News

SpaceX’s second Super Heavy booster enters production in South Texas

In a rare burst of visible activity, SpaceX’s South Texas Starship factory has begun fabricating a second Super Heavy booster and taken a significant step forward on the first prototype.

Set to be the largest operational rocket stage ever built by more than a factor of two, Super Heavy is the booster tasked with launching a fully fueled and loaded Starship (~1400 mT or 3 million lbs) out of the bulk of Earth’s atmosphere. Powered by up to 28 Raptor engines, Super Heavy and Starship will weigh upwards of 5000 metric tons (~11 million lbs) and produce anywhere from 5600 to 7700 metric tons (12.5-17 million lbf) of thrust at liftoff.

Most importantly, though SpaceX CEO Elon Musk has noted that an optimized Starship might be able to reach orbit on a one-way trip, a giant, reasonably efficient booster like Super Heavy is necessary to send Starship into a healthy orbit with all the extra hardware and mass needed to make the orbital spaceship reusable. More than twice as heavy and two-thirds as tall as SpaceX’s workhorse Falcon 9 rocket, that will be no small feat.

Following the appearance of Super Heavy booster number 1’s (BN1) unique common dome, extra-large ‘transfer tube’ segments, and a donut-like eight-Raptor thrust section last month, visible booster work settled down for the next several weeks. In the interim, Musk revealed that SpaceX aims to hop the first Super Heavy booster (BN1) just “a few months” into 2021, followed by the bombshell that the CEO wants to eventually catch Super Heavy boosters to avoid the need for landing legs entirely.

Two weeks after that latest info from Musk and a month after major booster-related factory activity, the first hardware intended for Super Heavy prototype BN2 was spotted on January 19th. Featuring a never-before-seen structural addition in the form of what looks like a hexagonal or octagonal steel ring, the booster’s unique forward dome represents the first real evidence of the modifications needed to install a variety of hardware specific to Super Heavy.

The limited nature and number of current views make it hard to conclude with certainty that the BN2 forward dome’s add-on is hexagonal or octagonal – either could technically be made to work. Barring a surprise design change, Super Heavy – like Falcon 9 and Heavy boosters – will sport four equally spaced grid fins and use them to ensure aerodynamic stability and control authority from hypersonic to supersonic velocities. Based on official SpaceX graphics, Super Heavy’s grid fins will be built out of welded steel, measure some 7 meters (23 ft) tall, and likely weigh 5+ metric tons apiece, thus requiring extremely powerful actuation systems and strong structural support.

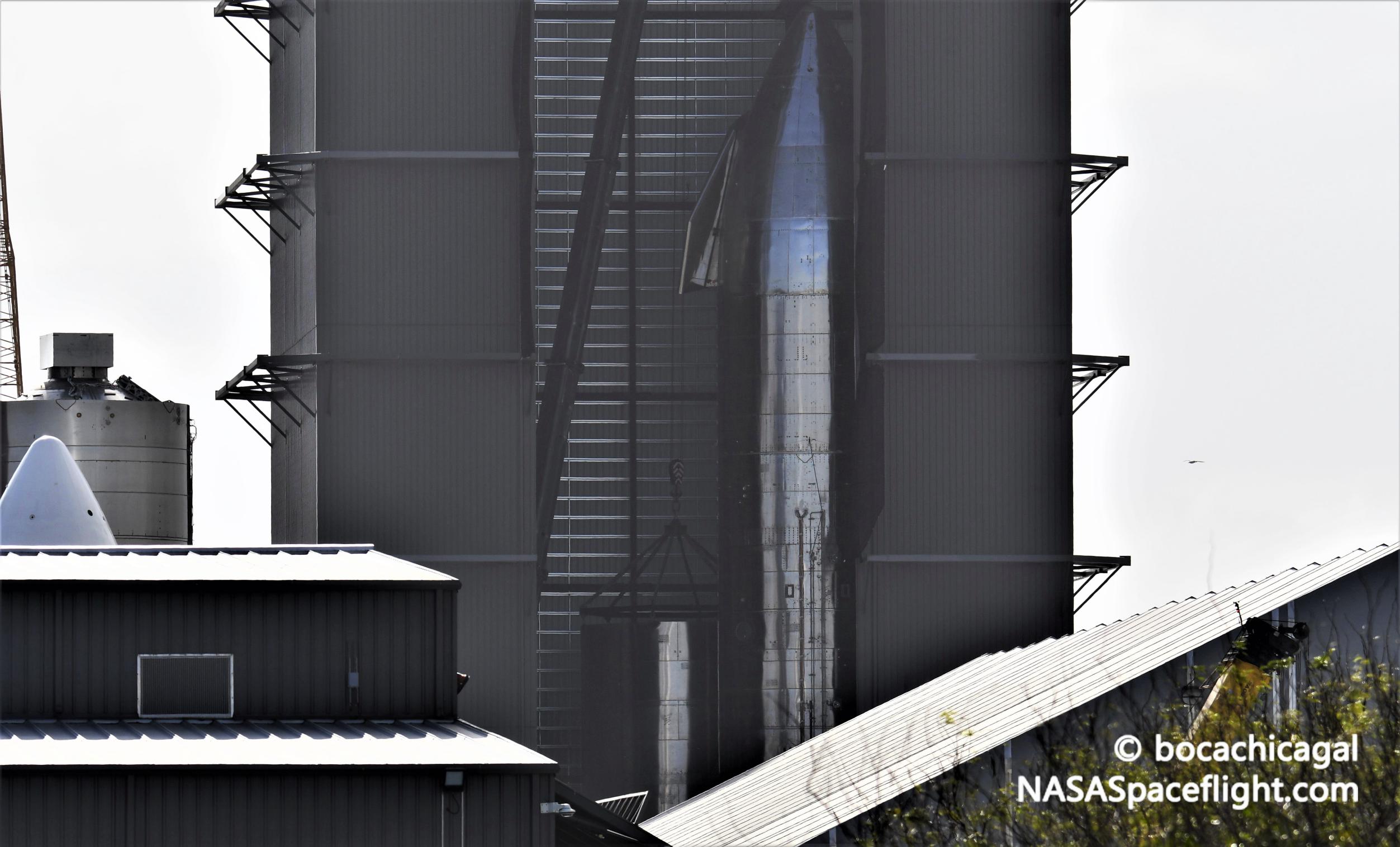

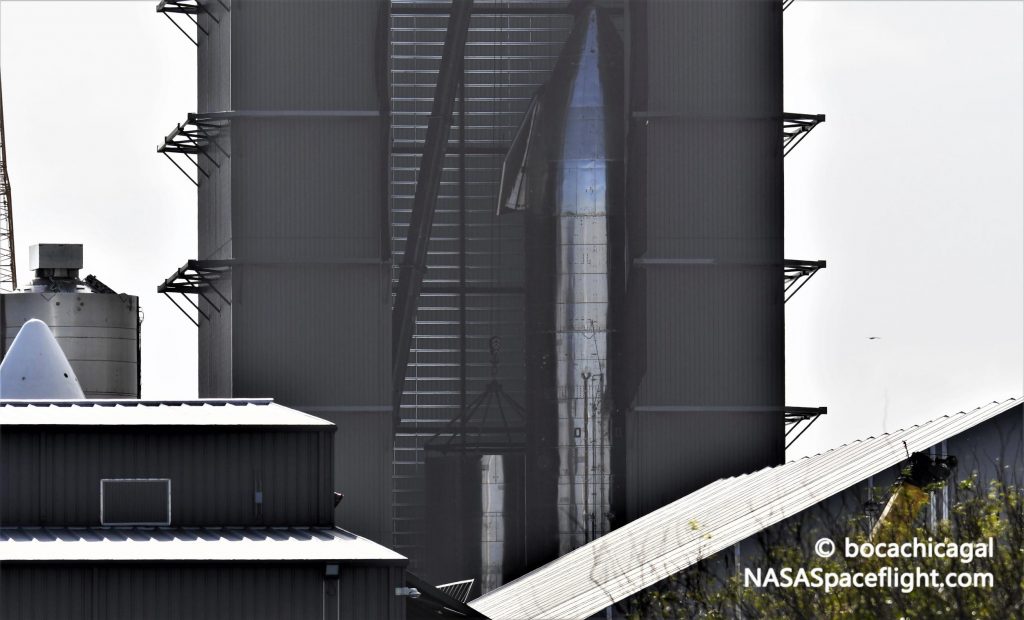

Meanwhile, beyond Super Heavy BN2’s first visible appearance, the process of assembling the first booster prototype also took a significant step forward. Sometime on January 19th, SpaceX ended a long period of inactivity, stacking the first Super Heavy ring sections since November 2020. More specifically, SpaceX teams appear to have installed either one or two four-ring sections on an existing booster segment already inside the high bay.

If at rest on top of the rest of the stack in Mary’s (BocaChicaGal) latest photo, one of two Super Heavy ‘stacks’ inside the high bay is now 12 rings (three sections) tall, representing almost a third of a complete 70-meter (~230 ft) tall booster. As of the most recent look inside the high bay, there were two separate stacks of Super Heavy rings – one with four and the other with eight. Based on the location of the new 12-ring stack, it’s more likely than not that SpaceX has simply combined the 12 rings last seen inside the high bay rather than adding one or two new ring sections to one of the two separate stacks.

Ultimately, the return of Super Heavy stacking activity after a two-month pause is an encouraging sign that SpaceX has settled on a design for the first few prototype boosters and could, in fact, be ready to start testing BN1 “a few months” from now.

News

Elon Musk gets brash response from Ryanair CEO, who thanks him for booking increase

Elon Musk got a brash response from Ryanair CEO Michael O’Leary, who said in a press conference on Wednesday afternoon that the Tesla frontman’s criticism of the airline not equipping Starlink has increased bookings for the next few months.

The two have had a continuing feud over the past several weeks after Musk criticized the airline for not using Starlink for its flights, which would enable fast, free, and reliable Wi-Fi on its aircraft.

Tesla CEO Elon Musk trolls budget airline after it refuses Starlink on its planes

Musk said earlier this week that he was entertaining the idea of purchasing Ryanair and putting someone named Ryan in charge, which would oust O’Leary from his position.

However, the barbs continued today, as O’Leary held a press conference, aiming to dispel any beliefs about Starlink and its use case for Ryanair flights, which are typically short in length.

O’Leary said in the press conference today:

“The Starlink people believe that 90% of our passengers would happily pay for wifi access. Our experience tells us less than 10% would pay; He (Elon) called me a retar*ed twat. He would have to join the back of a very, very long queue of people that already think I’m a retar*ed twat, including my four teenage children.”

He then went on to say that, due to Musk’s publicity, bookings for Ryanair flights have increased over the past few days, up 2 to 3 percent:

“But we do want to thank him for the wonderful boost in publicity. Our bookings are up 2-3% in the last few days. So thank you to Mr. Musk, but he’s wrong on the fuel drag. Non-European citizens cannot own a majority of European airlines, but if he wants to invest in Ryanair, we think it would be a very good investment.”

O’Leary didn’t end there, as he called Musk’s social media platform X a “cesspit,” and said he has no concern over becoming a member of it. However, Ryanair has been very active on X for several years, gaining notoriety for being comical and lighthearted.

🚨 Ryanair CEO’s comments on X and Starlink today at the planned presser.

Strange comments here, it just feels like it’s time to end all this crap https://t.co/NYeG95bM82

— TESLARATI (@Teslarati) January 21, 2026

The public spat between the two has definitely benefited Ryanair, and many are calling for it to end, especially those who support Musk, as they see it as a distraction.

Nevertheless, it is likely going to end with no real movement either way, and is more than likely just a bit of hilarity between the two parties that will end in the coming days.

News

Tesla CEO Elon Musk outlines expectations for Cybercab production

“…initial production is always very slow and follows an S-curve. The speed of production ramp is inversely proportionate to how many new parts and steps there are. For Cybercab and Optimus, almost everything is new, so the early production rate will be agonizingly slow, but eventually end up being insanely fast.”

Tesla CEO Elon Musk outlined expectations for Cybercab production as the vehicle is officially set to start rolling off manufacturing lines at the company’s Giga Texas factory in less than 100 days.

Cybercab is specifically designed and catered to Tesla’s self-driving platform and Robotaxi ride-hailing service. The company has been pushing hard to meet its self-set expectations for rolling out an effective self-driving suite, and with the Cybercab coming in under 100 days, it now needs to push for Unsupervised Self-Driving in the same time frame.

Tesla CEO Elon Musk confirms Robotaxi is set to go unsupervised

This is especially pertinent because the Cybercab is expected to be built without a steering wheel or pedals, and although some executives have said they would build the car with those things if it were necessary.

However, Musk has maintained that the Cybercab will not have either of those things: it will have two seats and a screen, and that’s it.

With production scheduled for less than 100 days, Musk broke down what people should expect from the initial manufacturing phases, being cautiously optimistic about what the early stages will likely entail:

“…initial production is always very slow and follows an S-curve. The speed of production ramp is inversely proportionate to how many new parts and steps there are. For Cybercab and Optimus, almost everything is new, so the early production rate will be agonizingly slow, but eventually end up being insanely fast.”

Musk knows better than most about the challenges of ramping up production of vehicles. With the Model 3, Musk routinely refers to it as “production hell.” The Cybertruck, because of its polarizing design and stainless steel exterior, also presented challenges to Tesla.

With the important caveat that initial production is always very slow and follows an S-curve.

The speed of the production ramp is inversely proportionate to how many new parts and steps there are.

For Cybercab and Optimus, almost everything is new, so the early production…

— Elon Musk (@elonmusk) January 20, 2026

The Cybercab definitely presents an easier production process for Tesla, and the company plans to build millions of units per year.

Musk said back in October 2024:

“We’re aiming for at least 2 million units a year of Cybercab. That will be in more than one factory, but I think it’s at least 2 million units a year, maybe 4 million ultimately.”

When April comes, we will find out exactly how things will move forward with Cybercab production.

News

Tesla reveals awesome Model 3 and Model Y incentive, but it’s ending soon

Tesla has revealed an awesome Model 3 and Model Y incentive to help consumers make the jump to one of its affordable mass-market vehicles, but it’s ending soon.

Tesla is offering one free upgrade on eligible inventory of the Model 3 and Model Y until February 2.

This would help buyers receive the most expensive paid option on the vehicle at no additional cost, meaning white interior or a more premium paint option will be free of charge if you take delivery on or before February 2.

Tesla states on its website for the offer:

“Only for limited inventory while supplies last. Price displayed on inventory listings already deducts the cost of the free option.”

Tesla says its one free upgrade offer on eligible U.S. inventory for the Model 3 and Model Y ends February 2.

With this incentive, buyers receive the most expensive paid option on the vehicle at no additional cost (up to $2k in savings). pic.twitter.com/IhoiURrsDI

— Sawyer Merritt (@SawyerMerritt) January 21, 2026

This latest incentive is just another advantage Tesla has by selling its vehicles directly and not using some sort of dealership model that relies on approvals from higher-ups. It is important to note that these programs are offered to help stimulate demand and push vehicles into customers’ hands.

It is not the only incentive Tesla is currently offering, either. In fact, there is a much larger incentive program that Tesla is working on, and it has to do with Full Self-Driving transfers, which could result in even more sales for the company through Q1.

Tesla is ending its FSD Transfer program on March 31, as it plans to transition to a Subscription-only basis with the self-driving suite for anyone who has not already purchased it outright.

This could help drive some on-the-fence buyers to new vehicles, but it remains to be seen. Given the timing of the program’s demise, it appears Tesla is hoping to use it to add additional sales and bolster a strong Q1 2026.

Interior and exterior paint colors can add up to $2,000 if you choose the most premium Ultra Red body color, or an additional $1,000 for the Black and White interior option. The discount, while small, could help get someone their preferred design configuration, instead of settling for something that is not quite what they want.