News

SpaceX’s South Texas Starship factory prepares for major upgrades

In what is probably a sign of things to come for SpaceX’s nascent Florida Starship factory, the company’s original Starbase facility in South Texas may be about to graduate from tents to more permanent buildings.

More than two years ago, in late 2019, SpaceX followed in the footsteps of Tesla and began constructing a surprisingly advanced factory out of a series of tents. Instead of Model 3s, though, SpaceX would be building and assembling sections of the largest and most powerful rocket ever built. Measuring approximately 120 meters (~390 ft) tall, 9 meters (~30 ft) wide, ~5000 tons (~11M lb) fully fueled, and capable of producing around 7500 tons (~16.5M lbf) of thrust at liftoff, Starship is a fully reusable rocket that aims to perfect what SpaceX has already achieved with partially reusable Falcon 9s and Heavies.

Nonetheless, Starship manufacturing represents a substantial departure from the methods SpaceX uses to build Falcon rockets.

Instead of heavily leaning on horizontal integration (meaning that the rockets are primarily assembled in a horizontal orientation), Starship and its Super Heavy booster are almost exclusively assembled vertically. Excluding the machining of major loadbearing structures, Starship manufacturing generally begins with giant rolls of thin (3-4mm or ~0.15 in) stainless steel. SpaceX uses a custom tool to unspool the sheet metal, cuts off a roughly 28-meter (~92 ft) long strip, and then welds the ends of that strip together to produce a cylindrical barrel. Repeat that process 57 times and you end up with enough rings to assemble a full Super Heavy booster and most of a Starship.

However, using increasingly custom tools, SpaceX first stacks and welds those individual rings together to form sections of two, three, four, or five. Each section is then prepared for its specific role with a range of cutouts, plumbing, reinforcements (vertical stringers or circumferential stiffeners), thrust structures (the plates that Raptor engines attach to), and other add-ons. Most importantly, certain stacks of rings are mated with large steel domes – welded together out of prefabricated steel plates – to form forward, common, and aft dome sections. For Starship, SpaceX also assembles the ship’s conical nose section in a similar manner.

Virtually all ring, dome, and nose assembly work is conducted in one of three massive tents – each about 114m x 35m (375′ x 110′) – that form the backbone of Starbase’s Starship factory. Finally, SpaceX has built a series of massive open-air bays where, once fully outfitted, each ship and booster section is stacked in a specific order and welded together to complete the basic structures of Starship and Super Heavy.

While SpaceX continues to speed towards the completion of Starbase’s largest and tallest Starship assembly bay yet, the latest news centers around Starbase’s tents. After physically relocating a smaller but still substantial tent believed to be used basic metalwork (laser/water cutting, presses, etc.), SpaceX has rapidly broken ground and partially completed the foundation of a massive, new building believed to be the start of an upgraded Starship factory.

According to RGV Aerial Photography, SpaceX isn’t merely expanding the main three-tent factory with a fourth larger, permanent building. Instead, it reportedly aims to replace all of Starbase’s tents with a single 300,000-square-foot (~28,000 square meter) building that will be about 18 meters (60 ft) tall and likely measure around 800 feet (250m) long and 400 feet (120m) wide. Starbase’s tents are roughly the same height but their tented roofs mean that only a fraction of that height can be used for ring work and only a fraction of the floor space for taller nose work.

In comparison, a 300,000 square-foot building would have almost two and half times as much covered floor space as Starbase’s three tents – all of which can theoretically be used for ring and nose section assembly. In fact, with a mostly flat 18-meter roof, SpaceX could feasibly expand most ‘stacks’ by a ring or two, which would reduce the number of sections (and thus stacking operations) needed to assemble a ship or booster.

All told, while tents (“sprung structures”) can clearly be indefinite solutions for things like automotive manufacturing, Starship production is one case in which a more permanent flat-ceiling building is undeniably superior. With more than two years of experience and data to draw from, SpaceX may finally be confident enough in its present-day Starship production methods to commit to the construction of Starbase’s next evolution. Stay tuned to see where it leads.

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.

Elon Musk

Music City Loop could highlight The Boring Company’s real disruption

The real story behind the tunneling startup’s Nashville tunnel project is the company’s targeted $25 million per mile construction cost.

Recent commentary on social media has highlighted what could very well prove to be The Boring Company’s real disruption.

The analysis was shared by tech watcher Aakash Gupta on social media platform X, where he argued that the real story behind the tunneling startup’s Nashville tunnel project is the company’s targeted $25 million per mile construction cost.

According to Gupta’s breakdown, Nashville’s 2018 light rail proposal was priced at roughly $200 million per mile. New York’s East Side Access project reportedly cost about $3.5 billion per mile, while Los Angeles Metro expansion projects have approached $1 billion per mile.

By comparison, The Boring Company has stated it can construct 13 miles of twin tunnels in the Music City Loop for between $240 million and $300 million total. That implies a cost near $25 million per mile, or roughly a 95% reduction from industry averages cited in the post.

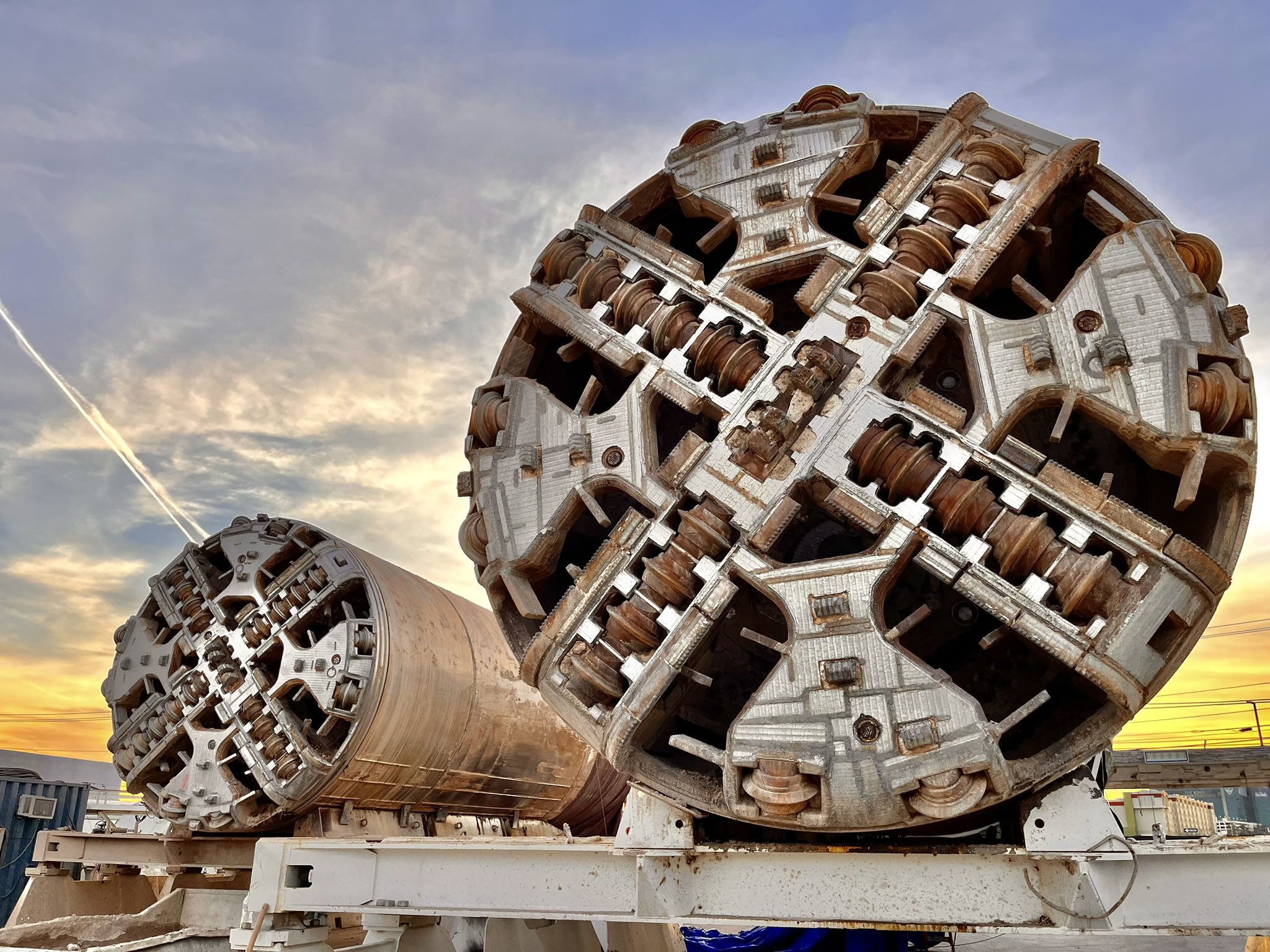

Several technical departures from conventional tunneling allow the Boring Company to lower its costs, from its smaller 12-foot diameter tunnels to its fully electric Prufrock machines that are designed to mine continuously with no personnel inside the tunnel and their capability to “porpoise” for easy launch and retrieval.

Tesla and Space CEO Elon Musk responded to the post on X, stating simply that “Tunnels are so underrated.”

The Boring Company has seen some momentum as of late, with the company recently signing a construction contract in Dubai and the Universal Orlando Loop progressing. Recent reports have also pointed to tunnels potentially being constructed to solve traffic congestion issues near the Giga Nevada area.

While The Boring Company’s tunnels have so far been used for Loop systems publicly for now, Elon Musk recently noted that the tunneling startup’s underground passages would not be limited only to ride-hailing vehicles.

In a reply to a post on X which discussed the specifications of the Music City Loop, Musk clarified that “any fully autonomous electric cars can use the tunnels.” This suggests that vehicles potentially running systems like FSD Supervised, even if they are not Teslas, could be used in systems like the Music City Loop in the future.