News

SpaceX CEO Elon Musk explains Starship’s ‘transpiring’ steel heat shield in Q&A

Speaking in a late-December 2018 interview with Popular Mechanics’ editor-in-chief, SpaceX CEO Elon Musk shared considerable insight into the thought processes that ultimately led him to – in his own words – “convince” his team that the company’s BFR rocket (now Starship and Super Heavy) should pivot from an advanced composite structure to a relatively common form of stainless steel.

Aside from steel’s relative ease of manipulation and affordability, Musk delved into the technical solution he arrived at for an advanced, ultra-reusable heat shield for Starship – build it out of steel and use water (or liquid methane) to wick reentry heat away.

When going to ~1750 Kelvin, specific heat is more important than latent heat of vaporization, which is why cryogenic fuel is a slightly better choice than water

— Elon Musk (@elonmusk) January 22, 2019

Although there has been some successful experimental research done on “transpirational” heat shields (relying on the heat capacity of vaporizing liquids or gases to soak up thermal energy during orbital rocket reentries), Musk is by no means wrong when he says that a stainless steel sandwich-hulled spaceship regeneratively cooled by microscopic holes and liquid water or propellant “has never been proposed before”. While the basic concept probably arose somewhere over the last 50-100 years, it does not appear that any serious theoretical or experimental research has been conducted to explore transpiration-cooled metallic heat shields, where metallic thermal protection systems (TPS) are already fairly exotic and unproven in the realm of modern aerospace.

“Very easy to work with steel. Oh, and I forgot to mention: [SpaceX’s high-quality] carbon fiber is $135 a kilogram, 35 percent scrap, so you’re starting to approach almost $200 a kilogram. [301] steel is $3 a kilogram.” – Elon Musk

While Musk’s solution could dramatically simplify what is needed for Starship’s high-performance heat shield, a stainless steel sandwich on half of Starship offers another huge benefit: the spacecraft can still gain many of the mass ratio benefits of stainless steel balloon tanks (metal tanks so thin that they collapse without positive pressure) while retaining structural rigidity even when depressurized. At the end of the day, Musk very well might be correct when he states that a stainless steel Starship can ultimately be more mass-efficient (“lighter”) than a Starship built out of advanced carbon composites, a characteristic he rightly describes as “counterintuitive”.

- Starhopper and SpaceX’s spartan assembly facilities are pictured here, showing the inside of the aft section and a completed tank dome. (Austin Barnard)

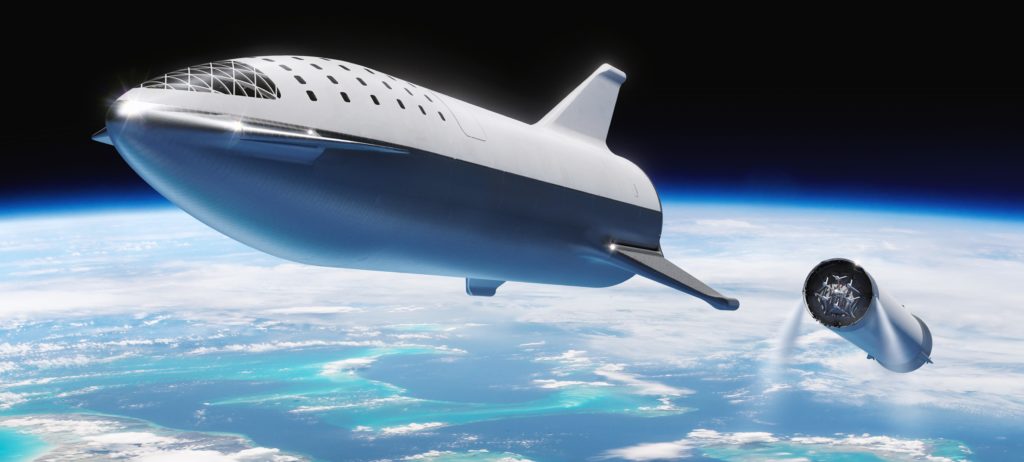

- Starship has been shown with actuating fins and canard wings since SpaceX’s September 2018 update. (SpaceX)

What does Science™ have to say?

Based on research done in the 2010s by German space agency (DLR), a porous thermal protection material called Procelit 170 (P170) – 91% aluminum oxide and 9% silicon oxide – was cooled from a peak heat of ~1750 C (3200 F) to ~25 C (75 F) during wind tunnel testing, demonstrating that an average of 0.065 kg (~2.3 oz) of water per second would be needed to cool a square meter of P170 to the same degree, assuming a heating rate of around 200 kW/m^2. Given that 300-series stainless steels have a comparatively huge capacity for radiating heat at high temperatures, will be dramatically thinner than Procelit in any given Starship use-case, and will not need to be cooled all the way to 25C/75F during hot operations, the DLR-derived number is barely relevant without another round of wind tunnel tests focused on metallic thermal protection systems. Still, it allows for the creation of a sort of worst-case scenario for BFS/Starship’s water-cooled shield.

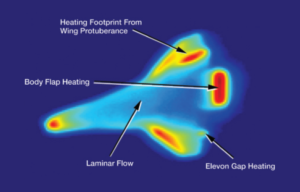

Assuming that the windward side of Starship’s regeneratively cooled heat shield has roughly the same surface area as half of a cylinder, 800 m^2 (8600 ft^2) will have to be actively cooled with water, translating to a water consumption rate of approximately 52 kg/s (115 lb/s) if the entire surface is being subjected to temperatures around ~1750 C. That is, of course, a grossly inaccurate generalization, as aerodynamic surfaces dramatically shape, dissipate, and concentrate airflows (and thus heat from friction) in complex and highly specific ways. Much like NASA’s Space Shuttle or DLR’s theoretical SpaceLiner, the reality of reentry heating is that that heat typically ends up being focused at leading edges and control surfaces, which thus require uniquely capable versions of thermal protection (TPS). Shuttle used fragile reinforced carbon-carbon tiles at those hotspots, while DLR was exploring water cooling as a viable and safer alternative for SpaceLiner.

- Starship’s first full-scale prototype is being rapidly assembled in South Texas. (NASASpaceflight – bocachicagal)

- Starship’s first full-scale prototype is being rapidly assembled in South Texas. (NASASpaceflight – bocachicagal)

- Meanwhile, giant 9m-diameter tank domes are being assembled and welded together a few hundred feet away from Starhopper. (NSF – bocachicagal)

- SpaceX’s Starhopper seen in a January render and a January photo. (SpaceX/Elon Musk)

- BFS seen standing vertically on the pads of its tripod fins. (SpaceX)

- A NASA team—via a US Navy aircraft—captured high-resolution, calibrated infrared imagery of Space Shuttle Discovery’s lower surface in addition to discrete instrumentation on the wing, downstream, and on the Boundary Layer Transition Flight Experiment protuberance. In the image, the red regions represent higher surface temperatures. (NASA)

Aside from heat flux, it’s also unclear when or how long the cooling system will need to be supplied with water during potential Starship reentries. At worst, the spacecraft would need to supply a constant 50+ kg/s throughout a 5+ minute (600+ second) regime of high-velocity, high-drag reentry conditions. Assuming that Starship will need to rely heavily on aerobraking to maintain efficient interplanetary operations, it might have to perform 2+ active-cooling cycles per reentry, potentially requiring a minimum of 15 tons of water per reentry. Given that SpaceX intends (at least as of September 2018) for Starship to be able to land more than 100 tons on the surface of Mars, 15t of water would cut drastically into payload margins and is thus likely an unfeasibly large mass reserve or any given interplanetary mission.

“You just need, essentially, [a stainless-steel sandwich]. You flow either fuel or water in between the sandwich layer, and then you have [very tiny] perforations on the outside and you essentially bleed water [or fuel] through them … to cool the windward side of the rocket.” – SpaceX CEO Elon Musk (Popular Mechanics, December 2018)

The assumptions needed for the above calculations do mean that 30T is an absolute worst-case scenario for a regeneratively-cooled Starship reentry, given that SpaceX may only have to vigorously cool a small fraction of its windward surface and will likely be able to cut more than half of the water needed by allowing Starship’s steel skin to heat quite a lot while still staying well below its melting point (likely around 800C/1500F or higher). This also fails to account for the fact that a regeneratively-cooled stainless steel heat shield would effectively let SpaceX do away with what would otherwise be a massive and heavy ablative heat shield and mounting mechanism. Perhaps the benefits of stainless steel might ultimately mean that carrying around 10-30T of coolant is actually performance-neutral or a minimal burden when all costs and benefits are properly accounted for.

Probability at 60% & rising rapidly due to new architecture

— Elon Musk (@elonmusk) December 27, 2018

Musk clearly believes with almost zero doubt that a stainless steel Starship and booster (Super Heavy) is the way forward for the company’s BFR program, and he has now twice indicated that the switch away from advanced carbon composites will actually “accelerate” the rocket’s development schedule. For now, all we can do is watch as the first Starship prototype – meant to perform short hop tests ASAP – gradually comes into being in South Texas.

News

Tesla begins Robotaxi certification push in Arizona: report

Tesla seems serious about expanding its Robotaxi service to several states in the coming months.

Tesla has initiated discussions with Arizona transportation regulators to certify its driverless Robotaxi service in the state, as per a recent report from Bloomberg News. The move follows Tesla’s launch of its Robotaxi pilot program in Austin, Texas, as well as CEO Elon Musk’s recent comments about the service’s expansion in the Bay Area.

The Arizona Department of Transportation confirmed to Bloomberg that Tesla has reached out to begin the certification process for autonomous ride-sharing operations in the state. While details remain limited, the outreach suggests that Tesla is serious about expanding its driverless Robotaxi service to several territories in the coming months.

The Arizona development comes as Tesla prepares to expand its service area in Austin this weekend, as per CEO Elon Musk in a post on X. Musk also stated that Tesla is targeting the San Francisco Bay Area as its next major market, with a potential launch “in a month or two,” pending regulatory approvals.

Tesla first launched its autonomous ride-hailing program on June 22 in Austin with a small fleet of Model Y vehicles, accompanied by a Tesla employee in the passenger seat to monitor safety. While still classified as a test, Musk has said the program will expand to about 1,000 vehicles in the coming months. Tesla will later upgrade its Robotaxi fleet with the Cyercab, a two-seater that is designed without a steering wheel.

Sightings of Cybercab castings around the Giga Texas complex suggests that Tesla may be ramping the initial trial production of the self-driving two-seater. Tesla, for its part, has noted in the past that volume production of the Cybercab is expected to start sometime next year.

In California, Tesla has already applied for a transportation charter-party carrier permit from the state’s Public Utilities Commission. The company is reportedly taking a phased approach to operating in California, with the Robotaxi service starting with pre-arranged rides for employees in vehicles with safety drivers.

News

Tesla sets November 6 date for 2025 Annual Shareholder Meeting

The automaker announced the date on Thursday in a Form 8-K.

Tesla has scheduled its 2025 annual shareholder meeting for November 6, addressing investor concerns that the company was nearing a legal deadline to hold the event.

The automaker announced the date on Thursday in a Form 8-K submitted to the United States Securities and Exchange Commission (SEC). The company also listed a new proposal submission deadline of July 31 for items to be included in the proxy statement.

Tesla’s announcement followed calls from a group of 27 shareholders, including the leaders of large public pension funds, which urged Tesla’s board to formally set the meeting date, as noted in a report from The Wall Street Journal.

The group noted that under Texas law, where Tesla is now incorporated, companies must hold annual meetings within 13 months of the last one if requested by shareholders. Tesla’s previous annual shareholder meeting was held on June 13, 2024, which placed the July 13 deadline in focus.

Tesla originally stated in its 2024 annual report that it would file its proxy statement by the end of April. However, an amended filing on April 30 indicated that the Board of Directors had not yet finalized a meeting date, at least at the time.

The April filing also confirmed that Tesla’s board had formed a special committee to evaluate certain matters related to CEO Elon Musk’s compensation plan. Musk’s CEO performance award remains at the center of a lengthy legal dispute in Delaware, Tesla’s former state of incorporation.

Due to the aftermath of Musk’s legal dispute about his compensation plan in Delaware, he has not been paid for his work at Tesla for several years. Musk, for his part, has noted that he is more concerned about his voting stake in Tesla than his actual salary.

At last year’s annual meeting, TSLA shareholders voted to reapprove Elon Musk’s compensation plan and ratified Tesla’s decision to relocate its legal domicile from Delaware to Texas.

Elon Musk

Grok coming to Tesla vehicles next week “at the latest:” Elon Musk

Grok’s rollout to Tesla vehicles is expected to begin next week at the latest.

Elon Musk announced on Thursday that Grok, the large language model developed by his startup xAI, will soon be available in Tesla vehicles. Grok’s rollout to Tesla vehicles is expected to begin next week at the latest, further deepening the ties between the two Elon Musk-led companies.

Tesla–xAI synergy

Musk confirmed the news on X shortly after livestreaming the release of Grok 4, xAI’s latest large language model. “Grok is coming to Tesla vehicles very soon. Next week at the latest,” Musk wrote in a post on social media platform X.

During the livestream, Musk and several members of the xAI team highlighted several upgrades to Grok 4’s voice capabilities and performance metrics, positioning the LLM as competitive with top-tier models from OpenAI and Google.

The in-vehicle integration of Grok marks a new chapter in Tesla’s AI development. While Tesla has long relied on in-house systems for autonomous driving and energy optimization, Grok’s integration would introduce conversational AI directly into its vehicles’ user experience. This integration could potentially improve customer interaction inside Tesla vehicles.

xAI and Tesla’s collaborative footprint

Grok’s upcoming rollout to Tesla vehicles adds to a growing business relationship between Tesla and xAI. Earlier this year, Tesla disclosed that it generated $198.3 million in revenue from commercial, consulting, and support agreements with xAI, as noted in a report from Bloomberg News. A large portion of that amount, however, came from the sale of Megapack energy storage systems to the artificial intelligence startup.

In July 2023, Musk polled X users about whether Tesla should invest $5 billion in xAI. While no formal investment has been made so far, 68% of poll participants voted yes, and Musk has since stated that the idea would be discussed with Tesla’s board.

-

Elon Musk1 week ago

Elon Musk1 week agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

Elon Musk21 hours ago

Elon Musk21 hours agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

Elon Musk3 days ago

Elon Musk3 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News7 days ago

News7 days agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

Elon Musk1 week ago

Elon Musk1 week agoxAI’s Memphis data center receives air permit despite community criticism

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla’s Omead Afshar, known as Elon Musk’s right-hand man, leaves company: reports

-

News2 weeks ago

News2 weeks agoXiaomi CEO congratulates Tesla on first FSD delivery: “We have to continue learning!”