AWD” options without drawing attention to them being decontented versions.

You can check out the differences between the “Standard” and “Premium” Model Y vehicles below:

@teslarati There are some BIG differences between the Tesla Model Y Standard and Tesla Model Y Premium #tesla #teslamodely ♬ Sia – Xeptemper