News

NASA has good news after SpaceX Crew Dragon parachute test accident

NASA has good news after SpaceX suffered an accident that destroyed a Crew Dragon mockup before it could complete a parachute test, indicating that the anomaly could have minimal impact on the spacecraft’s Demo-2 astronaut launch debut.

According to NASA, SpaceX and the space agency are still working to launch astronauts on Crew Dragon as early as “mid-to-late May”. While two recent challenges – the loss of the spacecraft’s most important parachute testing mockup and an unrelated in-flight rocket engine failure – could both singlehandedly delay Demo-2 in certain scenarios, NASA continues to state that a May timeframe is still in the cards. This is an excellent sign that both issues – as previously speculated on Teslarati – are probably much less of a problem than they otherwise could be.

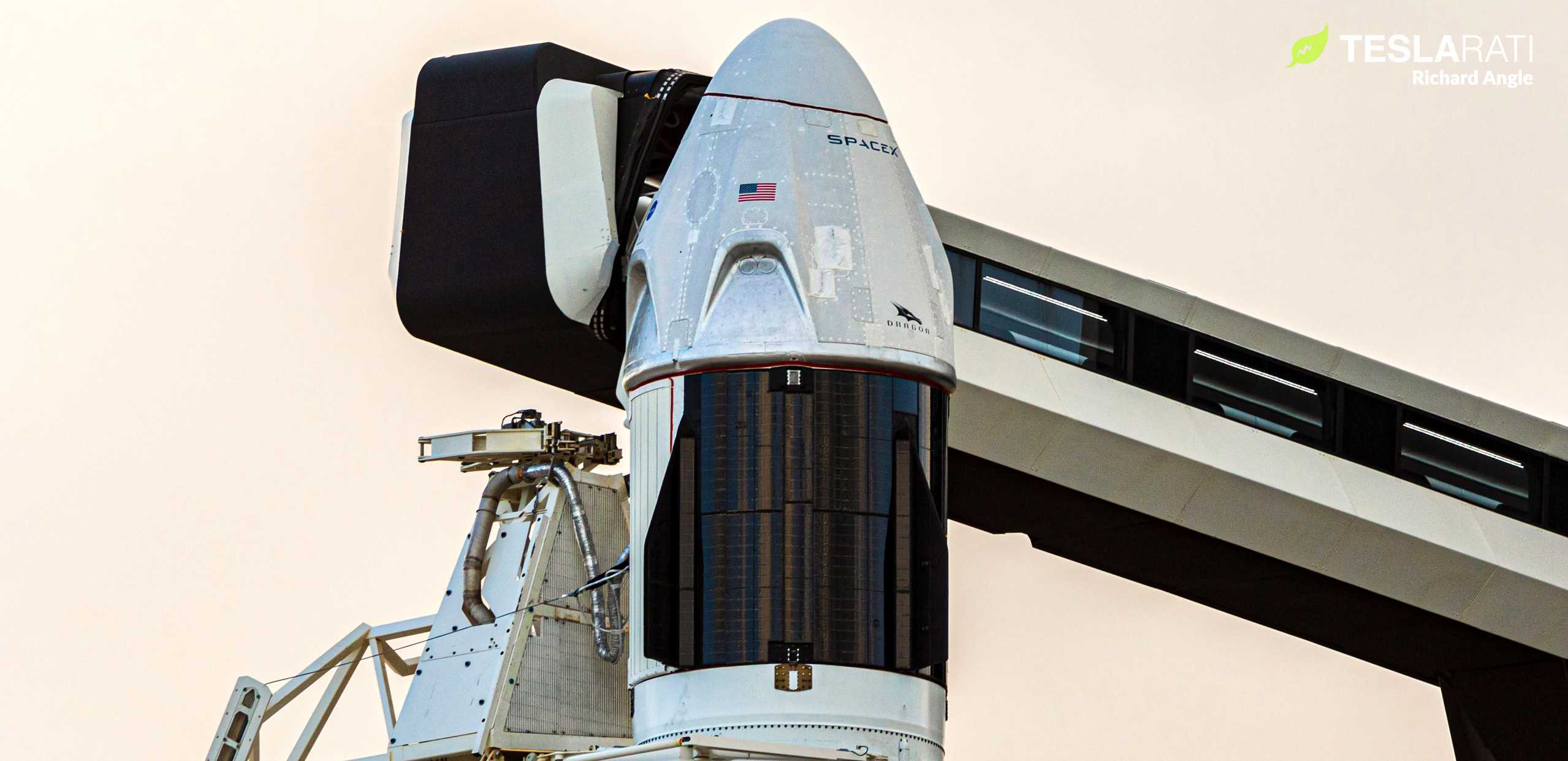

As of now, all Demo-2 hardware – including Falcon 9 booster B1058, a new Falcon upper stage, Crew Dragon capsule C206, and an expendable Dragon trunk – are all believed to be in Florida and technically ready for flight. Waiting for launch at and around Kennedy Space Center (KSC) Launch Complex 39A, the long straw for SpaceX’s inaugural astronaut launch is most likely the completion of formal paperwork and reviews, most of which must be done primarily by NASA employees. SpaceX’s latest technical challenges certainly toss some uncertainty into the mix and serve as a reminder that nothing can or should be taken for granted in human spaceflight but on the whole, there is reason for optimism.

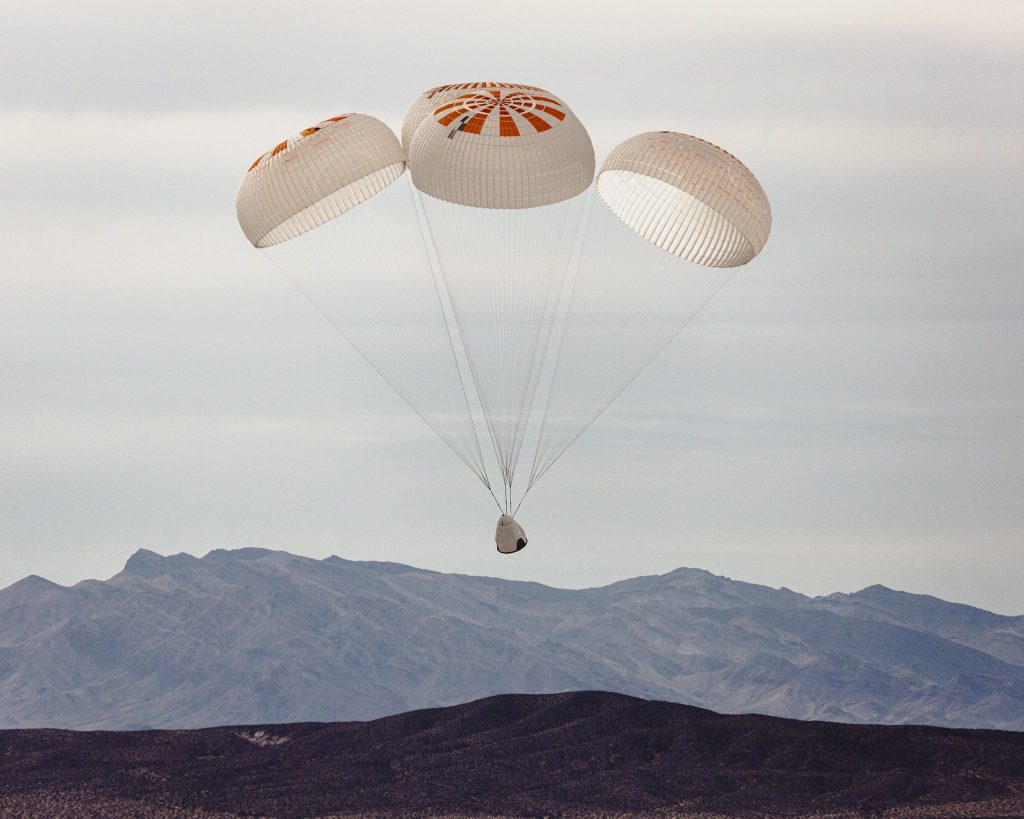

“To date, SpaceX has completed 24 tests of its upgraded Mark 3 parachute design they are working to certify for use on the Crew Dragon spacecraft that will fly NASA astronauts to the International Space Station. The system was used during the SpaceX in-flight abort test in January.

On March 24, SpaceX lost a spacecraft-like device used to test the Crew Dragon Mark 3 parachute design. The test requires a helicopter to lift the device suspended underneath it to reach the needed test parameters. However, the pilot proactively dropped the device in an abundance of caution to protect the test crew as the test device became unstable underneath the helicopter. At the time of the release, the testing device was not armed, and a test of the parachute design was not performed.

Although losing a test device is never a desired outcome, NASA and SpaceX always will prioritize the safety of our teams over hardware. We are looking at the parachute testing plan now and all the data we already have to determine the next steps ahead of flying the upcoming Demo-2 flight test in the mid-to-late May timeframe.”

NASA.gov — March 26th, 2020

While the challenges SpaceX and NASA still have to surmount are thus significant, it’s safe to say that Crew Dragon’s track record more than earns it some optimism as the spacecraft nears the T-1 month mark for what will arguably SpaceX’s most significant launch ever.

Following a successful Pad Abort test in May 2015, the company spent several years working head down. In mid-2018, SpaceX’s first finished Crew Dragon spacecraft successfully passed through electromagnetic interference (EMI) and thermal vacuum (TVac) testing, arriving at the launch site for preflight processing by July. Unfortunately, for unknown reasons, it took more than half a year more for NASA to finally permit Crew Dragon to launch.

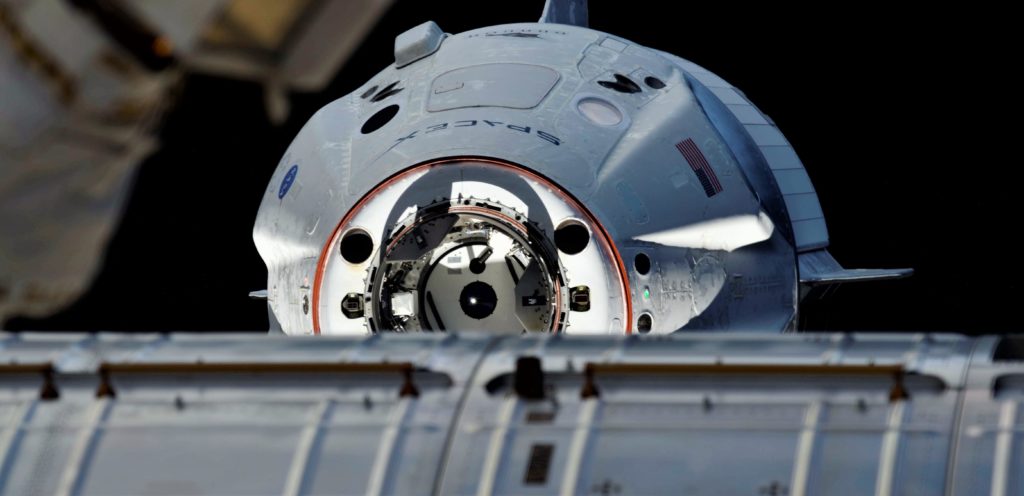

A month and a half after completing an integrated static fire test at Pad 39A, Falcon 9 and Crew Dragon lifted off for the first time ever on March 2nd, 2019. A flawless launch was followed by an equally flawless International Space Station (ISS) rendezvous and docking, completed autonomously and without issue on SpaceX’s first try. Crew Dragon capsule C201 spent five days at the station before autonomously departing, reentering Earth’s atmosphere, and gently splashing down in the Atlantic Ocean under four healthy parachutes.

Altogether, Crew Dragon’s orbital launch debut was such a flawless success that SpaceX’s own director of Crew Dragon mission management stated that he could barely believe how perfectly it went – likely expecting at least something to go slightly awry. That near-perfection certainly didn’t come easily for SpaceX. Boeing – NASA’s second Commercial Crew Program (CCP) partner – has had a far rougher go of things despite the fact that the company does technically have extensive experience building aircraft and rockets.

In November 2019, Boeing completed Starliner’s first fully integrated ‘flight’ test in the form of a pad abort. While the spacecraft was able to perform a soft landing, mishandling and bad quality control caused one of its three main parachutes to fail to deploy in an unintentional stress test. A little over a month later, a separate Starliner spacecraft performed its inaugural orbital launch on a ULA Atlas V rocket. From the moment Starliner separated from Atlas V, things began to go wrong. It would ultimately become clear that extremely shoddy software and an almost nonexistent integrated testing regime caused the spacecraft to waste most of its propellant and resulted in an extremely delayed orbital insertion.

While NASA and Boeing both managed to forget a second partial failure until media reporting shed light on it months later, it also turned out that another entirely separate instance of incomplete software may have nearly destroyed Starliner a matter of hours before it was scheduled to reenter Earth’s atmosphere. The spacecraft was ultimately prevented from even attempting a space station rendezvous, one of the major purposes of the test flight.

In simpler terms, Crew Dragon – even with the challenges it has and will soon face – is just shy of primed and ready for flight. As always, it’s better to be safe (and late) than sorry in human spaceflight, particularly the first such mission for SpaceX, but it’s looking increasingly likely that Crew Dragon will be on the launch pad and preparing to lift off with NASA astronauts just two or so months from now.

News

Tesla preps to build its most massive Supercharger yet: 400+ V4 stalls

The project will be an expansion of the current Eddie World Supercharger in Yermo, California, and will take place in several stages.

Tesla is preparing to build its most massive Supercharger yet, as it recently submitted plans for an over 400-stall Supercharging station in California, which would dwarf its massive 168-stall location in Lost Hills, California.

The project will be an expansion of the current Eddie World Supercharger in Yermo, California, and will take place in several stages.

The expansion, adjacent to the existing Eddie World Supercharger, which is currently comprised of 22 older V2 and V3 stalls limited to 150 kW, unfolds across six phases.

Construction on Phase 1 begins later this year with 72 V4 stalls. Subsequent stages will progressively add hundreds more, culminating in over 400 next-generation chargers. Site plans label expansive parking arrays across Phases 1–5 along Calico Boulevard, with Phase 6 design still to be determined.

Tesla is planning an absolutely massive Supercharger expansion in Yermo, California!!

Over the course of 6 phases, Tesla is set to add over 400 V4 stalls in a commercial development known as Eddie World 2.

The first phase, which should begin construction sometime this year,… pic.twitter.com/ks5Y5dE8lR

— MarcoRP (@MarcoRPi1) March 6, 2026

The project was first flagged by MarcoRP, a notable Tesla Supercharger watcher.

Strategically located midway on I-15 between Los Angeles and Las Vegas, the station targets heavy EV traffic on this high-demand corridor.

The surrounding 20-mile stretch already hosts over 200 high-power stalls (including 40 at 250 kW, 120 at 325 kW, and more), plus 96 in nearby Baker—yet bottlenecks persist during peak travel.

In scale, it eclipses all existing Tesla Superchargers. The current record holder, the solar- and Megapack-powered “Project Oasis” in Lost Hills, California, offers 164 stalls. Barstow’s former leader had 120. Eddie World 2 will be more than double that size, cementing Tesla’s dominance in ultra-high-capacity charging.

Tesla finishes its biggest Supercharger ever with 168 stalls

Development blends charging with convenience. Architectural drawings show integrated retail: a 10,100 square foot Cracker Barrel, a 4,300 square foot McDonald’s, a 3,800 square foot convenience store, additional restaurants, drive-thrus, outdoor dining, and lease space.

EV-centric features include pull-through bays for Cybertrucks and trailers, ensuring accessibility for larger vehicles and future Semi trucks.

News

Tesla makes latest move to remove Model S and Model X from its lineup

Tesla’s latest decisive step toward phasing out its flagship sedan and SUV was quietly removing the Model S and Model X from its U.S. referral program earlier this week.

Tesla has made its latest move that indicates the Model S and Model X are being removed from the company’s lineup, an action that was confirmed by the company earlier this quarter, that the two flagship vehicles would no longer be produced.

Tesla has ultimately started phasing out the Model S and Model X in several ways, as it recently indicated it had sold out of a paint color for the two vehicles.

Now, the company is making even more moves that show its plans for the two vehicles are being eliminated slowly but surely.

Tesla’s latest decisive step toward phasing out its flagship sedan and SUV was quietly removing the Model S and Model X from its U.S. referral program earlier this week.

The change eliminates the $1,000 referral discount previously available to new buyers of these vehicles. Existing Tesla owners purchasing a new Model S or Model X will now only receive a halved loyalty discount of $500, down from $1,000.

The updates extend beyond the two flagship vehicles. New Cybertruck buyers using a referral code on Premium AWD or Cyberbeast configurations will no longer get $1,000 off. Instead, both referrer and buyer receive three months of Full Self-Driving (Supervised).

The loyalty discount for Cybertruck purchases, excluding the new Dual Motor AWD trim level, has also been cut to $500.

NEWS: Tesla has removed the Model S and Model X from the referral program.

New owners also no longer get a $1,000 referral discount on a new Cybertruck Premium AWD or Cyberbeast. Instead, you now get 3 months of FSD (Supervised).

Additionally, Tesla has reduced the loyalty… pic.twitter.com/IgIY8Hi2WJ

— Sawyer Merritt (@SawyerMerritt) March 6, 2026

These adjustments apply only in the United States, and reflect Tesla’s broader strategy to optimize margins while boosting adoption of its autonomous driving software.

The timing is no coincidence. Tesla confirmed earlier this year that Model S and Model X production will end in the second quarter of 2026, roughly June, as the company reallocates factory capacity toward its Optimus humanoid robot and next-generation vehicles.

With annual sales of the low-volume flagships already declining (just 53,900 units in 2025), incentives are no longer needed to drive demand. Production is winding down, and Tesla expects strong remaining interest without subsidies.

Industry observers see this as the clearest sign yet of an “end-of-life” phase for the vehicles that once defined Tesla’s luxury segment. Community reactions on X range from nostalgia, “Rest in power S and X”, to frustration among long-time owners who feel perks are eroding just as the models approach discontinuation.

Some buyers are rushing orders to lock in final discounts before they vanish entirely.

Doug DeMuro names Tesla Model S the Most Important Car of the last 30 years

For Tesla, the move prioritizes efficiency: fewer discounts on outgoing models, a stronger push for FSD subscriptions, and a focus on high-margin Cybertruck trims amid surging orders.

Loyalists still have a narrow window to purchase a refreshed Plaid or Long Range model with remaining incentives, but the message is clear: Tesla’s lineup is evolving, and the era of the original flagships is drawing to a close.

News

Tesla Australia confirms six-seat Model Y L launch in 2026

Compared with the standard five-seat Model Y, the Model Y L features a longer body and extended wheelbase to accommodate an additional row of seating.

Tesla has confirmed that the larger six-seat Model Y L will launch in Australia and New Zealand in 2026.

The confirmation was shared by techAU through a media release from Tesla Australia and New Zealand.

The Model Y L expands the Model Y lineup by offering additional seating capacity for customers seeking a larger electric SUV. Compared with the standard five-seat Model Y, the Model Y L features a longer body and extended wheelbase to accommodate an additional row of seating.

The Model Y L is already being produced at Tesla’s Gigafactory Shanghai for the Chinese market, though the vehicle will be manufactured in right-hand-drive configuration for markets such as Australia and New Zealand.

Tesla Australia and New Zealand confirmed the vehicle will feature seating for six passengers.

“As shown in pictures from its launch in China, Model Y L will have a new seating configuration providing room for 6 occupants,” Tesla Australia and New Zealand said in comments shared with techAU.

Instead of a traditional seven-seat arrangement, the Model Y L uses a 2-2-2 layout. The middle row features two individual seats, allowing easier access to the third row while providing additional space for passengers.

Tesla Australia and New Zealand also confirmed that the Model Y L will be covered by the company’s updated warranty structure beginning in 2026.

“As with all new Tesla Vehicles from the start of 2026, the Model Y L will come with a 5-year unlimited km vehicle warranty and 8 years for the battery,” the company said.

The updated policy increases Tesla’s vehicle warranty from the previous four-year or 80,000-kilometer coverage.

Battery and drive unit warranties remain unchanged depending on the variant. Rear-wheel-drive models carry an eight-year or 160,000-kilometer warranty, while Long Range and Performance variants are covered for eight years or 192,000 kilometers.

Tesla has not yet announced official pricing or range figures for the Model Y L in Australia.