News

SpaceX moves next high-altitude Starship to launch pad after fixing fall damage

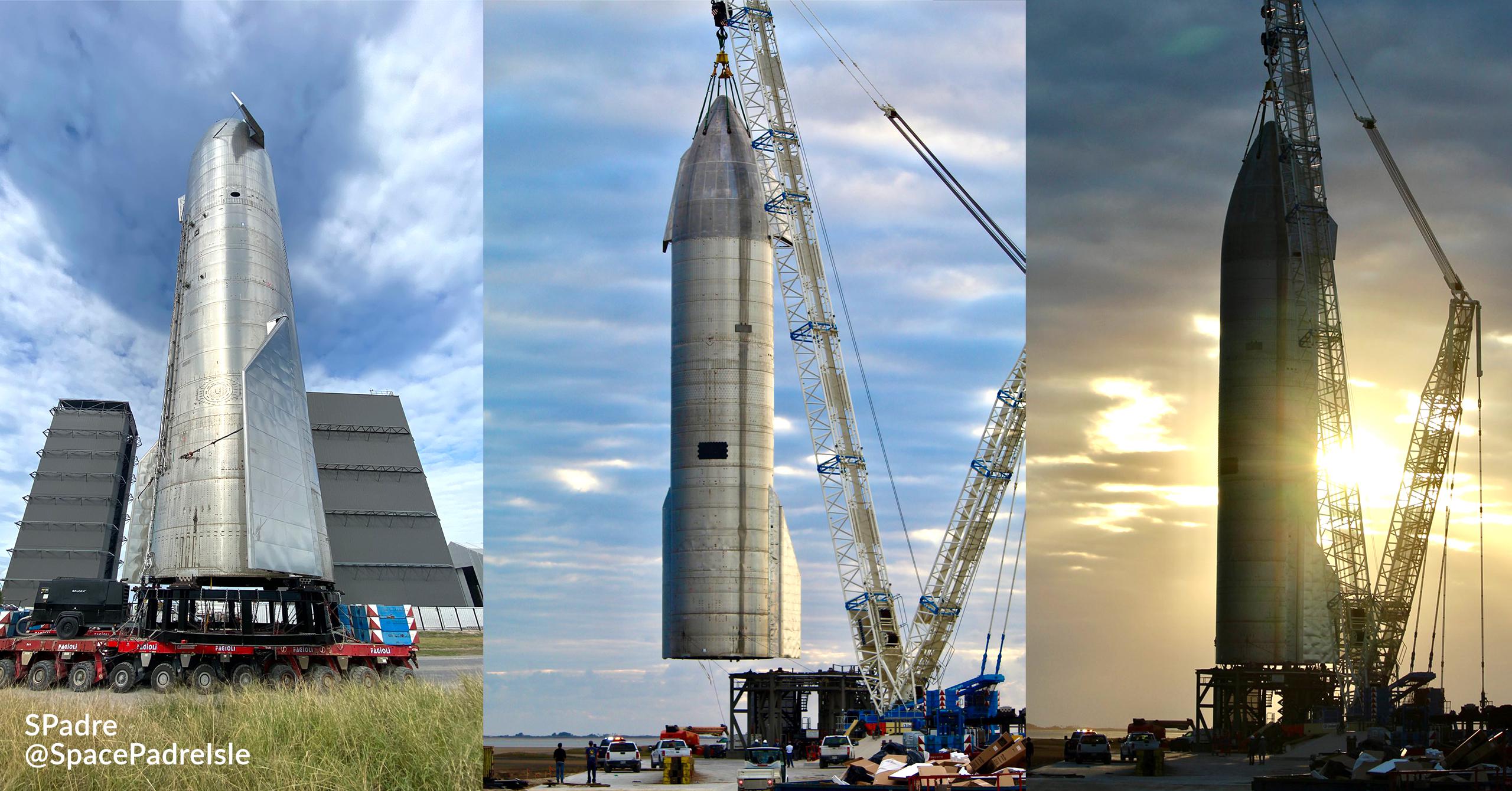

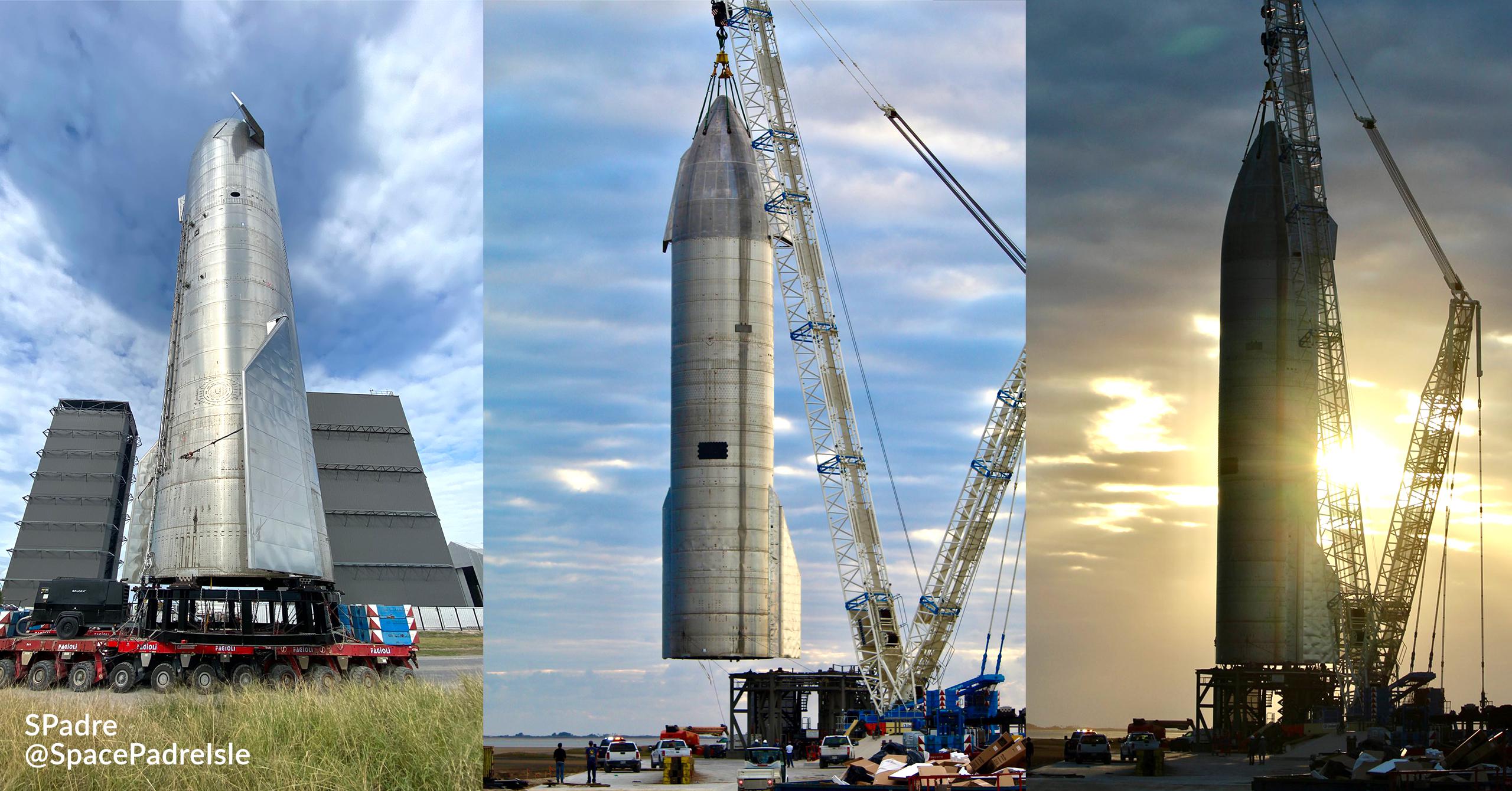

Update: Right on schedule, SpaceX rolled Starship serial number 9 (SN9) out of its ‘high bay’ assembly roost and transported the 50-meter-tall (~165 ft) stainless steel rocket to a launch pad about a mile down the road.

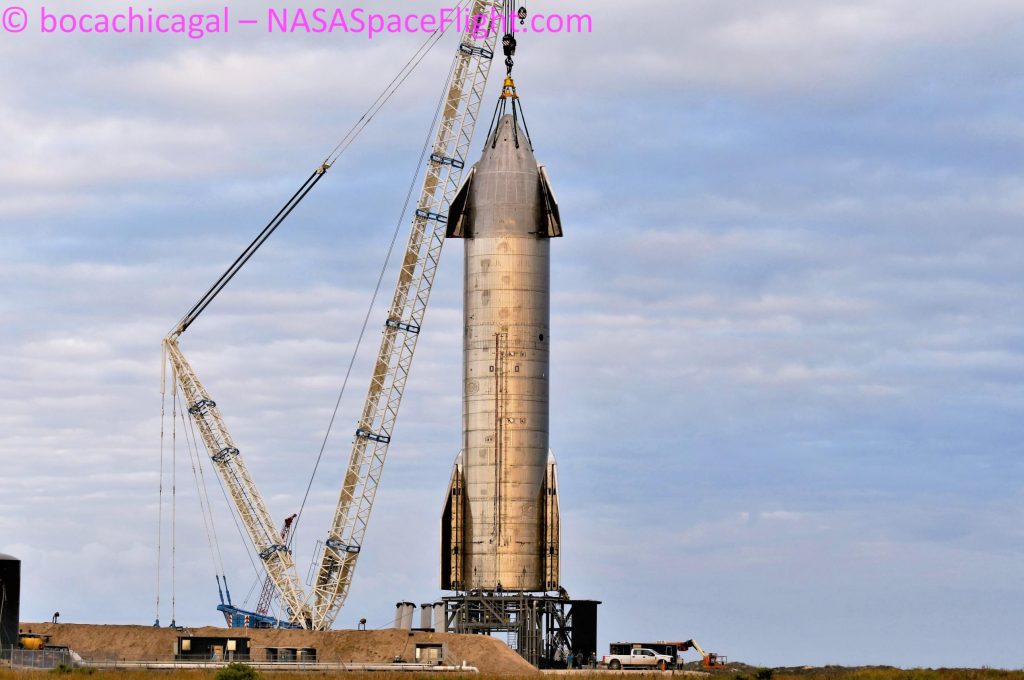

Wasting no time at all after having preemptively delivered a large crane from factory to pad the day prior, SpaceX began the process of lifting and installing Starship SN9 on one of two simple launch mounts less than three hours after arrival and began securing the rocket to the stand less than an hour after that. As discussed below, it’s nothing short of spectacular (and possibly unprecedented) that Starship SN9 was a victim of a workstand collapse, suffered some damage as a result, had that damage repaired or parts replaced, and was ready to roll to the launch pad to start pre-launch testing within a span of eleven days.

Additionally, SN9’s arrival means that SpaceX has now delivered a second complete Starship less than two weeks after Starship SN8 became the first full-size prototype to launch to high altitude atop multiple Raptor engines and skydive back to Earth. With the landing pad yet to be fully cleared after that launch debut, the crash-landed wreckage of SN8’s nose is even visible behind Starship SN9 in unofficial coverage of the new rocket’s pad transport and launch mount installation. As of December 22nd, SpaceX has one more road closure scheduled on Dec 23, followed by a trio from 8 am to 5 pm CST (UTC-6) from Dec 28-30. Stay tuned for updates as SpaceX prepares the second full-size Starship ever for tank proof and static fire testing!

A handful of days after a workstand collapse threatened to end SpaceX’s next high-altitude Starship before it could leave the cradle, the rocket appears to have shrugged off whatever damage was caused with ease.

On the morning of December 11th and less than 24 hours after SpaceX investors and VIPs like COO Gwynne Shotwell and CEO Elon Musk were standing almost underneath the rocket, an unknown issue cause Starship SN9’s workstand to partially collapse. Seemingly through sheer luck, the part of the circular stand that collapsed was towards the corner of the ‘high bay’ building housing SN9, causing the rocket to tip around five degrees before colliding with the wall’s steel frame.

Again, by some stroke of luck, the same angle of Starship SN9’s fall that prevented the rocket from tipping over onto Super Heavy’s in-work tank section (with workers possibly inside) seemingly allowed its flaps to absorb the bulk of that impact. One of two pairs used to keep the ship steady during a skydiver-like freefall maneuver, SN9’s forward and aft starboard flaps suffered obvious damage, perhaps unintentionally functioning like the crumple zones designed to protect passengers during car crashes.

Aside from one or two subtle dents caused by the thoroughly off-axis stresses, the rest of the fully-assembled vehicle remained visibly untouched, though it was a near-complete unknown if Starship was capable of surviving such an ordeal. For 99% of the world’s rockets, almost all of which are either built out of aluminum or carbon fiber, tipping from a vertical position into a steel wall at anything less than a snail’s pace would likely be the end of any normal propellant tank – probably up to and including even SpaceX’s own reusable Falcon boosters. At a minimum, extensive repairs would be required.

On December 20th, nine days after the incident and six days after a crane lifted SN9 back into a stable position, SpaceX quietly replaced the Starship’s crumpled forward flap after having removed both damaged flaps in the days prior. The installation of that replacement flap – possibly taken from Starship SN10’s nose – all but confirmed a best-case scenario, as it would be hard to remove the damaged hardware and install a new flap so quickly if the underlying hinge and mounting mechanisms had been damaged in the fall. If only the aft – but not forward – flap mechanism was somehow damaged, it would also make little sense to install a new forward flap.

Meanwhile, in another kind of encouraging sign, SpaceX moved the crane needed to lift Starships onto the launch mount from the build site to the launch pad on December 21st – right on schedule. It’s extremely unlikely that SpaceX would complete that move unless it was confident that a Starship prototype would be ready to roll to the launch pad, further implying that Starship SN9 really has shrugged off its workplace accident after less than two weeks of delays. Stay tuned for updates – road closures that could be used to transport SN9 are still in place from around 8 am to 5 pm CST on December 22nd and 23rd.

News

Tesla China breaks 8-month slump by selling 71,599 vehicles wholesale in June

Tesla China’s June numbers were released by the China Passenger Car Association (CPCA) on Tuesday.

Tesla China was able to sell 71,599 vehicles wholesale in June 2025, reversing eight consecutive months of year-over-year decline. The figure marks a 0.83% increase from the 71,599 vehicles sold wholesale in June 2024 and a 16.1% jump compared to the 61,662 vehicles sold wholesale in May.

Tesla China’s June numbers were released by the China Passenger Car Association (CPCA) on Tuesday.

Tesla China’s June results in focus

Tesla produces both the Model 3 and Model Y at its Shanghai Gigafactory, which serves as the company’s primary vehicle export hub. Earlier this year, Tesla initiated a changeover for its best-selling vehicle, the Model Y, resulting in a drop in vehicle sales during the first and second quarters.

Tesla’s second-quarter China sales totaled 191,720 units including exports. While these numbers represent a 6.8% year-over-year decline for Tesla China, Q2 did show sequential improvement, rising about 11% from Q1 2025, as noted in a CNEV Post report.

For the first half of the year, Tesla sold 364,474 vehicles wholesale. This represents a 14.6% drop compared to the 426,623 units sold wholesale in the first half of 2024.

China’s competitive local EV market

Tesla’s position in China is notable, especially as the new Model Y is gaining ground in the country’s BEV segment. That being said, Tesla is also facing competition from impressive local brands such as Xiaomi, whose new YU7 electric SUV is larger and more affordable than the Model Y.

The momentum of the YU7 is impressive, as the vehicle was able to secure 200,000 firm orders within three minutes and over 240,000 locked-in orders within 18 hours. Xiaomi’s previous model, the SU7 electric sedan, which is aimed at the Model, also remains popular, with June deliveries surpassing 25,000 units for the ninth straight month.

While China’s EV market is getting more competitive, Tesla’s new Model Y is also ramping its production and deliveries. Needless to say, Tesla China’s results for the remaining two quarters of 2025 will be very interesting.

Elon Musk

Tesla reveals it is using AI to make factories more sustainable: here’s how

Tesla is using AI in its Gigafactory Nevada factory to improve HVAC efficiency.

Tesla has revealed in its Extended Impact Report for 2024 that it is using Artificial Intelligence (AI) to enable its factories to be more sustainable. One example it used was its achievement of managing “the majority of the HVAC infrastructure at Gigafactory Nevada is now AI-controlled” last year.

In a commitment to becoming more efficient and making its production as eco-friendly as possible, Tesla has been working for years to find solutions to reduce energy consumption in its factories.

For example, in 2023, Tesla implemented optimization controls in the plastics and paint shops located at Gigafactory Texas, which increased the efficiency of natural gas consumption. Tesla plans to phase out natural gas use across its factories eventually, but for now, it prioritizes work to reduce emissions from that energy source specifically.

It also uses Hygrometric Control Logic for Air Handling Units at Giafactory Berlin, resulting in 17,000 MWh in energy savings each year. At Gigafactory Nevada, Tesla saves 9.5 GWh of energy through the use of N-Methylpyrrolidone refineries when extracting critical raw material.

Perhaps the most interesting way Tesla is conserving energy is through the use of AI at Gigafactory Nevada, as it describes its use of AI to reduce energy demand:

“In 2023, AI Control for HVAC was expanded from Nevada and Texas to now include our Berlin-Brandenburg and Fremont factories. AI Control policy enables HVAC systems within each factory to work together to process sensor data, model factory dynamics, and apply control actions that safely minimize the energy required to support production. In 2024, this system achieved two milestones: the majority of HVAC infrastructure at Gigafactory Nevada is now AI-controlled, reducing fan and thermal energy demand; and the AI algorithm was extended to manage entire chiller plants, creating a closed-loop control system that optimizes both chilled water consumption and the energy required for its generation, all while maintaining factory conditions.”

Tesla utilizes AI Control “primarily on systems that heat or cool critical factory production spaces and equipment.” AI Control communicates with the preexisting standard control logic of each system, and any issues can be resolved by quickly reverting back to standard control. There were none in 2024.

Tesla says that it is utilizing AI to drive impact at its factories, and it has proven to be a valuable tool in reducing energy consumption at one of its facilities.

Elon Musk

Tesla analysts believe Musk and Trump feud will pass

Tesla CEO Elon Musk and U.S. President Donald Trump’s feud shall pass, several bulls say.

Tesla analysts are breaking down the current feud between CEO Elon Musk and U.S. President Donald Trump, as the two continue to disagree on the “Big Beautiful Bill” and its impact on the country’s national debt.

Musk, who headed the Department of Government Efficiency (DOGE) under the Trump Administration, left his post in May. Soon thereafter, he and President Trump entered a very public and verbal disagreement, where things turned sour. They reconciled to an extent, and things seemed to be in the past.

However, the second disagreement between the two started on Monday, as Musk continued to push back on the “Big Beautiful Bill” that the Trump administration is attempting to sign into law. It would, by Musk’s estimation, increase spending and reverse the work DOGE did to trim the deficit.

Every member of Congress who campaigned on reducing government spending and then immediately voted for the biggest debt increase in history should hang their head in shame!

And they will lose their primary next year if it is the last thing I do on this Earth.

— Elon Musk (@elonmusk) June 30, 2025

President Trump has hinted that DOGE could be “the monster” that “eats Elon,” threatening to end the subsidies that SpaceX and Tesla receive. Musk has not been opposed to ending government subsidies for companies, including his own, as long as they are all abolished.

How Tesla could benefit from the ‘Big Beautiful Bill’ that axes EV subsidies

Despite this contentious back-and-forth between the two, analysts are sharing their opinions now, and a few of the more bullish Tesla observers are convinced that this feud will pass, Trump and Musk will resolve their differences as they have before, and things will return to normal.

ARK Invest’s Cathie Wood said this morning that the feud between Musk and Trump is another example of “this too shall pass:”

BREAKING: CATHIE WOOD SAYS — ELON AND TRUMP FEUD “WILL PASS” 👀 $TSLA

She remains bullish ! pic.twitter.com/w5rW2gfCkx

— TheSonOfWalkley (@TheSonOfWalkley) July 1, 2025

Additionally, Wedbush’s Dan Ives, in a note to investors this morning, said that the situation “will settle:”

“We believe this situation will settle and at the end of the day Musk needs Trump and Trump needs Musk given the AI Arms Race going on between the US and China. The jabs between Musk and Trump will continue as the Budget rolls through Congress but Tesla investors want Musk to focus on driving Tesla and stop this political angle…which has turned into a life of its own in a roller coaster ride since the November elections.”

Tesla shares are down about 5 percent at 3:10 p.m. on the East Coast.

-

Elon Musk2 days ago

Elon Musk2 days agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News7 days ago

News7 days agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

News2 weeks ago

News2 weeks agoTesla’s Grok integration will be more realistic with this cool feature

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk slams Bloomberg’s shocking xAI cash burn claims

-

News2 weeks ago

News2 weeks agoTesla China roars back with highest vehicle registrations this Q2 so far

-

News2 weeks ago

News2 weeks agoTexas lawmakers urge Tesla to delay Austin robotaxi launch to September

-

News2 weeks ago

News2 weeks agoTesla dominates Cars.com’s Made in America Index with clean sweep

-

Elon Musk1 week ago

Elon Musk1 week agoFirst Look at Tesla’s Robotaxi App: features, design, and more