News

Tesla Model X safety-first approach saves groom’s life after hit and run the night before his wedding

A groom-to-be behind the wheel of Tesla Model X is thankful to be alive after the vehicle was involved in a severe side-impact collision by a stolen vehicle that careened into the driver’s door of the all-electric SUV at 65 miles per hour.

The driver, an automation consultant for Tesla, rented a Model X for his wedding. After leaving the rehearsal dinner that took place the night before the wedding, the groom-to-be dropped off his fiancé and headed home. Then things took a turn for the unexpected. In a forum post entitled ‘I am alive today well BC of a Model X‘, the driver recounts:

“When I made my way out of the parking lot, I began to take a left turn onto the main street. Mid-turn, I noticed a silver car quickly approaching the driver’s side of the vehicle (I later learned that they were going over 65mph on a private road). I had no time to react, since the driver came from a blind spot on my left. At this point, it looked like the driver had no intention of slowing down, and I immediately thought that I was either going to get badly hurt or potentially die.

I quickly braced and gripped the steering wheel as I was pounded by the silver car, sending me over 20 feet away from my starting point. With the impact, all of the airbags deployed, instantly leaving me in shock. The outgassing of the airbags caused the car to smoke, making it difficult to see. I reached for the door handle with my right hand, but was not able to open it. Seeing no other option, I kicked open the door and was able to escape the vehicle. As I walked outside, I immediately saw the police chasing after the culprits driving the silver car. I looked around, dazed, and ended up falling to the ground. I am unsure of what happened next, but all I can remember is hearing voices from the people nearby, and Nancy screaming my name. When I came to consciousness, I was being helped by the police, paramedics, and fire department. The silver car was a mess, but the Model X only suffered a broken axle and bent wheel.”

An impact from a 3,000 pound Honda Civic traveling at 65 miles per hour into a nearly stationary vehicle would normally end with disastrous consequences but the Model X was able to sustain the impact by cocooning the driver with twelve airbags: head and knee airbags in the front, two side curtain airbags, four seat-mounted side airbags, and two door-mounted airbags, putting the safety-first design to the test in ways nobody would ever want to have to experience. We saw a similar occurrence last year when a Tesla Model X saved the life of an entire family and their pet after it was involved in a horrific traffic accident at an intersection. “I waited 4 years for this one and would wait 4 more if that is what it took to protect my family like this.” said the driver of the Model X at the time.

The groom-to-be that was saved in this latest accident had previously worked with Tesla as an automation consultant for the company in the stamping, body and paint production line, and worked directly with engineers involved in the Model S, X and Model 3. Having worked with many of the people who designed the vehicle instilled a respect for Tesla and its vehicles that was enough for him to choose a Model X as the vehicle to be used for his wedding.

“I wanted to write this to you in hopes that this raises visibility to the management chain at Tesla. I can’t thank Elon Musk, Tesla, and the team enough for what they do and want them to know that their car saved my life. While I also believe that I am still alive because of divine intervention, being in that car was definitely my shield and protector. I have made it a short term goal of mine to sell my cars and buy a Tesla as my next vehicle. That car saved my life. Thank you for your time and I hope this message gets passed through to everyone, especially Elon.”

This story highlights a critical differentiator between Tesla and other auto manufacturers. Tesla and Elon Musk have always put safety first which the company puts as a main focal point at each new vehicle reveal. This focus on safety led to the development of vehicles with larger crumple zones up front (the frunk) than any comparably-sized vehicle, better coverage from integrated airbags and a greatly reduced risk of rollover due to the floor-mounted battery.

Tesla summarizes the safety features of the Model X on its website:

Model X is designed with safety as the first priority. The floor-mounted battery lowers the center of gravity so that the risk of rollover is about half that of any vehicle in its class. The battery structure strengthens Model X against side impact intrusions. And without a gasoline engine, the large front trunk acts as a giant impact-absorbing crumple zone. Although the National Highway Traffic Safety Administration has not yet conducted crash testing on Model X, Tesla’s own internally conducted crash testing indicates that Model X should be the first SUV to receive the highest safety rating in every category.

Building on the world-class safe design of Tesla vehicles, a layer of active safety features that are included in every Tesla sold take this to the next level with features like Automatic Emergency Braking and side impact collision warnings.

The safety-first culture at Tesla extends beyond its vehicles and into the next generation of products the company is producing – its factory. In its recent blog post about safety, Tesla shared how a safety-first focus underpins the entire design process even going so far as to look for ergonomics concerns in virtual mock ups of its manufacturing lines before they are built.

Tesla is revolutionizing the way humans get around and at the same time, rethinking the safety systems that keep all the people in its care in ways that ultimately benefit everyone. The driver of the Model X in this accident has made it a short term goal to acquire a Tesla as his personal vehicle. That should speak volumes to anyone who has been in an accident, lost someone in an accident or wants to keep themselves and those they travel with as safe as possible.

Source: Teslarati Forums

News

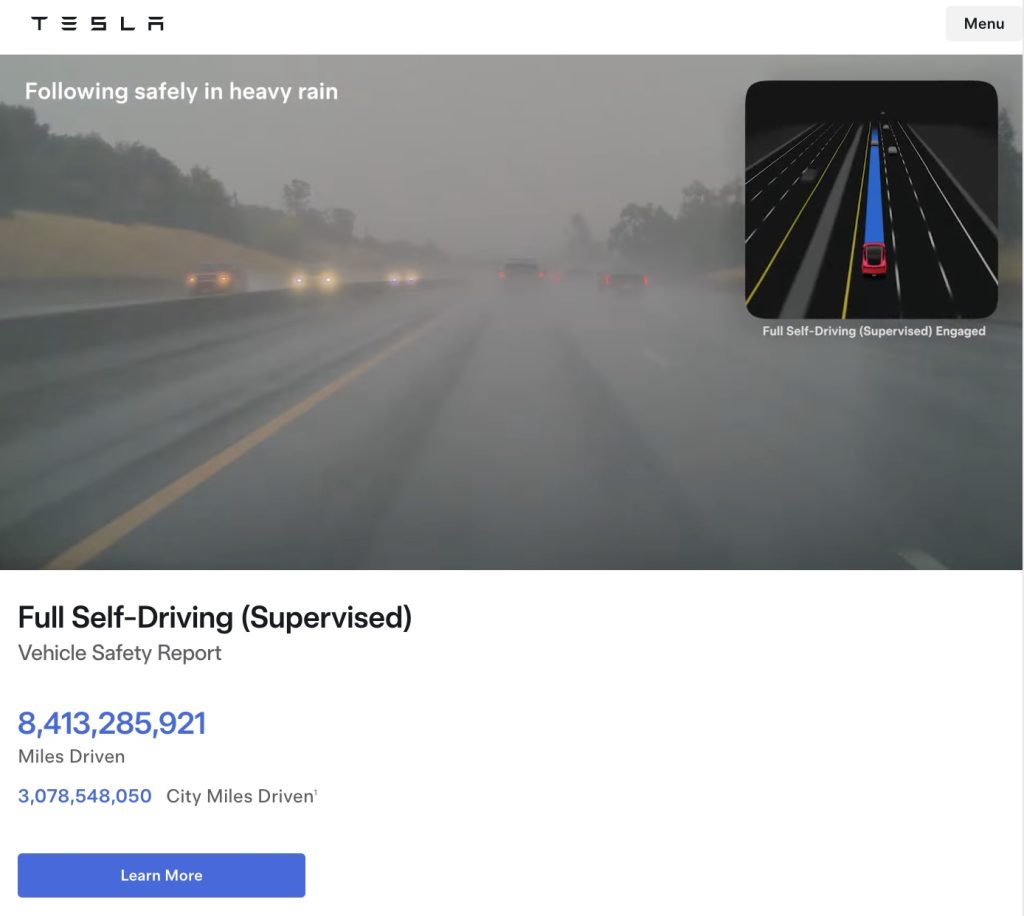

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.