News

SpaceX’s path to refueling Starships in space is clearer than it seems

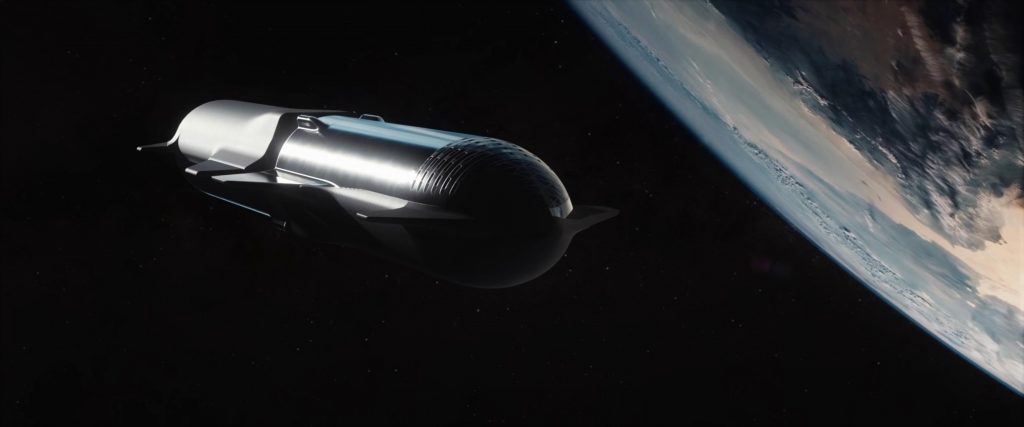

Perhaps the single biggest mystery of SpaceX’s Starship program is how exactly the company plans to refuel the largest spacecraft ever built after they reach orbit.

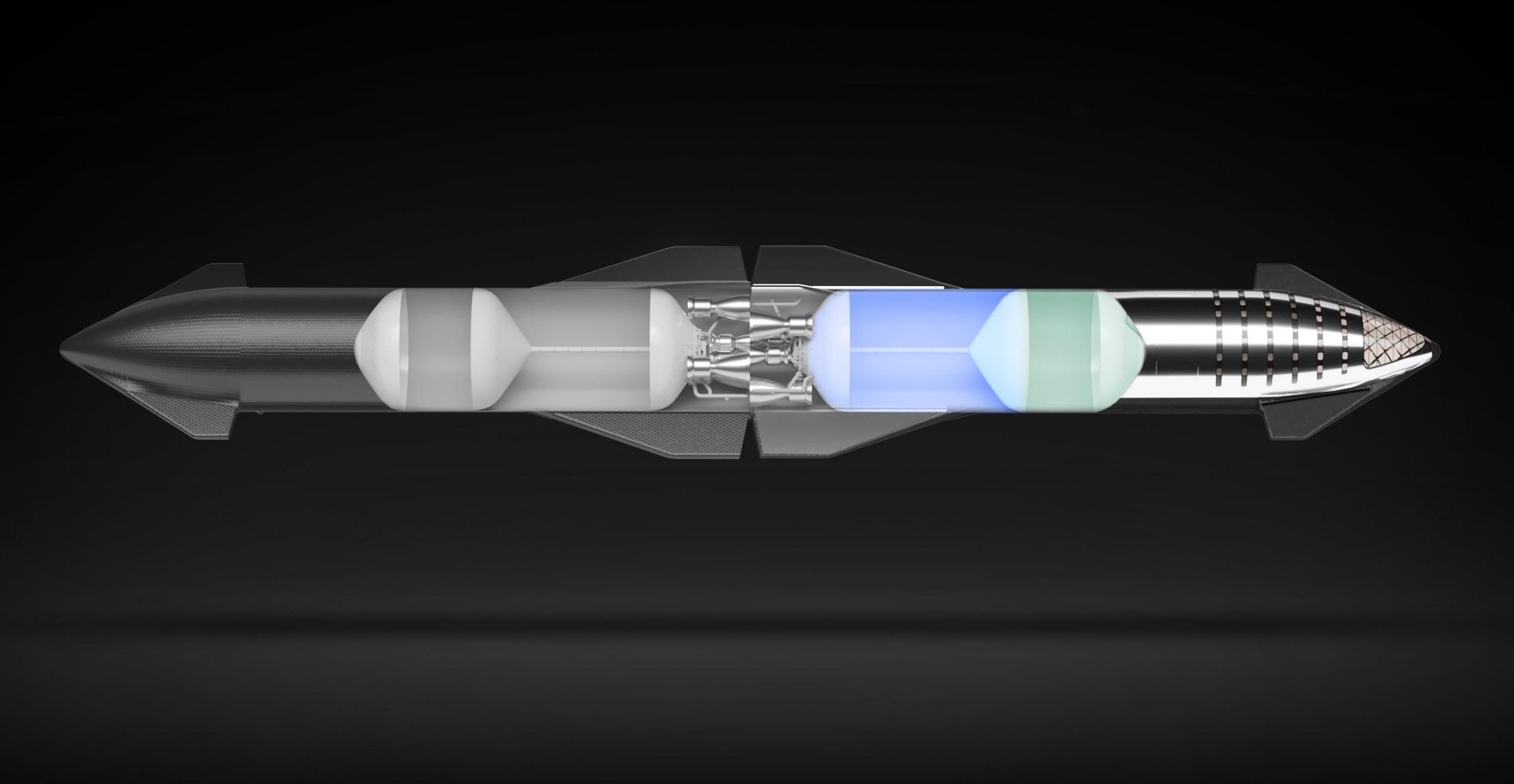

First revealed in September 2016 as the Interplanetary Transport System (ITS), SpaceX has radically redesigned its next-generation rocket several times over the last half-decade. Several crucial aspects have nevertheless persisted. Five years later, Starship (formerly ITS and BFR) is still a two-stage rocket powered by Raptor engines that burn a fuel-rich mixture of liquid methane (LCH4) and liquid oxygen (LOx). Despite being significantly scaled back from ITS, Starship will be about the same height (120 m or 390 ft) and is still on track to be the tallest, heaviest, and most powerful rocket ever launched by a large margin.

Building off of years of growing expertise from dozens of Falcon 9 and Falcon Heavy launches, the most important fundamental design goal of Starship is full and rapid reusability – propellant being the only thing intentionally ‘expended’ during launches. However, like BFR and ITS before it, the overarching purpose of Starship is to support SpaceX’s founding goal of making humanity multiplanetary and building a self-sustaining city on Mars. For Starship to have even a chance of accomplishing that monumental feat, SpaceX will not only have to build the most easily and rapidly reusable rocket and spacecraft in history, but it will also have to master orbital refueling.

The reuse/refuel equation

In the context of SpaceX’s goals of expanding humanity to Mars, a mastery of reusability and orbital refueling are mutually inclusive. Without both, neither alone will enable the creation of a sustainable city on Mars. A Starship launch system that can be fully reused on a weekly or even daily basis but can’t be rapidly and easily refueled in space simply doesn’t have the performance needed to affordably build, supply, and populate a city on another planet (or Moon). A Starship launch system that can be easily refueled but is not rapidly and fully reusable could allow for some degree of interplanetary transport and the creation of a minimal human outpost on Mars, but it would probably be one or two magnitudes more difficult, risky, and expensive to operate and would require a huge fleet of ships and boosters from the start.

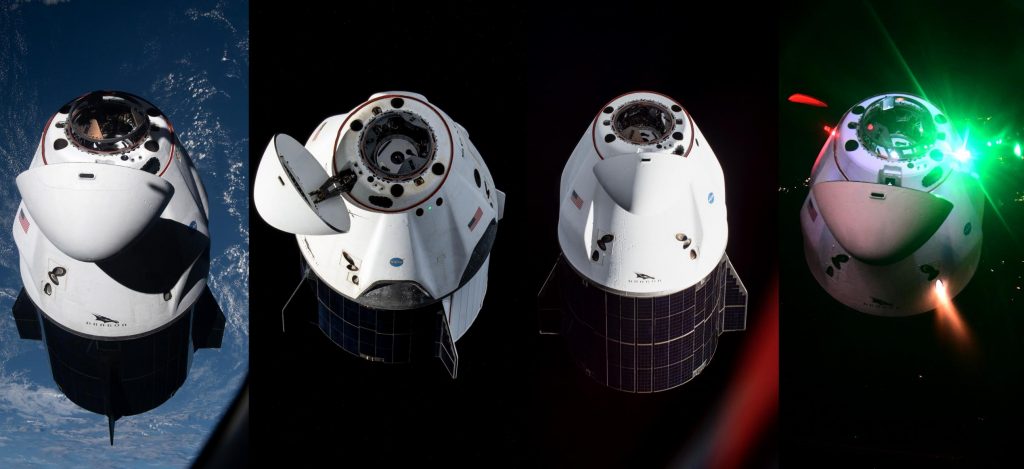

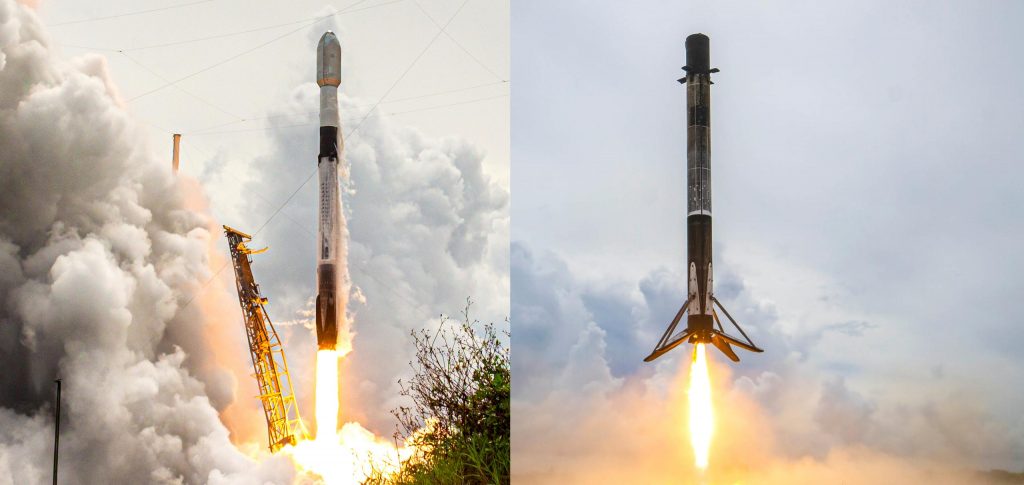

The question of how SpaceX will make Starship the world’s most rapidly, fully, and cheaply reusable rocket is a hard one, but it’s not all that difficult to extrapolate from where the company is today. Currently, the turnaround record (time between two flights) for Falcon boosters is two launches in less than four weeks (27 days). SpaceX’s orbital-class reuse is also making strides and the company recently flew the same orbital Crew Dragon capsule twice in just 137 days (less than five months) – fast approaching turnarounds similar to NASA’s Space Shuttle average, the only other reusable orbital spacecraft in history.

While Dragon and Falcon 9 are far smaller than Starship and Super Heavy, Dragon is only partially reusable and requires significant refurbishment after recovery and Falcon 9 boosters are fairly complex. Starship, on the other hand, should effectively serve as a fully reusable all-in-one Falcon upper stage, Dragon capsule, Dragon trunk, and fairing, making it far more complex but potentially far more reusable. To an extent, Super Heavy should also be mechanically simpler than Falcon boosters (no deployable legs or fins; no structural composite-metal joints; no dedicated maneuvering thrusters) and its clean-burning Raptor engines should be easier to reuse than Falcon’s Merlins. Put simply, there are precedents set and evidence provided by Falcon rockets and NASA’s Space Shuttle that suggest SpaceX will be able to solve the reusability half of the equation.

What about refueling?

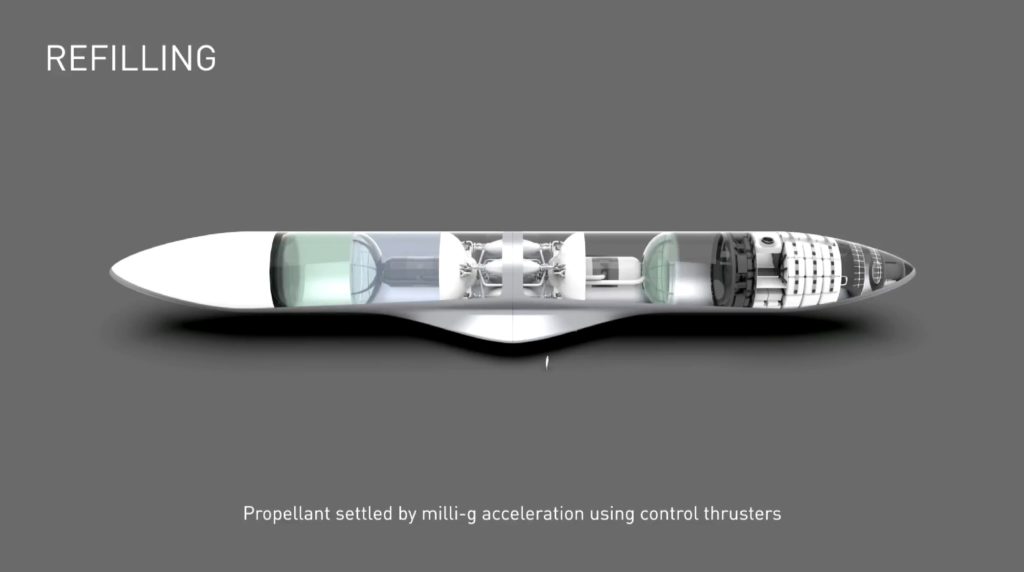

The other half of that equation, however, could not be more different. The sum total of SpaceX’s official discussions of orbital refueling can be summed up in a sentence included verbatim in CEO Elon Musk’s 2017, 2018, and 2019 Starship presentations: “propellant settled by milli G acceleration using control thrusters.”

On the face of it, that simple phrase doesn’t reveal much. However, with a few grains of salt, hints from what the company’s CEO has and hasn’t said, and context from the history of research into orbital propellant transfer, it’s possible to paint a fairly detailed picture of the exact mechanisms SpaceX will likely use to refill Starships in space. The cornerstone, somewhat ironically, is a 2006 paper – written by seven Lockheed Martin employees and a NASA engineer – titled “Settled Cryogenic Propellant Transfer.” Aside from the obvious corollaries just from the title alone, the paper focuses on what the authors argue is the simplest possible route to large-scale orbital propellant transfer.

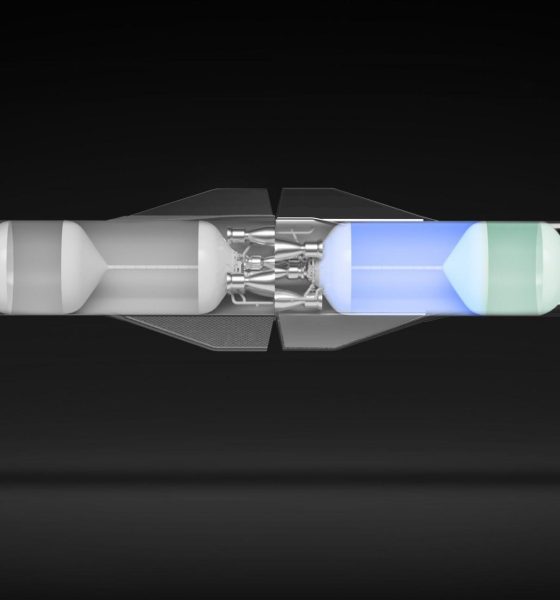

In orbit, under microgravity conditions, the propellant inside a spacecraft’s tanks is effectively detached from the structure. If a spacecraft applies thrust, that propellant will stay still until it splashes against its tank walls – the most basic Newtonian principle that objects at rest tend to stay at rest. If, say, a spacecraft thrusts in one direction and opens a hatch or valve on the tank in the opposite direction of that thrust, the propellant inside it – attempting to stay at rest – will naturally escape out of that opening. Thus, if a spacecraft in need of fuel docks with a tanker, their tanks are connected and opened, and the tanker attempts to accelerate away from the receiving ship, the propellant in the tanker’s tanks will effectively be pushed into the second ship as it tries to stay at rest.

The principles behind such a ‘settled propellant transfer’ are fairly simple and intuitive. The crucial question is how much acceleration the process requires and how expensive that continuous acceleration ends up being. According to Kutter et al’s 2006 paper, the answer is surprising: assuming a 100 metric ton (~220,000 lb) spacecraft pair accelerates at 0.0001G (one ten-thousandth of Earth gravity) to transfer propellant, they would need to consume just 45 kg (100 lb) of hydrogen and oxygen propellant per hour to maintain that acceleration.

In the most extreme hypothetical refueling scenario (i.e. a completely full tanker refueling a ship with a full cargo bay), two docked Starships would weigh closer to 1600 tons (~3.5M lb) and the “Milli G” acceleration SpaceX has repeatedly mentioned in presentation slides would be ten times greater than the maximum acceleration analyzed by Kutter et al. Still, according to their paper, that propellant cost scales linearly both with the required acceleration and with the mass of the system. Roughly speaking, using the same assumptions, that means that the thrusting Starship would theoretically consume just over 7 tons (half a percent) of its methane and oxygen propellant per hour to maintain milli-G acceleration.

With large enough pipes (on the order of 20-50 cm or 8-20 in) connecting each Starship’s tanks, SpaceX should have no trouble transferring 1000+ tons of propellant in a handful of hours. Ultimately, that means that settled propellant transfer even at the scale of Starship should incur a performance ‘tax’ of no more than 20-50 tons of propellant per refueling. All transfers leading up to the worst-case 1600-ton scenario should also be substantially more efficient. Overall, that means that fully refueling an orbiting Starship or depot with ~1200 tons of propellant – requiring anywhere from 8 to 14+ tanker launches – should be surprisingly efficient, with perhaps 80% or more of the propellant launched remaining usable by the end of the process.

A step further, Kutter et al note the amount of acceleration required is so small that a hypothetical spacecraft could potentially use ullage gas vents to achieve it, meaning that custom-designed settling thrusters might not even be needed. Coincidentally or not, SpaceX (or CEO Elon Musk) has recently decided to use strategically located ullage vents to replace purpose-built maneuvering thrusters on Starship’s Super Heavy booster. If SpaceX adds similar capabilities to Starship, it’s quite possible that the combination of cryogenic propellant naturally boiling into gas as it warms and the ullage vents used to relieve that added pressure could produce enough thrust to transfer large volumes of propellant.

Last but not least, writing more than a decade and a half ago, the only technological barrier Kutter et al could foresee to large-scale settled propellant transfer wasn’t even related to refueling but, rather, to the ability to autonomously rendezvous and dock in orbit. In 2006, while Russia was already routinely using autonomous docking and rendezvous technology on its Soyuz and Progress spacecraft, the US had never demonstrated the technology on its own. Jump to today and SpaceX Dragon spacecraft have autonomously rendezvoused with the International Space Station twenty seven times in nine years and completed ten autonomous dockings – all without issue – since 2019.

Even though SpaceX and its executives have never detailed their approach to refueling (or refilling, per Musk’s preferred term) Starships in space, there is a clear path established by decades of NASA and industry research. What little evidence is available suggests that that path is the same one SpaceX has chosen to travel. Ultimately, the key takeaway from that research and SpaceX’s apparent use of it should be this: while a relatively inefficient process, SpaceX has effectively already solved the last remaining technical hurdle for settled propellant transfer and should be able to easily refuel Starships in orbit with little to no major development required.

There’s a good chance that minor to moderate problems will be discovered and need to be solved once SpaceX begins to test refueling in orbit but crucially, there are no obvious showstoppers standing between SpaceX and the start of those flight tests. Aside from the obvious (preparing a new rocket for its first flight tests), the only major refueling problem SpaceX arguably needs to solve is the umbilical ports and docking mechanisms that will enable propellant transfer. SpaceX will also need to settle on a location for those ports/mechanisms and decide whether to implement ullage vent ‘thrusters’, cold gas thrusters like those on Falcon and current Starship prototypes, or more efficient hot-gas thrusters derived from Raptors. At the end of the day, though, those are all solved problems and just a matter of complex but routine systems engineering that SpaceX is an expert at.

Cybertruck

Tesla drops latest hint that new Cybertruck trim is selling like hotcakes

According to Tesla’s Online Design Studio, the new All-Wheel-Drive Cybertruck will now be delivered in April 2027. Earlier orders are still slated for early this Summer, but orders from here on forward are now officially pushed into next year:

Tesla’s new Cybertruck offering has had its delivery date pushed back once again. This is now the second time, and deliveries for the newest orders are now pushed well into 2027.

According to Tesla’s Online Design Studio, the new All-Wheel-Drive Cybertruck will now be delivered in April 2027. Earlier orders are still slated for early this Summer, but orders from here on forward are now officially pushed into next year:

🚨 Tesla has updated the $59,990 Cybertruck Dual Motor AWD’s estimated delivery date to April 2027.

First deliveries are still slated for June, but if you order it now, you’ll be waiting over a year.

Demand appears to be off the charts for the new Cybertruck and consumers are… pic.twitter.com/raDCCeC0zP

— TESLARATI (@Teslarati) February 26, 2026

Just three days ago, the initial delivery date of June 2026 was pushed back to early Fall, and now, that date has officially moved to April 2027.

The fact that Tesla has had to push back deliveries once again proves one of two things: either Tesla has slow production plans for the new Cybertruck trim, or demand is off the charts.

Judging by how Tesla is already planning to raise the price based on demand in just a few days, it seems like the company knows it is giving a tremendous deal on this spec of Cybertruck, and units are moving quickly.

That points more toward demand and not necessarily to slower production plans, but it is not confirmed.

Tesla Cybertruck’s newest trim will undergo massive change in ten days, Musk says

Tesla is set to hike the price on March 1, so tomorrow will be the final day to grab the new Cybertruck trim for just $59,990.

It features:

- Dual Motor AWD w/ est. 325 mi of range

- Powered tonneau cover

- Bed outlets (2x 120V + 1x 240V) & Powershare capability

- Coil springs w/ adaptive damping

- Heated first-row seats w/ textile material that is easy to clean

- Steer-by-wire & Four Wheel Steering

- 6’ x 4’ composite bed

- Towing capacity of up to 7,500 lbs

- Powered frunk

Interestingly, the price offering is fairly close to what Tesla unveiled back in late 2019.

Elon Musk

Elon Musk outlines plan for first Starship tower catch attempt

Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

Elon Musk has clarified when SpaceX will first attempt to catch Starship’s upper stage with its launch tower. The CEO’s update provides the clearest teaser yet for the spacecraft’s recovery roadmap.

Musk shared the details in recent posts on X. In his initial post, Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

“Starship V3 SN1 headed for ground tests. I am highly confident that the V3 design will achieve full reusability,” Musk wrote.

In a follow-up post, Musk addressed when SpaceX would attempt to catch the upper stage using the launch tower’s robotic arms.

“Should note that SpaceX will only try to catch the ship with the tower after two perfect soft landings in the ocean. The risk of the ship breaking up over land needs to be very low,” Musk clarified.

His remarks suggest that SpaceX is deliberately reducing risk before attempting a tower catch of Starship’s upper stage. Such a milestone would mark a major step towards the full reuse of the Starship system.

SpaceX is currently targeting the first Starship V3 flight of 2026 this coming March. The spacecraft’s V3 iteration is widely viewed as a key milestone in SpaceX’s long-term strategy to make Starship fully reusable.

Starship V3 features a number of key upgrades over its previous iterations. The vehicle is equipped with SpaceX’s Raptor V3 engines, which are designed to deliver significantly higher thrust than earlier versions while reducing cost and weight.

The V3 design is also expected to be optimized for manufacturability, a critical step if SpaceX intends to scale the spacecraft’s production toward frequent launches for Starlink, lunar missions, and eventually Mars.

News

Tesla FSD (Supervised) could be approved in the Netherlands next month: Musk

Musk shared the update during a recent interview at Giga Berlin.

Tesla CEO Elon Musk shared that Full Self-Driving (FSD) could receive regulatory approval in the Netherlands as soon as March 20, potentially marking a major step forward for Tesla’s advanced driver-assistance rollout in Europe.

Musk shared the update during a recent interview at Giga Berlin, noting that the date was provided by local authorities.

“Tesla has the most advanced real-world AI, and hopefully, it will be approved soon in Europe. We’re told by the authorities that March 20th, it’ll be approved in the Netherlands,’ what I was told,” Musk stated.

“Hopefully, that date remains the same. But I think people in Europe are going to be pretty blown away by how good the Tesla car AI is in being able to drive.”

Tesla’s FSD system relies on vision-based neural networks trained on real-world driving data, allowing vehicles to navigate using cameras and AI rather than traditional sensor-heavy solutions.

The performance of FSD Supervised has so far been impressive. As per Tesla’s safety report, Full Self-Driving Supervised has already traveled 8.3 billion miles. So far, vehicles operating with FSD Supervised engaged recorded one major collision every 5,300,676 miles.

In comparison, Teslas driven manually with Active Safety systems recorded one major collision every 2,175,763 miles, while Teslas driven manually without Active Safety recorded one major collision every 855,132 miles. The U.S. average during the same period was one major collision every 660,164 miles.

If approval is granted on March 20, the Netherlands could become the first European market to greenlight Tesla’s latest supervised FSD (Supervised) software under updated regulatory frameworks. Tesla has been working to secure expanded FSD access across Europe, where regulatory standards differ significantly from those in the United States. Approval in the Netherlands would likely serve as a foundation for broader EU adoption, though additional country-level clearances may still be required.