News

SpaceX considers Florida launch pad for both Falcon and Mars vehicle launches

Following a highly informative discussion at the ISS R&D conference, Elon Musk revealed that the updated, leaner version of SpaceX’s Mars architecture would likely have a diameter of around 9 meters.

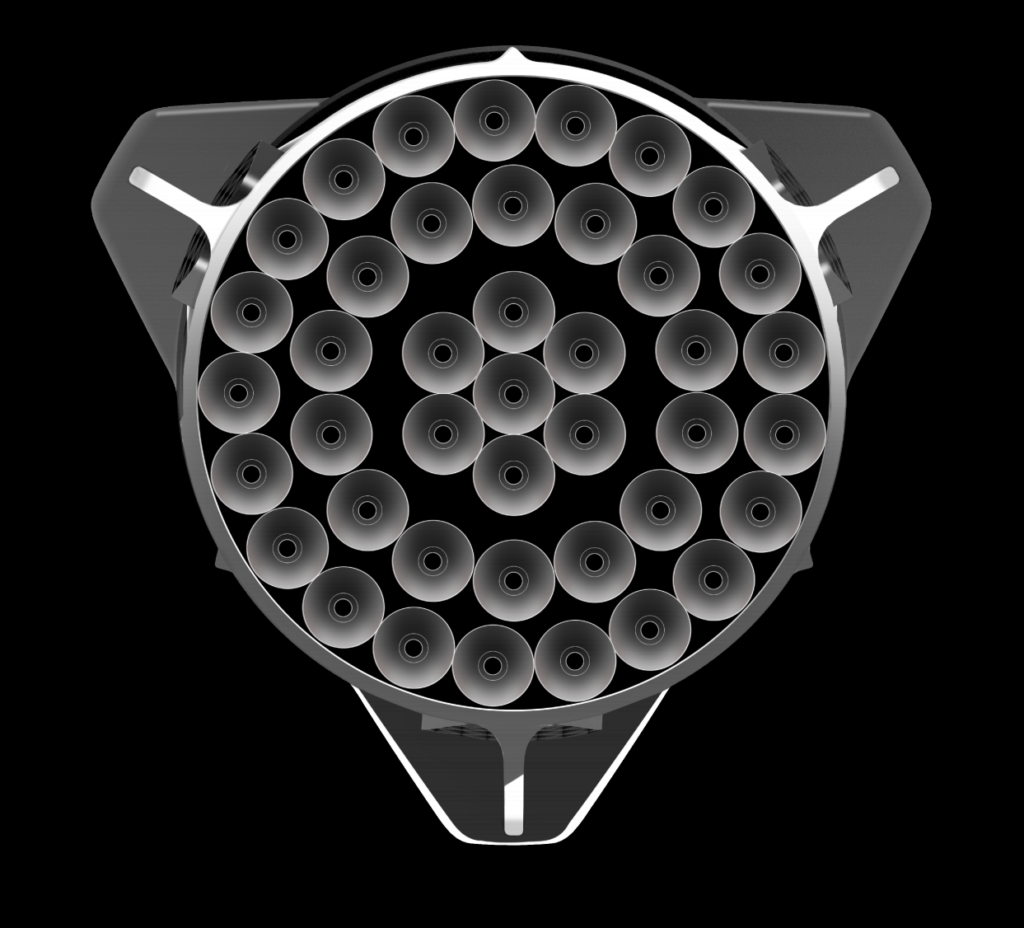

A 9m Interplanetary Transport System, while precisely 25% smaller than the 12m diameter version revealed last year, would have to either lose the outer ring of full scale Raptor engines, or pivot to a smaller version of Raptor in order to preserve the 42 engine configuration shown at the IAC. Given Musk’s adamant and harsh judgement of the complexity of 27 Merlin 1D engines simultaneously firing on Falcon Heavy, moving to a 21 engine first stage for SpaceX’s Mars vehicle is a fair bet, so long as the full scale Raptor engine is still planned. Extremely speculative calculations based on the limited information available suggest that this smaller ITS could launch a bit less than half the payload of the original, still almost double the capability of Saturn V.

- A Space Shuttle’s external tank makes its way through downtown Los Angeles in 2011. The ET had a diameter of 8.4m. (AP/Chris Carlson)

- The base of SpaceX’s ITS booster, circa 2016. Current plans make it likely that the outside ring of engines will be subtracted and the vehicle made leaner. (SpaceX)

Possibly the most significant information to come out of this tweet is the implication that SpaceX and Musk are now looking to utilize current manufacturing facilities for the construction of a smaller ITS. While it adds considerable expense, the transport of a Space Shuttle’s external fuel tank through the streets of Los Angeles in 2011 sets a precedent for it being possible for SpaceX to transport a 9m vehicle from its factory in Hawthorne, CA to a nearby port. If SpaceX is able to use the same facilities it currently has for developing its Mars vehicle, it would experience immense savings compared to the cost of developing entirely new factories and testing facilities. This matches up perfectly with Musk’s repeated statement that the updated ITS is focused on improving the economic case for the vehicle and making it significantly cheaper to develop.

A 9m diameter vehicle fits in our existing factories …

— Elon Musk (@elonmusk) July 22, 2017

Possibly the most crucial keystone of this economical update relates to the launch pad or pads that will be necessary to launch a rocket as large as either ITS. An oft-overlooked feature of the current LC-39A launch pad SpaceX leases and operates in Florida is that it and its LC-39B sibling were developed with a far larger and more powerful version of Saturn V in mind, known as Nova at the time. SpaceX is well aware of this, and is also painfully aware of just how expensive the construction of launch pads can be after having to undertake deep repairs of LC-40.

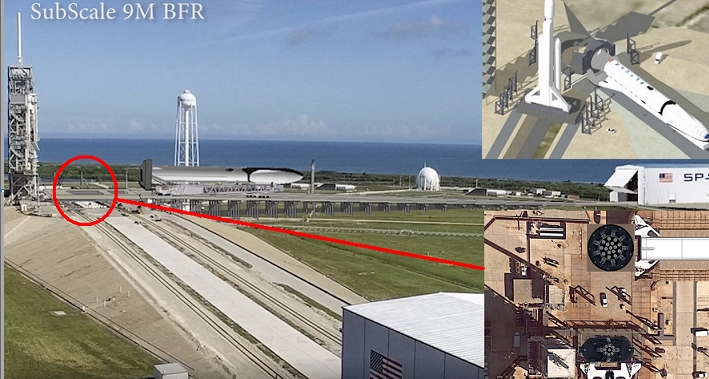

Mockups of potential solutions for a dual vehicle setup at LC-39A. With this arrangement, SpaceX would be able to continue crewed and Falcon Heavy launches from the pad while conducting initial tests and launches of their ITS. (Jay Deshetler, in addition to Cameron Byers and John Archer, based on notes from KSC pad engineers)(NASASpaceflight)

Buried in a fascinating article by Chris Bergin of NASASpaceflight.com fame, Bergin has revealed that documents and rumblings behind the scenes indicate that SpaceX is seriously considering either co-launching from LC-39B or modifying LC-39A with a second launch mount. This would require considerably modifications to the venerable pad, but it would not require the costly and time-consuming construction of an entirely new launch pad. Speculative renders and mockups (above) created by the skilled forum members of NASASpaceflight demonstrate this nicely, showing the launch mount for ITS and Falcon side by side.

Combined with Musk’s past statements about this updated version of ITS, the future is looking increasingly bright for what was initially a somewhat crazy architecture. Easier transport, recycled development facilities, and co-location on an already-constructed launch pad show that SpaceX are completely serious about their ambitions for Mars and are willing to do what is necessary to get to the Moon, the Red Planet, and beyond.

News

Ford is charging for a basic EV feature on the Mustang Mach-E

When ordering a new Ford Mustang Mach-E, you’ll now be hit with an additional fee for one basic EV feature: the frunk.

Ford is charging an additional fee for a basic EV feature on its Mustang Mach-E, its most popular electric vehicle offering.

Ford has shuttered its initial Model e program, but is venturing into a more controlled and refined effort, and it is abandoning the F-150 Lightning in favor of a new pickup that is currently under design, but appears to have some favorable features.

However, ordering a new Mustang Mach-E now comes with an additional fee for one basic EV feature: the frunk.

The frunk is the front trunk, and due to the lack of a large engine in the front of an electric vehicle, OEMs are able to offer additional storage space under the hood. There’s one problem, though, and that is that companies appear to be recognizing that they can remove it for free while offering the function for a fee.

Ford is now charging $495 on the Mustang Mach-E frunk (front trunk). What are your thoughts on that? pic.twitter.com/EOzZe3z9ZQ

— Alan of TesCalendar 📆⚡️ (@TesCalendar1) February 24, 2026

Ford is charging $495 for the frunk.

Interestingly, the frunk size varies by vehicle, but the Mustang Mach-E features a 4.7 to 4.8 cubic-foot-sized frunk, which measures approximately 9 inches deep, 26 inches wide, and 14 inches high.

When the vehicle was first released, Ford marketed the frunk as the ultimate tailgating feature, showing it off as a perfect place to store and serve cold shrimp cocktail.

Ford Mach-E frunk is perfect for chowders and chicken wings, and we’re not even joking

It appears the decision to charge for what is a simple advantage of an EV is not going over well, as even Ford loyal customers say the frunk is a “basic expectation” of an EV. Without it, it seems as if fans feel the company is nickel-and-diming its customers.

It will be pretty interesting to see the Mach-E without a frunk, and while it should not be enough to turn people away from potentially buying the vehicle, it seems the decision to add an additional charge to include one will definitely annoy some customers.

News

Tesla to improve one of its best features, coding shows

According to the update, Tesla will work on improving the headlights when coming into contact with highly reflective objects, including road signs, traffic signs, and street lights. Additionally, pixel-level dimming will happen in two stages, whereas it currently performs with just one, meaning on or off.

Tesla is looking to upgrade its Matrix Headlights, a unique and high-tech feature that is available on several of its vehicles. The headlights aim to maximize visibility for Tesla drivers while being considerate of oncoming traffic.

The Matrix Headlights Tesla offers utilize dimming of individual light pixels to ensure that visibility stays high for those behind the wheel, while also being considerate of other cars by decreasing the brightness in areas where other cars are traveling.

Here’s what they look like in action:

- Credit: u/ObjectiveScratch | Reddit

- Credit: u/ObjectiveScratch | Reddit

As you can see, the Matrix headlight system intentionally dims the area where oncoming cars would be impacted by high beams. This keeps visibility at a maximum for everyone on the road, including those who could be hit with bright lights in their eyes.

There are still a handful of complaints from owners, however, but Tesla appears to be looking to resolve these with the coming updates in a Software Version that is currently labeled 2026.2.xxx. The coding was spotted by X user BERKANT:

🚨 Tesla is quietly upgrading Matrix headlights.

Software https://t.co/pXEklQiXSq reveals a hidden feature:

matrix_two_stage_reflection_dip

This is a major step beyond current adaptive high beams.

What it means:

• The car detects highly reflective objects

Road signs,… pic.twitter.com/m5UpQJFA2n— BERKANT (@Tesla_NL_TR) February 24, 2026

According to the update, Tesla will work on improving the headlights when coming into contact with highly reflective objects, including road signs, traffic signs, and street lights. Additionally, pixel-level dimming will happen in two stages, whereas it currently performs with just one, meaning on or off.

Finally, the new system will prevent the high beams from glaring back at the driver. The system is made to dim when it recognizes oncoming cars, but not necessarily objects that could produce glaring issues back at the driver.

Tesla’s revolutionary Matrix headlights are coming to the U.S.

This upgrade is software-focused, so there will not need to be any physical changes or upgrades made to Tesla vehicles that utilize the Matrix headlights currently.

Elon Musk

xAI’s Grok approved for Pentagon classified systems: report

Under the agreement, Grok can be deployed in systems handling classified intelligence analysis, weapons development, and battlefield operations.

Elon Musk’s xAI has signed an agreement with the United States Department of Defense (DoD) to allow Grok to be used in classified military systems.

Previously, Anthropic’s Claude had been the only AI system approved for the most sensitive military work, but a dispute over usage safeguards has reportedly prompted the Pentagon to broaden its options, as noted in a report from Axios.

Under the agreement, Grok can be deployed in systems handling classified intelligence analysis, weapons development, and battlefield operations.

The publication reported that xAI agreed to the Pentagon’s requirement that its technology be usable for “all lawful purposes,” a standard Anthropic has reportedly resisted due to alleged ethical restrictions tied to mass surveillance and autonomous weapons use.

Defense Secretary Pete Hegseth is scheduled to meet with Anthropic CEO Dario Amodei in what sources expect to be a tense meeting, with the publication hinting that the Pentagon could designate Anthropic a “supply chain risk” if the company does not lift its safeguards.

Axios stated that replacing Claude fully might be technically challenging even if xAI or other alternative AI systems take its place. That being said, other AI systems are already in use by the DoD.

Grok already operates in the Pentagon’s unclassified systems alongside Google’s Gemini and OpenAI’s ChatGPT. Google is reportedly close to an agreement that will result in Gemini being used for classified use, while OpenAI’s progress toward classified deployment is described as slower but still feasible.

The publication noted that the Pentagon continues talks with several AI companies as it prepares for potential changes in classified AI sourcing.