SpaceX

3D-printed Mars habitat could be a perfect fit for early SpaceX Starship colonies

Space architecture startup AI SpaceFactory achieved second place in the latest phase of a NASA-led competition, pitting several groups against each other in pursuit of designing a 3D-printed Mars habitat and physically demonstrating some of the technologies needed to build them.

With a focus on ease of scalable 3D-printing and inhabitants’ quality of life, as well as the use of modular imported goods like windows and airlocks, MARSHA lends itself impeccably well to SpaceX’s goal of developing a sustainable human presence on Mars as quickly, safely, and affordably as possible with the support of its Starship/Super Heavy launch vehicle.

Aside from developing a custom 3D-printing material utilizing in-situ Martian resources and demonstrating the technology by successfully printing a 1200 gallon (4500 L) water tank, SpaceFactory’s habitat design – known as MARSHA – combines a unique level of pragmatism, functionality, and aesthetic elegance. After analyzing different structural options, the SpaceFactory team settled on a cocoon-like cylinder, taking advantage of the many benefits of the Martian environment while controlling for its several downsides. Most notably, Martian gravity is roughly 38% of Earth’s, while the small planet’s atmosphere is typically 80-150 times less dense at surface-level. As a consequence, the forces exerted by Martian winds are minuscule and can effectively be ignored, while the low gravity dramatically minimizes architectural challenges that arise from Earthbound structures having to battle their own weight.

Equally important, all Martian habitats will need to be pressurized to a level comfortable for long-term colonists, requiring that they be able to survive significant internal pressurization. The Martian radiation environment is also significantly less forgiving than Earth, although the dangers of Martian radiation are dramatically overblown. The material of choice SpaceFactory designed to 3D-print its MARSHA habitat – a biorenewable plastic (PLA) reinforced with locally-sourced basalt fiber – also accounts for many of Mars’ shortcomings, as plastics happen to be some of the best materials for radiation shielding per unit of mass. Featuring a duo of PLA shells placing a meter or more of plastic between living areas, MARSHA would permit relatively acceptable radiation levels while avoiding the downsides of locating habitats underground or burying them under several meters of Martian regolith.

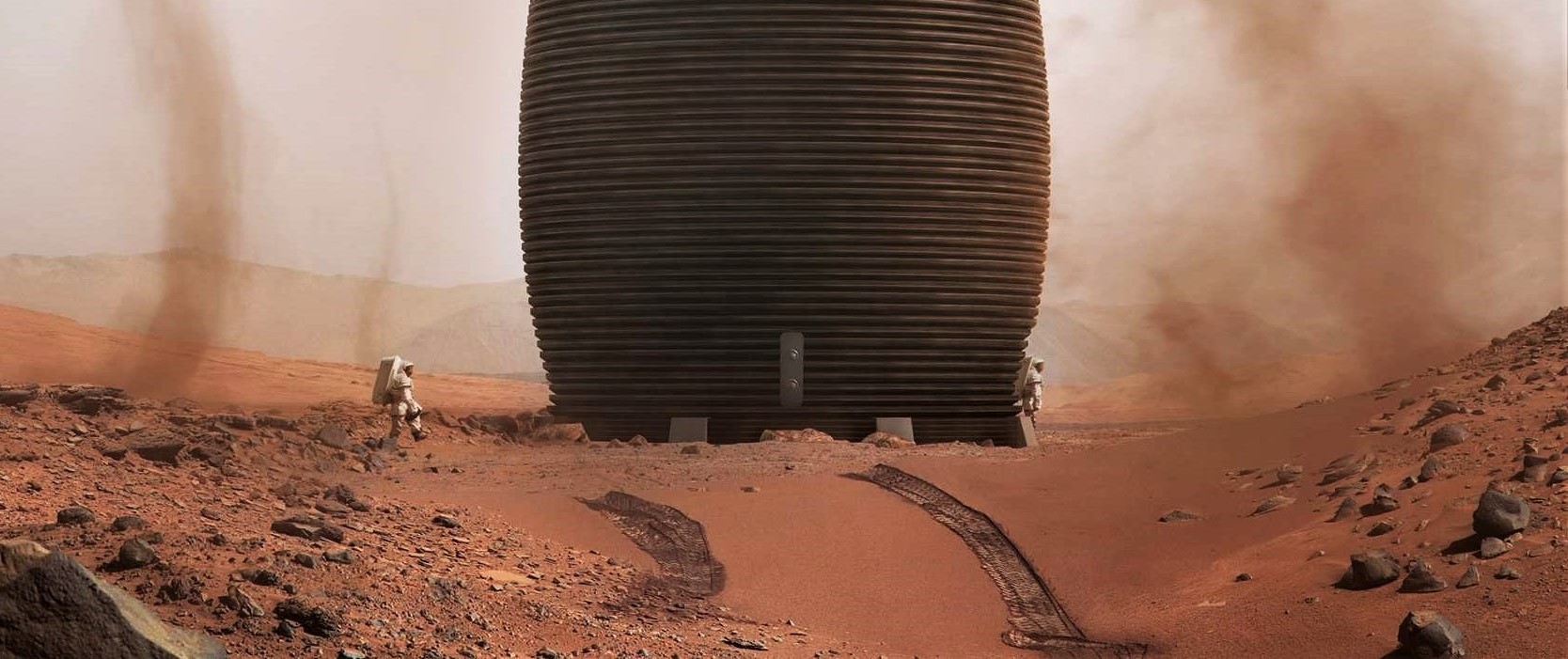

- An overview of a potential Mars base built around the MARSHA habitat design. (AI SpaceFactory & PLOMP)

- A glimpse into one floor of MARSHA’s Mars habitat interior. (AI SpaceFactory & PLOMP)

- A number of BFR (2018) spaceships seen landed at a future Mars base. (SpaceX)

Thanks to its cylindrical design and SpaceFactory’s attention to quality of life for astronauts residing within it, MARSHA is also exceptionally beautiful and more than a little alluring even from the perspective of Earthly habitation. MARSHA’s thoughtful design and polished aesthetic would likely mesh well with SpaceX CEO Elon Musk’s own established preferences, known (sometimes infamously so) for a predilection towards building things that value form at least as much as function. Due to the relatively compact nature of the hardware needed (in theory) to begin building MARSHA and the apparent potential for autonomous construction, SpaceFactory’s design also aligns with a number of critical aspects of SpaceX’s outlined Mars colonization architecture.

- AI SpaceFactory’s alluring vision of one route to humans living on Mars.

- A cutaway view of MARSHA at Martian dusk. (AI SpaceFactory)

- An outline of the main features of SpaceX’s “Mars Architecture”, present by Paul Wooster in August 2018. (SpaceX)

- An overview of an early SpaceX Mars colony, circa 2017. (SpaceX)

Up next for NASA’s 3D-printed habitat competition is “Phase 3”, effectively a grand finale: up to eight finalists are expected to compete to 3D-print a 1/3rd scale model of their Mars habitat design as early as May 2019. While not confirmed, it’s likely that SpaceFactory will be among those finalists, potentially helping to offer an early glimpse at what rapidly-printed Mars habitats might look like in real life. SpaceX CEO Elon Musk has also indicated that he would provide a more substantial update on the status of BFR (Starship/Super Heavy) and SpaceX’s Mars architecture soon after the company’s first Starship prototype – unofficially known as Starhopper – begins test flights. That milestone is like no fewer than 1-2 months away.

Check out Teslarati’s newsletters for prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes!

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.

Elon Musk

SpaceX pursues 5G-level connectivity with Starlink Mobile V2 expansion

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system.

SpaceX has previewed a major upgrade to Starlink Mobile, outlining next-generation satellites that aim to deliver significantly higher capacity and full 5G-level connectivity directly to mobile phones.

The update comes as Starlink rebrands its Direct-to-Cell service to Starlink Mobile, positioning the platform as a scalable satellite-to-mobile solution that’s integrated with global telecom partners.

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system. The company also noted that the new V2 satellites are designed to provide significantly higher throughput capability compared to its current iteration.

“The next generation of Starlink Mobile satellites – V2 – will deliver full cellular coverage to places never thought possible via the highest performing satellite-to-mobile network ever built.

“Driven by custom SpaceX-designed silicon and phased array antennas, the satellites will support thousands of spatial beams and higher bandwidth capability, enabling around 20x the throughput capability as compared to a first-generation satellite,” SpaceX wrote in its official Starlink Mobile page.

Thanks to the higher bandwidth of Starlink Mobile, users should be able to stream, browse the internet, use high-speed apps, and enjoy voice services comparable to terrestrial cellular networks.

In most environments, Starlink says the upgraded system will enable full 5G cellular connectivity with a user experience similar to existing ground-based networks.

The satellites function as “cell towers in space,” using advanced phased-array antennas and laser interlinks to integrate with terrestrial infrastructure in a roaming-like architecture.

“Starlink Mobile works with existing LTE phones wherever you can see the sky. The satellites have an antenna that acts like a cellphone tower in space, the most advanced phased array antennas in the world that connect seamlessly over lasers to any point in the globe, allowing network integration similar to a standard roaming partner,” SpaceX wrote.

Starlink Mobile currently operates with approximately 650 satellites in low-Earth orbit and is active across more than 32 countries, representing over 1.7 billion people through partnerships with mobile network operators. Starlink Mobile’s current partnerships span North America, Europe, Asia, Africa, and Oceania, allowing reciprocal access across participating nations.