Space

SpaceX is already preparing for operational astronaut missions

While the world’s attention is focused on the return of orbital human spaceflight from US soil after a nearly decade long absence with the upcoming May 27th Crew Dragon Demo-2 mission, SpaceX is simultaneously preparing for the first Crew Dragon operational mission certified by NASA, dubbed Crew-1, slated to occur later this year.

On Friday, April 24th, SpaceX treated its Twitter followers to some rare imagery of static fire testing completed at the company’s development facility in McGregor, Texas. The company spotlighted a fresh-from-the-factory Falcon 9 booster and Falcon 9 second stage Merlin Vaccum (MVac) engine intended for the Crew-1 mission. Crew-1, the follow-up mission to May’s Demo-2 mission and SpaceX’s first operational human spaceflight mission for NASA, will propel a crew of three NASA astronauts and one JAXA astronaut in a Crew Dragon capsule to the International Space Station.

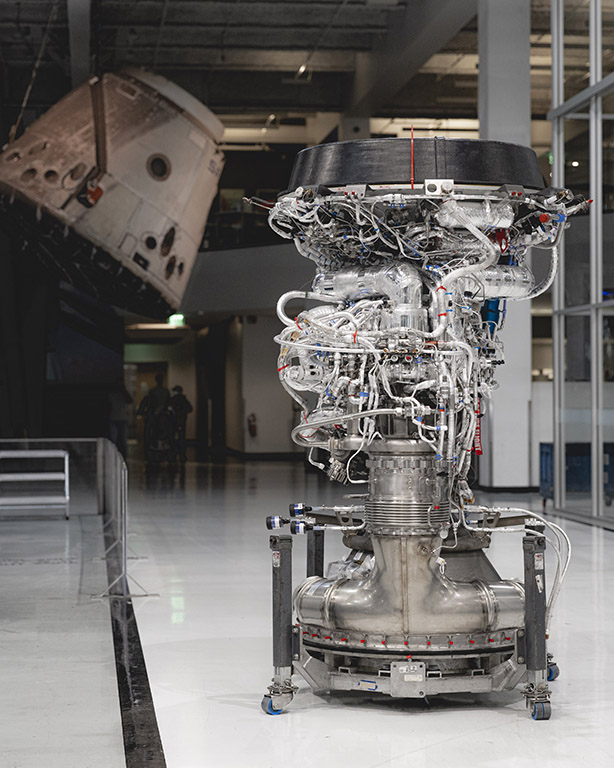

SpaceX also provided its followers with a view of the pristine second stage MVac engine of the Crew-1 mission before it was sent to Texas for testing. The one-hundredth production MVac engine is seen inside of SpaceX’s manufacturing facility located in Hawthorne, CA before being prepared for shipment. The second stage MVac engine is the only piece of Falcon 9 hardware that SpaceX does not actively recover and reuse, unlike the first-stage booster and protective payload fairing nosecone.

Part of the process

A static fire test is a typical occurrence before shipping the booster and second stage to Florida for payload integration and launch. The static fire process involves holding down the booster and igniting the engines to run for a full-duration firing. A similar test is also performed on with the second stage MVac engine. These test-fires are performed at the Mcgregor facility to proof the vehicle and check for any inconsistencies or off-nominal test readings that may occur before shipping to the vehicle to the launch site. Following the test-fire, the entire vehicle is inspected, cleaned, and prepared for shipment.

A test-fire in Mcgregor is not the last time the engines will be put through the paces before launch. Typically a week or so before the scheduled launch date, the Falcon 9 booster is transported to the launch pad. There, the booster is fully fueled with propellant while securely held to the launch mount. All nine Merlin-1D engines are once again ignited briefly (anywhere between 6 – 12 seconds) to test the propellant load process and collect engine-firing measurements such as temperature and pressure.

Certification before operation

Although the Crew-1 mission is tentatively on the books for later this year, SpaceX and the Crew Dragon capsule have yet to achieve NASA certification to begin operational missions to and from the International Space Station. The second orbital demonstration flight of the Crew Dragon capsule (Demo-2) will serve as the final end-to-end test of SpaceX’s crew transportation system.

However, SpaceX still faces a few obstacles before achieving a full go-ahead by NASA for the launch of Demo-2. As reported by SpaceNews.com NASA’s Aerospace Safety Advisory Panel (ASAP) met via teleconference on Thursday, April 23rd for a routine quarterly briefing. In that meeting, it was briefly discussed that there are still a few “technical items” that remain to be cleared by NASA before the launch of the Demo-2 mission.

Although not specified in the briefing – and likely to be followed up on during “part 2” of the ASAP meeting to be held in early May – those items likely refer to wrapping up the joint investigation of a recent in-flight engine failure of a Falcon 9 Merlin-1D engine and one more qualifying drop-test of the Crew Dragon Mark 3 parachutes. SpaceX, however, shows no plans letting formalities stop the preparation to support future astronaut missions.

Check out Teslarati’s newsletters for prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes.

News

SpaceX Ax-4 Mission prepares for ISS with new launch date

SpaceX, Axiom Space, and NASA set new launch date for the Ax-4 mission after addressing ISS & rocket concerns.

SpaceX is preparing for a new launch date for the Ax-4 mission to the International Space Station (ISS).

SpaceX, Axiom Space, and NASA addressed recent technical challenges and announced a new launch date of no earlier than Thursday, June 19, for the Ax-4 mission. The delay from June 12 allowed teams to assess repairs to small leaks in the ISS’s Zvezda service module.

NASA and Roscosmos have been monitoring leaks in the Zvezda module’s aft (back) segment for years. However, stable pressure could also result from air flowing across the hatch seal from the central station. As NASA and its partners adapt launch schedules to ensure station safety, adjustments are routine.

“Following the most recent repair, pressure in the transfer tunnel has been stable,” a source noted, suggesting the leaks may be sealed.

“By changing pressure in the transfer tunnel and monitoring over time, teams are evaluating the condition of the transfer tunnel and the hatch seal between the space station and the back of Zvezda,” the source added.

SpaceX has also resolved a liquid oxygen leak found during post-static fire inspections of the Falcon 9 rocket, completing a wet dress rehearsal to confirm readiness. The Ax-4 mission is Axiom Space’s fourth private astronaut trip to the ISS. It will launch from NASA’s Kennedy Space Center in Florida on a Falcon 9 rocket with a new Crew Dragon capsule.

“This is the first flight for this Dragon capsule, and it’s carrying an international crew—a perfect debut. We’ve upgraded storage, propulsion components, and the seat lash design for improved reliability and reuse,” said William Gerstenmaier, SpaceX’s vice president of build and flight reliability.

The Ax-4 mission crew is led by Peggy Whitson, Axiom Space’s director of human spaceflight and former NASA astronaut. The Ax-4 crew includes ISRO astronaut Shubhanshu Shukla as pilot, alongside mission specialists Sławosz Uznański-Wiśniewski from Poland and Tibor Kapu from Hungary. The international team underscores Axiom’s commitment to global collaboration.

The Ax-4 mission will advance scientific research during its ISS stay, supporting Axiom’s goal of building a commercial space station. As teams finalize preparations, the mission’s updated launch date and technical resolutions position it to strengthen private space exploration’s role in advancing space-based innovation.

News

Starlink India launch gains traction with telecom license approval

Starlink just secured its telecom license in India! High-speed satellite internet could go live in 2 months.

Starlink India’s launch cleared a key regulatory hurdle after securing a long-awaited license from the country’s telecom ministry. Starlink’s license approval in India paves the way for commercial operations to begin, marking a significant milestone after a three-year wait.

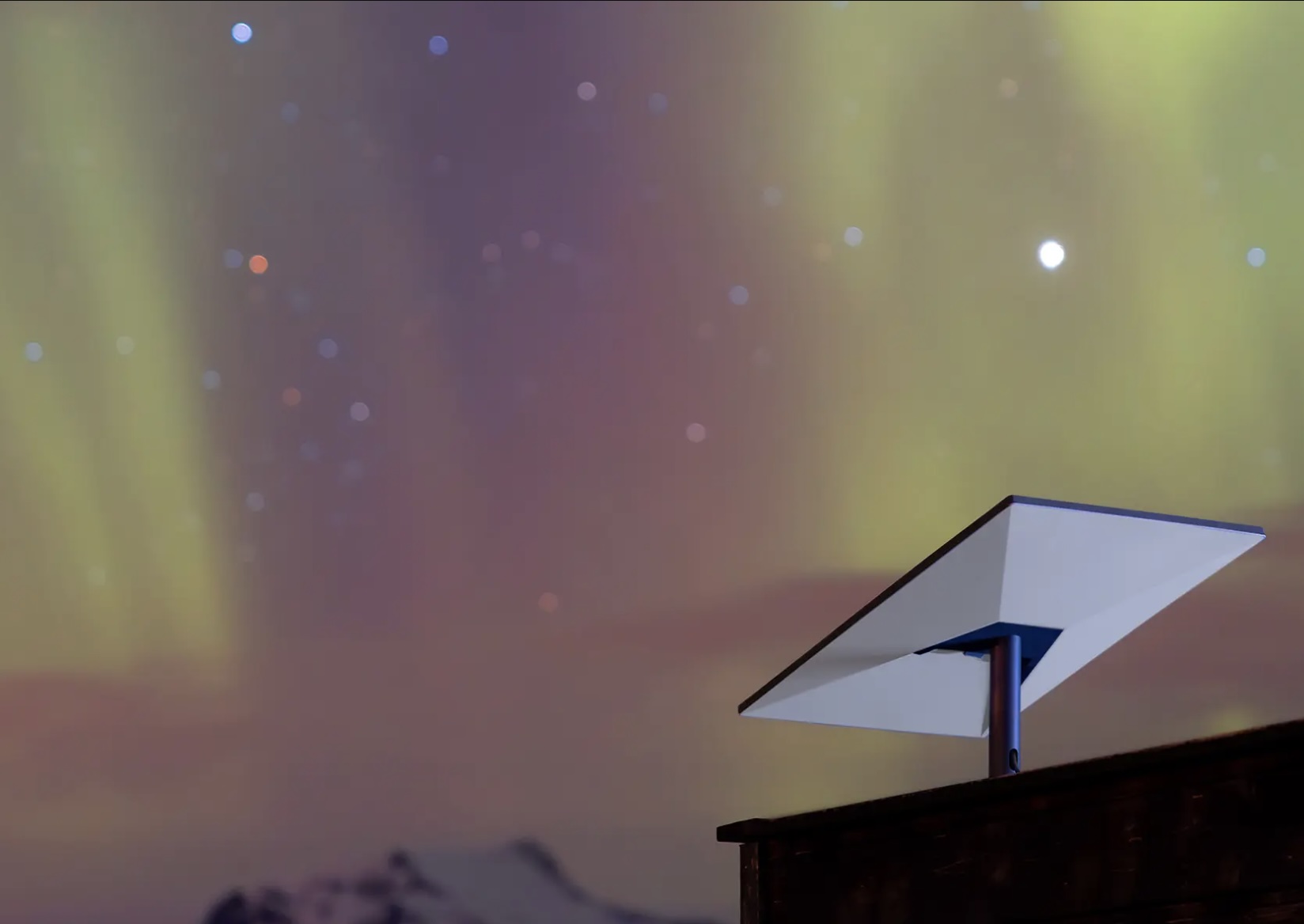

The Department of Telecommunications granted Starlink a Global Mobile Personal Communication by Satellite (GMPCS) license, enabling it to roll out its high-speed internet service. Local reports hinted that Starlink plans to launch its services within the next two months. Starlink India’s services are expected to be priced at ₹3,000 per month for unlimited data. Starlink service would require a ₹33,000 hardware kit, including a dish and router.

“Starlink is finally ready to enter the Indian market,” sources familiar with the rollout plans confirmed, noting a one-month free trial for new users.

Starlink’s low-Earth orbit satellite network promises low-latency, high-speed internet that is ideal for rural India, border areas, and hilly terrains. With over 7,000 satellites in orbit and millions of global users, Starlink aims to bridge India’s digital divide, especially in areas with limited traditional broadband.

Starlink has forged distribution partnerships with Indian telecom giants Reliance Jio and Bharti Airtel to streamline deployment and retail logistics. However, the company still awaits spectrum allocation and final clearances from India’s space regulator, IN-SPACe, and national security agencies before its full launch, expected before August 2025.

India’s satellite internet market is becoming increasingly competitive, with Starlink joining rivals like OneWeb and Jio Satellite Communications. While Starlink positions itself as a premium offering, its entry has sparked debate among domestic telecom operators over spectrum pricing.

Local reports noted that other players in the industry have raised concerns over the lower regulatory fees proposed for satellite firms compared to terrestrial operators, highlighting tensions in the sector.

Starlink India’s launch represents a transformative step toward expanding internet access in one of the world’s largest markets. Starlink could redefine connectivity for millions in underserved regions by leveraging its advanced satellite technology and strategic partnerships. As the company navigates remaining regulatory steps, its timely rollout could set a new standard for satellite internet in India, intensifying competition and driving innovation in the telecom landscape.

Elon Musk

SpaceX to decommission Dragon spacecraft in response to Pres. Trump war of words with Elon Musk

Elon Musk says SpaceX will decommission Dragon as a result of President Trump’s threat to end his subsidies and government contracts.

SpaceX will decommission its Dragon spacecraft in response to the intense war of words that President Trump and CEO Elon Musk have entered on various social media platforms today.

President Trump and Musk, who was once considered a right-hand man to Trump, have entered a vicious war of words on Thursday. The issues stem from Musk’s disagreement with the “Big Beautiful Bill,” which will increase the U.S. federal deficit, the Tesla and SpaceX frontman says.

How Tesla could benefit from the ‘Big Beautiful Bill’ that axes EV subsidies

The insults and threats have been brutal, as Trump has said he doesn’t know if he’ll respect Musk again, and Musk has even stated that the President would not have won the election in November if it were not for him.

President Trump then said later in the day that:

“The easiest way to save money in our Budget, Billions and Billions of Dollars, is to terminate Elon’s Government Subsidies and Contracts. I was always surprised that Biden didn’t do it!”

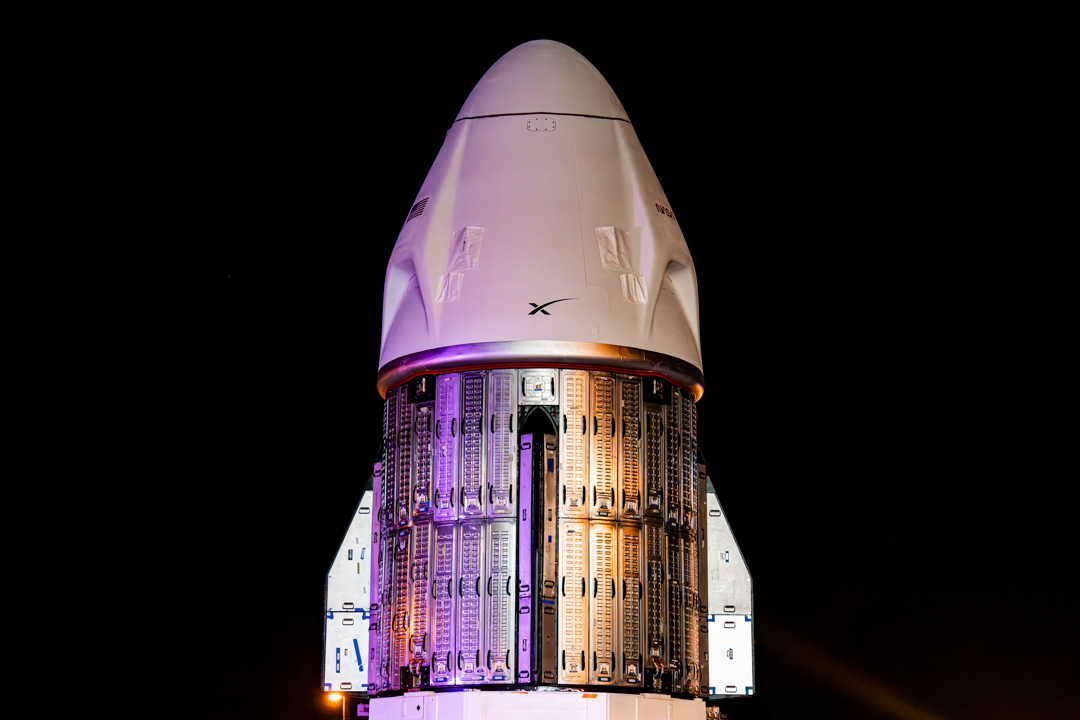

Musk’s response was simple: he will decommission the SpaceX capsule responsible for transporting crew and cargo to the International Space Station (ISS): Dragon.

🚨 Elon says Dragon will be decommissioned immediately due to President Trump’s threats to terminate SpaceX’s government contracts https://t.co/XNB0LflZIy

— TESLARATI (@Teslarati) June 5, 2025

Dragon has completed 51 missions, 46 of which have been to the ISS. It is capable of carrying up to 7 passengers to and from Earth’s orbit. It is the only spacecraft that is capable of returning vast amounts of cargo to Earth. It is also the first private spacecraft to take humans to the ISS.

The most notable mission Dragon completed is one of its most recent, as SpaceX brought NASA astronauts Butch Wilmore and Suni Williams back to Earth after being stranded at the ISS by a Boeing Starliner capsule.

SpaceX’s reluctance to participate in federally funded projects may put the government in a strange position. It will look to bring Boeing back in to take a majority of these projects, but there might be some reluctance based on the Starliner mishap with Wilmore and Williams.

SpaceX bails out Boeing and employees are reportedly ‘humiliated’

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

Elon Musk3 days ago

Elon Musk3 days agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

Elon Musk5 days ago

Elon Musk5 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News1 week ago

News1 week agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk1 week ago

Elon Musk1 week agoxAI’s Memphis data center receives air permit despite community criticism

-

News2 weeks ago

News2 weeks agoXiaomi CEO congratulates Tesla on first FSD delivery: “We have to continue learning!”

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla scrambles after Musk sidekick exit, CEO takes over sales

-

News2 weeks ago

News2 weeks agoTesla sees explosive sales growth in UK, Spain, and Netherlands in June