News

SpaceX’s used Falcon Heavy booster shown off in stunning detail [Gallery]

Less than two weeks after SpaceX’s Falcon Heavy performed a simultaneous first-stage landing, the Elon Musk-led space company has completed the process of recovering the massive rocket’s two side boosters, both of which can now lay claim to supporting two separate orbital missions. However, while fascinating in its own right, more interesting is the fact that SpaceX has chosen to very publicly display one of those two boosters front and center at the Kennedy Space Center Visitor Center (KSCVC).

It is likely no coincidence that the National Space Council is scheduled to have their second-ever meeting at Kennedy Space Center this Wednesday. One can readily imagine that SpaceX’s vast, sooty, flight-proven Falcon rockets can be quite an imposing and impressive sight, and it appears that the launch company is hoping to thoroughly impress the Space Council on Wednesday.

- Falcon Heavy’s side booster on display at the Kennedy Space Center visitor complex. (Tom Cross/Teslarati)

- This side booster is Core 1025, the same booster that launched and landed during the CRS-9 Cargo Dragon mission in 2016. (Tom Cross/Teslarati)

- A beautiful sunset eclipsed by SpaceX’s equally beautiful flight-proven Falcon Heavy booster. (Tom Cross/Teslarati)

Regardless of odd and interesting jockeying, the Falcon Heavy booster display is an absolutely unprecedented opportunity in SpaceX history, and Teslarati’s East coast photographer Tom Cross jumped on it. This rocket display is easily the first time the general public has ever been allowed to get so close to fresh rocket hardware, let alone the entire booster of a brand new launch vehicle. Tom has captured some extraordinarily detailed photos of various flight-proven rocket hardware, ranging from titanium grid fins to Merlin engines and even more esoteric parts, like landing leg connecting points.

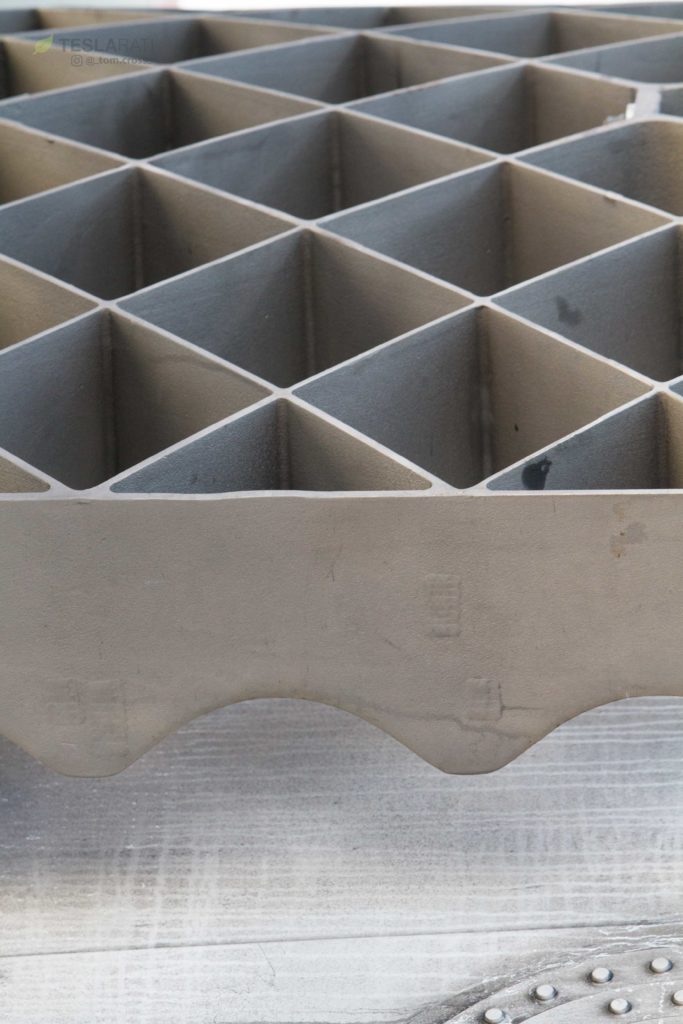

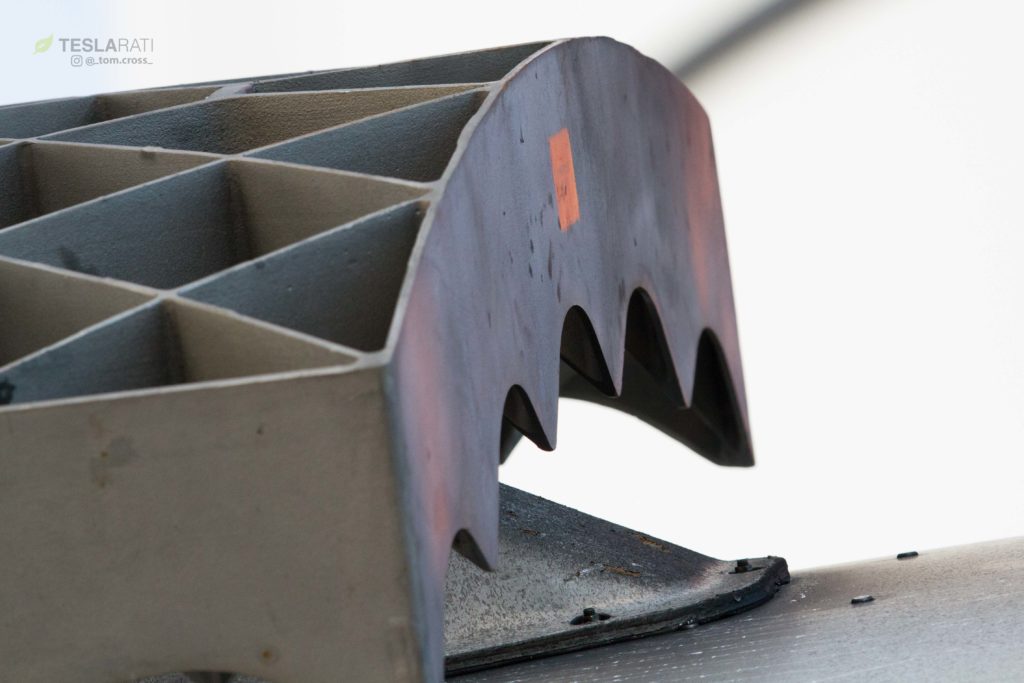

Titanium grid fins

Appearing nearly unscathed after exposure to reentry temperatures that are often less kind to aluminum, SpaceX’s second flight-test of titanium grid fins has been a resounding success. It’s been hinted by CEO Elon Musk that these massive pieces of cast metal are probably the most expensive individual components on a Falcon 9, and they certainly look every bit the part. Check out these pieces of metalworking art in the best detail yet.

Falcon rockets are constructed largely of aluminum and painted with compounds that are designed to burn off under the heat of reentry, known as ablation. (Tom Cross/Teslarati)

- Falcon Heavy side booster 1025’s flight-proven nose con and grid fins, girdled by one of SpaceX’s rocket transporters. (Tom Cross/Teslarati)

- RIP B1044’s titanium grid fins. May they make a happy little reef at the bottom of the ocean. (Tom Cross)

- Note the serial number, this grid fin appears to be the 3rd titanium fin ever produced- SN00003. (Tom Cross/Teslarati)

- Details of the grid fin. (Tom Cross/Teslarati)

- Rather menacing, eh? (Tom Cross/Teslarati)

- The sinuous curves of the grid fins allow them to better attack the air at the highest pressure points during reentry. (Tom Cross/Teslarati)

- They also happen to look incredibly beautiful. (Tom Cross/Teslarati)

Merlin engines and octaweb details

Taking the brunt of the force and heat of reentry, Falcon Heavy booster 1025’s business end is a powerful display of the intense environment SpaceX’s rockets must survive in order to successfully find their way to land (or sea). Around each Merlin engine is an insulating ceramic fiber blanket intended to protect the more sensitive components of rocket plumbing from the intense heat and buffeting experienced by the engine bells. The octaweb and engine area is also lined with a fair amount of cork – yes, the same material you cork a wine bottle with – designed to sap up the heat of reentry and often ablate. This simple material has worked incredibly well for the rocket company, although it is considerably less than reusable, and likely has to be replaced each launch. Falcon 9 Block 5, expected to begin integrated testing in Texas just days from now, will likely switch to a more reusable material for its octaweb heat shield.

Falcon Heavy booster 1025’s well-worn octaweb. The Merlin engines are underneath their blue cozies. (Tom Cross/Teslarati)

A beautiful capture of one of the booster’s nine Merlin engines, showing off the pipe used to cool the engine bell, as well as the ceramic blanket that protects its more sensitive plumbing. (Tom Cross/Teslarati)

- All nine Merlin 1Ds displayed with their adorable cozies. (Tom Cross/Teslarati)

- Falcon Heavy side booster B1025 gives a sense of the sheer brutality of reentry conditions. (Tom Cross)

- An incredibly detail shot of the side of the octaweb. The large chunk of smooth metal in the center is actually one of the booster’s connection points to the Falcon Heavy center core. (Tom Cross/Teslarati)

- SpaceX’s 338th Merlin engine on display. This particular component circulates cold propellant around the engine bell to cool it down. (Tom Cross/Teslarati)

- A beautiful capture of one of the booster’s nine Merlin engines, showing off the pipe used to cool the engine bell, as well as the ceramic blanket that protects its more sensitive plumbing. (Tom Cross/Teslarati)

- Note the pieces of cork that have been torn off by the buffeting and heat on the lefthand side. (Tom Cross)

Ultimately, this Falcon Heavy booster display is an incredible show of force to the National Space Council, as well as an extraordinary opportunity and inspiration for KSC visitors. Teslarati photographer Tom Cross has given us one of the most detailed looks yet at a complete SpaceX rocket, not to mention such a historic and flight-proven specimen.

The National Space Council meets early tomorrow morning (10:00 am EST, Feb. 21), and will be live-streamed here. SpaceX’s very own President and COO Gwynne Shotwell is expected to be in attendance, and will likely present a brief statement to the council.

Be sure to follow Teslarati’s space team for exclusive backstage access to SpaceX, coast-to-coast:

News

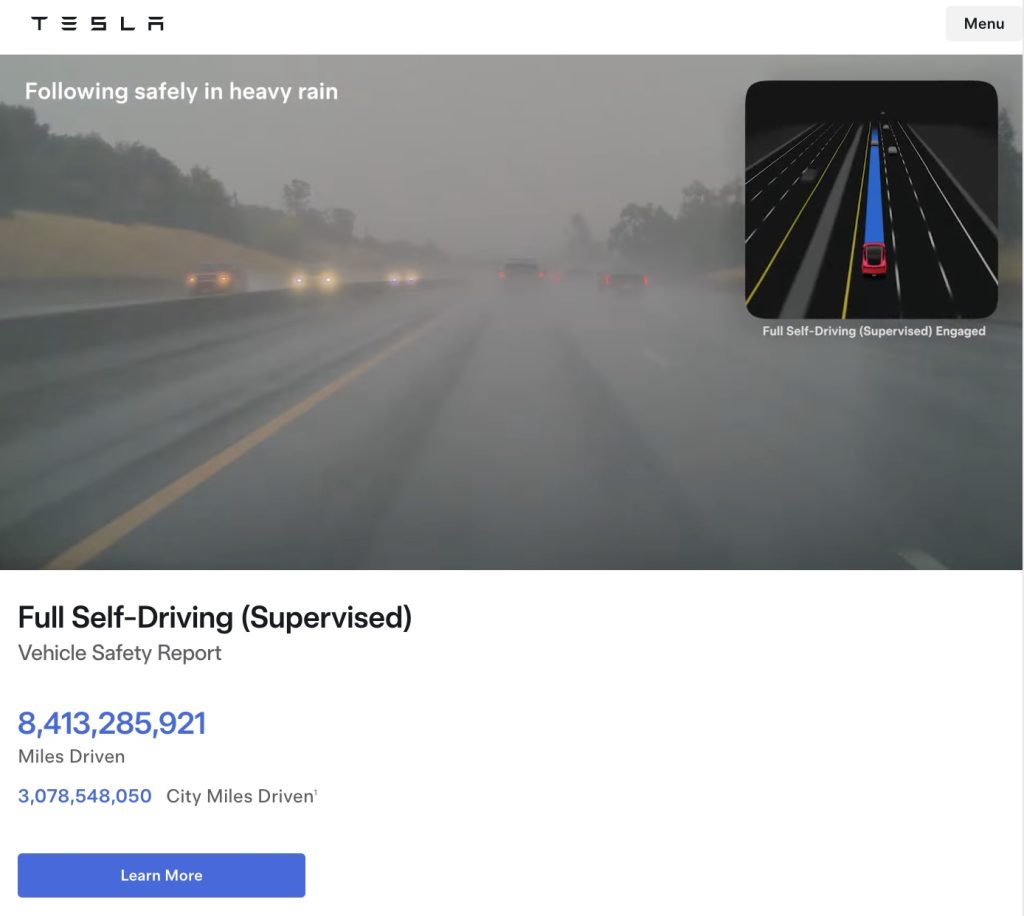

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.