News

SpaceX gets ready to fire up Falcon Heavy for the first time at Cape Canaveral

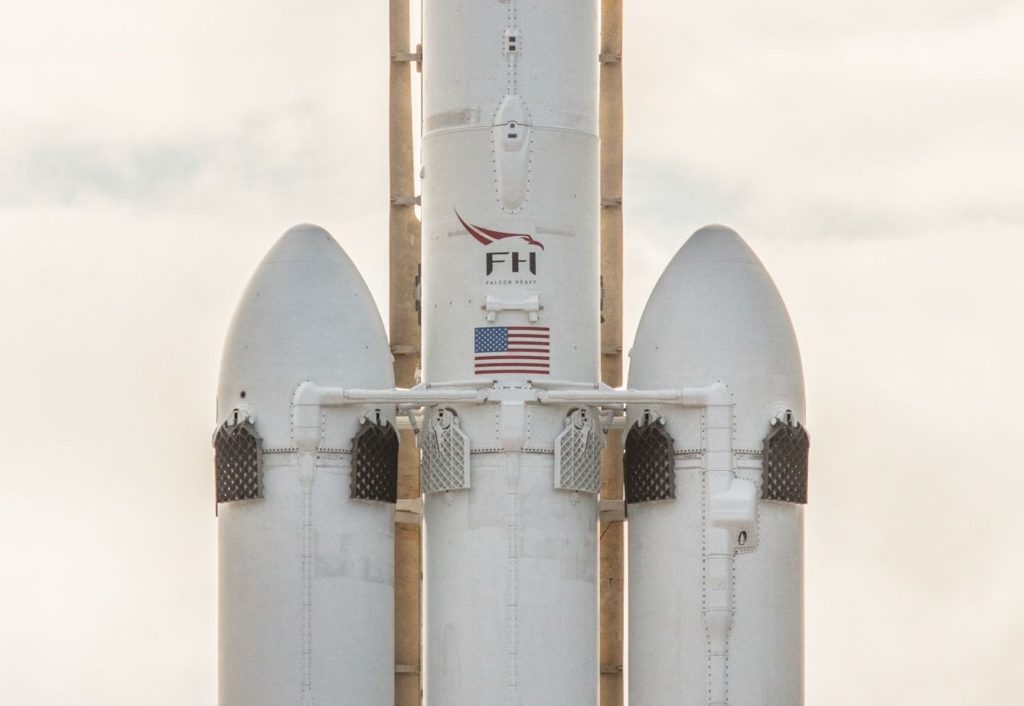

As it gradually nears a launch date sometime in late January or early February, SpaceX’s new super-heavy launch vehicle (SHLV) Falcon Heavy has weathered a number of schedule delays in preparation for a historic and crucial moment – its first static fire/test ignition that’s currently scheduled for Tuesday, January 16, beginning at 4pm EST (2100 GMT).

Those focused on the gritty details of SpaceX’s prelaunch procedures will have immediately noted how different Falcon Heavy’s operations are when compared with SpaceX’s workhorse rocket and Heavy’s progenitor, Falcon 9. For a typical launch of Falcon 9, the rocket and payload will normally arrive at the given launch pad around a month or so before the anticipated launch date. Next, the satellite payload is encapsulated inside Falcon 9’s payload fairing, typically two or so weeks before launch. Pad facilities would be thoroughly examined after the previous launch to remedy any wear and tear and ensure that it is in good working order ahead of the next mission. Approximately a week before launch, Falcon 9’s first and second stages are mated together inside the pad’s integration facilities, the pad’s Transport/Erector/Launcher (TEL) is rolled into the integration facilities, and the Falcon 9 booster and second stage (sans payload) are mounted onto the TEL. Finally, the TEL and rocket are rolled out to the launch pad for a brief 3-5 second static fire around 5-7 days before launch. After testing is completed, the TEL is rolled back to the integration facilities, the payload fairing and payload are attached to the rocket, and the whole stack is once more rolled back to the pad, ready for launch.

- The TEL seen at LC-39A in early 2017. (SpaceX)

- The base of the TEL now sports multiple additional launch clamps (large grey protrusions) that will be needed for Falcon Heavy’s three first stage cores. (SpaceX)

- Finally, the fairing is transported vertically to the HIF, where it can be flipped horizontal and attached to its rocket. (Reddit /u/St-Jed-of-Calumet)

For a used booster, this is the sum total of the prelaunch procedures it will go through at the pad, after recovery and refurbishment. For all new boosters, however, SpaceX currently conducts a thorough slate of tests for all Merlin 1D and MVac (2nd stage) rocket engines, as well as both the integrated first and second stages at its McGregor, Texas facilities. These tests last far longer than those conducted at the launch pad, and typically run for the full length of a launch in order to better simulate the stresses flight hardware will end up experiencing. In other words, new Falcon 9 hardware always has to make it through hundreds of seconds of live firing and post-test analysis before finally being shipped to SpaceX’s launch facilities, where it conducts the aforementioned brief static fire at the pad.

A whole new bird of prey

To put it simply, Falcon Heavy is a whole different animal when it comes to prelaunch testing. Due to the rocket’s sheer size and power in its fully integrated state, McGregor simply does not have the capability to conduct the same tests it does with Falcon 9. While two of the first Heavy’s three first stage boosters are modified flight-proven Falcon 9s (from Thaicom-8 and CRS-9), the center core required a far more extensive suite of changes from a normal Falcon 9 in order to survive the added stresses it would experience during a Falcon Heavy launch. Although the full-up vehicle could not be tested in Texas with a full-length firing, each of its three first stages and upper stage went through the same tests as a normal Falcon 9. Before that, both side core and center core structural test articles (STA) went through a large amount of mechanical stress testing to verify that Falcon Heavy’s re-engineered design would be able to easily survive the stresses of launch and then some. In short, months and months of work have gone into the hardware that both preceded and makes up the Falcon Heavy rocket currently vertical and weeks from launch at Kennedy Space Center.

However, SpaceX has learned the hard way that simulation and partial physical testing can only go so far, and cannot be completely trusted when it comes to flying new hardware, as evidenced by the both Falcon 1 and the company’s several first attempts at recovering a Falcon 9 booster (intact, at least…). Even the best and most brilliant engineers and technicians can only do so much without testing the real thing in real conditions, something that can often result in unintended failures – especially the case with new technologies. Falcon Heavy is indeed a new technology to some extent or at least incorporates numerous new technologies that SpaceX has little to no operational experience with. These and relatively untried aspects include the simultaneous ignition and operation of twenty seven already powerful Merlin 1D engines, new stresses on the center booster during launch, a unique non-explosive side booster separation mechanism, the also near-simultaneous recovery of three first stages, and a second stage tasked with placing an unusual payload in the highest orbit SpaceX has yet to attempt.

Hence Elon Musk’s aggressive expectation maintenance over the last year or so, in which he spared no punches while imparting upon several audiences the likelihood that Falcon Heavy’s first launch would fail entirely, and maybe even destroy the launch pad. In reality, SpaceX is clearly doing everything in their power to ensure that the massive rocket’s first launch is a total success.

- Falcon Heavy vertical at Pad 39A on Thursday, January 11. After a successful rehearsal, the static fire was scrubbed due to a small hardware bug. (Tom Cross/Teslarati)

- The white bars in this photo are half of Falcon Heavy’s seperation mechanism. A number of actuators take the place of the more common solid rocket motors used with vehicles like the Delta IV Heavy. (SpaceX)

- Falcon Heavy’s three boosters and 27 Merlin 1D engines on full display. (SpaceX)

What’s next for Falcon Heavy?

Recent delays to the vehicle’s first static fire test at SpaceX’s Launch Complex 39A are strong examples of this cautious approach. While fans and outsiders alike may be nipping at the bit for the vehicle’s long-awaited inaugural static fire and launch, SpaceX clearly is laser-focused on very thoroughly testing the vehicle and is exerting great caution. After the first static fire attempt was delayed, reportedly due to a buggy launch clamp, SpaceX had nevertheless completed its first (presumably successful) wet dress rehearsal (WDR), which saw the vehicle prepared for launch with a full load of propellant and other miscellaneous fluids. After a brief period back horizontal at the pad, likely to repair whatever fault initially caused the delay, Falcon Heavy has been vertical at the pad for the last several days. Intriguingly, albeit unsurprisingly, tank venting was reported early Sunday by local observers. This indicates that SpaceX conducted at least one additional wet dress rehearsal with Falcon Heavy, likely both contributing to an additional delay of the replacement static fire date (Monday) and solidifying confidence in the new test date, Tuesday, January 16.

Compared with the results of the first WDR (a three-day delay), the one day delay that followed Sunday’s rehearsal is great news for what is effectively a mature launch vehicle prototype. SpaceX’s confidence is clearly growing, and while all delays of the static fire will likely push back the launch date at least as much, Falcon Heavy will almost certainly find itself days away from its inaugural liftoff sometime in very late January or February 2018.

Follow along live as Teslarati’s launch photographer Tom Cross covers Falcon Heavy’s exciting series of events while they happen on our Instagram.

News

Ford is charging for a basic EV feature on the Mustang Mach-E

When ordering a new Ford Mustang Mach-E, you’ll now be hit with an additional fee for one basic EV feature: the frunk.

Ford is charging an additional fee for a basic EV feature on its Mustang Mach-E, its most popular electric vehicle offering.

Ford has shuttered its initial Model e program, but is venturing into a more controlled and refined effort, and it is abandoning the F-150 Lightning in favor of a new pickup that is currently under design, but appears to have some favorable features.

However, ordering a new Mustang Mach-E now comes with an additional fee for one basic EV feature: the frunk.

The frunk is the front trunk, and due to the lack of a large engine in the front of an electric vehicle, OEMs are able to offer additional storage space under the hood. There’s one problem, though, and that is that companies appear to be recognizing that they can remove it for free while offering the function for a fee.

Ford is now charging $495 on the Mustang Mach-E frunk (front trunk). What are your thoughts on that? pic.twitter.com/EOzZe3z9ZQ

— Alan of TesCalendar 📆⚡️ (@TesCalendar1) February 24, 2026

Ford is charging $495 for the frunk.

Interestingly, the frunk size varies by vehicle, but the Mustang Mach-E features a 4.7 to 4.8 cubic-foot-sized frunk, which measures approximately 9 inches deep, 26 inches wide, and 14 inches high.

When the vehicle was first released, Ford marketed the frunk as the ultimate tailgating feature, showing it off as a perfect place to store and serve cold shrimp cocktail.

Ford Mach-E frunk is perfect for chowders and chicken wings, and we’re not even joking

It appears the decision to charge for what is a simple advantage of an EV is not going over well, as even Ford loyal customers say the frunk is a “basic expectation” of an EV. Without it, it seems as if fans feel the company is nickel-and-diming its customers.

It will be pretty interesting to see the Mach-E without a frunk, and while it should not be enough to turn people away from potentially buying the vehicle, it seems the decision to add an additional charge to include one will definitely annoy some customers.

News

Tesla to improve one of its best features, coding shows

According to the update, Tesla will work on improving the headlights when coming into contact with highly reflective objects, including road signs, traffic signs, and street lights. Additionally, pixel-level dimming will happen in two stages, whereas it currently performs with just one, meaning on or off.

Tesla is looking to upgrade its Matrix Headlights, a unique and high-tech feature that is available on several of its vehicles. The headlights aim to maximize visibility for Tesla drivers while being considerate of oncoming traffic.

The Matrix Headlights Tesla offers utilize dimming of individual light pixels to ensure that visibility stays high for those behind the wheel, while also being considerate of other cars by decreasing the brightness in areas where other cars are traveling.

Here’s what they look like in action:

- Credit: u/ObjectiveScratch | Reddit

- Credit: u/ObjectiveScratch | Reddit

As you can see, the Matrix headlight system intentionally dims the area where oncoming cars would be impacted by high beams. This keeps visibility at a maximum for everyone on the road, including those who could be hit with bright lights in their eyes.

There are still a handful of complaints from owners, however, but Tesla appears to be looking to resolve these with the coming updates in a Software Version that is currently labeled 2026.2.xxx. The coding was spotted by X user BERKANT:

🚨 Tesla is quietly upgrading Matrix headlights.

Software https://t.co/pXEklQiXSq reveals a hidden feature:

matrix_two_stage_reflection_dip

This is a major step beyond current adaptive high beams.

What it means:

• The car detects highly reflective objects

Road signs,… pic.twitter.com/m5UpQJFA2n— BERKANT (@Tesla_NL_TR) February 24, 2026

According to the update, Tesla will work on improving the headlights when coming into contact with highly reflective objects, including road signs, traffic signs, and street lights. Additionally, pixel-level dimming will happen in two stages, whereas it currently performs with just one, meaning on or off.

Finally, the new system will prevent the high beams from glaring back at the driver. The system is made to dim when it recognizes oncoming cars, but not necessarily objects that could produce glaring issues back at the driver.

Tesla’s revolutionary Matrix headlights are coming to the U.S.

This upgrade is software-focused, so there will not need to be any physical changes or upgrades made to Tesla vehicles that utilize the Matrix headlights currently.

Elon Musk

xAI’s Grok approved for Pentagon classified systems: report

Under the agreement, Grok can be deployed in systems handling classified intelligence analysis, weapons development, and battlefield operations.

Elon Musk’s xAI has signed an agreement with the United States Department of Defense (DoD) to allow Grok to be used in classified military systems.

Previously, Anthropic’s Claude had been the only AI system approved for the most sensitive military work, but a dispute over usage safeguards has reportedly prompted the Pentagon to broaden its options, as noted in a report from Axios.

Under the agreement, Grok can be deployed in systems handling classified intelligence analysis, weapons development, and battlefield operations.

The publication reported that xAI agreed to the Pentagon’s requirement that its technology be usable for “all lawful purposes,” a standard Anthropic has reportedly resisted due to alleged ethical restrictions tied to mass surveillance and autonomous weapons use.

Defense Secretary Pete Hegseth is scheduled to meet with Anthropic CEO Dario Amodei in what sources expect to be a tense meeting, with the publication hinting that the Pentagon could designate Anthropic a “supply chain risk” if the company does not lift its safeguards.

Axios stated that replacing Claude fully might be technically challenging even if xAI or other alternative AI systems take its place. That being said, other AI systems are already in use by the DoD.

Grok already operates in the Pentagon’s unclassified systems alongside Google’s Gemini and OpenAI’s ChatGPT. Google is reportedly close to an agreement that will result in Gemini being used for classified use, while OpenAI’s progress toward classified deployment is described as slower but still feasible.

The publication noted that the Pentagon continues talks with several AI companies as it prepares for potential changes in classified AI sourcing.