News

Tesla patent points to battery cell improvements with clever deformation detection process

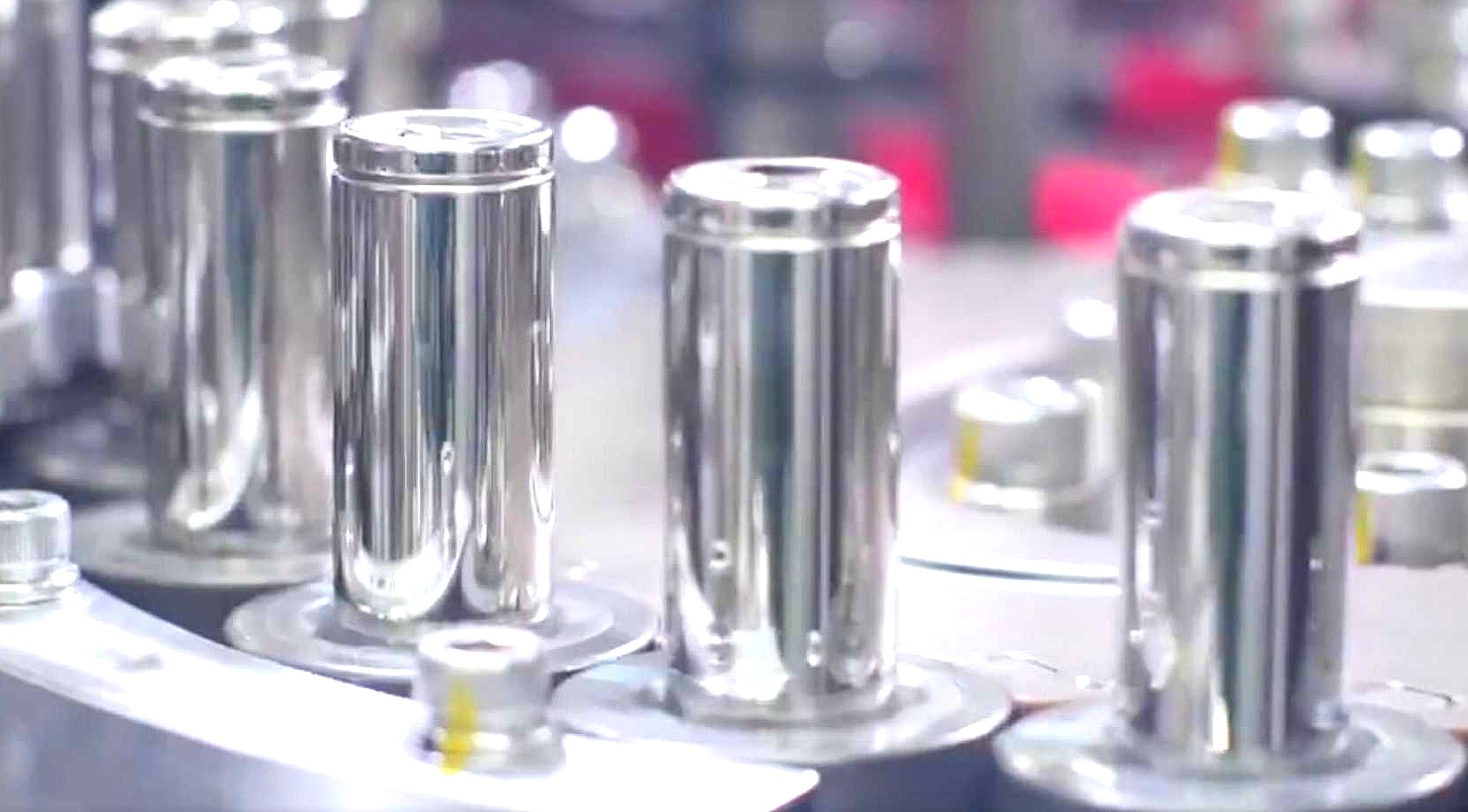

A recent patent published late August has revealed that Tesla is working on a monitoring system and apparatus that will allow the electric car maker to detect deformations in battery cells in a more effective manner.

Tesla’s patent application, titled “Apparatus and Method for Detection of Deformation in Battery Cells,” notes that battery cycle life is among the most crucial parameters to ensure optimal performance in machines such as electric vehicles and energy storage devices. Over the course of their lifetime, battery cells will be subjected to multiple charge and discharge cycles, at times in vastly varying conditions and environments.

As noted by the company in its patent application, there are instances when cells operate in an environment where the ambient temperature may intermittently surge to levels above the stable thermal temperature for normal operations. Cells could also be subjected to high charge and discharge rates and large periodic loads, which could result in significant heating, among other reactions.

Subjected to these factors, battery cells could experience several effects, such as the thickening of electrodes or the volume expansion of electrochemically active materials within the cell itself. These expansions could ultimately result in cells experiencing deformation, which could, in turn, result in both reversible and irreversible mechanical strain, as well as the potential degradation of the battery’s electrodes.

These battery cell deformations are traditionally monitored using strain gauges or optical gauges that exclusively detect and evaluate deformations at single points in a cell. Tesla noted that this system has space for improvements, since optical evaluations might not provide the correct status of deformation across the entire surface of a battery. This could result in strain and deformation measurements that are inaccurate.

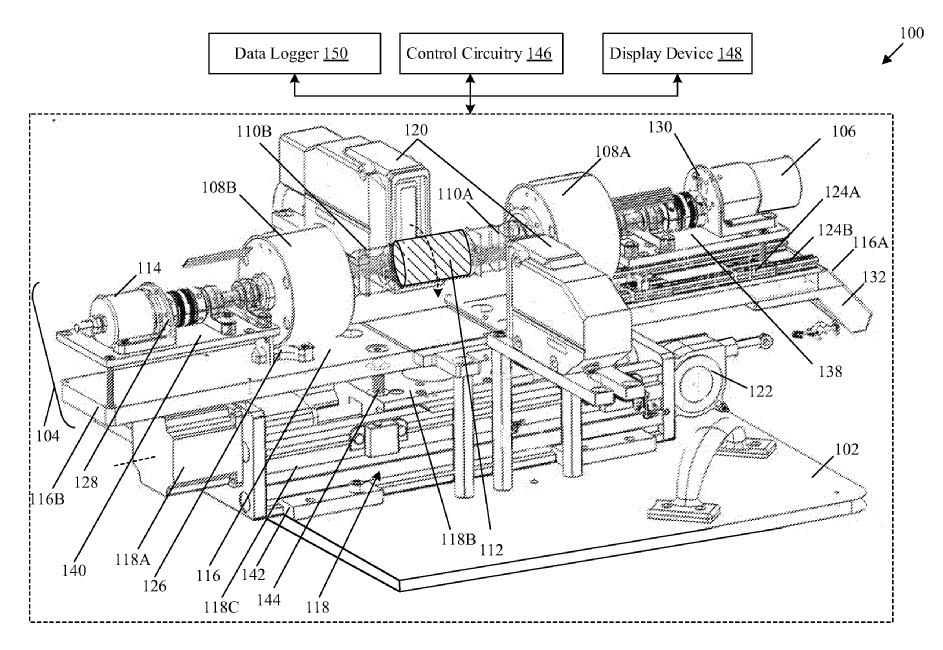

With these factors in mind, Tesla has come up with a deformation detection apparatus that enables the contactless detection of deformations and/or swelling of the battery across the entire surface of the cell itself. Tesla describes the deformation detection apparatus as follows.

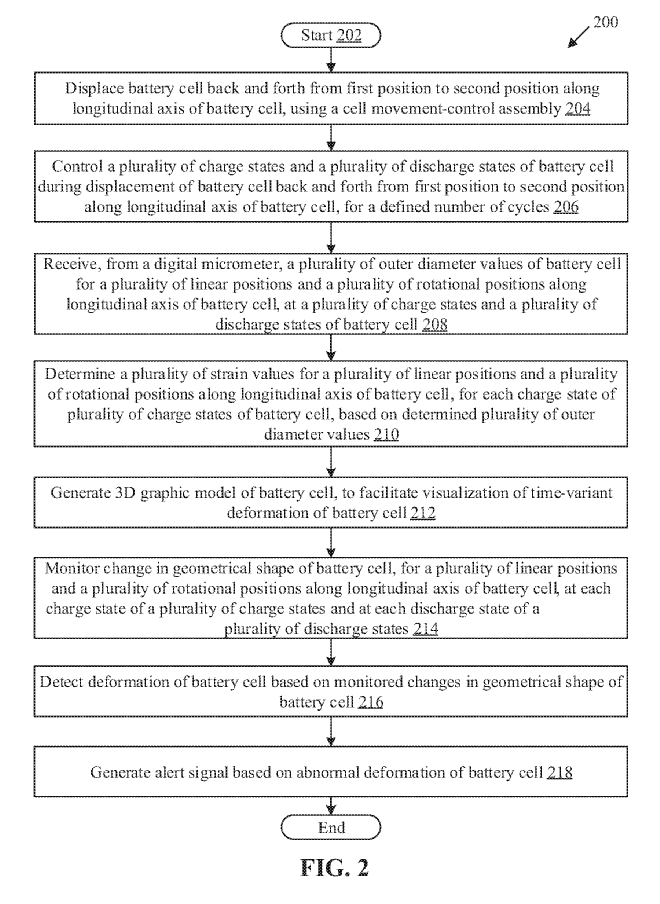

“A deformation detection apparatus includes a cell movement-control assembly to handle a linear motion and a rotational motion of a battery cell, a body that supports the cell movement-control assembly, a digital micrometer, and control circuitry. The control circuitry controls a displacement of the battery cell between a first position and a second position along a longitudinal axis through a scanning region of the digital micrometer and a plurality of rotational positions of the battery cell at a plurality of charge states and a plurality of discharge states. The control circuitry measures a plurality of outer diameter values of the battery cell for a plurality of linear positions and a plurality of rotational positions along the longitudinal axis of the battery cell and determines a change in a geometrical shape (deformation and/or strain) of the battery cell for the plurality of linear positions and the plurality of rotational positions.”

According to the electric car maker, the battery cell deformation monitoring process outlined in its patent will provide advantages over traditional monitoring methods.

“The disclosed apparatus, such as the apparatus 100 and method of determination of deformations in the battery cell 112 advantageously provides a contactless solution for deformation detection in the battery cells, as compared to conventional contact-based solutions. Further, instead of measuring the plurality of outer diameter values/strain values at a specific point in time, the disclosed apparatus 100 advantageously facilitates measurement of the plurality of outer diameter values/strain values at a plurality of points on the battery cell 112. The apparatus 100 enables detection of localized/non-localized deformation regions on the battery cell 112, which may exhibit signs of deformation at different charge/discharge states at different points in time.”

Tesla’s recently published patent application for its new battery cell deformation detection apparatus could be accessed in full here.

The implications of Tesla’s recent patent are notable. By adopting its deformation detection system, the company would be able to evaluate the quality of its cells and their operating limits more effectively. This could open the doors to improvements in the company’s batteries, which could, in turn, result in even more range and performance for Tesla’s electric vehicles.

Tesla holds a notable lead among automakers in terms of battery technology, as exhibited by the company’s electric vehicles’ vastly superior range compared to the competition. This is represented by Tesla’s recent “Raven” update to the 100 kWh Model X, which allowed the SUV to travel 325 miles in one charge. This is notably impressive, considering that the Audi e-tron, a smaller, lighter vehicle equipped with a 95 kWh battery pack (5% smaller than the Model X), is only EPA-rated for 204 miles per charge (38% less range than Tesla’s larger, heavier vehicle). A report from German business newspaper Wirtschaftswoche has also determined that Tesla’s batteries for the Model 3 have over four times less cobalt compared to the batteries utilized by Volkswagen today.

News

Tesla Robotaxi has already surpassed Waymo in this key metric

Tesla Robotaxi has already overtaken Waymo in Austin in one key metric, but there’s still more work to do.

Tesla Robotaxi has already surpassed Waymo in one extremely important key metric: size of service area.

Tesla just expanded its service area in Austin on Monday morning, pushing the boundaries of its Robotaxi fleet in an interesting fashion with new capabilities to the north. Yes, we know what it looks like:

🚨 Tesla’s new Robotaxi geofence is…

Finish the sentence 🥸 pic.twitter.com/3bjhMqsRm5

— TESLARATI (@Teslarati) July 14, 2025

The expansion doubled Tesla Robotaxi’s potential travel locations, which now include the University of Texas at Austin, a school with over 53,000 students.

The doubling of the service area by Tesla has already made its travel area larger than Waymo’s, which launched driverless rides in October 2024. It became available to the public in March 2025.

According to Grok, the AI agent on X, Tesla Robotaxi’s current service area spans 42 square miles, which is five square miles larger than Waymo’s service area of 37 square miles.

Tesla Robotaxi (red) vs. Waymo geofence in Austin.

Much can be said about the shape… but the Robotaxi area is now ~3.9 mi² (10 km²) larger than Waymo’s!! pic.twitter.com/dVfh2ODxJC

— Robin (@xdNiBoR) July 14, 2025

The service area is one of the most important metrics in determining how much progress a self-driving ride-hailing service is making. Safety is the priority of any company operating a ride-hailing network, especially ones that are making it a point to use autonomy to deploy it.

However, these companies are essentially racing for a larger piece of the city or cities they are in. Waymo has expanded to several different regions around the United States, including Arizona and Los Angeles.

Tesla is attempting to do the same in the coming months as it has already filed paperwork in both California and Arizona to deploy its Robotaxi fleet in states across the U.S.

As the platform continues to show more prowess and accuracy in its operation, Tesla will begin to expand to new areas, eventually aiming for a global rollout of its self-driving service.

News

Tesla Megapacks arrive for massive battery replacing coal plant

Tesla Megapacks have started arriving on-site to the Stanwell Battery Project, just as Queensland prepares to wind down the Stanwell coal plant.

The first of over 300 Tesla Megapacks have arrived to the site of a massive battery energy storage system (BESS) being built in Australia, dubbed the Stanwell Battery Project after a coal plant it’s set to replace.

In a press release last week, the Stanwell Battery Project announced that the first Tesla Megapack 2XL units had arrived to the site, which is located outside of Rockhampton in Queensland, Australia. The project will eventually feature 324 Megapack units, set to arrive in the coming months, in order to support the 300MW/1,200MWh battery project.

“The Stanwell Battery is part of the diversification of our portfolio, to include cleaner and more flexible energy solutions,” said Angie Zahra, Stanwell Central Generation General Manager. “It is just one part of the 800 MW of battery energy storage capacity we have in our pipeline.

“Capable of discharging 300 MW of energy for up to four hours (1,200 MWh), our mega battery will be one of the largest in Queensland.”

Credit: Stanwell

Did you know Tesla’s Lathrop facility churns out a Megapack every 68 minutes? That’s enough energy to power 3,600 homes for an hour per unit! ⚡️ pic.twitter.com/bG6fpHkB9O

— TESLARATI (@Teslarati) June 11, 2025

READ MORE ON TESLA MEGAPACKS: Tesla Lathrop Megafactory celebrates massive Megapack battery milestone

The state is working with government-owned company Yurika to facilitate construction, and the process is expected to create roughly 80 jobs. The project is expected to come fully online in May 2027, with initial commissioning of the Megapacks aiming for November 2025.

The Stanwell Battery is set to replace the nearby Stanwell coal generation plant, which the government is planning to wind down starting in 2026 as part of efforts to reach an 80 percent renewable energy generation ratio by 2035. Meanwhile, the government is also set to begin winding down the Tarong and Callide coal plants, while several other Megapack projects are being built or coming online. o ya

Tesla currently has two Megapack production facilities, located in Lathrop, California, in the U.S. and another that came online earlier this year in Shanghai, China. The Shanghai Megafactory shipped its first units to Australia in March, while both factories are expected to be capable of producing 10,000 Megapack units per year upon reaching volume production.

News

The Tesla Diner is basically finished—here’s what it looks like

The company first broke ground on the Diner, Drive-in, and Supercharger location in September 2023. Now, it has served one of its first internal customers.

Tesla has finally completed the construction of its highly anticipated Diner, Drive-in, and Supercharger in Los Angeles, and recent photos of the interior’s “retro-futuristic” style are making their way around the internet.

X user Brad Goldberg shared photos from the Tesla Diner site last Tuesday, depicting some of the Supercharger stalls, indoor and outdoor seating areas, multiple neon lights, and even an Optimus robot. Goldberg also noted that there had been a “flurry of activity on site” while he was snapping the photos last week, suggesting that the restaurant location could be getting close to opening.

The Tesla Diner also served one of its first internal customers in the past few days, as Elon Musk posted on X on early Monday morning that he had just finished up eating a meal at the site:

I just had dinner at the retro-futuristic Tesla diner and Supercharger.

Team did great work making it one of the coolest spots in LA!

The photos also show that the site is pretty much done, with some of them even showing vehicles charging at the charging stalls.

You can see some of the latest photos of the Tesla Diner below.

Credit: BradGoldbergMD | X

Credit: BradGoldbergMD | X

Credit: BradGoldbergMD | X

Credit: BradGoldbergMD | X

Credit: TeslaKing420 | X

Credit: TeslaKing420 | X

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

Credit: Brad Goldberg (via Sawyer Merritt on X)

READ MORE ON TESLA’S LA DINER: Tesla readies Drive-In Diner Supercharger for launch with app inclusion

When will the Tesla Diner open to external customers?

While it’s still not open to external customers yet, the news again suggests that the company could be close to an official opening date. Tesla first broke ground on the Diner in September 2023, after receiving a wave of building permit approvals throughout that year. Teslarati also covered much of the construction progress throughout last year, including when crews installed the first and second drive-in screens.

Located at 7001 West Santa Monica Boulevard, the idea was first discussed in 2018 by Musk and a few others on Twitter, featuring 1950s rock and roll, waiters on roller skates, and drive-in movie theater screens playing clips from some of history’s best movies. Notably, the photos of the front doors also show that the site will be open 24 hours a day, 7 days a week, whenever it does end up opening.

Tesla’s progress on Supercharger with diner, drive-in seen in aerial footage

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News2 days ago

News2 days agoTesla debuts hands-free Grok AI with update 2025.26: What you need to know

-

Elon Musk4 days ago

Elon Musk4 days agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

Elon Musk6 days ago

Elon Musk6 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News1 week ago

News1 week agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI’s Memphis data center receives air permit despite community criticism

-

News4 days ago

News4 days agoTesla begins Robotaxi certification push in Arizona: report

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla scrambles after Musk sidekick exit, CEO takes over sales