News

SpaceX’s orbital Starship gains a nose as East Coast prototype makes progress

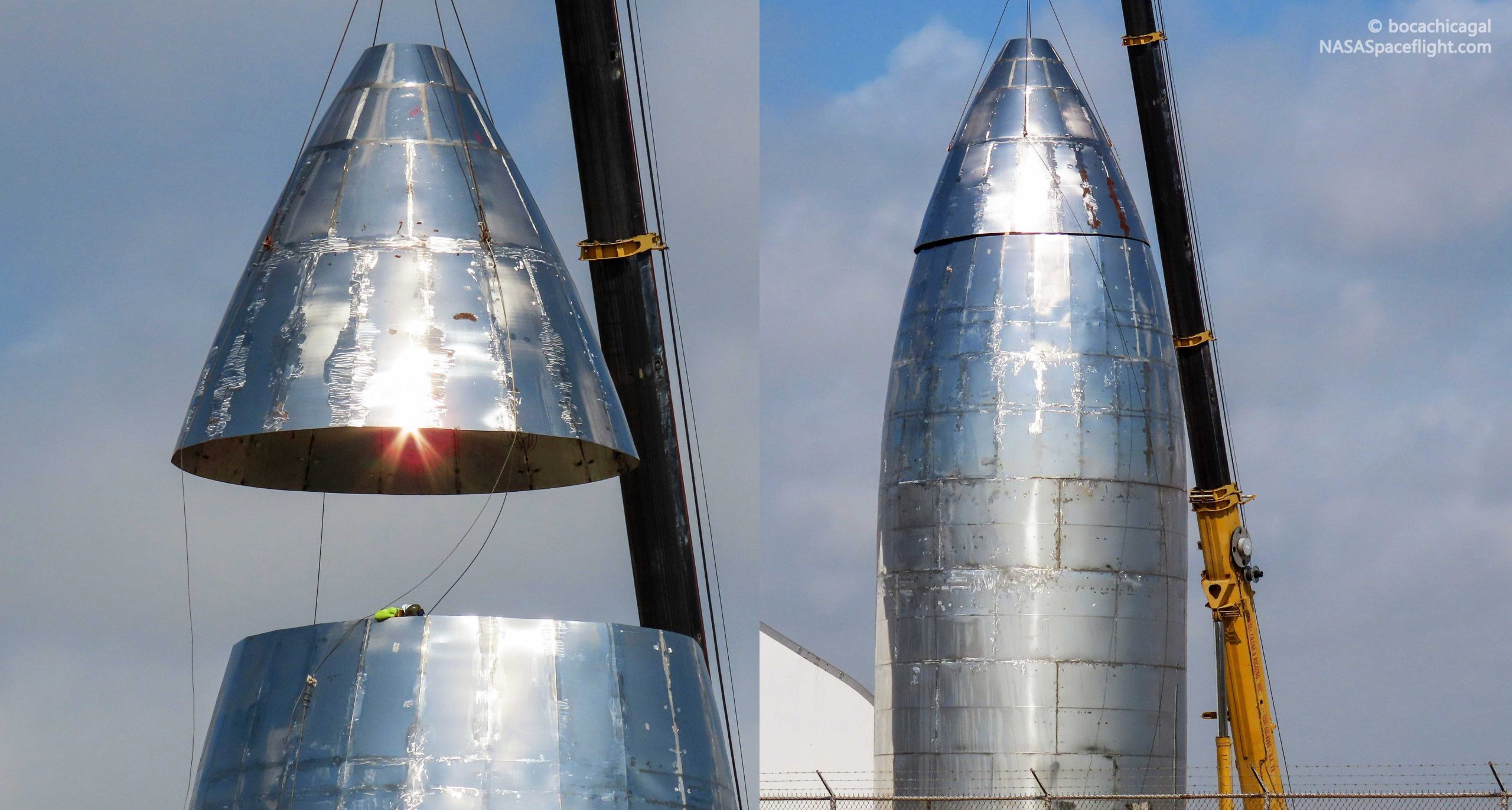

On May 20th, SpaceX technicians successfully stacked a nosecone on top of the company’s Boca Chica orbital Starship prototype. Simultaneously, a separate team of technicians and engineers have been hard at work building a second similar-but-different Starship prototype near Cape Canaveral, Florida.

Officially confirmed last week by Elon Musk, the SpaceX CEO revealed that the company was not only building two orbital Starship prototypes simultaneously – not news in itself – but that those prototypes were being built as a sort of internal competition between different teams and ideas. The competition is not cutthroat – knowledge is shared between Texas and Florida – but the strategy is fairly similar. In lieu of actual commercial competitors, SpaceX is attempting to compete with itself to more rapidly and effectively develop a brand new launch vehicle – the stainless steel Starship/Super Heavy.

A Starship rises in the East

In just the last week, both SpaceX groups have made major progress. On the East Coast, the general public saw the first photo of SpaceX’s Florida Starship build precisely seven days ago. It appears that SpaceX has more or less taken over a Cocoa, Florida facility known to be the prior home of Coastal Steel, a repeat NASA contractor known for steelwork.

It’s unclear if SpaceX has fully acquired Coastal Steel or is simply partnering with the small company in the early stages of its Florida Starship buildup. Regardless, even from perspectives quite a bit more distant than those available in Texas, it’s clear that the metal workmanship is at least on par with Boca Chica, if not giving them a run for their money.

Admittedly, the playing field is not exactly level. SpaceX’s South Texas team has been working just a few thousand feet away from the unobstructed Gulf of Mexico in conditions that would make for an excellent traditional-aerospace horror show. Aside from a lone tent, all welding, assembly, integration, and testing has been done while fully exposed to the elements. SpaceX’s Florida team appears to have the luxury of an established warehouse – previously used for steelwork – to use as a covered and partially insulated work and staging area. The Florida team effectively had everything they needed (give or take) on hand from the moment work began, while Texas had to quite literally build all of its facilities from nothing.

Be it the facility luxuries or Cape Canaveral’s far larger pool of local aerospace talent, it’s clear that SpaceX’s Florida team will be a competitive force to be reckoned with despite Texas’ apparent head start. In the seven days since the first photos of the Florida Starship were published, SpaceX technicians have almost doubled the height of the largest welded section, raising it from ~5.5m to ~9m (18-30 ft).

Meanwhile, those working inside the staging warehouse continue to crank out 2x9m subsections, already making way for what appears to be the first tapered nose section of the Florida Starship. At this rate, Florida could very well catch up to SpaceX’s Texas Starship just a month or two from now. It’s worth noting that the Florida team does not appear to be involved in any Starhopper activities. SpaceX Boca Chica, on the other hand, has spent a major portion of the last several months building out Starhopper and preparing the odd prototype for untethered hop tests.

The (slightly) Old(er) Guard

Despite Starship Florida’s rapid progress, Starship Texas has not exactly been standing around. In the last week or so, SpaceX technicians and engineers have been simultaneously working on major new integration, assembly, and test campaigns with both Starhopper and the first orbital Starship prototype. A dedicated Starhopper article will come later this week as SpaceX’s South Texas team nears Raptor reinstallation and an untethered hop test campaign, scheduled to begin as early as the end of May.

On the orbital Starship side of things, Boca Chica took a major symbolic step towards aeroshell completion by capping off the upper half of the prototype with a stainless steel nose section. Altogether, the Starship assembly now stands about 25m (80 ft) tall from tip to tail, roughly 60% as tall as a Falcon 9 booster (first stage). With the installation of the craft’s nose, SpaceX has also implicitly confirmed that most – if not all – of the Starship prototype’s tankage still needs to be built, unless a great deal of hardware is hiding inside Boca Chica’s on-site tent.

What could either be the orbital Starship’s seven-Raptor engine section or the start of its liquid oxygen or methane tank is also being built a few hundred feet distant. That mystery segment was recently lifted onto a second concrete jig for easier access, while SpaceX has also been hard at work building a dedicated integration facility similar to the warehouse being used in Florida.

Altogether, SpaceX’s South Texas team appears to be 30-40% away from completing a Starship-sized steel aeroshell. A huge amount of work remains to be done on the inside of the theoretically orbit-capable vehicle, including propellant tanks, a thrust structure capable of supporting seven Raptor engines, landing legs/fins, and a jungle of plumbing and avionics installation. Still, the amount of progress already visible is undeniably impressive, made even more intriguing by the existence of a separate Starship build effort to the east.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

Investor's Corner

Tesla gets tip of the hat from major Wall Street firm on self-driving prowess

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet,” BoA wrote.

Tesla received a tip of the hat from major Wall Street firm Bank of America on Wednesday, as it reinitiated coverage on Tesla shares with a bullish stance that comes with a ‘Buy’ rating and a $460 price target.

In a new note that marks a sharp reversal from its neutral position earlier in 2025, the bank declared Tesla’s Full Self-Driving (FSD) technology the “leading consumer autonomy solution.”

Analysts highlighted Tesla’s camera-only architecture, known as Tesla Vision, as a strategic masterstroke. While technically more challenging than the multi-sensor setups favored by rivals, the vision-based approach is dramatically cheaper to produce and maintain.

This cost edge, combined with Tesla’s rapidly expanding real-world data engine, positions the company to scale robotaxis far more profitably than competitors, BofA argues in the new note:

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet.”

The bank now attributes roughly 52% of Tesla’s total valuation to its Robotaxi ambitions. It also flagged meaningful upside from the Optimus humanoid robot program and the fast-growing energy storage business, suggesting the auto segment’s recent headwinds, including expired incentives, are being eclipsed by these higher-margin opportunities.

Tesla’s own data underscores exactly why Wall Street is waking up to FSD’s potential. According to Tesla’s official safety reporting page, the FSD Supervised fleet has now surpassed 8.4 billion cumulative miles driven.

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

That total ballooned from just 6 million miles in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and a staggering 4.25 billion in 2025 alone. In the first 50 days of 2026, owners added another 1 billion miles — averaging more than 20 million miles per day.

This avalanche of real-world, camera-captured footage, much of it on complex city streets, gives Tesla an unmatched training dataset. Every mile feeds its neural networks, accelerating improvement cycles that lidar-dependent rivals simply cannot match at scale.

Tesla owners themselves will tell you the suite gets better with every release, bringing new features and improvements to its self-driving project.

The $460 target implies roughly 15 percent upside from recent trading levels around $400. While regulatory and safety hurdles remain, BofA’s endorsement signals growing institutional conviction that Tesla’s data advantage is not hype; it’s a tangible moat already delivering billions of miles of proof.

News

Tesla to discuss expansion of Samsung AI6 production plans: report

Tesla has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla is reportedly discussing an expansion of its next-generation AI chip supply deal with Samsung Electronics.

As per a report from Korean industry outlet The Elec, Tesla purchasing executives are reportedly scheduled to meet Samsung officials this week to negotiate additional production volume for the company’s upcoming AI6 chip.

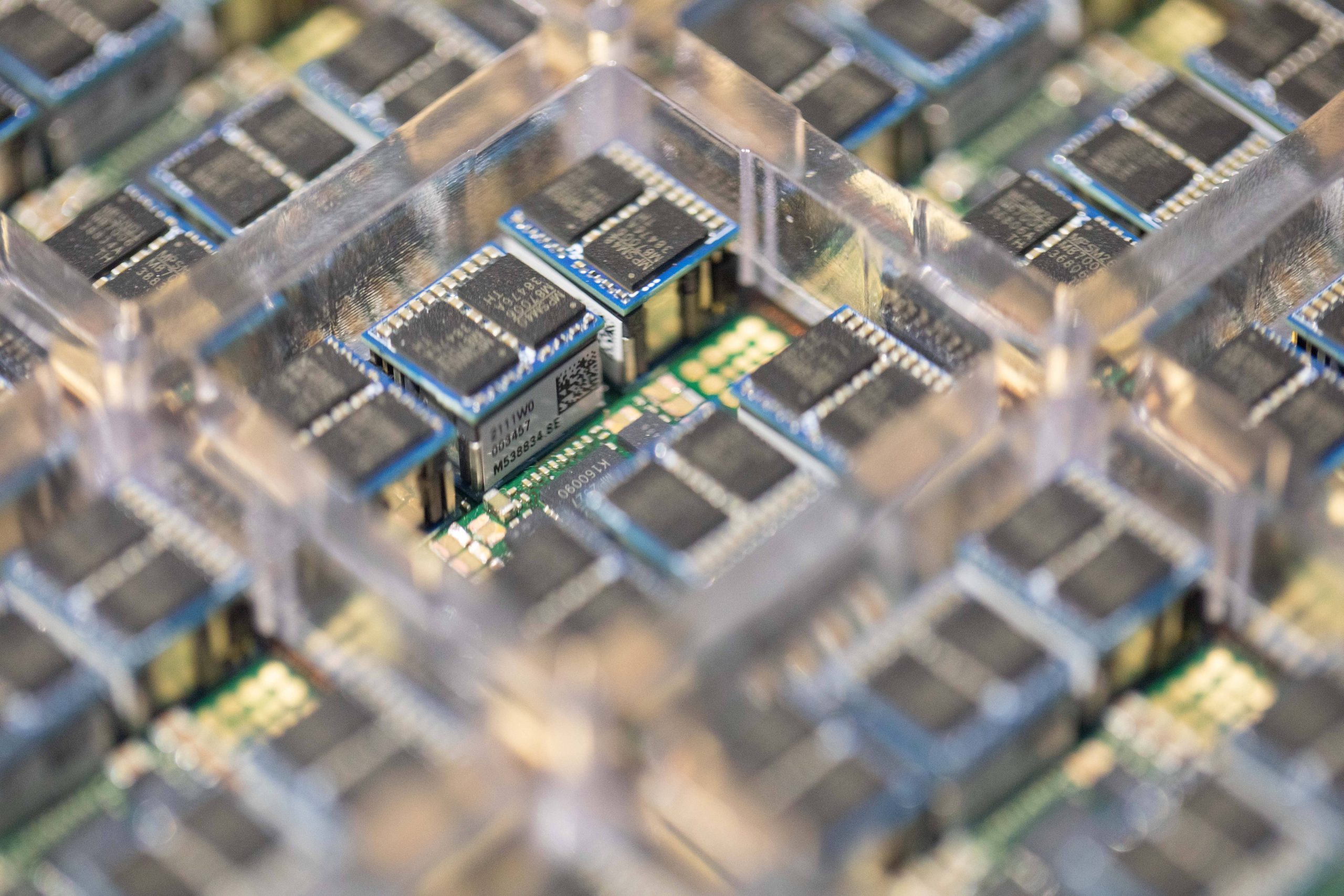

Industry sources cited in the report stated that Tesla is pushing to increase the production volume of its AI6 chip, which will be manufactured using Samsung’s 2-nanometer process.

Tesla previously signed a long-term foundry agreement with Samsung covering AI6 production through December 31, 2033. The deal was reportedly valued at about 22.8 trillion won (roughly $16–17 billion).

Under the existing agreement, Tesla secured approximately 16,000 wafers per month from the facility. The company has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla purchasing executives are expected to discuss detailed supply terms during their visit to Samsung this week.

The AI6 chip is expected to support several Tesla technologies. Industry sources stated that the chip could be used for the company’s Full Self-Driving system, the Optimus humanoid robot, and Tesla’s internal AI data centers.

The report also indicated that AI6 clusters could replace the role previously planned for Tesla’s Dojo AI supercomputer. Instead of a single system, multiple AI6 chips would be combined into server-level clusters.

Tesla’s semiconductor collaboration with Samsung dates back several years. Samsung participated in the design of Tesla’s HW3 (AI3) chip and manufactured it using a 14-nanometer process. The HW4 chip currently used in Tesla vehicles was also produced by Samsung using a 5-nanometer node.

Tesla previously planned to split production of its AI5 chip between Samsung and TSMC. However, the company reportedly chose Samsung as the primary partner for the newer AI6 chip.

Elon Musk

Elon Musk: Tesla could be first to build AGI in humanoid form

Musk’s statement was shared in a post on social media platform X.

Elon Musk predicted that Tesla could become one of the developers of Artificial General Intelligence (AGI) in humanoid form. Musk’s statement was shared in a post on social media platform X.

In his post, Musk stated that “Tesla will be one of the companies to make AGI and probably the first to make it in humanoid/atom-shaping form.”

The comment comes as Tesla expands development of its Optimus humanoid robot.

During Tesla’s Q4 earnings report, Elon Musk stated that production of the Model S and Model X would be phased out at its Fremont, California, facility. The vehicles’ production line will then be converted to a pilot line for Optimus. Tesla is looking to produce 1 million units of the humanoid robots annually to start.

Musk has previously stated that Optimus could eventually function as a von Neumann probe. The concept, proposed by mathematician John von Neumann, describes a machine capable of replicating itself using planetary resources and sending those replicas to other worlds.

Optimus would likely only be able to achieve this potential if it manages to achieve Artificial General Intelligence.

Other leaders in the AI sector have also expressed strong expectations about AGI’s potential. Demis Hassabis, CEO of Google DeepMind, recently spoke about the technology at the India AI Impact Summit 2026, as noted in a Benzinga report.

“It’s going to be something like ten times the impact of the Industrial Revolution, but happening at ten times the speed,” Hassabis said.

Elon Musk’s recent comments about Tesla producing a product with AGI could hint at further collaboration among his companies. So far, Tesla is actively pursuing autonomous driving, but it is xAI that is pursuing AGI with its Grok program.

Considering that Elon Musk mentioned a Tesla humanoid product with AGI, it appears that an Optimus robot running xAI’s AI models could become a reality.

xAI had recently merged with SpaceX, though reports suggest that Elon Musk is also considering an even bigger merger for all his companies, including Tesla.