SpaceX

SpaceX President talks BFR and Mars exploration in laid-back Madrid Q&A session

Speaking at a Q&A session hosted for a Madrid university’s Master’s of Business Administration students, SpaceX President and COO Gwynne Shotwell talked for nearly an hour about the launch company’s next-generation BFR rocket, the reality of long-term life on Mars, and more, revealing a number of interesting tidbits in the process.

Almost entirely led by questions from the unusually well-informed audience, the graduate students and professors predominately kept the famous SpaceX exec more or less focused on the company’s future, delving into the reasoning behind BFR. Shotwell had only praise for the next-generation launch vehicle, which is targeting initial hop tests in late 2019 and its first full launches as early as 2021, a delay of several months from previous schedule estimates targeting hops in early 2019 and orbit by 2020.

Aside from schedule updates, Shotwell had more still to say about the rocket:

- “The flexibility that [BFR] offers will change how we do everything in space.”

- “BFR has the capability to open its payload bay, bring [a] satellite back in, close it, pressurize it, work on it (repair, upgrade, etc), and redeploy it”

- “BFR will basically allow people to work and live in space”

Although she offered some self-deprecating humor on SpaceX’s often-optimistic schedules for future projects, she was for the most part positive about the company’s ultimate aspirations of completing and perfecting BFR, stating without hesitation that “something terrible [would] have to happen at SpaceX for us to not be on our way to Mars and back in 10 years.”

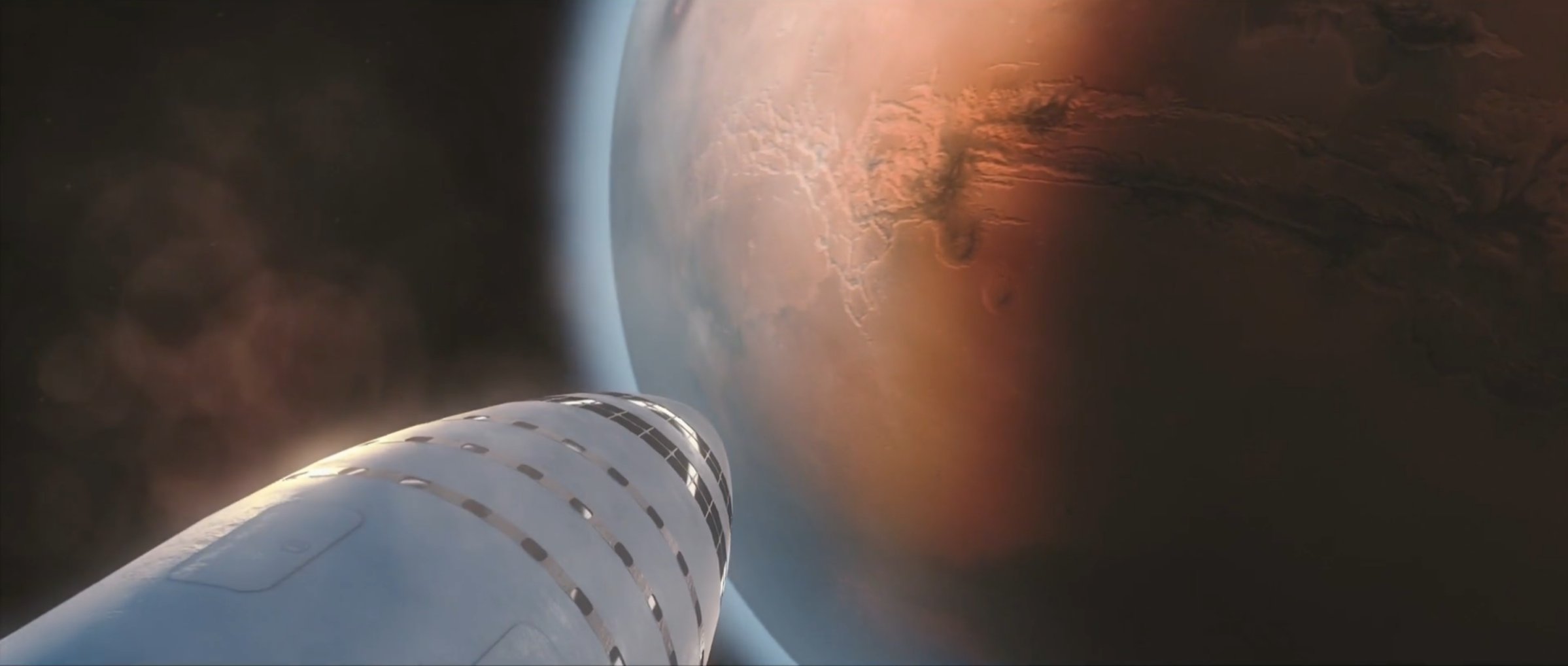

- SpaceX’s BFR visualized just before launch at a heavily-upgraded Pad 39A. (SpaceX)

- Note the 2017/early-2018 variant’s single delta-wing and extendable leg pods (silver). (SpaceX)

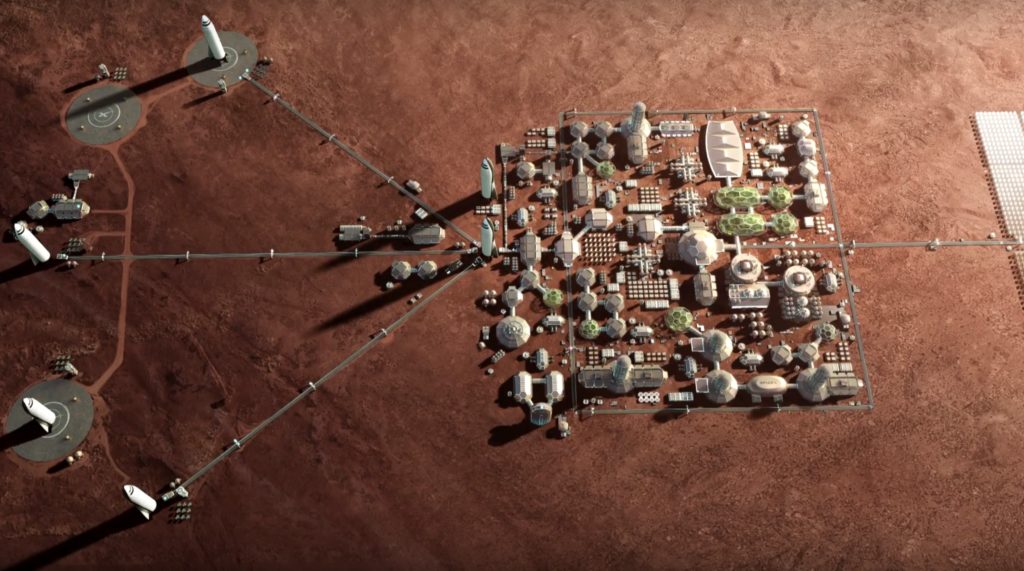

- We’re not here just yet, but SpaceX is pushing hard to build BFR and get humanity to Mars as quickly as practicable. (SpaceX)

Shotwell acknowledged that some of the hurdles in the way of those goals could become headaches, particularly the decision to build the rocket’s propellant tanks solely out of carbon fiber composites, but also expressed her belief that most of the difficulty of designing and building BFR’s advanced Raptor engine was already behind SpaceX. Roughly two times as powerful as Merlin 1D and dramatically more efficient, SpaceX’s Raptor development team has conducted extensive hot-fire testing (at least 1200 seconds) of the engine, optimizing it to the point that the company is already building (and maybe already hot-fire testing) flight-grade hardware.

Other miscellaneous comments showed Shotwell at her best, ad-libbing one-liners that were lucid, accurate, and entertaining.

- “We’ll be going to Mars … with NASA and with ESA. It’s gonna be like extreme camping… for 100 years. And then it might be okay.”

- “[Space] tourism is inevitable but [SpaceX] doesn’t want to do it too soon”, the goal is to launch “test pilots before families”

- “The first cars on Mars will be Teslas.”

Watch the full Shotwell Q&A – graciously recorded by the business student and SpaceX subreddit member LordsofDecay – at the link below.

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.

Elon Musk

SpaceX pursues 5G-level connectivity with Starlink Mobile V2 expansion

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system.

SpaceX has previewed a major upgrade to Starlink Mobile, outlining next-generation satellites that aim to deliver significantly higher capacity and full 5G-level connectivity directly to mobile phones.

The update comes as Starlink rebrands its Direct-to-Cell service to Starlink Mobile, positioning the platform as a scalable satellite-to-mobile solution that’s integrated with global telecom partners.

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system. The company also noted that the new V2 satellites are designed to provide significantly higher throughput capability compared to its current iteration.

“The next generation of Starlink Mobile satellites – V2 – will deliver full cellular coverage to places never thought possible via the highest performing satellite-to-mobile network ever built.

“Driven by custom SpaceX-designed silicon and phased array antennas, the satellites will support thousands of spatial beams and higher bandwidth capability, enabling around 20x the throughput capability as compared to a first-generation satellite,” SpaceX wrote in its official Starlink Mobile page.

Thanks to the higher bandwidth of Starlink Mobile, users should be able to stream, browse the internet, use high-speed apps, and enjoy voice services comparable to terrestrial cellular networks.

In most environments, Starlink says the upgraded system will enable full 5G cellular connectivity with a user experience similar to existing ground-based networks.

The satellites function as “cell towers in space,” using advanced phased-array antennas and laser interlinks to integrate with terrestrial infrastructure in a roaming-like architecture.

“Starlink Mobile works with existing LTE phones wherever you can see the sky. The satellites have an antenna that acts like a cellphone tower in space, the most advanced phased array antennas in the world that connect seamlessly over lasers to any point in the globe, allowing network integration similar to a standard roaming partner,” SpaceX wrote.

Starlink Mobile currently operates with approximately 650 satellites in low-Earth orbit and is active across more than 32 countries, representing over 1.7 billion people through partnerships with mobile network operators. Starlink Mobile’s current partnerships span North America, Europe, Asia, Africa, and Oceania, allowing reciprocal access across participating nations.