SpaceX

SpaceX Falcon 9 Block 5 booster preps for next launch as fairing fragments surface

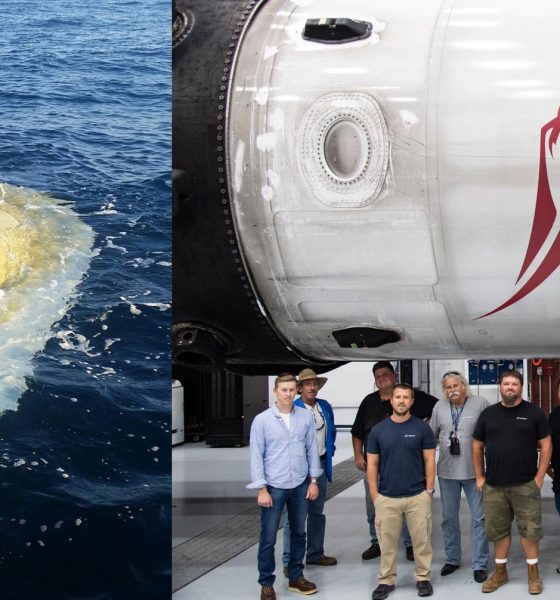

As part of a recent 10-year anniversary celebration of SpaceX’s first successful launch to reach orbit, Falcon 9 B1047 was spotted undergoing inspections and refurbishment after the Block 5 booster’s launch debut, placing the 7-ton Telstar 19V communications satellite in orbit on July 22nd.

Meanwhile, a bit north of B1047’s cozy Cape Canaveral refurbishment hangar, battered fragments of a Falcon 9 payload fairing half – part of the very same Telstar 19V mission – were discovered by a fisherman off the coast of South Carolina.

https://twitter.com/SpaceXJobs/status/1045832573471969281?ref_src=twsrc%5Etfw%7Ctwcamp%5Etweetembed%7Ctwterm%5E1045832573471969281&ref_url=https%3A%2F%2Fwww.teslarati.com%2Fwp-admin%2Fpost.php%3Fpost%3D84909%26action%3Dedit

A tale of two halves

Around nine minutes after lifting off from SpaceX’s LC-40 pad, Falcon 9 B1047 gracefully landed on drone ship Of Course I Still Love You (OCISLY), followed soon after by confirmation of Falcon 9 Block 5’s second launch success. Perhaps a tad toasty after what one might call a ‘medium-well’ reentry, the upgraded booster was otherwise perfectly intact. A minute after B1047 separated from Falcon 9’s upper stage and Telstar 19V payload, the fairing – tasked with protecting the satellite from the stresses of high-speed atmospheric flight – was jettisoned from the second stage, splitting into two halves and falling away from the rocket in order to save precious mass on S2’s push towards orbit.

Falcon 9’s first stage separates from the upper stage for quite different reasons, cued quite literally by its propellant tanks essentially reaching “empty” – albeit an “empty” that typically includes some fumes for the booster’s safe recovery. The payload fairing, on the other hand, is detached from the second stage the moment that Falcon rises above a particular point in Earth’s atmosphere, only exposing its sensitive satellite(s) to the elements once in near-vacuum conditions. Ultimately, fairing halves separate from Falcon 9 at velocities significantly higher than that of the booster but are subjected to far more forgiving reentry conditions, requiring just a minimal of thermal protection to make it to (or just above…) the ground/ocean unscathed.

Detailed images of GO Pursuit returning to Port Canaveral this afternoon with a partial fairing half following Sunday’s launch of Falcon 9 and Telstar 19V. Damage is no surprise, as these east coast fairings — for now — land in the water. pic.twitter.com/AxkwUQH67b

— John Kraus (@johnkrausphotos) July 24, 2018

SpaceX recently began seriously attempting to recover Falcon 9 payload fairings, albeit almost exclusively during West Coast launches in order to let Mr. Steven attempt to catch the parasailing halves in the Pacific Ocean. Thus far, SpaceX engineers and technicians have not yet solved the challenging problems, although fairing halves have reportedly landed as few as 50 meters from Mr. Steven’s grasp and at least five have been recovered intact after landing gently on the ocean surface. On the East Coast, Falcon fairings are not nearly as lucky, typically alternating between smashing directly into the ocean and landing gently upon it, depending SpaceX’s need for experimental recovery data.

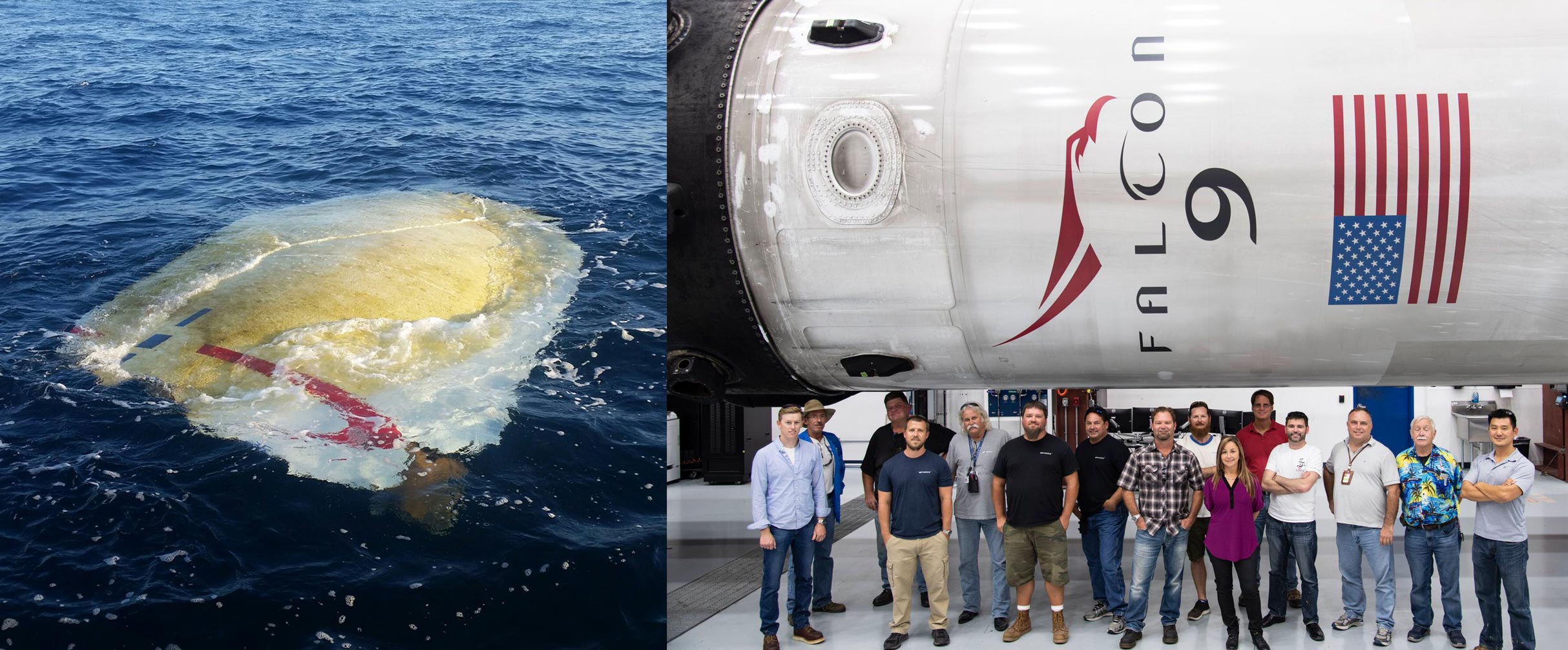

By all appearances, B1047’s fairing halves both plummeted – unarrested – into the Atlantic, shattering into pieces of fragile carbon fiber-aluminum honeycomb. Thanks to the extremely lightweight nature of their composition, even waterlogged fairing fragments tend to float almost indefinitely, winding up in far-flung places many hundreds or thousands of miles from the point of impact. A particularly large fairing fragment from Telstar 19V clearly survived its greater halve’s violent ends, floating its way 600-800 miles northwest to the coast of South Carolina. After taking photos, the fisherman rather poetically let it float away, permitting it several more weeks of freedom before washing up on some shoreline and making its way onto eBay.

- A Falcon 9 fairing fragment was discovered floating off the coast of South Carolina two months after launching with Telstar 19V. (TheHullTruth /u/gofish)

- Telstar 19V’s Falcon fairing artwork, a dead-ringer for the fairing flotsam. (SpaceX)

- B1047 returned safe and sound to Pad 39A for refurbishment less than a week after launching and landing. (Instagram /u/d_lo_ags)

Ultimately, SpaceX engineers and technicians will continue to work towards successful, reliable, and routine fairing recoveries, inevitably experiencing many failures before a functional solution is found and optimized, just like the teams that brought Falcon 9 first stage recovery from blueprint to reality. In the meantime, serendipitous events like this will continue to serve as both stark reminders of the unforgiving hurdles along the path to orbital-class rocket hardware recovery and the undeniable fact that it already can and has been done before.

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.