News

Tesla announced its first European Gigafactory 1 year ago today: A timeline

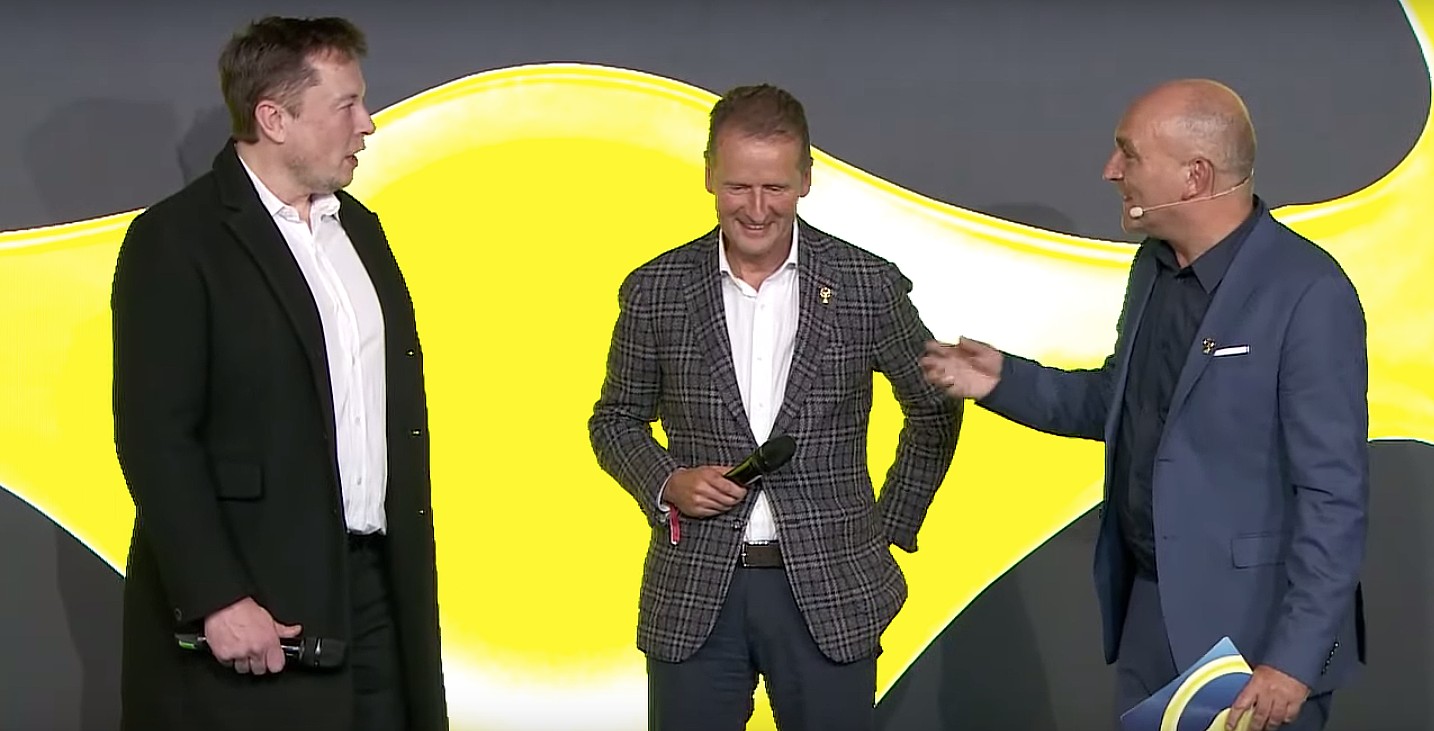

One year ago today, Tesla CEO Elon Musk announced that the automaker would open a production facility in Germany. Upon accepting an award at the Golden Steering Wheel awards alongside Volkswagen CEO Herbert Diess, Musk shocked Tesla fans everywhere by revealing its intentions. But what has transpired for the electric automaker since then is a culmination of hard work, dedication, efficiency, and a little bit of luck, and Tesla has been able to erect several buildings of the facility just eleven months after the beginning of the construction process.

November 12, 2019: Elon Musk announces Giga Berlin

“Everyone knows that German engineering is outstanding, for sure. That’s part of the reason why we are locating our Gigafactory Europe in Germany. We are also going to create an engineering and design center in Berlin, because Berlin has some of the best art in the world,” Musk said at the Golden Steering Wheel Awards in Germany last year. Musk also stated that the Model Y would be the initial focus of the new Gigafactory’s production lines.

Tesla CEO Elon Musk and Volkswagen CEO Herbert Diess exchange compliments at an award ceremony. (Credit: YouTube/AUTO BILD)

December 2019: Permits and Regulatory Approval

Tesla was working with the local government in Brandenburg to gain regulatory approval to begin ground clearing measures on the 741-acre plot of land that the automaker had purchased for a bargain price. After the land sale price was finalized, along with the permission of local authorities, Tesla could begin making progress on the land.

Credit: YouTube/J.-U. Koehler

January 2020: Ground clearing begins

After Tesla received preliminary approval, ground clearing began. While this sparked some controversy and concern from environmental groups, Tesla had already been planning to replace trees in areas surrounding Brandenburg, promising to replant three times as many trees as it had removed from the property. To be clear, the trees that were removed were of “inferior quality,” according to Grünheide Mayor Arne Christiani, as they were used for commercial cardboard production.

Credit: Emil Senkel

April 2020: Groundbreaking imminent, land preparation nears completion

On April 20th, Giga Berlin construction crews worked on the ground leveling and excavation of the land at the site. With only 90 hectares of land free from the trees, Tesla had its work cut out. Just a few days before ground leveling, the final tree was removed from the land, making it completely clear of any trees, all while not harming any wildlife.

Credit: YouTube | Giga Berlin / Gigafactory4, build GIGABERLIN

May 2020: Foundational work gets approval, begins

Foundational work began appearing at the site in late May. Tesla had to abide by some guidelines to keep drinking water protected and keep the noise down after 10 pm. Aquifers were also installed to protect any groundwater, which was a growing concern among local residents.

Credit: Twitter | @tobilindh

June 2020: Structures begin appearing, pillars and beams installed

The main pillars of the Drive Unit facility began appearing at the site, which were transported by train. Additionally, the installation of these pillars began just a few days later. It was the first structural portion of any of Giga Berlin’s facilities to be implemented, and prefabricated construction methods contributed to an accelerated construction effort at the site.

Credit: Twitter | @tobilindh

August 2020: Body In White construction begins, Drive Unit facility nears completion

The rapid pace of construction was evident as the Drive Unit facility neared completion, and the Body-in-White facility started construction. With pillars and beams being installed just two months prior for the first time, the rate of construction was certainly impressive. There was still plenty of work to go, however.

The Northern wall of the Drive Unit is nearly completed. (Credit: @gigafactory_4 on Twitter)

September 2020: Elon Musk’s First Visit to Giga Berlin

In a long-overdue visit because of the COVID-19 pandemic, Musk detailed Model Y redesign and battery cell production at the facility. Met with a warm reception, Musk’s first visit to Giga Berlin included visits with local politicians, including vocal supporter Jörg Steinbach, an economic minister.

Credit: @tobilindh | Twitter

Today: Where does Giga Berlin’s progress stand?

Currently, both the Drive Unit and Body-In-White facilities are constructed, with interior fittings being installed. Flooring and machinery have yet to make its way into these facilities, but progress is well ahead of schedule. While Tesla still lists Giga Berlin’s starting production date as Summer 2021, some of those in Europe have stated that deliveries could be expected in Q1 or Q2 2021.

Cybertruck

Tesla confirms date when new Cybertruck trim will go up in price

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this.

Tesla has confirmed the date when its newest Cybertruck trim level will increase in price, after CEO Elon Musk noted that the All-Wheel-Drive configuration of the all-electric pickup would only be priced at its near-bargain level for ten days.

Last week, Tesla launched the All-Wheel-Drive configuration of the Cybertruck. Priced at $59,990, the Cybertruck featured many excellent features and has seemingly brought some demand to the pickup, which has been underwhelming in terms of sales figures over the past couple of years.

Tesla launches new Cybertruck trim with more features than ever for a low price

When Tesla launched it, many fans and current owners mulled the possibility of ordering it. However, Musk came out and said just hours after launching the pickup that Tesla would only keep it at the $59,990 price level for ten days.

What it would be priced at subsequently was totally dependent on how much demand Tesla felt for the new trim level, which is labeled as a “Dual Motor All-Wheel-Drive” configuration.

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this:

NEWS: Tesla has officially announced that the price of the new Cybertruck Dual-Motor AWD will be increasing after February 28th. pic.twitter.com/vZpA521ZwC

— Sawyer Merritt (@SawyerMerritt) February 24, 2026

Many fans and owners have criticized Tesla’s decision to unveil a trim this way, and then price it at something, only to change that price a few days later based on how well it sells.

Awful way to treat customers – particularly when they already sent out a marketing email announcing the $59,990 truck…with zero mention of it being a limited-time offer.

— Ryan McCaffrey (@DMC_Ryan) February 24, 2026

It seems the most ideal increase in price would be somewhere between $5,000 and $10,000, but it truly depends on how many orders Tesla sees for this new trim level. The next step up in configuration is the Premium All-Wheel-Drive, which is priced at $79,990.

The difference between the Dual Motor AWD Cybertruck and the Premium AWD configuration comes down to towing, interior quality, and general features. The base package is only capable of towing up to 7,500 pounds, while the Premium can handle 11,000 pounds. Additionally, the seats in the Premium build are Vegan Leather, while the base trim gets the textile seats.

It also has only 7 speakers compared to the 15 that the Premium trim has. Additionally, the base model does not have an adjustable ride height, although it does have a coil spring with an adaptive damping suspension package.

Cybertruck

Tesla set to activate long-awaited Cybertruck feature

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, as the company has officially added the feature to its list of features by trim on its website.

Tesla is set to activate a long-awaited Cybertruck feature, and no matter when you bought your all-electric pickup, it has the hardware capable of achieving what it is designed to do.

Tesla simply has to flip the switch, and it plans to do so in the near future.

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, according to Not a Tesla App, as the company has officially added the feature to its list of features by trim on its website.

Tesla rolls out Active Road Noise Reduction for new Model S and Model X

The ANC feature suddenly appeared on the spec sheet for the Premium All-Wheel-Drive and Cyberbeast trims, which are the two configurations that have been delivered since November 2023.

However, those trims have both had the ANC disabled, and although they are found in the Model S and Model X, and are active in those vehicles, Tesla is planning to activate them.

In Tesla’s Service Toolbox, it wrote:

“ANC software is not enabled on Cybertruck even though the hardware is installed.”

Tesla has utilized an ANC system in the Model S and Model X since 2021. The system uses microphones embedded in the front seat headrests to detect low-frequency road noise entering the cabin. It then generates anti-noise through phase-inverted sound waves to cancel out or reduce that noise, creating quieter zones, particularly around the vehicle’s front occupants.

The Model S and Model X utilize six microphones to achieve this noise cancellation, while the Cybertruck has just four.

Tesla Cybertruck Dual Motor AWD estimated delivery slips to early fall 2026

As previously mentioned, this will be activated through a software update, as the hardware is already available within Cybertruck and can simply be activated at Tesla’s leisure.

The delays in activating the system are likely due to Tesla Cybertruck’s unique design, which is unlike anything before. In the Model S and Model X, Tesla did not have to do too much, but the Cybertruck has heavier all-terrain tires and potentially issues from the aluminum castings that make up the vehicle’s chassis, which are probably presenting some challenges.

Unfortunately, this feature will not be available on the new Dual Motor All-Wheel-Drive configuration, which was released last week.

News

Tesla Model S and X customization options begin to thin as their closure nears

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

Tesla Model S and Model X customization options are beginning to thin for the first time as the closure of the two “sentimental” vehicles nears.

We are officially seeing the first options disappear as Tesla begins to work toward ending production of the two cars and the options that are available to those vehicles specifically.

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

🚨 Tesla Model S and Model X availability is thinning, as Tesla has officially shown that the Lunar Silver color option on both vehicles is officially sold out

To be fair, Frost Blue is still available so no need to freak out pic.twitter.com/YnwsDbsFOv

— TESLARATI (@Teslarati) February 25, 2026

Tesla is making way for the Optimus humanoid robot project at the Fremont Factory, where the Model S and Model X are produced. The two cars are low-volume models and do not contribute more than a few percent to Tesla’s yearly delivery figures.

With CEO Elon Musk confirming that the Model S and Model X would officially be phased out at the end of the quarter, some of the options are being thinned out.

This is an expected move considering Tesla’s plans for the two vehicles, as it will make for an easier process of transitioning that portion of the Fremont plant to cater to Optimus manufacturing. Additionally, this is likely one of the least popular colors, and Tesla is choosing to only keep around what it is seeing routine demand for.

During the Q4 Earnings Call in January, Musk confirmed the end of the Model S and Model X:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Fremont will now build one million Optimus units per year as production is ramped.