SpaceX

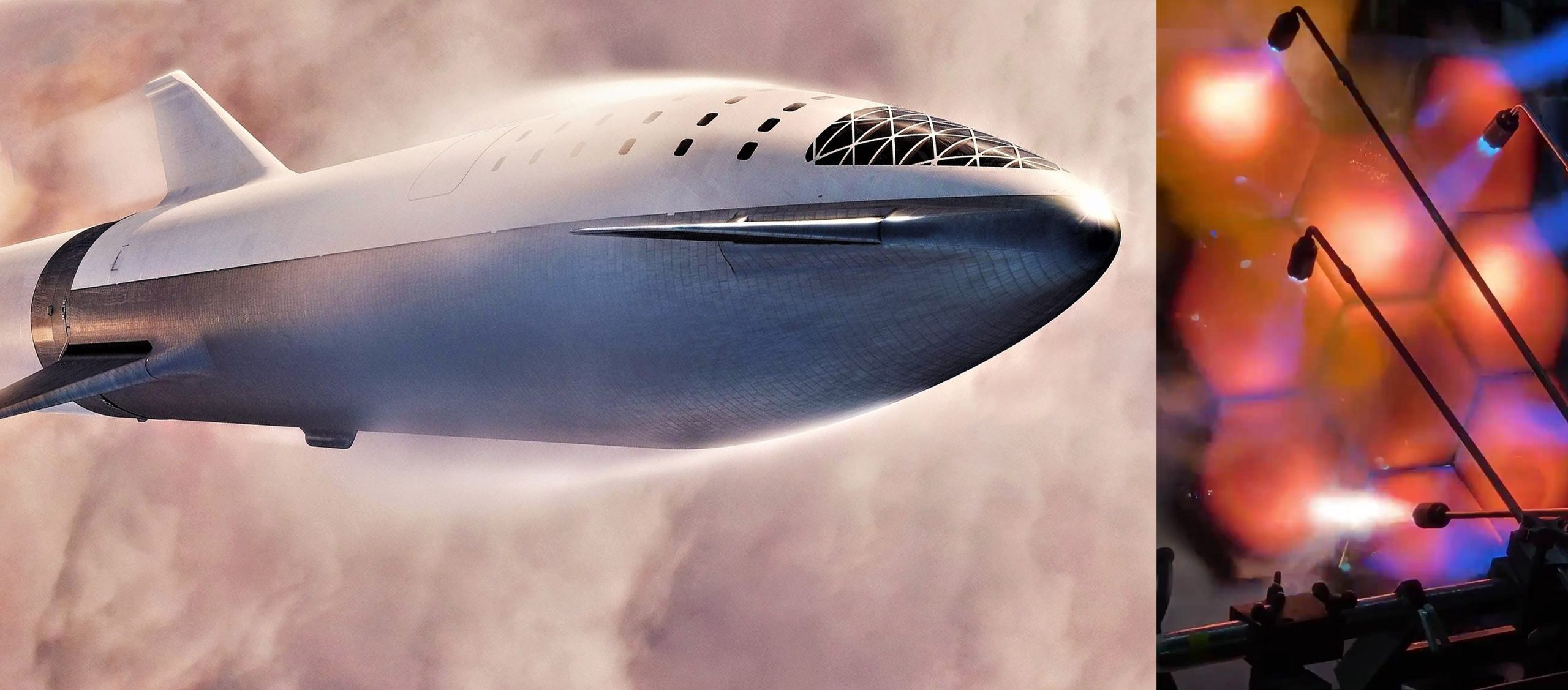

SpaceX’s first orbital Starship begins assembly as steel heat shield passes tests

SpaceX CEO Elon Musk says that the company’s South Texas workforce has already begun to fabricate the first orbital-class Starship prototype, while Hawthorne engineers and technicians are in the midst of performing small-scale testing of the vehicle’s unprecedented stainless steel heat shield.

To be assembled out of hexagonal tiles of (presumably) stainless steel, Starship’s metallic heat shield will be one of the most crucial aspects of the orbital spacecraft, particularly with respect to ensuring that it’s extraordinarily easy to reuse. To survive extreme interplanetary-velocity reentry conditions at Mars, Earth, and beyond and remain in a functional, flight-ready condition after landing, SpaceX will need to implement the world’s first orbital-class, large-scale metallic heat shield with an immature technology known as transpirational cooling.

By quite literally drilling tiny holes (pores) into heat shield plates at the hottest parts of Starship’s hull, transpirational cooling effectively allows a large portion of the heat of reentry to be wicked away by the flash evaporation of a liquid, typically water. For SpaceX’s Starship, it’s likely that the coolant of choice would be either liquid water or liquid methane, the former of which offers better cooling per unit of mass at the cost of added plumbing complexity and spaceship mass, while the latter would make use of the same propellant fueling the ship at the cost of worse cooling per unit of mass. Either way, SpaceX will be heading into unproven territory, demanding extensive ground and flight testing to first ensure that the concept is truly viable and then to verify that it can be made as reliable and reusable as it simply has to be.

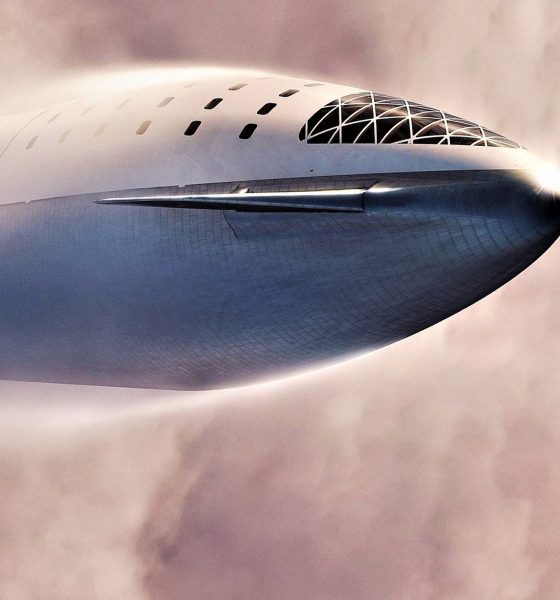

Tests like those shown on March 17th by Musk indicate that SpaceX is indeed deep into the process of extensive and often destructive testing, something the company has proven to be exceptionally good at. It’s unclear if the above test of Starship’s hexagonal heat shield tiles – likely made out of a variant of 300-series stainless steel – involved tiles with active or passive cooling, but Musk suggested that the hot-spots created with spin-forming torches reached temperatures as high as 1650 Kelvin (2500ºF/1400ºC. Unlike the ablative heat shields SpaceX is familiar with building and operating through its Crew and Cargo Dragon spacecraft, a stainless steel heat shield would be expected to almost entirely resist erosion (i.e. ablation) during extremely high-velocity reentries of at least 12-14 km/s (~31,000 mph, Mach 40+).

Update on the fairing and the unknown “2nd fairing” pic.twitter.com/5PMBYyBDAi— Austin Barnard? (@austinbarnard45) March 16, 2019

Meanwhile, Musk also confirmed that SpaceX has decided to skip constructing a replacement nosecone/fairing for Starhopper, a functional Starship prototype that will be used to conduct extremely short hop tests like Falcon 9’s development-era Grasshopper and F9R test articles. Over the last several weeks, SpaceX technicians have been rapidly assembling what was initially assumed to be the replacement fairing Musk had previously suggested would be built. Instead, the duo of stainless steel barrel sections – relying on steel much thinner than the heavy-duty stuff used to build Starhopper – are apparently the beginnings of the first orbital-class Starship prototype, said by Musk to be aiming for flight-readiness as early as June 2019 around two months ago.

While still an extraordinarily ambitious target for a vehicle that has yet to conduct any integrated hops or flight-tests in any form, the fact that SpaceX is began the process of building the first orbital Starship in late February could actually give the company’s engineers and technicians a fighting chance to complete Starhopper testing and Starship assembly over the next 90-100 days.

If stacked atop each other, the two new steel sections in work would likely stretch a solid 20-30 meters (65-100 ft) tall. Meanwhile, the first orbital-grade tank domes and/or conical nose section is also in the process of being welded together out of smaller segments, already fast approaching something ready to be installed inside the steel barrel sections.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.