News

Tesla emphasizes factory safety, preempts possible smear campaign by auto union

Tesla released a blog post Sunday evening that reemphasizes the company’s goal to become the safest auto factory in the world. The post comes after the United Auto Workers Union (UAW) attempted to rally support earlier this year from Fremont factory workers in favor of unionizing.

Tesla states that it has received several media inquiries over allegations about safety at its Fremont, California factory. The well-timed nature of the inquiries, and similarity in topic, led Tesla to believe that the UAW was spreading anti-Tesla propaganda to the media in an attempt to provoke a response from the public, and from Tesla employees. In typical fashion, Tesla acted quickly and took to the offensive to defend the company’s approach to manufacturing, and maintaining the health and safety of its employees. The company has gone as far as forming dedicated Ergonomics Teams that have exclusive focus on “improving health and safety and reducing ergonomic risk for current and future production”.

“We are building entirely new vehicles from the ground up, using entirely new technology, production, and manufacturing methods, and ramping them at high volume. Getting this right is extremely difficult, and we deeply appreciate the hard work that all our employees do to help us achieve what most regard as impossible.” says Tesla through its blog post.

Tesla notes that in just 15 years, the company has become the largest manufacturing employer in California with over 10,000 production jobs in the Fremont factory and surrounding Bay Area.

Tesla has a proven track record of putting safety first as made evident by the award-winning safety ratings for its Model S and Model X. Vehicles have taken the brunt of the impact for their occupants, have swerved to avoid accidents and have even accelerated to avoid accidents. The innovative safety features Tesla has built into its vehicles is unsurpassed in the automotive world.

Though Tesla’s safety record to date is already better than industry-average, according to its press release, the company indicates that it continues to learn and apply new production processes aimed at improving employee well-being. Among the improvements are:

- Added 3rd shift to the manufacturing schedule to cut overtime because the employees asked for it and it was the right thing to do.

- Hired dedicated Ergonomist and established an Ergonomics team to ensure that current and future Tesla manufacturing lines are ergonomically friendly for employees.

- Model 3 has been designed with manufacturing employee ergonomics in mind. The Tesla Ergonomics Team works closely with design and engineering teams to catch ergonomics issues before they happen and proactively drive these improvements back into the design of the equipment and the car. Yes, you heard that right. Tesla will redesign the car if it is resulting in ergonomically challenging situations for its manufacturing employees.

- Established safety teams in every department which meets regularly to ensure safety is a top focus in its manufacturing operating departments.

These changes are not just skin deep and the company is seeing the results of the changes already. Tesla says it has collectively reduced 52% in lost time incidents and a 30% reduction in recordable incidents in the first quarter of 2017 versus the same period last year. These more granular metrics support an improvement in the industry standard Total Recordable Incident Rate (TRIR) which at the end of Q1 2017 was 4.6, a full 32% better than the industry standard of 6.7.

Anyone who has worked in an industry where safety is important can tell you that a culture of safety awareness is built day by day, month by month over many years. Tesla has a demonstrated history of superior results. The steps it has outlined to drive further improvements at the factory are evidence of a continued focus on safety and its employees.

The full post from the Tesla Blog reads as follows:

Creating the Safest Car Factory in the World

Earlier this year, the United Automobile Workers (UAW) announced it was attempting to organize workers in Tesla’s Fremont factory. The latest phase of their campaign involves a concerted and professional media push intended to raise questions about safety at Tesla.

We have received calls from multiple journalists at different publications, all around the same time, with similar allegations from seemingly similar sources about safety in the Tesla factory. Safety is an issue the UAW frequently raises in campaigns it runs against companies, and a topic its organizers have been promoting on social media about Tesla.

Some of the publications who have contacted us have rejected covering this “story” because they understand it is a misleading narrative based on anecdotes, not facts. However, there will likely be a few publications that choose to publish stories regardless, so we want to make sure the public also has the facts. Watch for these articles to downplay or ignore our actual 2017 safety data and to instead focus on a small number of complaints and anecdotes that are not representative of what is actually occurring in our factory of over 10,000 workers.

First, some context is important. The difficulty of starting a successful U.S. car company cannot be overstated, as evidenced by the fact that Ford is the only other U.S. car company to have never gone bankrupt. We are attempting to break this trend in order to fulfill our mission of accelerating the world’s transition to sustainable energy.

We are building entirely new vehicles from the ground up, using entirely new technology, production, and manufacturing methods, and ramping them at high volume. Getting this right is extremely difficult, and we deeply appreciate the hard work that all our employees do to help us achieve what most regard as impossible. While we still have a long way to go, in less than 15 years, we have become California’s largest manufacturing employer, creating more than 10,000 high-quality production jobs in the Bay Area, many of which had previously disappeared with the closure of NUMMI under the stewardship of the UAW.

As we work to achieve our mission, nothing is more important to us than protecting the health and safety of our employees. As we look at our safety record in prior years, we realize that we have not been perfect. No car factory is perfect, but particularly given that Model S and X were the first cars we built at more than tiny volumes, we fully acknowledge that they were not designed for ease of manufacturing – far from it. As would be expected, we have since learned many lessons, including how to improve the production process for the well-being of our colleagues.

Here are just some of the improvements that we have made:

- Historically, depending on production needs, some Tesla employees have worked significant amounts of overtime because it was necessary for the company to survive. However, working overtime can be challenging for employees and their families. Last year, we added a third shift to reduce the overtime burden on each team member and to improve safety. We did this because our employees asked for it, and because it was the right thing to do.

- As a result of this change, the average amount of hours worked by production team members has dropped to about 42 hours per week, and the level of overtime decreased by more than 60%. We hired our first dedicated Ergonomist in 2013, and in 2015 established an Ergonomics Team exclusively focused on improving health and safety and reducing ergonomic risk for current and future production.

- In addition to improving the process of building Model S and X, Model 3 has been designed specifically with ergonomics in mind. Our ergonomics team has worked hand-in-hand with our engineers on the design process. As just one example, we created simulations that showed us where reaching or bending by employees was most likely to occur, which in turn allowed us to redesign the equipment and the car to eliminate these issues as much as possible.

- Each department now has a Safety Team that meets regularly to increase safety awareness and recommend improvements, many of which have already been implemented.

- We are continuing to establish health and safety management procedures to scale with our operational growth.

The third shift, ergonomic improvements and increased safety awareness have collectively led to a 52% reduction in lost time incidents and a 30% reduction in recordable incidents from the first quarter of 2016 to the first quarter of 2017. In addition, through the end of Q1 2017, the factory’s total recordable incident rate (TRIR), the leading metric for workplace safety, is 4.6, which is 32% better than the industry average of 6.7. This data shows that there has been a dramatic improvement in employee safety, we are now significantly better than industry-average, and we continue to improve each day. A few anecdotes in a factory of over 10,000 people can always be given, but these are the facts.

Tesla’s safety record is much better than industry average, but it is not enough. Our goal is to have as close to zero injuries as humanly possible and to become the safest factory in the auto industry. We will get there by continuing to ask our employees to raise safety concerns and to keep proposing ideas that make things even better.

The alternative is to stop improving and to instead do what the rest of the industry, including the UAW, has always done. But being industry average would make our safety 32% worse. We care too much about our team to go backwards.

Elon Musk

Tesla Full Self-Driving’s newest behavior is the perfect answer to aggressive cars

According to a recent video, it now appears the suite will automatically pull over if there is a tailgater on your bumper, the most ideal solution for when a driver is riding your bumper.

Tesla Full Self-Driving appears to have a new behavior that is the perfect answer to aggressive drivers.

According to a recent video, it now appears the suite will automatically pull over if there is a tailgater on your bumper, the most ideal solution for when a driver is riding your bumper.

With FSD’s constantly-changing Speed Profiles, it seems as if this solution could help eliminate the need to tinker with driving modes from the person in the driver’s seat. This tends to be one of my biggest complaints from FSD at times.

A video posted on X shows a Tesla on Full Self-Driving pulling over to the shoulder on windy, wet roads after another car seemed to be following it quite aggressively. The car looks to have automatically sensed that the vehicle behind it was in a bit of a hurry, so FSD determined that pulling over and letting it by was the best idea:

Tesla appears to be implementing some sort of feature that will now pull over if someone is tailgating you to let the car by

Really cool feature, definitely get a lot of this from those who think they drive race cars

— TESLARATI (@Teslarati) February 26, 2026

We can see from the clip that there was no human intervention to pull over to the side, as the driver’s hands are stationary and never interfere with the turn signal stalk.

This can be used to override some of the decisions FSD makes, and is a great way to get things back on track if the semi-autonomous functionality tries to do something that is either unneeded or not included in the routing on the in-car Nav.

FSD tends to move over for faster traffic on the interstate when there are multiple lanes. On two-lane highways, it will pass slower cars using the left lane. When faster traffic is behind a Tesla on FSD, the vehicle will move back over to the right lane, the correct behavior in a scenario like this.

Perhaps one of my biggest complaints at times with Full Self-Driving, especially from version to version, is how much tinkering Tesla does with Speed Profiles. One minute, they’re suitable for driving on local roads, the next, they’re either too fast or too slow.

When they are too slow, most of us just shift up into a faster setting, but at times, even that’s not enough, see below:

What has happened to Mad Max?

At one point it was going 32 in a 35. Traffic ahead had pulled away considerably https://t.co/bjKvaMVTNX pic.twitter.com/aaZSWmLu5v

— TESLARATI (@Teslarati) January 24, 2026

There are times when it feels like it would be suitable for the car to just pull over and let the vehicle that is traveling behind pass. This, at least up until this point, it appears, was something that required human intervention.

Now, it looks like Tesla is trying to get FSD to a point where it just knows that it should probably get out of the way.

Elon Musk

Tesla Megapack powers $1.1B AI data center project in Brazil

By integrating Tesla’s Megapack systems, the facility will function not only as a major power consumer but also as a grid-supporting asset.

Tesla’s Megapack battery systems will be deployed as part of a 400MW AI data center campus in Uberlândia, Brazil. The initiative is described as one of Latin America’s largest AI infrastructure projects.

The project is being led by RT-One, which confirmed that the facility will integrate Tesla Megapack battery energy storage systems (BESS) as part of a broader industrial alliance that includes Hitachi Energy, Siemens, ABB, HIMOINSA, and Schneider Electric. The project is backed by more than R$6 billion (approximately $1.1 billion) in private capital.

According to RT-One, the data center is designed to operate on 100% renewable energy while also reinforcing regional grid stability.

“Brazil generates abundant energy, particularly from renewable sources such as solar and wind. However, high renewable penetration can create grid stability challenges,” RT-One President Fernando Palamone noted in a post on LinkedIn. “Managing this imbalance is one of the country’s growing infrastructure priorities.”

By integrating Tesla’s Megapack systems, the facility will function not only as a major power consumer but also as a grid-supporting asset.

“The facility will be capable of absorbing excess electricity when supply is high and providing stabilization services when the grid requires additional support. This approach enhances resilience, improves reliability, and contributes to a more efficient use of renewable generation,” Palamone added.

The model mirrors approaches used in energy-intensive regions such as California and Texas, where large battery systems help manage fluctuations tied to renewable energy generation.

The RT-One President recently visited Tesla’s Megafactory in Lathrop, California, where Megapacks are produced, as part of establishing the partnership. He thanked the Tesla team, including Marcel Dall Pai, Nicholas Reale, and Sean Jones, for supporting the collaboration in his LinkedIn post.

Elon Musk

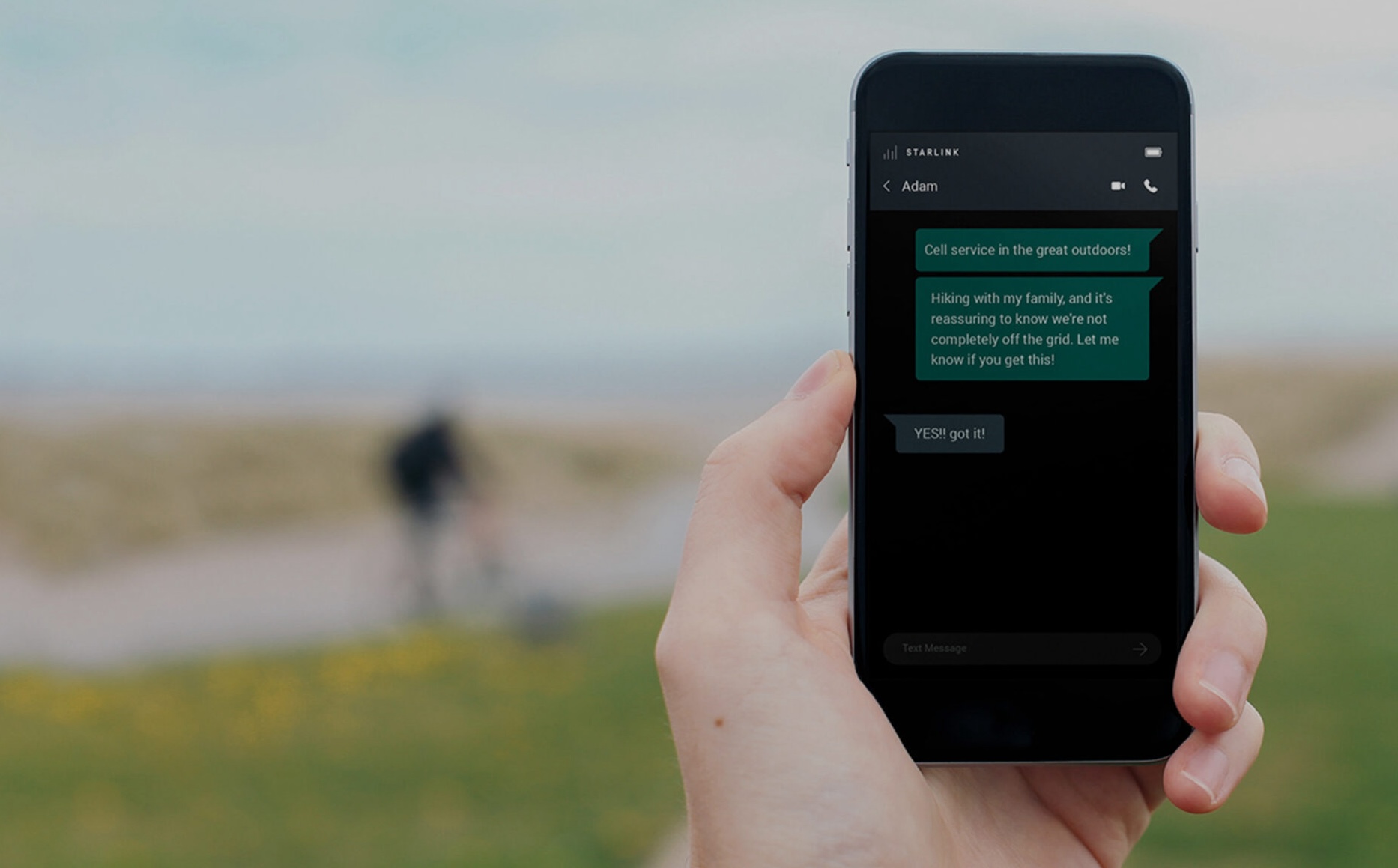

Starlink powers Europe’s first satellite-to-phone service with O2 partnership

The service initially supports text messaging along with apps such as WhatsApp, Facebook Messenger, Google Maps and weather tools.

Starlink is now powering Europe’s first commercial satellite-to-smartphone service, as Virgin Media O2 launches a space-based mobile data offering across the UK.

The new O2 Satellite service uses Starlink’s low-Earth orbit network to connect regular smartphones in areas without terrestrial coverage, expanding O2’s reach from 89% to 95% of Britain’s landmass.

Under the rollout, compatible Samsung devices automatically connect to Starlink satellites when users move beyond traditional mobile coverage, according to Reuters.

The service initially supports text messaging along with apps such as WhatsApp, Facebook Messenger, Google Maps and weather tools. O2 is pricing the add-on at £3 per month.

By leveraging Starlink’s satellite infrastructure, O2 can deliver connectivity in remote and rural regions without building additional ground towers. The move represents another step in Starlink’s push beyond fixed broadband and into direct-to-device mobile services.

Virgin Media O2 chief executive Lutz Schuler shared his thoughts about the Starlink partnership. “By launching O2 Satellite, we’ve become the first operator in Europe to launch a space-based mobile data service that, overnight, has brought new mobile coverage to an area around two-thirds the size of Wales for the first time,” he said.

Satellite-based mobile connectivity is gaining traction globally. In the U.S., T-Mobile has launched a similar satellite-to-cell offering. Meanwhile, Vodafone has conducted satellite video call tests through its partnership with AST SpaceMobile last year.

For Starlink, the O2 agreement highlights how its network is increasingly being integrated into national telecom systems, enabling standard smartphones to connect directly to satellites without specialized hardware.