Energy

Tesla patents custom cooling system for longer-lasting energy storage devices

A significant part of Tesla’s business relies heavily on the durability and longevity of its battery packs, and in the spirit of disruptive innovation, the Silicon Valley-based company has continued to make improvements to its battery technology to make them more durable and more efficient. Tesla was able to achieve this through several ways, one of which was discussed in a recently published patent application.

It is pertinent for battery packs, particularly those that are used for energy storage, to be robust enough that they last for a very long time. To accomplish this, battery packs must be able to handle multiple charge and discharge cycles on a regular basis. They must also be able to weather faults in the system, including those that may cause damage to the actual cells in the pack itself.

Such a system was outlined by Tesla in a patent simply titled “Energy Storage System.” Explaining its rationale, the Silicon Valley-based company stated that “cells and other components in a pack generate heat during operation, both during the charging process to store the energy and during the discharge process when energy is consumed.” Tesla further explains that “when the cells fail, they typically release hot gases. These gases may impact the integrity of other cells in the pack and may cause substantial damage to the functional cells which have not failed.”

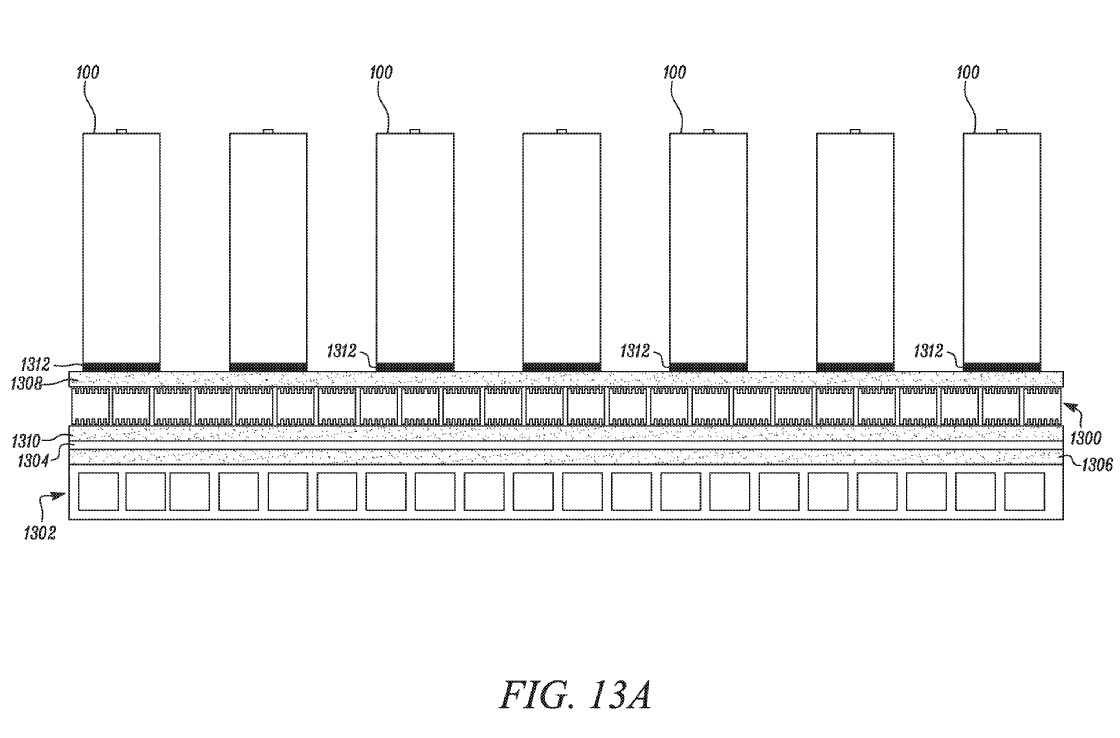

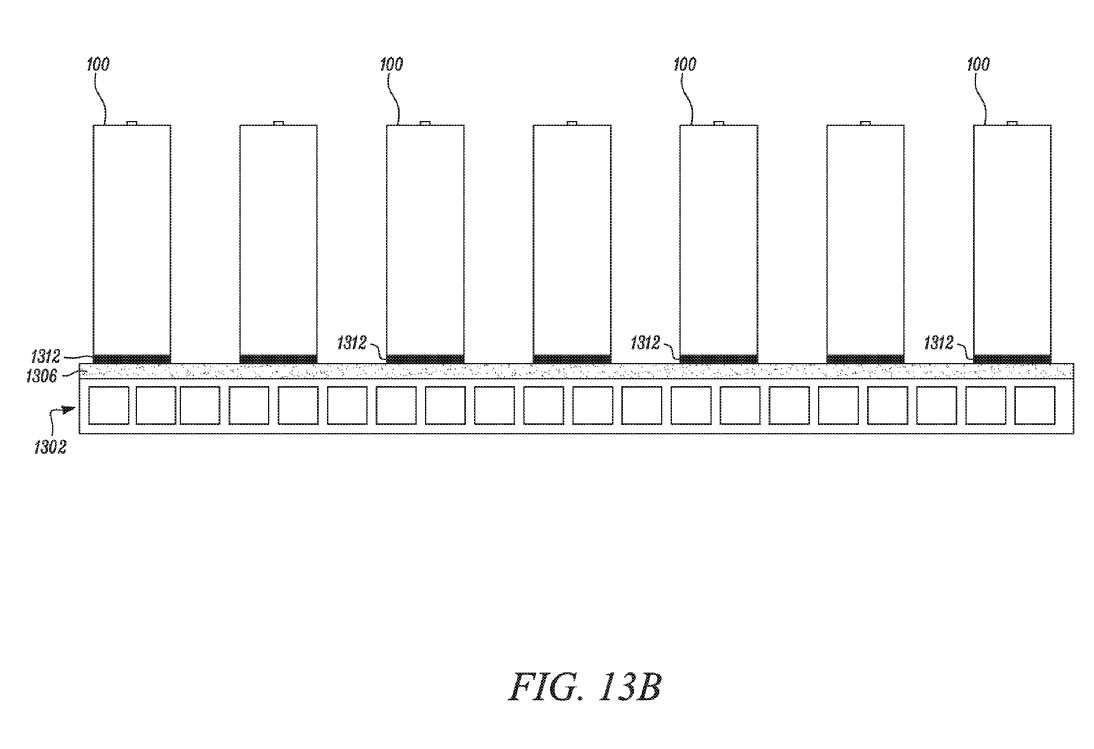

With this in mind, Tesla maintains that there is a need to develop an “improved energy storage system” that will be capable of reducing or removing “one or more of the issues mentioned.” Tesla’s patent describes two strategies that could improve its battery packs. One of these involves the use of a novel system that utilizes a cold plate, which could help remove heat generated by the battery pack during use. Heat pipes may also be used together with a cold plate to achieve this purpose.

“In certain embodiments, a cold plate (which provides liquid cooling) may be in thermal connection with the battery cells 100 to further remove heat generated during system use. The cold plate may be in direct thermal contact with the battery cells 100 or, alternatively, one or more layers and/or features may be between the cold plate and the battery cells 100. In certain embodiments, the battery cells 100 are in contact with one or more heat pipes to remove excess heat disposed under the battery cells. A cold plate is disposed below the heat pipe or pipes (on the side of the heat pipe away from the battery cells 100) that helps dissipate the heat contained in the heat pipe.”

“In certain embodiments, the cold plate may be in thermal contact with one side of the cells without any heat pipes disposed between the cells. The cold plate may physically consist of a single plate or multiple plates that are thermally connected to the cells and/or one another. In other embodiments, one or more heat pipes are disposed between the battery cells 100 and a cold plate is disposed below the battery cells 100. The heat pipes and the cold plate may be in thermal connection with one another.”

Apart from the use of cold plates, Tesla also described a battery pack with regions that are designed to give way when mechanical failures happen. By using such a system, the majority of the cells in a battery pack become protected even if some cells were to fail.

“The top plate includes one or more weak areas above the one or more battery cell. The weak areas are regions that have less integrity and thus, where mechanical failure is more likely to occur if a battery cell releases gas. These regions may be physically weaker areas compared to the surrounding areas and may rupture when pressure builds up due to a failed cell. Alternatively, the weak areas may be chemically weaker and preferentially rupture when exposed to the caustic gases released by a failed battery cell. The weak areas may also fail due to a combination of physical and chemical weakening.”

The full text of Tesla’s Energy Storage System patent could be accessed here.

Tesla’s focus on battery integrity in its recently published patent application suggests that the Silicon Valley-based company is looking to develop packs that are capable of lasting a very long time. Such improvements have been teased before, especially in a paper released by Tesla lead battery researcher Jeff Dahn and members of the Department of Physics and Atmospheric Science at Dalhousie University. The cells described in the paper are capable of lasting over 1 million miles on the road, or 20 years if used in grid energy storage.

Looking at these initiatives, as well as the battery pack contingencies outlined in the recently released patent, it appears that Tesla is building up towards creating an ecosystem of products that are capable of lasting decades. This, of course, plays a huge part in pushing Tesla’s overall goal of accelerating the advent of sustainable energy.

Energy

Tesla meets Giga New York’s Buffalo job target amid political pressures

Giga New York reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease.

Tesla has surpassed its job commitments at Giga New York in Buffalo, easing pressure from lawmakers who threatened the company with fines, subsidy clawbacks, and dealership license revocations last year.

The company reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease at the state-built facility.

As per an employment report reviewed by local media, Tesla employed 2,399 full-time workers at Gigafactory New York and 1,060 additional employees across the state at the end of 2025. Part-time roles pushed the total headcount of Tesla’s New York staff above the 3,460-job target.

The gains stemmed in part from a new Long Island service center, a Buffalo warehouse, and additional showrooms in White Plains and Staten Island. Tesla also said it has invested $350 million in supercomputing infrastructure at the site and has begun manufacturing solar panels.

Empire State Development CEO Hope Knight said the agency was “very happy” with Giga New York’s progress, as noted in a WXXI report. The current lease runs through 2029, and negotiations over updated terms have included potential adjustments to job requirements and future rent payments.

Some lawmakers remain skeptical, however. Assemblymember Pat Burke questioned whether the reported job figures have been fully verified. State Sen. Patricia Fahy has also continued to sponsor legislation that would revoke Tesla’s company-owned dealership licenses in New York. John Kaehny of Reinvent Albany has argued that the project has not delivered the manufacturing impact originally promised as well.

Knight, for her part, maintained that Empire State Development has been making the best of a difficult situation.

“(Empire State Development) has tried to make the best of a very difficult situation. There hasn’t been another use that has come forward that would replace this one, and so to the extent that we’re in this place, the fact that 2,000 families at (Giga New York) are being supported through the activity of this employer. It’s the best that we can have happen,” the CEO noted.

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

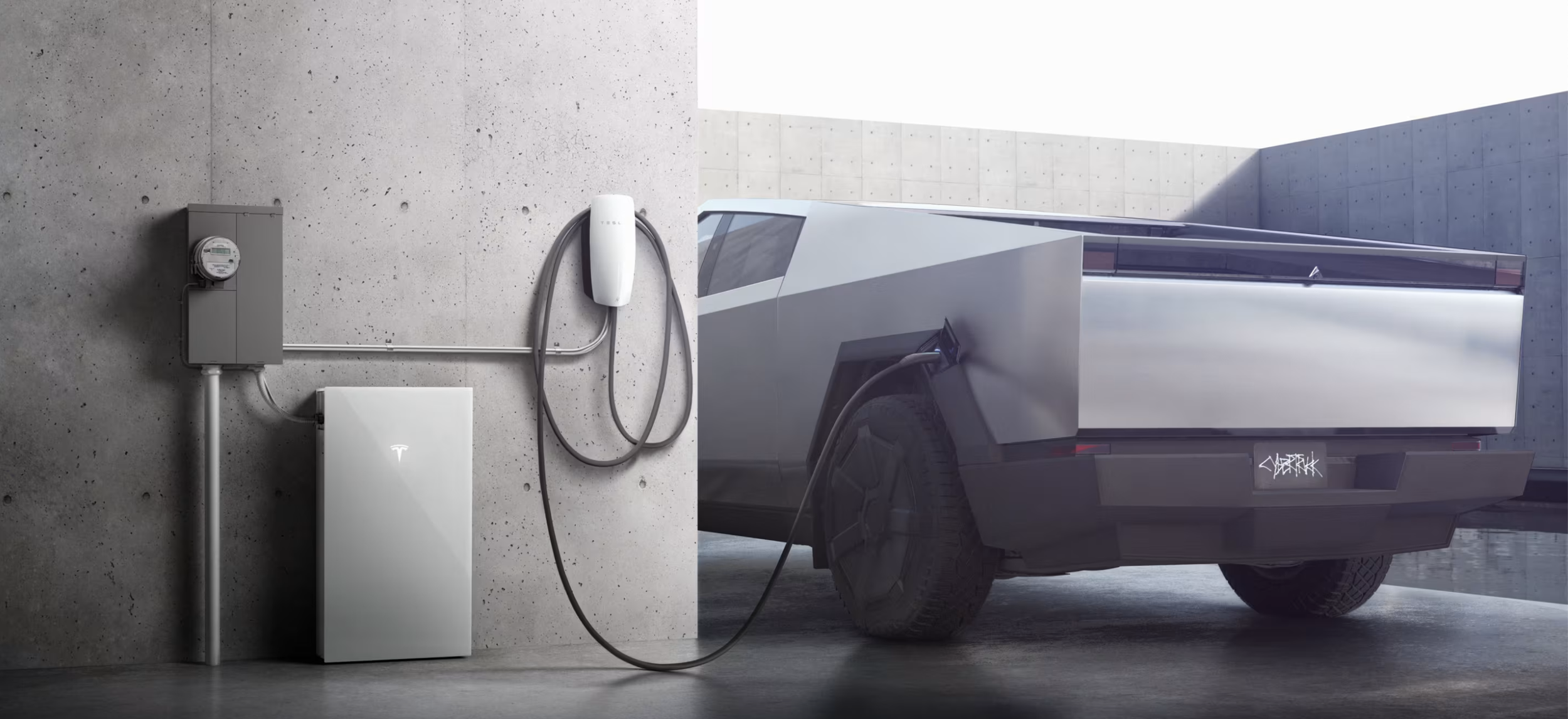

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.

Cybertruck

Tesla updates Cybertruck owners about key Powershare feature

Tesla is updating Cybertruck owners on its timeline of a massive feature that has yet to ship: Powershare with Powerwall.

Powershare is a bidirectional charging feature exclusive to Cybertruck, which allows the vehicle’s battery to act as a portable power source for homes, appliances, tools, other EVs, and more. It was announced in late 2023 as part of Tesla’s push into vehicle-to-everything energy sharing, and acting as a giant portable charger is the main advantage, as it can provide backup power during outages.

Cybertruck’s Powershare system supports both vehicle-to-load (V2L) and vehicle-to-home (V2H), making it flexible and well-rounded for a variety of applications.

However, even though the feature was promised with Cybertruck, it has yet to be shipped to vehicles. Tesla communicated with owners through email recently regarding Powershare with Powerwall, which essentially has the pickup act as an extended battery.

Powerwall discharge would be prioritized before tapping into the truck’s larger pack.

However, Tesla is still working on getting the feature out to owners, an email said:

“We’re writing to let you know that the Powershare with Powerwall feature is still in development and is now scheduled for release in mid-2026.

This new release date gives us additional time to design and test this feature, ensuring its ability to communicate and optimize energy sharing between your vehicle and many configurations and generations of Powerwall. We are also using this time to develop additional Powershare features that will help us continue to accelerate the world’s transition to sustainable energy.”

Owners have expressed some real disappointment in Tesla’s continuous delays in releasing the feature, as it was expected to be released by late 2024, but now has been pushed back several times to mid-2026, according to the email.

Foundation Series Cybertruck buyers paid extra, expecting the feature to be rolled out with their vehicle upon pickup.

Cybertruck’s Lead Engineer, Wes Morrill, even commented on the holdup:

As a Cybertruck owner who also has Powerwall, I empathize with the disappointed comments.

To their credit, the team has delivered powershare functionality to Cybertruck customers who otherwise have no backup with development of the powershare gateway. As well as those with solar…

— Wes (@wmorrill3) December 12, 2025

He said that “it turned out to be much harder than anticipated to make powershare work seamlessly with existing Powerwalls through existing wall connectors. Two grid-forming devices need to negotiate who will form and who will follow, depending on the state of charge of each, and they need to do this without a network and through multiple generations of hardware, and test and validate this process through rigorous certifications to ensure grid safety.”

It’s nice to see the transparency, but it is justified for some Cybertruck owners to feel like they’ve been bait-and-switched.