News

SpaceX’s first Starship booster a step closer as custom parts arrive

While SpaceX remains focused on Starship flight testing as the dust settles from SN8’s launch debut, the company continues to make slow but steady progress building the first Super Heavy booster prototype.

For the most part, SpaceX has learned from trial and error and developed a decent stainless steel rocket manufacturing process by building a dozen Starship prototypes over the last ~12 months, ranging from a lone nosecone tip to stout test tanks and Starship SN8, which launched to 12.5 km (~7.8 mi) earlier this month. Practically identical below the nose, Super Heavy directly benefits from that maturity and is more or less an extended Starship tank section with more engines and bigger legs.

In many ways, Super Heavy can be much simpler than Starship, as a suborbital booster has no need for header tanks, flaps, or a nosecone, and can be much stronger and heavier in all aspects. However, carrying three or more times as propellant as Starship (and carrying Starship itself), Super Heavy also needs to be stronger. All those changes – requiring new design work and new fabrication – take time. In a great sign that most of that work is complete, some of that custom hardware needed to strengthen and power Super Heavy has begun to arrive over the last several weeks.

SpaceX began stacking the first Super Heavy booster (BN1) on November 8th and appears to have more or less paused integration operations after joining eight rings. Production continued apace, however, and no less than five ring sections destined for Super Heavy appeared over the next several weeks. Why assembly slowed down is unclear but it’s reasonable to assume that SpaceX was trying to keep its focus primarily on Starship SN8’s launch debut and the preparation of several other full-scale ships, where early work on Super Heavy could ultimately be for naught if Starship flight tests uncover major design flaws.

Regardless of the reason, BN1 remains eight rings (14.5m/48ft) tall as of December 14th, representing one-fifth of Super Heavy’s full 70-meter (~230 ft) height.

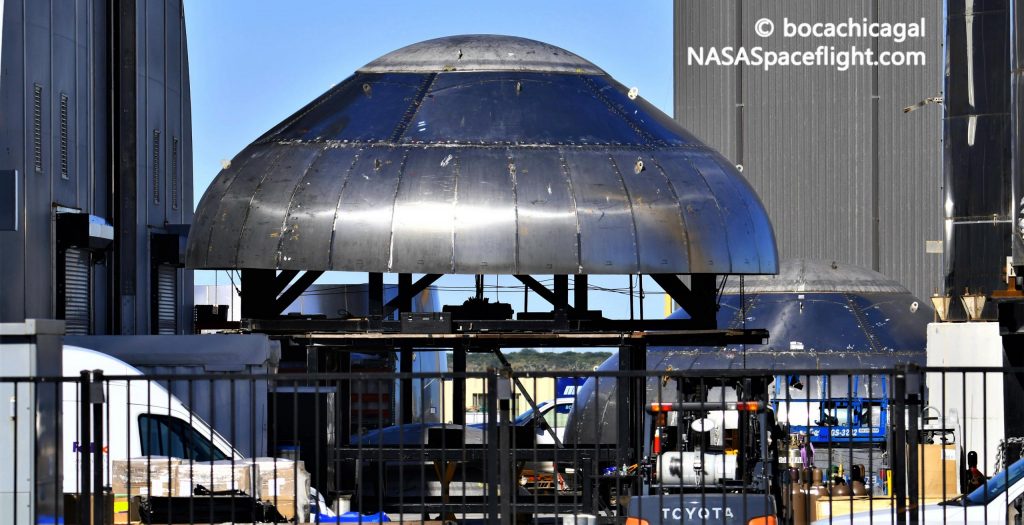

On December 17th, one of the parts unique to Super Heavy unexpectedly appeared in SpaceX’s South Texas shipyard, labeled “B1 FWD PIPE DOME”. The dome was quickly sleeved with a stack of three steel rings with labels confirming that the assembly was Super Heavy BN1’s common tank dome – “common” because it’s shared by both booster propellant tanks. The new dome is unique to all previous Starship domes, featuring a smaller, more reinforced cutout – likely because Super Heavy doesn’t need header tanks.

It also appears to borrow from Starship’s forward dome design, using the same rougher steel normally used to cap off Starship methane tanks.

Unlike Starship common domes, which place a spherical methane header tank at the bottom, Super Heavy’s common dome will have a transfer tube welded directly to its nozzle-like opening. As it turns out, what could be the first Super Heavy methane transfer tube was delivered to Boca Chica late last month.

Unlike Starship transfer tubes, the new plumbing appeared to have a much wider diameter and was delivered in four sections, meshing well with the fact that Super Heavy tanks are roughly twice as tall as Starship’s. Able to support as many as 28 Raptors compared to Starship’s 6, Super Heavy transfer tubes will also need to pump more than five times as much methane per second at full thrust, which could explain the larger diameter.

Finally and perhaps most significantly, aerial photos from RGV Photography appeared to capture the first glimpse of what might be the hardest custom part required by Super Heavy – a thrust structure designed to support up to 28 Raptor engines. On December 10th, casually sitting between Starship Mk1’s remains (on the white concrete mount) and a tent, a flat ring with clear eightfold symmetry and a donut-like cutout large enough to fit a Starship thrust puck with room to spare was easily visible.

The hexagonal symmetry was the main giveaway, matching comments from CEO Elon Musk that Super Heavy’s thrust structure will feature a central ring of eight engines surrounded by an outer ring of up to 20 more Raptors. Assuming the first Super Heavy booster only flies with a few Raptor engines, that sole eight-engine ‘puck’ may be all that SpaceX needs to complete BN1.

Cybertruck

Tesla confirms date when new Cybertruck trim will go up in price

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this.

Tesla has confirmed the date when its newest Cybertruck trim level will increase in price, after CEO Elon Musk noted that the All-Wheel-Drive configuration of the all-electric pickup would only be priced at its near-bargain level for ten days.

Last week, Tesla launched the All-Wheel-Drive configuration of the Cybertruck. Priced at $59,990, the Cybertruck featured many excellent features and has seemingly brought some demand to the pickup, which has been underwhelming in terms of sales figures over the past couple of years.

Tesla launches new Cybertruck trim with more features than ever for a low price

When Tesla launched it, many fans and current owners mulled the possibility of ordering it. However, Musk came out and said just hours after launching the pickup that Tesla would only keep it at the $59,990 price level for ten days.

What it would be priced at subsequently was totally dependent on how much demand Tesla felt for the new trim level, which is labeled as a “Dual Motor All-Wheel-Drive” configuration.

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this:

NEWS: Tesla has officially announced that the price of the new Cybertruck Dual-Motor AWD will be increasing after February 28th. pic.twitter.com/vZpA521ZwC

— Sawyer Merritt (@SawyerMerritt) February 24, 2026

Many fans and owners have criticized Tesla’s decision to unveil a trim this way, and then price it at something, only to change that price a few days later based on how well it sells.

Awful way to treat customers – particularly when they already sent out a marketing email announcing the $59,990 truck…with zero mention of it being a limited-time offer.

— Ryan McCaffrey (@DMC_Ryan) February 24, 2026

It seems the most ideal increase in price would be somewhere between $5,000 and $10,000, but it truly depends on how many orders Tesla sees for this new trim level. The next step up in configuration is the Premium All-Wheel-Drive, which is priced at $79,990.

The difference between the Dual Motor AWD Cybertruck and the Premium AWD configuration comes down to towing, interior quality, and general features. The base package is only capable of towing up to 7,500 pounds, while the Premium can handle 11,000 pounds. Additionally, the seats in the Premium build are Vegan Leather, while the base trim gets the textile seats.

It also has only 7 speakers compared to the 15 that the Premium trim has. Additionally, the base model does not have an adjustable ride height, although it does have a coil spring with an adaptive damping suspension package.

Cybertruck

Tesla set to activate long-awaited Cybertruck feature

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, as the company has officially added the feature to its list of features by trim on its website.

Tesla is set to activate a long-awaited Cybertruck feature, and no matter when you bought your all-electric pickup, it has the hardware capable of achieving what it is designed to do.

Tesla simply has to flip the switch, and it plans to do so in the near future.

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, according to Not a Tesla App, as the company has officially added the feature to its list of features by trim on its website.

Tesla rolls out Active Road Noise Reduction for new Model S and Model X

The ANC feature suddenly appeared on the spec sheet for the Premium All-Wheel-Drive and Cyberbeast trims, which are the two configurations that have been delivered since November 2023.

However, those trims have both had the ANC disabled, and although they are found in the Model S and Model X, and are active in those vehicles, Tesla is planning to activate them.

In Tesla’s Service Toolbox, it wrote:

“ANC software is not enabled on Cybertruck even though the hardware is installed.”

Tesla has utilized an ANC system in the Model S and Model X since 2021. The system uses microphones embedded in the front seat headrests to detect low-frequency road noise entering the cabin. It then generates anti-noise through phase-inverted sound waves to cancel out or reduce that noise, creating quieter zones, particularly around the vehicle’s front occupants.

The Model S and Model X utilize six microphones to achieve this noise cancellation, while the Cybertruck has just four.

Tesla Cybertruck Dual Motor AWD estimated delivery slips to early fall 2026

As previously mentioned, this will be activated through a software update, as the hardware is already available within Cybertruck and can simply be activated at Tesla’s leisure.

The delays in activating the system are likely due to Tesla Cybertruck’s unique design, which is unlike anything before. In the Model S and Model X, Tesla did not have to do too much, but the Cybertruck has heavier all-terrain tires and potentially issues from the aluminum castings that make up the vehicle’s chassis, which are probably presenting some challenges.

Unfortunately, this feature will not be available on the new Dual Motor All-Wheel-Drive configuration, which was released last week.

News

Tesla Model S and X customization options begin to thin as their closure nears

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

Tesla Model S and Model X customization options are beginning to thin for the first time as the closure of the two “sentimental” vehicles nears.

We are officially seeing the first options disappear as Tesla begins to work toward ending production of the two cars and the options that are available to those vehicles specifically.

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

🚨 Tesla Model S and Model X availability is thinning, as Tesla has officially shown that the Lunar Silver color option on both vehicles is officially sold out

To be fair, Frost Blue is still available so no need to freak out pic.twitter.com/YnwsDbsFOv

— TESLARATI (@Teslarati) February 25, 2026

Tesla is making way for the Optimus humanoid robot project at the Fremont Factory, where the Model S and Model X are produced. The two cars are low-volume models and do not contribute more than a few percent to Tesla’s yearly delivery figures.

With CEO Elon Musk confirming that the Model S and Model X would officially be phased out at the end of the quarter, some of the options are being thinned out.

This is an expected move considering Tesla’s plans for the two vehicles, as it will make for an easier process of transitioning that portion of the Fremont plant to cater to Optimus manufacturing. Additionally, this is likely one of the least popular colors, and Tesla is choosing to only keep around what it is seeing routine demand for.

During the Q4 Earnings Call in January, Musk confirmed the end of the Model S and Model X:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Fremont will now build one million Optimus units per year as production is ramped.