News

Tesla’s next Gigafactory location unknown, but all signs point toward India

In May, Tesla CEO Elon Musk said the electric automaker would likely announce its next Gigafactory location by year’s end.

While there have been rumors of deep talks in Spain, numerous meetings with French government officials, and heavy speculation regarding a relationship with Canada, Indonesia, and South Korea, it is becoming overwhelmingly clear that all signs are pointing toward India, a location where Tesla has mulled a factory for several years.

It all started back in 2015 when Indian Prime Minister Narendra Modi and Musk had their first meeting at the Fremont Factory in Northern California.

At the time, Tesla was still a young-and-scrappy car company, pushing out just thousands of units each year as it only offered the Model S and Model X at the time. Electric vehicles were still a far cry from what they are today, and while there were other options on the market, gas-powered options still dominated the overall market.

Fast-forward to 2018, when Tesla decided to open its first vehicle production factory outside of the United States in Shanghai. The Chinese EV production plant quickly became Tesla’s most effective, accumulating thousands of workers and producing a majority of the automaker’s annual volume. It went from a domestic production facility for Chinese customers to an “export hub” that would feed some of the best-selling EVs to the European market.

This all happened before Tesla would commit to building a factory near Berlin in 2019, and then another factory in Mexico in 2023.

In 2021, Tesla seemed primed to announce it would make a substantial investment in India. It had a team of executives lined up, which included David Feinstein, Tesla vet who would be named Director of Global Trade and New Markets. Vaibhav Taneja was assigned as the Chief Accounting Officer for the India plant, and Prashanth R. Menon assumed the role of Director of Tesla India.

The team was even rounded out with Manuj Khurana for Policy and Development, Nishant Nishant for Charging Infrastructure, and Chithra Thomas for Human Resources. Samir Jain was set to take over India’s Service Operations for Tesla after seven years at Porsche, where he headed Aftersales for the German automaker’s operations in India.

However, the team Tesla would put together for India would never get to work in the market, as it was set to establish the plant there.

Tesla had certain demands it needed to fulfill before committing to a Gigafactory there, and India had certain demands it needed to fulfill before giving Tesla what it wanted.

Tesla’s ‘challenges’ with India gov’t halt potential rescue of $27B manufacturing initiative

India has some of the highest import duties on vehicles in the world. The taxes would double the price of any car priced over $40,000 and 60 percent to any car under that threshold. Because of this, Tesla requested import duties be reduced to 40 percent, which would help the company determine if demand for its cars was high enough to move forward.

If Tesla is able to succeed with imported vehicles, then a factory in India is quite likely.

— Elon Musk (@elonmusk) July 23, 2021

However, Indian officials were reluctant to oblige to Tesla’s demands, arguing that “company-specific” duty rollbacks would not be possible.

The government has made its stance against company-specific incentives clear,” government officials from India said. “This also applies for one particular company requesting industrywide changes to existing policy. Over the past four years, multiple demands were made by a large US-based firm to open up the market at lower import duties as well. Now, they locally produce in India and are ramping up capacity.”

India has a $27B manufacturing initiative called “Make In India,” which encourages companies from all corners of the globe to develop, produce, and assemble products in India with sizeable investments. This initiative was first introduced in 2014 by Modi.

Because Tesla would be importing vehicles from other countries, most likely China, into India’s marketplace, government officials were unfavorable of the idea of rolling back duties. However, they were willing to do so, only if Tesla would commit to building the factory in the first place, which completely eliminated the purpose of testing demand in the first place.

Two years later, it appears Tesla and India have come to some kind of agreement. Although the terms of a partnership or investment are unknown currently, both Modi and Musk have put forth statements that seem to indicate Tesla’s next factory will be in India.

“I am confident Tesla will be in India, and we’ll do so as soon as humanly possible,” Musk said. “Hopefully, we’ll be able to announce something in the not-too-distant future.”

We don’t want to jump the gun on an announcement,” he added, “but it’s quite likely that there will be a significant investment and relationship in the future.”

#Breaking | ELON MUSK SPEAKS TO REPUBLIC

Elon Musk speaks to Republic after meeting PM Modi, announces he and Tesla are coming to India pic.twitter.com/x2CxFEDM2Z

— Republic (@republic) June 20, 2023

Modi also posted his own photo with Musk on his Twitter account, thanking the Tesla CEO for a “great meeting.”

Great meeting you today @elonmusk! We had multifaceted conversations on issues ranging from energy to spirituality. https://t.co/r0mzwNbTyN pic.twitter.com/IVwOy5SlMV

— Narendra Modi (@narendramodi) June 21, 2023

Because of the widespread speculation regarding Tesla’s next factory, we can all speculate on where it will end up. But if there is any indication of what the automaker wants and what the government wants, the long-standing attempts to get a deal done may indicate Tesla is most likely to end up in India.

I’d love to hear from you! If you have any comments, concerns, or questions, please email me at joey@teslarati.com. You can also reach me on Twitter @KlenderJoey, or if you have news tips, you can email us at tips@teslarati.com.

News

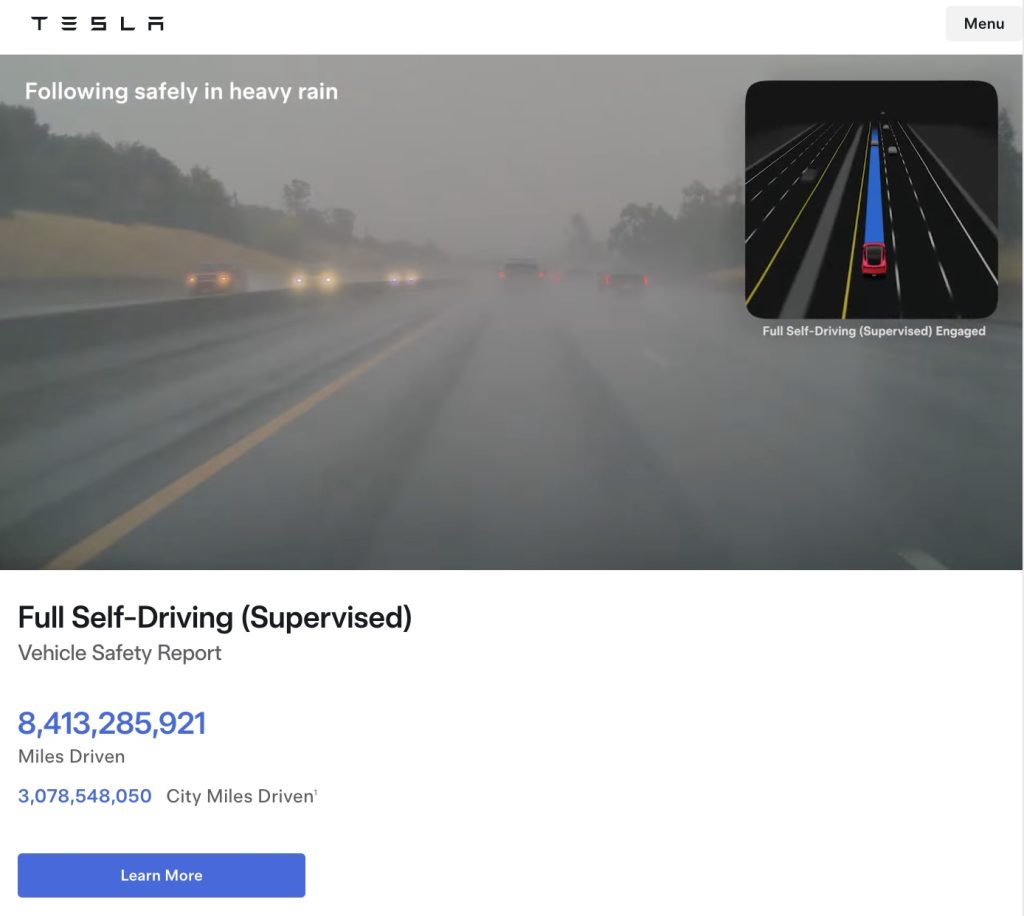

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.