News

Tesla Semi production specs: powertrain, battery, Megacharger output, and more

The Tesla Semi has already been delivered to its first customers, but the actual production specs of the vehicle remain largely unknown or unconfirmed at best. Fortunately, a recent trip to PepsiCo’s Frito Lay facility in Modesto, Caifornia has provided some details that otherwise reveal the Tesla Semi production specs.

When Tesla held the first deliveries of the Semi, CEO Elon Musk highlighted that sustainable long-haulers are needed because in the transportation sector, semi trucks comprise about just 1% of vehicles on the road but they account for 20% of the emissions. Vehicles like the Tesla Semi are then designed to challenge this status quo.

Automotive publication MotorTrend was able to visit PepsiCo’s Modesto Frito Lay facility to check out the company’s first Tesla Semi units. As noted by the publication, the Modesto facility is a perfect fit for the Semi as the site already uses other green vehicles like BYD 8Y yard tractors, Peterbilt 220EV electric box trucks, and natural-gas-powered Volvo VNL trucks. The Tesla Semi fleet is used for out-and-back trips across the region.

The publication was able to gather some details about the Class 8 all-electric truck from its drivers and Tesla representatives who were at the location during the visit. Following are some key specs of the Tesla Semi.

Powertrain

The Tesla Semi features a modified Plaid tri-motor powertrain that’s spun backward. The Model S’ front motor drives the Semi’s rear axle and acts as the vehicle’s high-efficiency “highway drive unit.” The Model S Plaid’s dual rear motors, on the other hand, are installed on the rear axle. With this in mind, MotorTrend estimated that the Tesla Semi likely matches the Model S and Model X Plaid’s 1,020 horsepower and 1,050 pounds-feet of torque.

This estimate makes sense considering that a Tesla representative reportedly noted that the Tesla Semi makes “three times the power of an average diesel semi.” The US’ best-selling semi is the Freightliner Cascadia, whose base model features 350 horsepower. Three times the base Cascadia’s horsepower certainly aligns with the estimate that the Semi has about 1,020 horsepower. On a side note, the Tesla Semi production version does not have a frunk, unlike the vehicle’s prototype units.

Battery

Drivers of the Tesla Semi reportedly noted that the all-electric Class 8 truck is fitted with a 1,000 kWh battery pack. Tesla lists the Semi’s range as 500 miles per charge, and Elon Musk has also highlighted that the vehicle would consume only 2 kW per mile traveled.

If these estimates prove accurate, then the Semi’s 300-mile variant would likely have a battery pack that’s around 600 kWh. That’s still a lot of batteries, so Tesla would have to ensure that its production is optimized to ensure that the Semi is profitable.

Megacharger Output

The Tesla Semi features a charging port that’s different from all the vehicles that the company has released so far. The motoring publication noted that the Tesla Semi’s Megachargers installed on the Modesto facility could provide around 750 kW of power, or about three times the output of the company’s Supercharger V3 network.

The cables for the Tesla Semi’s Megachargers are thick, though they are reportedly easy to manage compared to some DC fast charging networks in the market. Charging the Semi from almost empty to 70% typically takes about 30 minutes. A full charge all the way to 100% reportedly takes around 90 minutes.

Physical Controls

While the Tesla Semi’s controls are mostly centered on its two infotainment systems, the vehicle also sports several physical buttons. Among these are the parking brake, trailer-brake air supply, and the vehicle’s hazards. Other physical controls include stalks similar to those found in the Tesla Model 3 and Model Y, though some buttons on the steering wheel resemble those in the new Model S and Model X.

Interior Space

The cabin of the Tesla Semi is cavernous, similar to the company’s other vehicles. MotorTrend noted that there’s enough space to enable a six-foot person to walk around and stretch in the Tesla Semi’s 3×7 foot cabin. So far, PepsiCo’s drivers seem to like the Semi, with some telling the motoring publication that the all-electric truck was very comfortable and “drove like a car.”

Other Details

The use of the Tesla Semi’s dual infotainment systems is quite interesting. The right display functions as the Tesla Semi’s main infotainment unit, while the left display exclusively shows pertinent information about the truck, such as its tire pressure. The windows in the Semi’s cabin also open when needed, though they do not roll down. Some space in the cabin also seem to be reserved for customers who wish to order the Tesla Semi with a sleeper cabin. Images taken of the Semi’s displays also confirm that the vehicle is equipped with Tesla’s Full Self-Driving computer.

Don’t hesitate to contact us with news tips. Just send a message to simon@teslarati.com to give us a heads up.

Elon Musk

Celebrating SpaceX’s Falcon Heavy Tesla Roadster launch, seven years later (Op-Ed)

Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

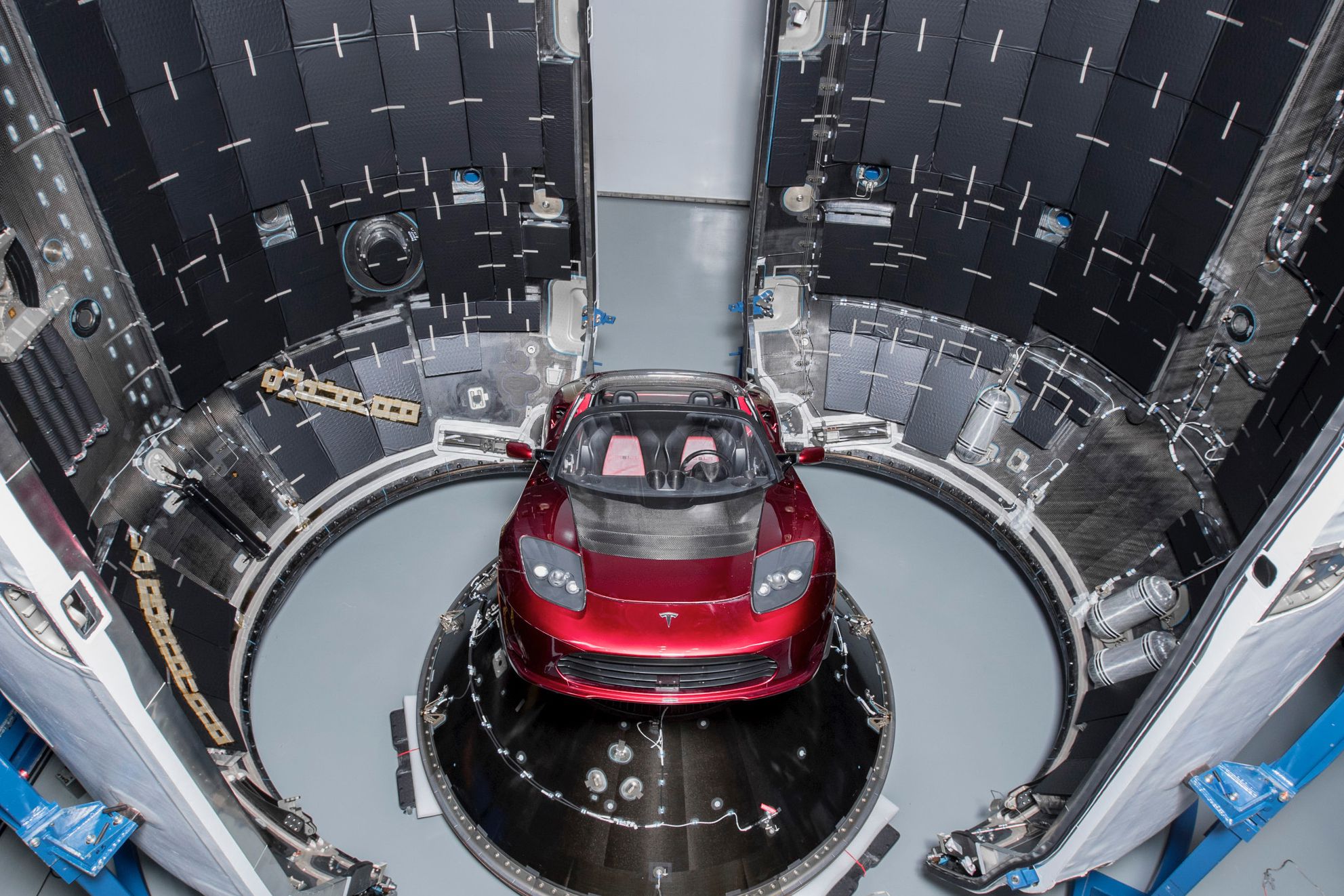

When Falcon Heavy lifted off in February 2018 with Elon Musk’s personal Tesla Roadster as its payload, SpaceX was at a much different place. So was Tesla. It was unclear whether Falcon Heavy was feasible at all, and Tesla was in the depths of Model 3 production hell.

At the time, Tesla’s market capitalization hovered around $55–60 billion, an amount critics argued was already grossly overvalued. SpaceX, on the other hand, was an aggressive private launch provider known for taking risks that traditional aerospace companies avoided.

The Roadster launch was bold by design. Falcon Heavy’s maiden mission carried no paying payload, no government satellite, just a car drifting past Earth with David Bowie playing in the background. To many, it looked like a stunt. For Elon Musk and the SpaceX team, it was a bold statement: there should be some things in the world that simply inspire people.

Inspire it did, and seven years later, SpaceX and Tesla’s results speak for themselves.

Today, Tesla is the world’s most valuable automaker, with a market capitalization of roughly $1.54 trillion. The Model Y has become the best-selling car in the world by volume for three consecutive years, a scenario that would have sounded insane in 2018. Tesla has also pushed autonomy to a point where its vehicles can navigate complex real-world environments using vision alone.

And then there is Optimus. What began as a literal man in a suit has evolved into a humanoid robot program that Musk now describes as potential Von Neumann machines: systems capable of building civilizations beyond Earth. Whether that vision takes decades or less, one thing is evident: Tesla is no longer just a car company. It is positioning itself at the intersection of AI, robotics, and manufacturing.

SpaceX’s trajectory has been just as dramatic.

The Falcon 9 has become the undisputed workhorse of the global launch industry, having completed more than 600 missions to date. Of those, SpaceX has successfully landed a Falcon booster more than 560 times. The Falcon 9 flies more often than all other active launch vehicles combined, routinely lifting off multiple times per week.

Falcon 9 has ferried astronauts to and from the International Space Station via Crew Dragon, restored U.S. human spaceflight capability, and even stepped in to safely return NASA astronauts Butch Wilmore and Suni Williams when circumstances demanded it.

Starlink, once a controversial idea, now dominates the satellite communications industry, providing broadband connectivity across the globe and reshaping how space-based networks are deployed. SpaceX itself, following its merger with xAI, is now valued at roughly $1.25 trillion and is widely expected to pursue what could become the largest IPO in history.

And then there is Starship, Elon Musk’s fully reusable launch system designed not just to reach orbit, but to make humans multiplanetary. In 2018, the idea was still aspirational. Today, it is under active development, flight-tested in public view, and central to NASA’s future lunar plans.

In hindsight, Falcon Heavy’s maiden flight with Elon Musk’s personal Tesla Roadster was never really about a car in space. It was a signal that SpaceX and Tesla were willing to think bigger, move faster, and accept risks others wouldn’t.

The Roadster is still out there, orbiting the Sun. Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

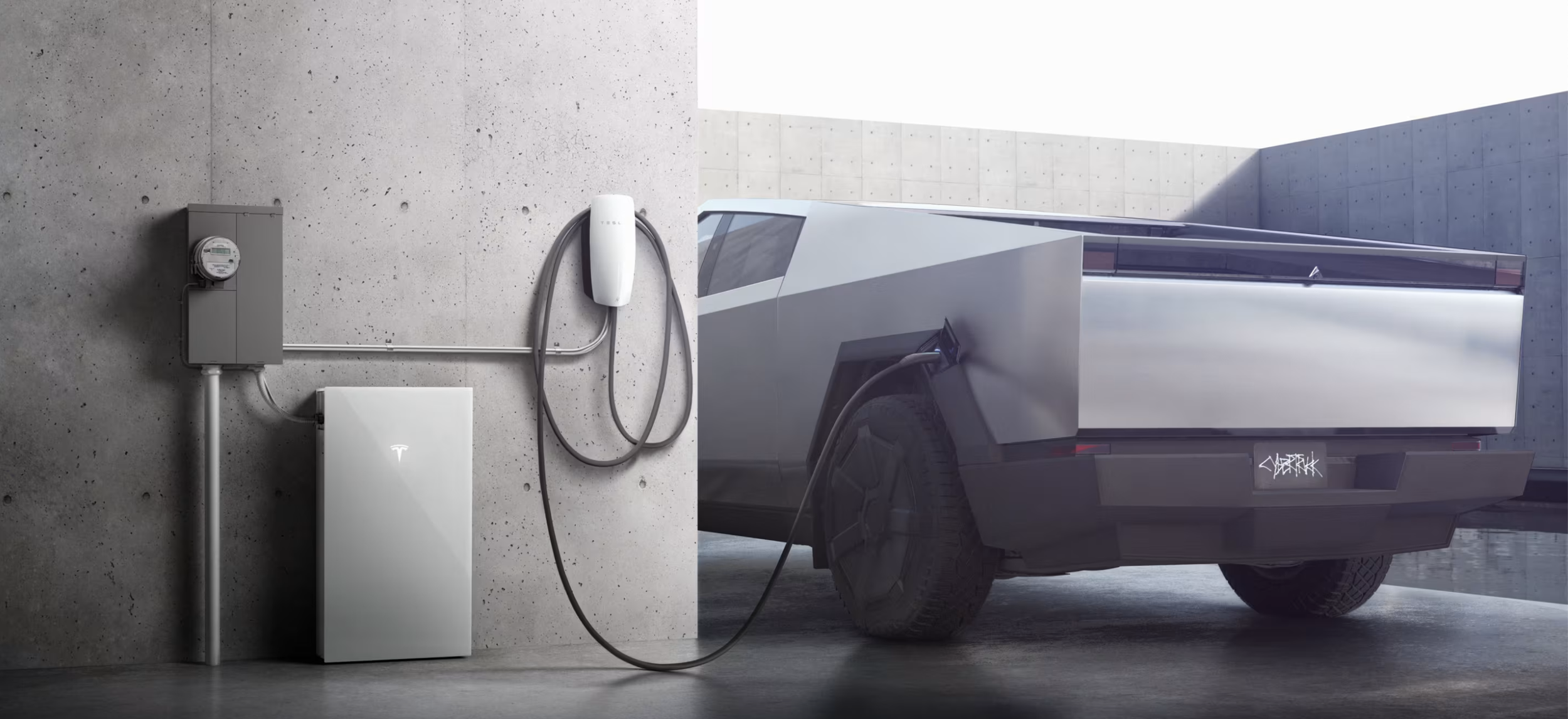

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.

News

Samsung nears Tesla AI chip ramp with early approval at TX factory

This marks a key step towards the tech giant’s production of Tesla’s next-generation AI5 chips in the United States.

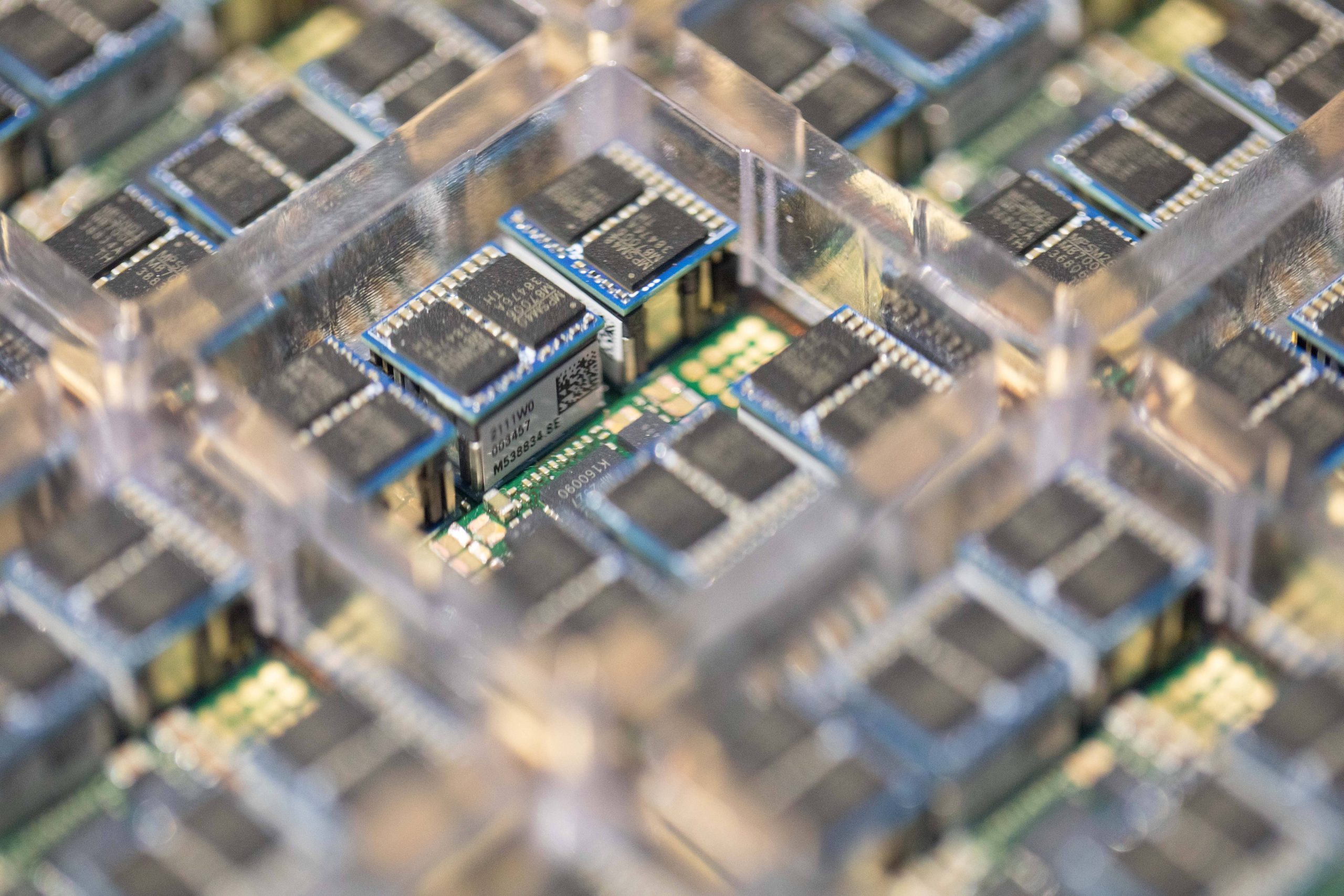

Samsung has received temporary approval to begin limited operations at its semiconductor plant in Taylor, Texas.

This marks a key step towards the tech giant’s production of Tesla’s next-generation AI5 chips in the United States.

Samsung clears early operations hurdle

As noted in a report from Korea JoongAng Daily, Samsung Electronics has secured temporary certificates of occupancy (TCOs) for a portion of its semiconductor facility in Taylor. This should allow the facility to start operations ahead of full completion later this year.

City officials confirmed that approximately 88,000 square feet of Samsung’s Fab 1 building has received temporary approval, with additional areas expected to follow. The overall timeline for permitting the remaining sections has not yet been finalized.

Samsung’s Taylor facility is expected to manufacture Tesla’s AI5 chips once mass production begins in the second half of the year. The facility is also expected to produce Tesla’s upcoming AI6 chips.

Tesla CEO Elon Musk recently stated that the design for AI5 is nearly complete, and the development of AI6 is already underway. Musk has previously outlined an aggressive roadmap targeting nine-month design cycles for successive generations of its AI chips.

Samsung’s U.S. expansion

Construction at the Taylor site remains on schedule. Reports indicate Samsung plans to begin testing extreme ultraviolet (EUV) lithography equipment next month, a critical step for producing advanced 2-nanometer semiconductors.

Samsung is expected to complete 6 million square feet of floor space at the site by the end of this year, with an additional 1 million square feet planned by 2028. The full campus spans more than 1,200 acres.

Beyond Tesla, Samsung Foundry is also pursuing additional U.S. customers as demand for AI and high-performance computing chips accelerates. Company executives have stated that Samsung is looking to achieve more than 130% growth in 2-nanometer chip orders this year.

One of Samsung’s biggest rivals, TSMC, is also looking to expand its footprint in the United States, with reports suggesting that the company is considering expanding its Arizona facility to as many as 11 total plants. TSMC is also expected to produce Tesla’s AI5 chips.