News

SpaceX resurrects California Starship factory plan just one year after abandoning it

Just nine months after scrapping temporary Starship facilities built at a Los Angeles port, the company has unexpectedly reconsidered that decision, restarting talks to build a steel Starship factory in California.

In March 2018, nearly two years ago, the public first became aware of SpaceX’s plans to build a Starship factory in Port of Los Angeles. Begun while Starship was still known as BFR (Big Falcon Rocket) and designed to be built almost entirely out of carbon-fiber composites, the company’s first in-house effort to build its next-generation rocket began in an unassuming tent erected on port property around December 2017. Unintentionally foreshadowing the future of both Tesla Model 3 and SpaceX Starship production, that temporary tent was completed in just a month or two and officially began supporting BFR prototype production in April 2018.

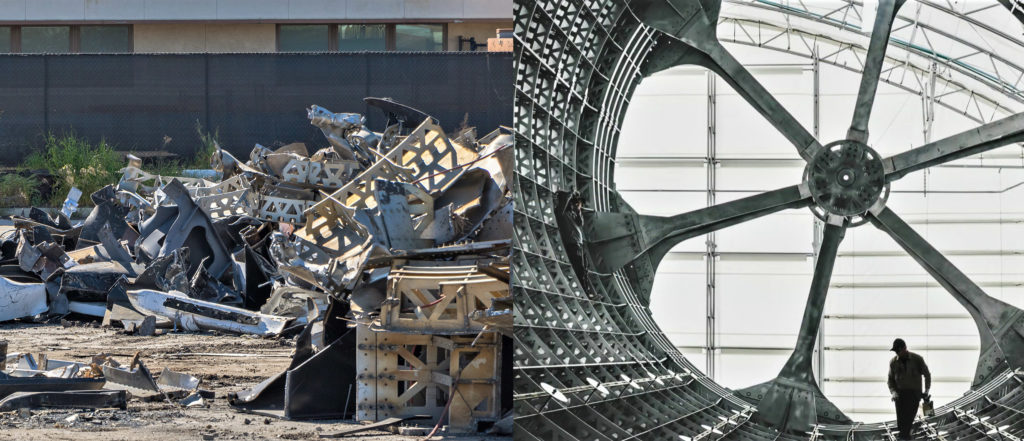

In December 2018, CEO Elon Musk rebranded BFR as Starship and revealed that SpaceX would take the extraordinary step of redesigning the fully-reusable rocket to use stainless steel instead of carbon fiber. One year after SpaceX began building carbon fiber hardware, Musk moved quickly to make the radical move to steel permanent, literally scrapping its BFR prototype tent and abandoning its lease of a separate facility that was meant to host a more permanent composite Mars rocket factory in the near future. Now, almost exactly a year canceling its Port of LA factory, SpaceX has returned with plans to build and finish new port-based Starship production facilities just a few months from now.

Completed in September 2018, the closest SpaceX ever got to producing its 2017 BFR iteration was a large ring-like composite structure, also known as a barrel section. Measuring some 9m (30 ft) wide and 4-6m (12-20 ft) long, both 2016, 2017, and 2018 variants of SpaceX’s next-generation fully-reusable rocket would have been assembled from a number of similar components — all to be built out of carbon composites with giant mandrels (a bit like inverse molds).

While it’s more than likely that SpaceX could have managed the feat, building a reusable orbital spacecraft like Starship out of carbon fiber posed a vast array of challenges. When Musk revealed that SpaceX would move from carbon fiber to steel in December 2018, the CEO went into some detail to explain several of those challenges and why the major change was thus worth the substantial body of work it would force the company to scrap and redo from scratch.

The two biggest hurdles for BFR were quite simple. From a technical perspective, carbon fiber is dramatically less temperature-resistant than most metals (especially steel), meaning that despite it offering a much higher strength-to-weight ratio on paper, almost every inch of the spaceship and booster’s exposed surfaces would have to be insulated. For Starship, this would be exceptionally challenging given that the spacecraft must fundamentally be able to survive numerous orbital-velocity reentries with little to no refurbishment in between. While a steel Starship would still need a proper heat shield on its windward half, the other half of its steel hull could likely be almost entirely unshielded thanks to the fact that most steels remain structural sound at much higher temperatures.

Beyond the “delightfully counterintuitive” technical properties that could make a steel Starship as light or even lighter than the carbon composite alternative, Musk also noted that a huge motivator for the switch was the fact that the cutting-edge composites SpaceX would have to buy were incredibly expensive. In September 2019, Musk stated that composites would have cost some $130,000 per ton, whereas a ton of the stainless steel SpaceX is now using can be purchased for just $2500. In simpler terms, from a material cost perspective, steel Starships and Super Heavy boosters could cost an incredible 50 times less than their carbon composite twins.

Port Factory 2.0

For now, it’s unclear exactly what SpaceX foresees for Starship’s newly re-proposed Port of LA factory. The same primary constraint remains: there is still no affordable way to ship full-scale 9m-diameter Starship hardware by road. The most likely explanation for the resurrected interest in port facilities is that SpaceX still wants to keep some major aspects of Starship manufacturing within reach of California’s vast aerospace talent pool, as well as the company’s own California headquarters, situated just 20 or so miles from Port of LA.

At the same time, SpaceX probably has all the space it could possibly want at its Hawthorne, CA headquarters after a massive Triumph facility was recently vacated, meaning that any intentional expansion in Port of LA is probably motivated by the need to transport massive rocket parts from California to Texas and Florida. Daily Breeze also reports that “SpaceX would manufacture its…Starship spacecraft and…Super Heavy [booster] on the property” if it receives approval, seemingly implying interest in full-scale rocket production at its prospective port factory.

Regardless of whether SpaceX wants to build smaller Starship subcomponents (i.e. nose cones, header tanks, fins, plumbing, crew compartments, etc.) or complete spaceships and boosters, the company is seemingly far more eager to get port facilities in place, this time around. Specifically, SpaceX told a city council member that it wanted to get a Port of LA facility up and running just 90 days after it expressed new interest in the concept.

To do so, SpaceX will copy the methods used to create both Tesla’s General Assembly 4 factory addition and its own massive Starship production space in South Texas, relying on Sprung Instant Structures to erect a massive semi-permanent tent or two in an extremely short period of time. Unfortunately, because of how abruptly SpaceX abandoned its Port of LA factory lease, the company will have to repeat the permitting and environmental review process from scratch, making it very unlikely that it will be able to begin construction within the next month or two.

Regardless, SpaceX certainly remains as agile as ever. Stay tuned for updates on this surprise resurgence of plans for a Port of LA Starship factory.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

Elon Musk

SpaceX targets 150Mbps per user for upgraded Starlink Direct-to-Cell

If achieved, the 150Mbps goal would represent a significant jump from the current performance of Starlink Direct-to-Cell.

SpaceX is targeting peak download speeds of 150Mbps per user for its next-generation Direct-to-Cell Starlink service. The update was shared by SpaceX Spectrum & Regulatory Affairs Lead Udrivolf Pica during the International Telecommunication Union’s Space Connect conference.

“We are aiming at peak speeds of 150Mbps per user,” Pica said during the conference. “So something incredible if you think about the link budgets from space to the mobile phone.”

If achieved, the 150Mbps goal would represent a significant jump from the current performance of Starlink Direct-to-Cell.

Today, SpaceX’s cellular Starlink service, offered in partnership with T-Mobile under the T-Satellite brand, provides speeds of roughly 4Mbps per user. The service is designed primarily for texts, low-resolution video calls, and select apps in locations that traditionally have no cellular service.

By comparison, Ookla data shows median 5G download speeds of approximately 309Mbps for T-Mobile and 172Mbps for AT&T in the United States, as noted in a PCMag report. While 150Mbps would still trail the fastest terrestrial 5G networks, it would place satellite-to-phone broadband much closer to conventional carrier performance, even in remote areas.

Pica indicated that the upgraded system would support “video, voice, and data services, clearly,” moving beyond emergency connectivity and basic messaging use cases.

To reach that target, SpaceX plans to upgrade its existing Starlink Direct-to-Cell satellites and add significant new capacity. The company recently acquired access to radio spectrum from EchoStar, which Pica described as key to expanding throughput.

“More spectrum means a bigger pipeline, and this means that we can expand what we can do with partners. We can expand the quality of service. And again, we can do cellular broadband basically, cellular broadband use cases, like AI or daily connectivity needs,” he stated.

SpaceX has also requested regulatory approval to deploy 15,000 additional Direct-to-Cell satellites, beyond the roughly 650 currently supporting the system. The upgraded architecture is expected to begin rolling out in late 2027.

News

Tesla seeks approval to test FSD Supervised in new Swedish city

Tesla has applied to conduct local Full Self-Driving (Supervised) testing in the city of Jönköping, Sweden.

Tesla has applied to conduct local Full Self-Driving (Supervised) testing in the city of Jönköping, Sweden.

As per local outlet Jönköpings-Posten, Tesla has contacted the municipality with a request to begin FSD (Supervised) tests in the city. The company has already received approval to test its Full Self-Driving (Supervised) software in several Swedish municipalities, as well as on the national road network.

Sofia Bennerstål, Tesla’s Head of Public Policy for Northern Europe, confirmed that an application has been submitted for FSD’s potential tests in Jönköping.

“I can confirm that we have submitted an application, but I cannot say much more about it,” Bennerstål told the news outlet. She also stated that Tesla is “satisfied with the tests” in the region so far.

The planned tests in Jönköping would involve a limited number of Tesla-owned vehicles. Trained Tesla safety drivers would remain behind the wheel and be prepared to intervene if necessary.

Tesla previously began testing in Nacka municipality after receiving local approval. At the time, the company stated that cooperation between authorities, municipalities, and industry enables technological progress and helps integrate future transport systems into real-world traffic conditions, as noted in an Allt Om Elbil report.

If approved, Jönköping would become the latest Swedish municipality to allow local Full Self-Driving (Supervised) testing.

Tesla’s Swedish testing program is part of the company’s efforts to validate its supervised autonomous driving software in everyday traffic environments. Municipal approvals allow Tesla to gather data in urban settings that include roundabouts, complex intersections, and mixed traffic conditions.

Sweden has become an increasingly active testing ground for Tesla’s driver-assistance software in Europe, with regulatory coordination between local authorities and national agencies enabling structured pilot programs.

Elon Musk

Microsoft partners with Starlink to expand rural internet access worldwide

The update was shared ahead of Mobile World Congress.

Microsoft has announced a new collaboration with Starlink as part of its expanding digital access strategy, following the company’s claim that it has extended internet connectivity coverage to more than 299 million people worldwide.

The update was shared ahead of Mobile World Congress, where Microsoft detailed how it surpassed its original goal of bringing internet access to 250 million people by the end of 2025.

In a blog post, Microsoft confirmed that it is now working with Starlink to expand connectivity in rural and hard-to-reach regions.

“Through our collaboration with Starlink, Microsoft is combining low-Earth orbit satellite connectivity with community-based deployment models and local ecosystem partnerships,” the company wrote.

The partnership is designed to complement Microsoft’s existing work with local internet providers and infrastructure companies across Africa, Latin America, and India, among other areas. Microsoft noted that traditional infrastructure alone cannot meet demand in some regions, making low-Earth orbit satellite connectivity an important addition.

Kenya was cited as an early example. Working with Starlink and local provider Mawingu Networks, Microsoft is supporting connectivity for 450 community hubs in rural and underserved areas. These hubs include farmer cooperatives, aggregation centers, and digital access facilities intended to support agricultural productivity and AI-enabled services.

Microsoft stated that 2.2 billion people globally remain offline, and that connectivity gaps risk widening as AI adoption accelerates.

Starlink’s expanding constellation, now numbering more than 9,700 satellites in orbit, provides near-global coverage, making it one of the few systems capable of delivering broadband to remote regions without relying on terrestrial infrastructure.

Starlink is expected to grow even more in the coming years as well, especially as SpaceX transitions its fleet to Starship, which is capable of carrying significantly larger payloads compared to its current workhorse, the Falcon 9.