SpaceX

SpaceX builds new orbital Starship sections as Starhopper loses its engine

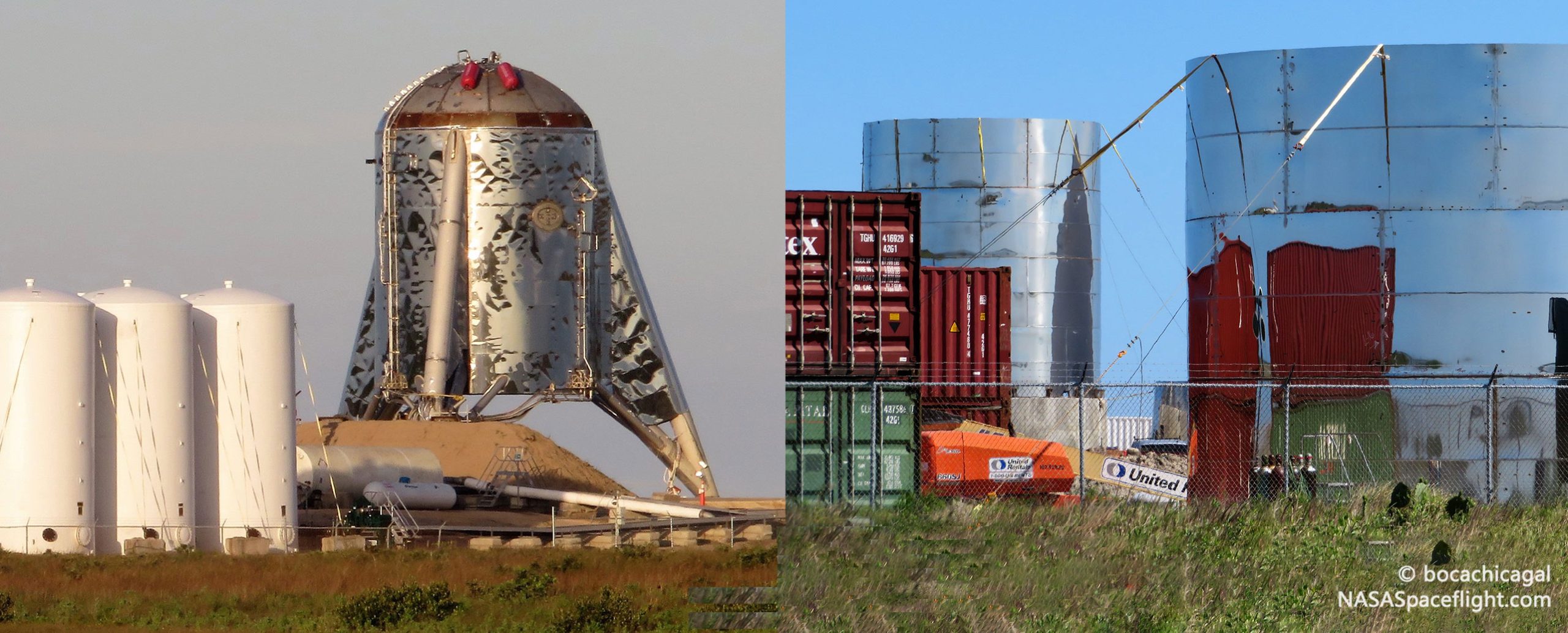

Amidst the growing buzz centered around the imminent second launch of Falcon Heavy, SpaceX’s South Texas team has continued to work on Starhopper and the first orbital Starship prototype. wrapping up the first major tests of the former and making new progress on the latter’s aeroshell.

For unknown reasons, SpaceX technicians uninstalled Starhopper’s Raptor – the second full-scale engine ever built – shortly after the vehicle’s first true hop test and proceeded to package it up for shipment elsewhere, likely McGregor’s test facilities or the Hawthorne factory. Simultaneously, the third completed Raptor (SN03) was recently installed in McGregor according to photos and observations published by NASASpaceflight.com, preparing to continue to the engineering verification tests that began in February. Once those tests are complete and the engine design is modified to account for the lessons learned with Raptor SN01, SpaceX’s next step will be to begin ramping Raptor production in preparation for multi-engine Starhopper testing and – eventually – the completion of the first orbit-capable Starship prototype.

Needless to say, SpaceX is juggling a lot of interconnected projects in an effort to speed its Starship/Super Heavy (formerly BFR) development program, none of which are being discussed by the company in more than a cursory manner. What follows is thus meant to be an informed but speculative estimate of what is currently going on and what is next for BFR.

Starhopper slips the surly bonds

Over the course of the last two weeks, SpaceX has been almost continuously testing the first integrated Starship prototype, a partial-fidelity vehicle known as Starhopper. The testing primarily involved almost a dozen wet dress rehearsals (WDRs) in which the rocket was filled with some quantity of liquid oxygen and methane propellant and helium for pressurization as engineers and technicians worked through several bugs preventing Raptor from safely operating. According to CEO Elon Musk, some form of ice – potentially methane, oxygen, or even water – was forming in or around parts known as “prevalves”, likely referring to valves involved in the process of supply rocket engines with the right amount of fuel and oxidizer.

Less than 24 hours later, those valve issues were apparently solved as Starhopper’s Raptor ignited for the first time in a spectacular nighttime fireball. 48 hours after that first ignition, SpaceX once again fueled Starhopper and ignited its Raptor engine, lifting a spectacular handful of feet into the air before reaching the end of its very short tethers. According to Musk, the first Raptor ignition was completed with “all systems green”. After the second test, no additional comments were made. Less than three days later, SpaceX technicians uninstalled Starhopper’s Raptor (SN02) and shipped it somewhere offsite, indicating that it may have suffered a fault similar to the one that caused relatively minor damage to Raptor SN01 at the end of its February test campaign. Regardless, it appears that this development will keep Starhopper grounded for the indefinite future barring the imminent shipment of Raptor SN04 or the completion of SN01’s refurbishment.

The Raptor pack grows

Starhopper’s unplanned grounding ties

While the exact strategy behind SpaceX’s Raptor and BFR propulsion development programs

Regardless, the somewhat buggy behavior exhibited by the integrated Raptor and Starhopper indicate the obvious: both are fairly immature hardware still in some form of development, be it the late (Raptor) or the very earliest stages (Starhopper). By performing even more testing and continuing to optimize and gain familiarity with the hardware at hand, the fairly predictable process of development will arrive at more or less finished products.

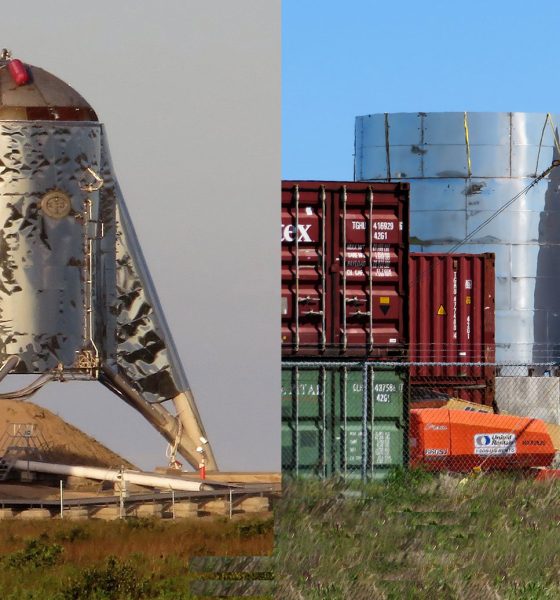

Starship’s first orbital prototype

Last but not least, work continues on what will hopefully become the first orbit-capable Starship prototype, built in full-scale out of sheets of stainless steel that are far thinner than the metal used to construct Starhopper. This, too, is a normal process of development – as progress is made, prototypes will gradually lose an emergency cushion of performance margins, a bit like a sculptor starting with a solid block of marble and whittling it down to a work of art. Starhopper is that marble block, with inelegant, rough angles and far more material bulk than truly necessary.

As seen above, the orbital prototype – just the second in a presumably unfinished series – is already dramatically more refined. Instead of the first facade-like nose cone built for Starhopper, Starship’s nose section is being built out of smoothly tapered stainless steel panels that appear identical to those used to assemble the rocket’s growing aeroshell and tankage. As of now, there are five publicly visible Starship sections in various forms of fabrication, followed by a half-dozen or so tank dome segments waiting to be welded together as finished bulkheads.

Intriguingly, the only quasi-public official render of SpaceX’s steel Starship features visible sections very similar to those seen on the orbital prototype’s welded hull. They aren’t all visible in the render, but those that are are a distinct match to the aspect ratio of the welded sections visible in South Texas.

Extrapolating from this observation, Starship, as rendered, is comprised of approximately 16 large cylinder sections and 4-8 tapered nose sections. Based on the real orbital prototype, each large section is 9m in diameter and ~2.5m tall. Assuming Starship is 55 meters (180 ft) tall, this would translate into 22 2.5m sections, a nearly perfect fit with what is shown in the official render. Back in South Texas, SpaceX has 6 tapered sections and 7 cylinder sections in work, meaning that they would reach around 32.5m (~105 ft) – about 60% of a Starship hull – if stacked today.

If we assume that SpaceX follows Falcon procedures to build the seven-Raptor thrust structure separately (~2 sections) and excludes most of the cargo bay (~2-3 sections) on the first orbit-capable Starship, those ~13 in-work sections could be just a tapered nose cone away from the prototype’s full aeroshell. Time will tell…

Check out Teslarati’s newsletters for prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes.

Elon Musk

Elon Musk outlines plan for first Starship tower catch attempt

Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

Elon Musk has clarified when SpaceX will first attempt to catch Starship’s upper stage with its launch tower. The CEO’s update provides the clearest teaser yet for the spacecraft’s recovery roadmap.

Musk shared the details in recent posts on X. In his initial post, Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

“Starship V3 SN1 headed for ground tests. I am highly confident that the V3 design will achieve full reusability,” Musk wrote.

In a follow-up post, Musk addressed when SpaceX would attempt to catch the upper stage using the launch tower’s robotic arms.

“Should note that SpaceX will only try to catch the ship with the tower after two perfect soft landings in the ocean. The risk of the ship breaking up over land needs to be very low,” Musk clarified.

His remarks suggest that SpaceX is deliberately reducing risk before attempting a tower catch of Starship’s upper stage. Such a milestone would mark a major step towards the full reuse of the Starship system.

SpaceX is currently targeting the first Starship V3 flight of 2026 this coming March. The spacecraft’s V3 iteration is widely viewed as a key milestone in SpaceX’s long-term strategy to make Starship fully reusable.

Starship V3 features a number of key upgrades over its previous iterations. The vehicle is equipped with SpaceX’s Raptor V3 engines, which are designed to deliver significantly higher thrust than earlier versions while reducing cost and weight.

The V3 design is also expected to be optimized for manufacturability, a critical step if SpaceX intends to scale the spacecraft’s production toward frequent launches for Starlink, lunar missions, and eventually Mars.

Elon Musk

Starlink powers Europe’s first satellite-to-phone service with O2 partnership

The service initially supports text messaging along with apps such as WhatsApp, Facebook Messenger, Google Maps and weather tools.

Starlink is now powering Europe’s first commercial satellite-to-smartphone service, as Virgin Media O2 launches a space-based mobile data offering across the UK.

The new O2 Satellite service uses Starlink’s low-Earth orbit network to connect regular smartphones in areas without terrestrial coverage, expanding O2’s reach from 89% to 95% of Britain’s landmass.

Under the rollout, compatible Samsung devices automatically connect to Starlink satellites when users move beyond traditional mobile coverage, according to Reuters.

The service initially supports text messaging along with apps such as WhatsApp, Facebook Messenger, Google Maps and weather tools. O2 is pricing the add-on at £3 per month.

By leveraging Starlink’s satellite infrastructure, O2 can deliver connectivity in remote and rural regions without building additional ground towers. The move represents another step in Starlink’s push beyond fixed broadband and into direct-to-device mobile services.

Virgin Media O2 chief executive Lutz Schuler shared his thoughts about the Starlink partnership. “By launching O2 Satellite, we’ve become the first operator in Europe to launch a space-based mobile data service that, overnight, has brought new mobile coverage to an area around two-thirds the size of Wales for the first time,” he said.

Satellite-based mobile connectivity is gaining traction globally. In the U.S., T-Mobile has launched a similar satellite-to-cell offering. Meanwhile, Vodafone has conducted satellite video call tests through its partnership with AST SpaceMobile last year.

For Starlink, the O2 agreement highlights how its network is increasingly being integrated into national telecom systems, enabling standard smartphones to connect directly to satellites without specialized hardware.

Elon Musk

Elon Musk’s Starbase, TX included in $84.6 million coastal funding round

The funds mark another step in the state’s ongoing beach restoration and resilience efforts along the Gulf Coast.

Elon Musk’s Starbase, Texas has been included in an $84.6 million coastal funding round announced by the Texas General Land Office (GLO). The funds mark another step in the state’s ongoing beach restoration and resilience efforts along the Gulf Coast.

Texas Land Commissioner Dawn Buckingham confirmed that 14 coastal counties will receive funding through the Coastal Management Program (CMP) Grant Cycle 31 and Coastal Erosion Planning and Response Act (CEPRA) program Cycle 14. Among the Brownsville-area recipients listed was the City of Starbase, which is home to SpaceX’s Starship factory.

“As someone who spent more than a decade living on the Texas coast, ensuring our communities, wildlife, and their habitats are safe and thriving is of utmost importance. I am honored to bring this much-needed funding to our coastal communities for these beneficial projects,” Commissioner Buckingham said in a press release.

“By dedicating this crucial assistance to these impactful projects, the GLO is ensuring our Texas coast will continue to thrive and remain resilient for generations to come.”

The official Starbase account acknowledged the support in a post on X, writing: “Coastal resilience takes teamwork. We appreciate @TXGLO and Commissioner Dawn Buckingham for their continued support of beach restoration projects in Starbase.”

The funding will support a range of coastal initiatives, including beach nourishment, dune restoration, shoreline stabilization, habitat restoration, and water quality improvements.

CMP projects are backed by funding from the National Oceanic and Atmospheric Administration and the Gulf of Mexico Energy Security Act, alongside local partner matches. CEPRA projects focus specifically on reducing coastal erosion and are funded through allocations from the Texas Legislature, the Texas Hotel Occupancy Tax, and GOMESA.

Checks were presented in Corpus Christi and Brownsville to counties, municipalities, universities, and conservation groups. In addition to Starbase, Brownsville-area recipients included Cameron County, the City of South Padre Island, Willacy County, and the Willacy County Navigation District.