Update: Shortly after publishing, SpaceX began a much more ambitious series of tests with the Starship launch tower’s two main arms, which are designed to lift and (one day) catch Starships and Super Heavy boosters.

After lifting the arm carriage about 15m (~50 ft), several times higher than January 3rd’s far more conservative kickoff, SpaceX fired up each arm’s main hydraulic actuator and opened them about as wide as they’re able to move. Unsurprisingly, the arms’ first powered lateral movement happened very slowly, obviously telegraphing caution but probably also hinting at the start of a calibration process needed to determine their full range of motion and associate those positions with certain sensor readings or telemetry to ensure they can be safely controlled. As of midnight CST, that testing has continued well into the night.

Regardless of the purpose, substantial powered movement is a major milestone for the tower’s main arms and all but guarantees that more extensive tests and simulations are soon to come.

SpaceX has moved Starbase’s rocket-catching “chopstick” arms for the first time since they were installed on the orbital Starship pad’s ‘launch tower’ two months ago.

After a shockingly brisk three-month period of assembly, the first arm installed in late August 2021 was a lone structure designed to swing in; grab and stabilize Super Heavy with its claw; fuel and power Starship; and quickly detach and swing away from the rocket during launch. A month and a half later, SpaceX begin installing a much larger pair of more complex arms in mid-October. Unlike the Starship quick-disconnect (QD) arm, the pair of arms that followed were almost nothing like anything built as part of another rocket launch complex.

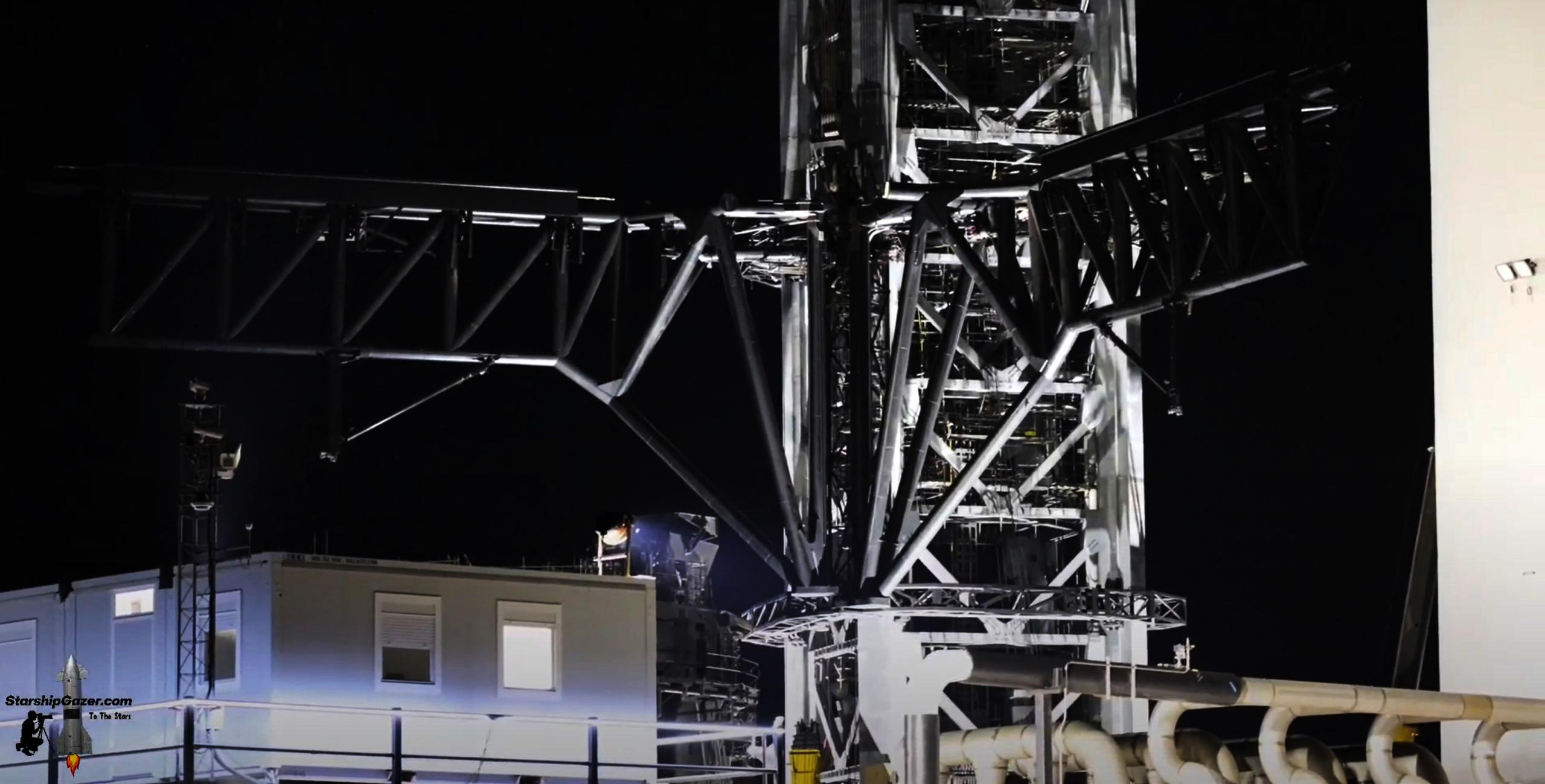

Unlike other ‘arms’ related to other rocket launch facilities, the pair SpaceX began to install on Starbase’s launch tower were colossal, measuring more than 30m (100+ ft) long and 5-10m (15-30 ft) tall. Built out of heavy-duty steel pipe and affixed to an even sturdier pair of claw-like supports that grab onto the launch tower, the combined assembly likely weighs hundreds of tons. Aside from their sheer scale, Starbase’s main tower arms are also attached to a complex system of cables and an industrial-strength ‘drawworks’ commonly used on giant oil rigs and derricks.

They also feature huge actuators that allow the two arms to open and close, revealing a bit of their purpose. While the main reason they likely exist is to provide SpaceX with an all-weather alternative to cranes for lifting, manipulating, and precisely stacking Starships and Super Heavy boosters at the launch pad, the headline – ever since Musk revealed the idea – has always been plans to use those same arms to literally catch rockets out of mid-air.

To do so, they’ll need to be able to actuate and move extremely quickly and precisely up and down the Starship launch tower, matching the velocity and autonomously determining the position of landing Super Heavy boosters (and possibly Starships) to avoid major damage or the loss of entire vehicles. While arguably an unnecessary gamble and an attempt to micro-optimize the concept of operations of a rocket that’s yet to attempt a single orbital-class launch, SpaceX’s CEO is clearly committed to the idea and – whether or not the first iteration works – has fully delivered on the first complete lift-and-catch system.

On January 3rd, 2022, after removing a large amount of scaffolding in the days prior, SpaceX briefly and slightly moved the installed arms for the first time, using the drawworks to lift the entire arm-and-carriage assembly a few meters (~6 ft) up and down the tower. Once a few minor additional steps are taken, the chopsticks could be ready for much more extensive testing, beginning with basic lift, descent, and arm actuation tests to calibrate and then proof the first-of-its-kind mechanism. Later, SpaceX will likely simulate catching rockets in a wide range of scenarios. Somewhere before, during, or after that testing, SpaceX may perform another fit test with Starship S20 and Super Heavy B4 – but this time using the arms to lift and install the stages.

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.