News

SpaceX adds new ship to fleet after fairing catcher Ms. Tree nails second recovery in a row

In a telltale sign that SpaceX is growing much more confident in its ability to consistently recover Falcon 9 fairings, the company has accepted delivery of second recovery ship almost identical to GO Ms. Tree (formerly Mr. Steven) just days after nailing its second fairing catch in a row.

Previously known as M/V Captain Elliott, the new ship appears to have been acquired (or leased) by Guice Offshore (GO) from SEACOR Marine, who purchased Elliott from struggling marine services company Seatran Marine in 2017. One way or another, SpaceX now has a pair of Port Canaveral-based fairing recovery ships in hand – named Ms. Tree and Ms. Chief – and is thus making excellent progress towards catching and reusing both halves of the same Falcon 9 (or Heavy) fairing.

Splurging on ‘ships

Put simply, whoever is paying for or has paid for the two fast supply vessels (FSVs) that are now a part of SpaceX’s rocket recovery fleet has/had a tidy sum to spend. For ships as large, new, and high-performance as Ms. Tree and Ms. Chief, both completed in the mid-2010s, SpaceX or GO would be lucky to pay less than $10M apiece and each ship could easily cost more than $20M, depending on a variety of unknowns. Previous owner Seatran Marine is/was admittedly in dire financial straits, so that could have resulted in an effective fire-sale discount.

Regardless, this is to say that SpaceX was likely willing to splurge and open its wallet wide for extremely high-quality fairing recovery vessels because of just how expensive those fairings are. According to CEO Elon Musk circa 2017, it costs SpaceX $5-6M total to produce a set of Falcon fairing halves, equivalent to roughly 10% of the cost of a Falcon 9 launch ($50M-60M).

As an example, assume that SpaceX paid a full $50M for Ms. Tree and Ms. Chief – effectively a worst-case cost scenario. Assume that recovering and reusing net-caught Falcon fairings still costs half as much as building new fairings ($3M for two halves), also likely a worst-case scenario given the relative mechanical and propulsive simplicity of fairings.

In this mediocre-at-best scenario, it would still take SpaceX less than 20 launches with both halves recovered to completely recoup the cost of both fairing recovery ships. In the event that reusing caught fairings is only 25% as expensive as building new fairings, SpaceX could recoup its fleet investments in just 10 launches. In fact, cost reduction may even be a secondary consideration next to the potential for effectively doubling fairing production with the same facilities. From that perspective, spending, say, $50M on development and another $50M on cutting-edge recovery vessels could easily be a bargain, especially compared to the $1B+ SpaceX has spent deloping Falcon 9 booster reusability.

Fairing-catcher Mk4

With GO Ms. Chief’s August 10th arrival at Port Canaveral, SpaceX’s team of Florida-based recovery engineers and technicians will now be tasked with modifying the ship for Falcon fairing catching. SpaceX completed its first fairing recovery-focused modifications back in late 2017, likely producing what was the first version of fairing recovery tech (Mk1). The net proved to be far too small and was replaced in summer 2018 with a net and arms likely 4X larger (Mk2).

Roughly half a year and several missed catches after Mr. Steven’s Mk2 net was installed, the ship transited the Panama Canal and arrived at Port Canaveral in February 2019. Barely a week or two later, Mr. Steven suffered a failure at sea – well before a planned catch attempt – that saw the ship limp back to port missing the entirety of its net and two of four arms.

After another four months in port, SpaceX installed a third net and arms system on Mr. Steven, featuring distinct differences and apparent upgrades that likely make it Mk3. Shortly after installation and a quick renaming from Mr. Steven to GO Ms. Tree, Ms. Tree’s inaugural Mk3 recovery attempt culminated in SpaceX’s first and second successful fairing catches – back-to-back – on June 24th and August 6th.

Finally, this brings us to the blank slate that is GO Ms. Chief. Compared to Ms. Tree, both vessels are nearly identical: both are built by Gulf Craft, LLC, both are 205 ft x 34 ft (62m x 10m), both have decks rated for ~405 metric tons (900,000 lb), and have top speeds of 26-32 knots (30-37 mph, 50-60 km/h; fully-loaded vs. empty). The lone point of difference is power: Ms. Chief’s engines produce 500 more horsepower and its generators produce an additional 120 kW of power, respective improvements of 5% and 16% relative to Ms. Tree (Mr. Steven).

Despite both ships being nearly identical, SpaceX is unlikely to simply copy and paste Ms. Tree’s thus far successful arms and net, likely instead doing what the company is famous for and fabricating a new and improved variant of the fairing recovery mechanism. This would presumably translate to Mk4. Conveniently, SpaceX appears to be heading into a rare period of no launches, likely stretching almost three months from August 6th (AMOS-17) to late October.

If Mr. Steven and Ms. Tree’s transformations are anything to go by, that hefty chunk of time that should be more than sufficient to fully outfit Ms. Chief with a fresh fairing recovery mechanism, assuming SpaceX has been simultaneously fabricating the hardware in anticipation of Ms. Chief’s arrival.

For now, we’ll have to wait and see if SpaceX’s next launches – both believed to be 60-satellite Starlink missions – will mark the recovery debut of Ms. Chief, as well as the first attempted catch of both Falcon fairing halves. Additionally, following SpaceX’s second successful fairing half catch on August 6th, it’s possible that the company has two recovered halves capable of making a full, flight-proven fairing. Either way, a Starlink launch will likely support the flight-debut of a reused fairing and will almost certainly host the first attempted simultaneous recovery of both fairing halves.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

Tesla Full Self-Driving v14.2.2.5 might be the most confusing release ever

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

Tesla Full Self-Driving v14.2.2.5 hit my car back on Valentine’s Day, February 14, and since I’ve had it, it has become, in my opinion, the most confusing release I’ve ever had.

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

It has been about three weeks of driving on v14.2.2.5; I’ve used it for nearly every mile traveled since it hit my car. I’ve taken short trips of 10 minutes or less, I’ve taken medium trips of an hour or less, and I’ve taken longer trips that are over 100 miles per leg and are over two hours of driving time one way.

These are my thoughts on it thus far:

Speed Profiles Are a Mixed Bag

Speed Profiles are something Tesla seems to tinker with quite frequently, and each version tends to show a drastic difference in how each one behaves compared to the previous version.

I do a vast majority of my FSD travel using Standard and Hurry modes, although in bad weather, I will scale it back to Chill, and when it’s a congested city on a weekend or during rush hour, I’ll throw it into Mad Max so it takes what it needs.

Early on, Speed Profiles really felt great. This is one of those really subjective parts of the FSD where someone might think one mode travels too quickly, whereas another person might see the identical performance as too slow or just right.

To me, I would like to see more consistency from release to release on them, but overall, things are pretty good. There are no real complaints on my end, as I had with previous releases.

In a past release, Mad Max traveled under the speed limit quite frequently, and I only had that experience because Hurry was acting the same way. I’ve had no instances of that with v14.2.2.5.

Strange Turn Signal Behavior

This is the first Full Self-Driving version where I’ve had so many weird things happen with the turn signals.

Two things come to mind: Using a turn signal on a sharp turn, and ignoring the navigation while putting the wrong turn signal on. I’ve encountered both things on v14.2.2.5.

On my way to the Supercharger, I take a road that has one semi-sharp right-hand turn with a driveway entrance right at the beginning of the turn.

Only recently, with the introduction of v14.2.2.5, have I had FSD put on the right turn signal when going around this turn. It’s obviously a minor issue, but it still happens, and it’s not standard practice:

How can we get Full Self-Driving to stop these turn signals?

There’s no need to use one here; the straight path is a driveway, not a public road. The right turn signal here is unnecessary pic.twitter.com/7uLDHnqCfv

— TESLARATI (@Teslarati) February 28, 2026

When sharing this on X, I had Tesla fans (the ones who refuse to acknowledge that the company can make mistakes) tell me that it’s a “valid” behavior that would be taught to anyone who has been “professionally trained” to drive.

Apparently, if you complain about this turn signal, you are also claiming you know more than Tesla engineers…okay.

Nobody in their right mind has ever gone around a sharp turn when driving their car and put on a signal when continuing on the same road. You would put a left turn signal on to indicate you were turning into that driveway if that’s what your intention was.

Like I said, it’s a totally minor issue. However, it’s not really needed, and nor is it normal. If I were in the car with someone who was taking a simple turn on a road they were traveling, and they signaled because the turn was sharp, I’d be scratching my head.

I’ve also had three separate instances of the car completely ignoring the navigation and putting on a signal that is opposite to what the routing says. Really quite strange.

Parking Performance is Still Underwhelming

Parking has been a complaint of mine with FSD for a long time, so much so that it is pretty rare that I allow the vehicle to park itself. More often than not, it is because I want to pick a spot that is relatively isolated.

However, in the times I allow it to pull into a spot, it still does some pretty head-scratching things.

Recently, it tried to back into a spot that was ~60% covered in plowed snow. The snow was piled about six feet high in a Target parking lot.

A few days later, it tried backing into a spot where someone failed the universal litmus test of returning their shopping cart. Both choices were baffling and required me to manually move the car to a different portion of the lot.

I used Autopark on both occasions, and it did a great job of getting into the spot. I notice that the parking performance when I manually choose the spot is much better than when the car does the entire parking process, meaning choosing the spot and parking in it.

It’s Doing Things (For Me) It’s Never Done Before

Two things that FSD has never done before, at least for me, are slow down in School Zones and avoid deer. The first is something I usually take over manually, and the second I surprisingly have not had to deal with yet.

I had my Tesla slow down at a school zone yesterday for the first time, traveling at 20 MPH and not 15 MPH as the sign suggested, but at the speed of other cars in the School Zone. This was impressive and the first time I experienced it.

I would like to see this more consistently, and I think School Zones should be one of those areas where, no matter what, FSD will only travel the speed limit.

Last night, FSD v14.2.2.5 recognized a deer in a roadside field and slowed down for it:

🚨 Cruising home on a rainy, foggy evening and my Tesla on Full Self-Driving begins to slow down suddenly

FSD just wanted Mr. Deer to make it home to his deer family ❤️ pic.twitter.com/cAeqVDgXo5

— TESLARATI (@Teslarati) March 4, 2026

Navigation Still SUCKS

Navigation will be a complaint until Tesla proves it can fix it. For now, it’s just terrible.

It still has not figured out how to leave my neighborhood. I give it the opportunity to prove me wrong each time I leave my house, and it just can’t do it.

It always tries to go out of the primary entrance/exit of the neighborhood when the route needs to take me left, even though that exit is a right turn only. I always leave a voice prompt for Tesla about it.

It still picks incredibly baffling routes for simple navigation. It’s the one thing I still really want Tesla to fix.

Investor's Corner

Tesla gets tip of the hat from major Wall Street firm on self-driving prowess

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet,” BoA wrote.

Tesla received a tip of the hat from major Wall Street firm Bank of America on Wednesday, as it reinitiated coverage on Tesla shares with a bullish stance that comes with a ‘Buy’ rating and a $460 price target.

In a new note that marks a sharp reversal from its neutral position earlier in 2025, the bank declared Tesla’s Full Self-Driving (FSD) technology the “leading consumer autonomy solution.”

Analysts highlighted Tesla’s camera-only architecture, known as Tesla Vision, as a strategic masterstroke. While technically more challenging than the multi-sensor setups favored by rivals, the vision-based approach is dramatically cheaper to produce and maintain.

This cost edge, combined with Tesla’s rapidly expanding real-world data engine, positions the company to scale robotaxis far more profitably than competitors, BofA argues in the new note:

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet.”

The bank now attributes roughly 52% of Tesla’s total valuation to its Robotaxi ambitions. It also flagged meaningful upside from the Optimus humanoid robot program and the fast-growing energy storage business, suggesting the auto segment’s recent headwinds, including expired incentives, are being eclipsed by these higher-margin opportunities.

Tesla’s own data underscores exactly why Wall Street is waking up to FSD’s potential. According to Tesla’s official safety reporting page, the FSD Supervised fleet has now surpassed 8.4 billion cumulative miles driven.

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

That total ballooned from just 6 million miles in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and a staggering 4.25 billion in 2025 alone. In the first 50 days of 2026, owners added another 1 billion miles — averaging more than 20 million miles per day.

This avalanche of real-world, camera-captured footage, much of it on complex city streets, gives Tesla an unmatched training dataset. Every mile feeds its neural networks, accelerating improvement cycles that lidar-dependent rivals simply cannot match at scale.

Tesla owners themselves will tell you the suite gets better with every release, bringing new features and improvements to its self-driving project.

The $460 target implies roughly 15 percent upside from recent trading levels around $400. While regulatory and safety hurdles remain, BofA’s endorsement signals growing institutional conviction that Tesla’s data advantage is not hype; it’s a tangible moat already delivering billions of miles of proof.

News

Tesla to discuss expansion of Samsung AI6 production plans: report

Tesla has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla is reportedly discussing an expansion of its next-generation AI chip supply deal with Samsung Electronics.

As per a report from Korean industry outlet The Elec, Tesla purchasing executives are reportedly scheduled to meet Samsung officials this week to negotiate additional production volume for the company’s upcoming AI6 chip.

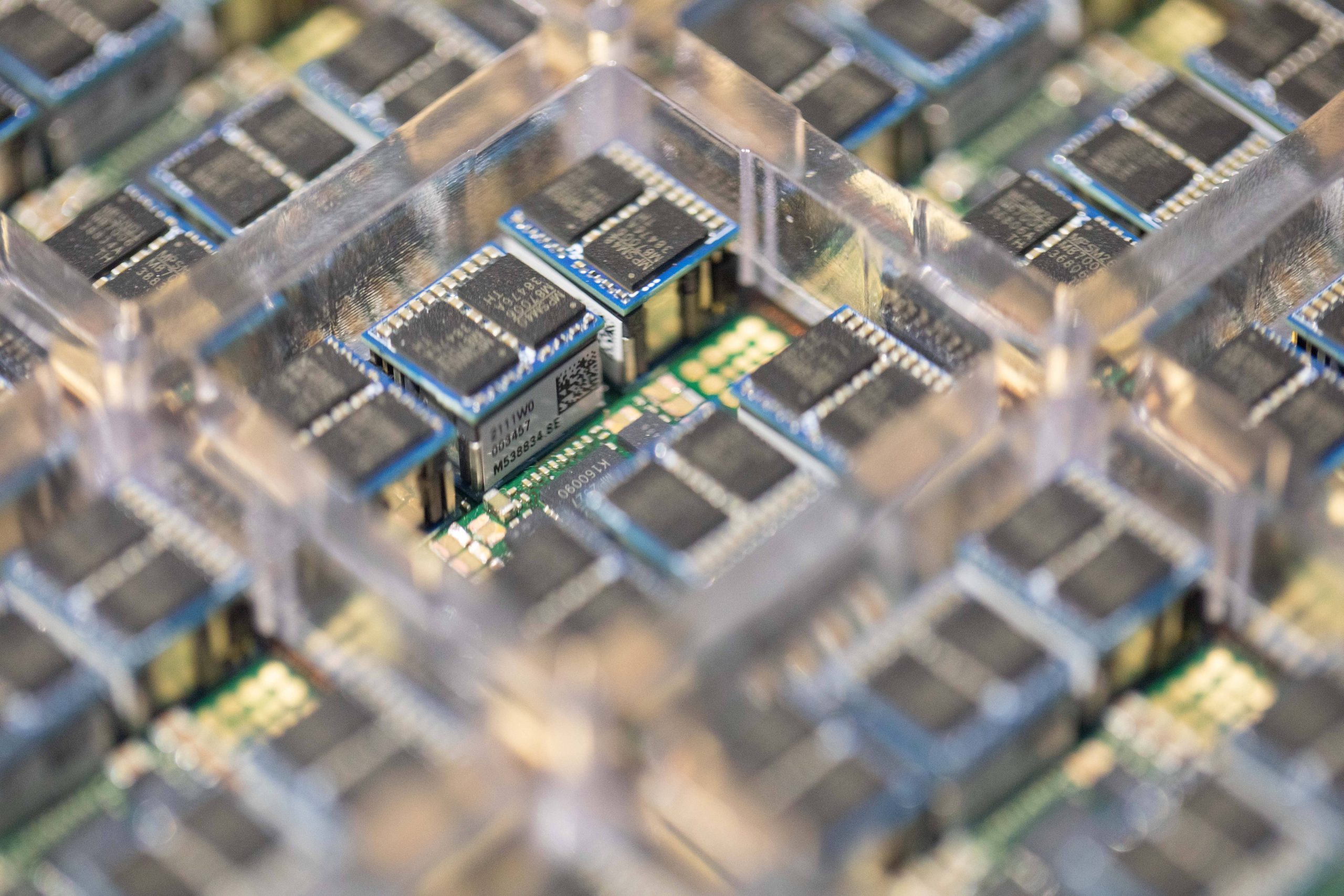

Industry sources cited in the report stated that Tesla is pushing to increase the production volume of its AI6 chip, which will be manufactured using Samsung’s 2-nanometer process.

Tesla previously signed a long-term foundry agreement with Samsung covering AI6 production through December 31, 2033. The deal was reportedly valued at about 22.8 trillion won (roughly $16–17 billion).

Under the existing agreement, Tesla secured approximately 16,000 wafers per month from the facility. The company has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla purchasing executives are expected to discuss detailed supply terms during their visit to Samsung this week.

The AI6 chip is expected to support several Tesla technologies. Industry sources stated that the chip could be used for the company’s Full Self-Driving system, the Optimus humanoid robot, and Tesla’s internal AI data centers.

The report also indicated that AI6 clusters could replace the role previously planned for Tesla’s Dojo AI supercomputer. Instead of a single system, multiple AI6 chips would be combined into server-level clusters.

Tesla’s semiconductor collaboration with Samsung dates back several years. Samsung participated in the design of Tesla’s HW3 (AI3) chip and manufactured it using a 14-nanometer process. The HW4 chip currently used in Tesla vehicles was also produced by Samsung using a 5-nanometer node.

Tesla previously planned to split production of its AI5 chip between Samsung and TSMC. However, the company reportedly chose Samsung as the primary partner for the newer AI6 chip.