Energy

Tesla’s Gigafactory continues to reshape Reno: Transforming education, housing and the small business sector

Reno, a city just four hours away from Silicon Valley, has been home of Tesla’s Gigafactory – a city whose economy once chiefly relied on the low-wage casino industry, where bankruptcy and crime were frequent and unpredictable. Hit hard with the housing crash and recession, Reno fell into hard times in 2010 with a 14 percent unemployment rate. Once home to mostly thrifters and passersby, Reno’s outlook started to change with talks of Tesla’s plans for technological revitalization. Startups and incubators have been popping up to attract more millennials, new murals are being painted onto derelict walls, all are response to the hope that Tesla will be able to inject into the local economy sustainable, higher-paying jobs.

Tesla announced three years ago, in 2014, that construction would begin for its new Gigafactory in Reno, Nevada. As of now, battery cell production is well underway, and the factory has become the main production facility for Model 3 battery packs and drive units.

The introduction of Tesla into the region has not only infused Reno’s economy with jobs that have shifted it out of its economic drought, but also incentivized enrollment in neighboring schools, especially in STEM-related subjects. Nearby professors at the University of Nevada commented to eenews that the Tech Sector may be the area with the most secure employment base. The construction of the factory has provided over 4000 local jobs for the Reno economy, and will support close to 10,000 jobs when complete, up from a previous estimate of 6,500 jobs.

- Are we seeing a pathway leading from the main Gigafactory 1 facility leads to a new “parking lot”? [Photo: Teslarati]

Tesla Gigafactory flyover July 2017 captures parking lot expansion

This will in turn increase the retention rate at schools, both secondary and professional/university, creating a positive feedback cycle within the job sector and the education sector, thus securing the longevity of both. In fact, in 2013, a large part of the economic recovery was due to STEM jobs, driving unemployment down to 6.4 percent, reported the Atlantic. Additionally, STEM jobs pay from 28 to 68 more than non-STEM jobs.

The presence of Tesla is complemented by other tech companies such as Apple and Amazon, with more expected to come. It’s very likely that the landscape of Reno in the years to come will be vastly different than it was before the introduction of Tesla, and many experts and officials dub this the “Tesla Effect”.

Hillary Schieve, the Mayor of Reno, defined the “Tesla Effect” as “a positive shift toward changing Reno’s national perception for the better….Reno’s emerging neighborhoods, such as Midtown, downtown, and the Fourth Street corridor…due in large part to [the] booming technology industry with billions of dollars being invested from some of Fortune’s highest-ranked companies, which includes Tesla, Switch, Amazon and Microsoft.”

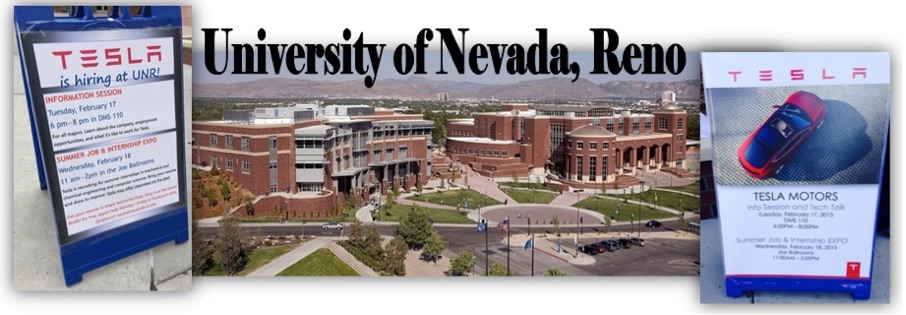

Tesla recruiting from the University of Nevada, Reno in 2015

The growth from the “Tesla Effect” extends beyond just the technology sector. Applied Economics presented a study in 2014 to Nevada Governor’s Office of Economic Development stating that “Tesla would be an important contributor to the region’s economy and could serve as a catalyst for additional manufacturing and logistics development in the region with its worldwide name recognition and cutting-edge technology. In addition, all of the jobs created by the company would be net new jobs thereby growing the economy both locally and regionally. The attraction of this company to Washoe County and Storey County would not only create a large number of new direct jobs, but also support a sizeable amount of additional economic activity, jobs and payroll at related local supplier and consumer businesses.” The study further broke down the revenues streams into different sections and explained where each calculated value was estimated from. You can see the full report here.

The presence of Tesla has pushed for market diversification within Reno. The building of the factory continues to draw in slews of local businesses to supplement the needs of both the factory and the people. Demands for food, supplies, gas and food will increase, bringing in more employment and more cash flow.

Drawing new businesses also could have the potential to diversify and infuse culture into the local neighborhood, highlighting flairs and quirks that will make it competitively attractive culturally to job seekers against neighborhoods such as the rich-cultured Austin.

Siena Hotel Spa & Casino in Reno, NV outside of nearby Tesla Gigafactory in Sparks. Source: Siena Hotel & Casino

With neighborhood changes, come real estate changes. The median rent prices along with the amount of rentals saw a sharp spike followed by a steady increase beginning around February 2017, according to trulia.com. But while the tech boom creates a great demand for apartments and housing, the boom does not seem like it would expand into areas stricken by poverty and food deserts so far. According to the Atlantic, the boom has not yet worked to create enough affordable housing, possibly stratifying the inequality levels in correlation to distance from the tech center. The consequence could be creating a real-estate scenario similar to that of San Francisco’s. However, better local government regulations and sanctions could possibly ameliorate the problem, since the factory has not officially opened all of its doors yet to potential job-seekers.

With the influx of jobs and traffic, infrastructure and transportation will be greatly impacted. According to the Reno Gazette Journal, “USA Parkway’s still-unbuilt 16 miles to U.S. Highway 50 in Silver Springs will be “fast-tracked” to completion in as soon as two years, they said, opening up access to Lyon County and the Dayton Valley and to Carson City beyond”. Increasing the connectivity of the community may better bridge the divides between individual counties and neighborhoods, and between Reno and the outside world, facilitating more efficient transfers of material, information and persons.

With shifting concerns and economies, cities are made to be more adaptable to the different cultural, demographic and social climates. Jobs markets created by fossil fuels will meet diminishing futures in face of environmental and climate concerns. The redirection towards clean energy leaves white space for the development and creation of jobs in the clean energy technologies. Creating a technological oasis centered around sustainability in complement with the current economy will secure both long term and short term profits. It will insure a steady revenue stream for the state and poise itself for the transition into a green future.

Energy

Tesla Powerwall distribution expands in Australia

Inventory is expected to arrive in late February and official sales are expected to start mid-March 2026.

Supply Partners Group has secured a distribution agreement for the Tesla Powerwall in Australia, with inventory expected to arrive in late February and official sales beginning in mid-March 2026.

Under the new agreement, Supply Partners will distribute Tesla Powerwall units and related accessories across its national footprint, as noted in an ecogeneration report. The company said the addition strengthens its position as a distributor focused on premium, established brands.

“We are proud to officially welcome Tesla Powerwall into the Supply Partners portfolio,” Lliam Ricketts, Co-Founder and Director of Innovation at Supply Partners Group, stated.

“Tesla sets a high bar, and we’ve worked hard to earn the opportunity to represent a brand that customers actively ask for. This partnership reflects the strength of our logistics, technical services and customer experience, and it’s a win for installers who want premium options they can trust.”

Supply Partners noted that initial Tesla Powerwall stock will be warehoused locally before full commercial rollout in March. The distributor stated that the timing aligns with renewed growth momentum for the Powerwall, supported by competitive installer pricing, consumer rebates, and continued product and software updates.

“Powerwall is already a category-defining product, and what’s ahead makes it even more compelling,” Ricketts stated. “As pricing sharpens and capability expands, we see a clear runway for installers to confidently spec Powerwall for premium residential installs, backed by Supply Partners’ national distribution footprint and service model.”

Supply Partners noted that a joint go-to-market launch is planned, including Tesla-led training for its sales and technical teams to support installers during the home battery system’s domestic rollout.

Energy

Tesla Megapack Megafactory in Texas advances with major property sale

Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet.

Tesla’s planned Megapack factory in Brookshire, Texas has taken a significant step forward, as two massive industrial buildings fully leased to the company were sold to an institutional investor.

In a press release, Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet. The properties are 100% leased to Tesla under a long-term agreement and were acquired by BGO on behalf of an institutional investor.

The two facilities, located at 100 Empire Boulevard in Brookshire, Texas, will serve as Tesla’s new Megafactory dedicated to manufacturing Megapack battery systems.

According to local filings previously reported, Tesla plans to invest nearly $200 million into the site. The investment includes approximately $44 million in facility upgrades such as electrical, utility, and HVAC improvements, along with roughly $150 million in manufacturing equipment.

Building 9, spanning roughly 1 million square feet, will function as the primary manufacturing floor where Megapacks are assembled. Building 10, covering approximately 600,000 square feet, will be dedicated to warehousing and logistics operations, supporting storage and distribution of completed battery systems.

Waller County Commissioners have approved a 10-year tax abatement agreement with Tesla, offering up to a 60% property-tax reduction if the company meets hiring and investment targets. Tesla has committed to employing at least 375 people by the end of 2026, increasing to 1,500 by the end of 2028, as noted in an Austin County News Online report.

The Brookshire Megafactory will complement Tesla’s Lathrop Megafactory in California and expand U.S. production capacity for the utility-scale energy storage unit. Megapacks are designed to support grid stabilization and renewable-energy integration, a segment that has become one of Tesla’s fastest-growing businesses.

Energy

Tesla meets Giga New York’s Buffalo job target amid political pressures

Giga New York reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease.

Tesla has surpassed its job commitments at Giga New York in Buffalo, easing pressure from lawmakers who threatened the company with fines, subsidy clawbacks, and dealership license revocations last year.

The company reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease at the state-built facility.

As per an employment report reviewed by local media, Tesla employed 2,399 full-time workers at Gigafactory New York and 1,060 additional employees across the state at the end of 2025. Part-time roles pushed the total headcount of Tesla’s New York staff above the 3,460-job target.

The gains stemmed in part from a new Long Island service center, a Buffalo warehouse, and additional showrooms in White Plains and Staten Island. Tesla also said it has invested $350 million in supercomputing infrastructure at the site and has begun manufacturing solar panels.

Empire State Development CEO Hope Knight said the agency was “very happy” with Giga New York’s progress, as noted in a WXXI report. The current lease runs through 2029, and negotiations over updated terms have included potential adjustments to job requirements and future rent payments.

Some lawmakers remain skeptical, however. Assemblymember Pat Burke questioned whether the reported job figures have been fully verified. State Sen. Patricia Fahy has also continued to sponsor legislation that would revoke Tesla’s company-owned dealership licenses in New York. John Kaehny of Reinvent Albany has argued that the project has not delivered the manufacturing impact originally promised as well.

Knight, for her part, maintained that Empire State Development has been making the best of a difficult situation.

“(Empire State Development) has tried to make the best of a very difficult situation. There hasn’t been another use that has come forward that would replace this one, and so to the extent that we’re in this place, the fact that 2,000 families at (Giga New York) are being supported through the activity of this employer. It’s the best that we can have happen,” the CEO noted.