News

Rivian shows off new details at NY Auto Show before heading home

Rivian has been on a promotional whirlwind since the company came out of the shadows last year at the 2018 LA Auto Show, and with it, the all-electric adventure company’s attendance at the New York International Auto Show this year has now generated quite a few more vehicle detail revelations from interviews posted online by show attendees.

Thanks for the warm welcome, #NY! See you again soon. pic.twitter.com/RNTHh5bYy3

— Rivian (@Rivian) April 28, 2019

Brian Gase, Rivian’s Chief Engineer of Special Projects, appeared in a number of videos describing features of the R1T truck and R1S SUV that are unique and otherwise not commonly known about the vehicles.

First, the number of storage compartments were one of the smaller details that stood out. In the R1T, the back passenger seats have bins underneath the cushions, and both vehicles have sliding bins underneath the driver and shotgun seats. A full size spare tire is in the R1T bed and can be removed for even more storage if needed, but to save space for storage and its usable third row seating, the R1S has an inflatable spare tire under the trunk floor.

Rivian’s plans for interior color options were also mentioned, and there are three: Forest Edge (the green inside the demo R1T), Lunar Rock (the grey inside the demo R1S), and black. Additional premium options will be offered for interior fabrics which are already a blend of traditional materials and the types of fabrics you’d find in durable outerwear. The cabins also feature quad-zone climate control.

On the performance side, 170 kW of independent power is provided to each wheel which also provides for torque vectoring. The approximately 750-800 total horsepower in each vehicle works out to about 180 hp per wheel from each of the four motors.

- Rivian R1S SUV at New York Auto Show 2019. | Image: Dacia J. Ferris/Teslarati

- Rivian R1S SUV at New York Auto Show 2019. | Image: Dacia J. Ferris/Teslarati

- Rivian R1S SUV at New York Auto Show 2019. | Image: Dacia J. Ferris/Teslarati

Rivian’s high density battery pack, complete with a thermal control system that adapts according to charging and driving behavior, then powers the whole package. A giant battery might not seem like it would be a great choice for four-wheel adventures, but Rivian has tightly encased its vehicles’ power supply using advanced materials science to be capable of wading up to three feet of water. Since there’s no engine requiring air, only buoyancy prevents a deeper crawl.

Progress in the automotive self-driving arena is moving fast, and Rivian has already integrated that reality into the R1T and R1S designs. The camera and radar hardware on production vehicles will be capable of Level 3 autonomous driving that’s upgradable via over-the-air software updates. Rivian’s initial vehicles will ship with Level 2 capabilities and use data accumulated from its customers’ driving sent to the cloud to develop its Level 3 transition, very similar to Tesla’s strategy. Previously, Rivian has additionally suggested Jurassic Park-style autonomous tours might be available for owners wanting a guided, real-world adventure experience.

Rivian has several test mules on the road using F-150 bodies, but only one production design model of each car has been made to be used at shows and in videos.

Finally, you might know that Rivian was founded in 2009 by CEO RJ Scaringe, an MIT graduate (he holds an MS and PhD in mechanical engineering), but it seems lesser known how his personal life story is imprinted right in the company’s name. Scaringe grew up near the Indian River region of Florida, and that’s where the Rivian name is derived (RIV(er)-(Ind)IAN).

BACK TO BASICS

All of those tidbits will now join the overall more well known features driving the appeal of Rivian’s R1T truck and R1S SUV. A recap of the basics may put them into a better perspective still.

On battery packs, Rivian’s focus on outdoor adventure means that decent battery capacity and range are key components if their product ideas are to be successful, and their much-touted 180 kWh battery “megapack” boasting a 400+ mile range seems to fit that bill. The mid-range 135 kWh pack claiming a 300 mile range is also decent for well-planned routes, and it just so happens to have a fun number of 2170 battery cells – 7,777 exactly if you count the battery inside the in-door flashlight. The 135 kWh battery pack vehicles are also the versions that will do 0-60 mph in 3 seconds, although all versions are speed limited to 125 mph. A lower end 105 kWh pack with a 230 mile range will be produced last, per the usual new EV strategy of offering premium cars before more affordable variations.

https://twitter.com/PrincessDeixa/status/1118957811285811200

The first R1S and R1T deliveries are set for the end of 2020, and Rivian is currently taking preorder deposits to reserve their upcoming vehicles. Purchase prices will start at $69,000 for the R1T and $72,500 for the R1S before tax incentives.

Aside from being first to unveil a near-production all-electric pickup truck, two other features in Rivian’s electric cars have stood out. First, the quad-motor “skateboard” chassis that forms the base of current and future vehicles centralizes and simplifies Rivian’s innovations into a flexible electric car platform for its future product lines. This feature has also drawn interest from big-name partners like GM and Ford, the latter having just signed a $500 million deal with Rivian to use its tech to develop their first all-electric vehicle.

A somewhat new tidbit about the skateboard platform is the size difference between the R1S version and the R1T version. The R1S chassis is 375 mm shorter than the R1T to boost its off-road capabilities. Both vehicles’ towing capacity is around 11,000 pounds.

The second well-known feature about Rivian’s two outdoor-purposed vehicles is the amount of storage space incorporated into the designs. The frunks are spacious with a 330 mL capacity, and the R1T truck has what they call a ‘gear tunnel’, which is essentially a large cargo space tunneled through the lower middle of the truck’s cab. It looks to have the makings of the next social media photo craze, but that’s obviously speculation.

- Rivian R1T truck at the NY Auto Show 2019. | Image: Dacia J. Ferris/Teslarati

- Rivian R1T truck at the NY Auto Show 2019. | Image: Dacia J. Ferris/Teslarati

Both the frunk and tailgates have powered open and close functions for ease of use, the tailgate opening a full 180 degrees, and the bed has a powered built-in tonneau cover strong enough to support loading. Also included in the truck bed are 110V power outlets, onboard air, lights to illuminate the bed, and a gear cable that’s electronically connected to the vehicle. If the cable is cut or disconnected for any reason, the owner receives a notification on their Rivian app.

Other details to mention are the electrochromatic glass roof built into both the R1T and R1S that can change color on demand, specifically in response to outside weather and light conditions, and the daytime running lights that also act as turn signals and charging status indicator lights. A charging status indicator is also in the back of the vehicles.

Check these #rivian R1T features out! The sun roof changing colors and the height adjustable air springs in action! #NYautoshow2019 #electricvehicles #electrictruck #truck pic.twitter.com/Wc517rt8dM

— DJ (@PrincessDeixa) April 18, 2019

The last major Rivian feature to mention is the adaptable air suspension. Both vehicles’ ride height can be easily raised or lowered depending on road conditions to adjust comfort and handling characteristics. There’s even a ‘kneel’ mode to ease vehicle entry and exit.

STILL TO COME

Rivian’s R1T truck and R1S SUV already have enough innovative details to drive their consumer appeal as-is, but the company has even more developments going on in the background. Recently published patent applications have revealed a modular system for swapping out vehicle components based on activity need and a digital jerry can to extend the battery range even further for longer trips away from a charging network.

Additionally, trademark applications filed with the US Patent and Trademark Office have teased several other products in the works with names like 1C, 1A, and 2R. An interview with RJ Scaringe published by Bloomberg confirmed that Rivian is indeed working on six other products.

Details surrounding Rivian’s plans for a service network are still slim despite the abundance of other important information about the Michigan-based company. The R1S and R1T vehicles will use CCS charging ports, but whether a charging partnership or a home-grown effort is planned remains to be seen.

A NY International Auto Show attendee recently posted on Reddit details gathered from speaking with Rivian’s team, including Scaringe, and indications were made that the company is interested in using Tesla’s Superchargers, although they’ve had some difficulties with the effort. A potential roadshow tour offering test drives was also mentioned.

A couple of the Rivian video interviews can be watched below:

News

Tesla Full Self-Driving v14.2.2.5 might be the most confusing release ever

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

Tesla Full Self-Driving v14.2.2.5 hit my car back on Valentine’s Day, February 14, and since I’ve had it, it has become, in my opinion, the most confusing release I’ve ever had.

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

It has been about three weeks of driving on v14.2.2.5; I’ve used it for nearly every mile traveled since it hit my car. I’ve taken short trips of 10 minutes or less, I’ve taken medium trips of an hour or less, and I’ve taken longer trips that are over 100 miles per leg and are over two hours of driving time one way.

These are my thoughts on it thus far:

Speed Profiles Are a Mixed Bag

Speed Profiles are something Tesla seems to tinker with quite frequently, and each version tends to show a drastic difference in how each one behaves compared to the previous version.

I do a vast majority of my FSD travel using Standard and Hurry modes, although in bad weather, I will scale it back to Chill, and when it’s a congested city on a weekend or during rush hour, I’ll throw it into Mad Max so it takes what it needs.

Early on, Speed Profiles really felt great. This is one of those really subjective parts of the FSD where someone might think one mode travels too quickly, whereas another person might see the identical performance as too slow or just right.

To me, I would like to see more consistency from release to release on them, but overall, things are pretty good. There are no real complaints on my end, as I had with previous releases.

In a past release, Mad Max traveled under the speed limit quite frequently, and I only had that experience because Hurry was acting the same way. I’ve had no instances of that with v14.2.2.5.

Strange Turn Signal Behavior

This is the first Full Self-Driving version where I’ve had so many weird things happen with the turn signals.

Two things come to mind: Using a turn signal on a sharp turn, and ignoring the navigation while putting the wrong turn signal on. I’ve encountered both things on v14.2.2.5.

On my way to the Supercharger, I take a road that has one semi-sharp right-hand turn with a driveway entrance right at the beginning of the turn.

Only recently, with the introduction of v14.2.2.5, have I had FSD put on the right turn signal when going around this turn. It’s obviously a minor issue, but it still happens, and it’s not standard practice:

How can we get Full Self-Driving to stop these turn signals?

There’s no need to use one here; the straight path is a driveway, not a public road. The right turn signal here is unnecessary pic.twitter.com/7uLDHnqCfv

— TESLARATI (@Teslarati) February 28, 2026

When sharing this on X, I had Tesla fans (the ones who refuse to acknowledge that the company can make mistakes) tell me that it’s a “valid” behavior that would be taught to anyone who has been “professionally trained” to drive.

Apparently, if you complain about this turn signal, you are also claiming you know more than Tesla engineers…okay.

Nobody in their right mind has ever gone around a sharp turn when driving their car and put on a signal when continuing on the same road. You would put a left turn signal on to indicate you were turning into that driveway if that’s what your intention was.

Like I said, it’s a totally minor issue. However, it’s not really needed, and nor is it normal. If I were in the car with someone who was taking a simple turn on a road they were traveling, and they signaled because the turn was sharp, I’d be scratching my head.

I’ve also had three separate instances of the car completely ignoring the navigation and putting on a signal that is opposite to what the routing says. Really quite strange.

Parking Performance is Still Underwhelming

Parking has been a complaint of mine with FSD for a long time, so much so that it is pretty rare that I allow the vehicle to park itself. More often than not, it is because I want to pick a spot that is relatively isolated.

However, in the times I allow it to pull into a spot, it still does some pretty head-scratching things.

Recently, it tried to back into a spot that was ~60% covered in plowed snow. The snow was piled about six feet high in a Target parking lot.

A few days later, it tried backing into a spot where someone failed the universal litmus test of returning their shopping cart. Both choices were baffling and required me to manually move the car to a different portion of the lot.

I used Autopark on both occasions, and it did a great job of getting into the spot. I notice that the parking performance when I manually choose the spot is much better than when the car does the entire parking process, meaning choosing the spot and parking in it.

It’s Doing Things (For Me) It’s Never Done Before

Two things that FSD has never done before, at least for me, are slow down in School Zones and avoid deer. The first is something I usually take over manually, and the second I surprisingly have not had to deal with yet.

I had my Tesla slow down at a school zone yesterday for the first time, traveling at 20 MPH and not 15 MPH as the sign suggested, but at the speed of other cars in the School Zone. This was impressive and the first time I experienced it.

I would like to see this more consistently, and I think School Zones should be one of those areas where, no matter what, FSD will only travel the speed limit.

Last night, FSD v14.2.2.5 recognized a deer in a roadside field and slowed down for it:

🚨 Cruising home on a rainy, foggy evening and my Tesla on Full Self-Driving begins to slow down suddenly

FSD just wanted Mr. Deer to make it home to his deer family ❤️ pic.twitter.com/cAeqVDgXo5

— TESLARATI (@Teslarati) March 4, 2026

Navigation Still SUCKS

Navigation will be a complaint until Tesla proves it can fix it. For now, it’s just terrible.

It still has not figured out how to leave my neighborhood. I give it the opportunity to prove me wrong each time I leave my house, and it just can’t do it.

It always tries to go out of the primary entrance/exit of the neighborhood when the route needs to take me left, even though that exit is a right turn only. I always leave a voice prompt for Tesla about it.

It still picks incredibly baffling routes for simple navigation. It’s the one thing I still really want Tesla to fix.

Investor's Corner

Tesla gets tip of the hat from major Wall Street firm on self-driving prowess

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet,” BoA wrote.

Tesla received a tip of the hat from major Wall Street firm Bank of America on Wednesday, as it reinitiated coverage on Tesla shares with a bullish stance that comes with a ‘Buy’ rating and a $460 price target.

In a new note that marks a sharp reversal from its neutral position earlier in 2025, the bank declared Tesla’s Full Self-Driving (FSD) technology the “leading consumer autonomy solution.”

Analysts highlighted Tesla’s camera-only architecture, known as Tesla Vision, as a strategic masterstroke. While technically more challenging than the multi-sensor setups favored by rivals, the vision-based approach is dramatically cheaper to produce and maintain.

This cost edge, combined with Tesla’s rapidly expanding real-world data engine, positions the company to scale robotaxis far more profitably than competitors, BofA argues in the new note:

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet.”

The bank now attributes roughly 52% of Tesla’s total valuation to its Robotaxi ambitions. It also flagged meaningful upside from the Optimus humanoid robot program and the fast-growing energy storage business, suggesting the auto segment’s recent headwinds, including expired incentives, are being eclipsed by these higher-margin opportunities.

Tesla’s own data underscores exactly why Wall Street is waking up to FSD’s potential. According to Tesla’s official safety reporting page, the FSD Supervised fleet has now surpassed 8.4 billion cumulative miles driven.

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

That total ballooned from just 6 million miles in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and a staggering 4.25 billion in 2025 alone. In the first 50 days of 2026, owners added another 1 billion miles — averaging more than 20 million miles per day.

This avalanche of real-world, camera-captured footage, much of it on complex city streets, gives Tesla an unmatched training dataset. Every mile feeds its neural networks, accelerating improvement cycles that lidar-dependent rivals simply cannot match at scale.

Tesla owners themselves will tell you the suite gets better with every release, bringing new features and improvements to its self-driving project.

The $460 target implies roughly 15 percent upside from recent trading levels around $400. While regulatory and safety hurdles remain, BofA’s endorsement signals growing institutional conviction that Tesla’s data advantage is not hype; it’s a tangible moat already delivering billions of miles of proof.

News

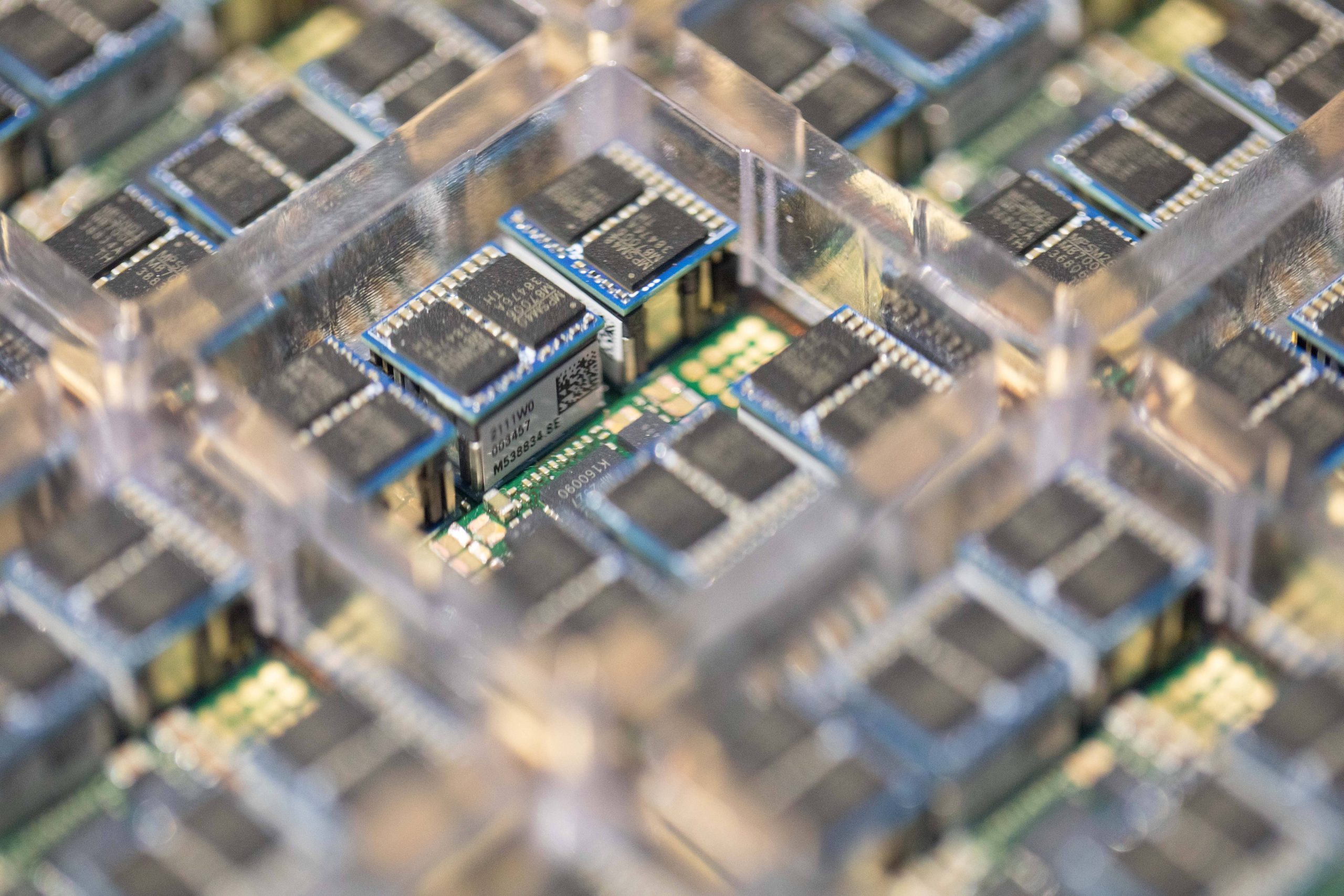

Tesla to discuss expansion of Samsung AI6 production plans: report

Tesla has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla is reportedly discussing an expansion of its next-generation AI chip supply deal with Samsung Electronics.

As per a report from Korean industry outlet The Elec, Tesla purchasing executives are reportedly scheduled to meet Samsung officials this week to negotiate additional production volume for the company’s upcoming AI6 chip.

Industry sources cited in the report stated that Tesla is pushing to increase the production volume of its AI6 chip, which will be manufactured using Samsung’s 2-nanometer process.

Tesla previously signed a long-term foundry agreement with Samsung covering AI6 production through December 31, 2033. The deal was reportedly valued at about 22.8 trillion won (roughly $16–17 billion).

Under the existing agreement, Tesla secured approximately 16,000 wafers per month from the facility. The company has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla purchasing executives are expected to discuss detailed supply terms during their visit to Samsung this week.

The AI6 chip is expected to support several Tesla technologies. Industry sources stated that the chip could be used for the company’s Full Self-Driving system, the Optimus humanoid robot, and Tesla’s internal AI data centers.

The report also indicated that AI6 clusters could replace the role previously planned for Tesla’s Dojo AI supercomputer. Instead of a single system, multiple AI6 chips would be combined into server-level clusters.

Tesla’s semiconductor collaboration with Samsung dates back several years. Samsung participated in the design of Tesla’s HW3 (AI3) chip and manufactured it using a 14-nanometer process. The HW4 chip currently used in Tesla vehicles was also produced by Samsung using a 5-nanometer node.

Tesla previously planned to split production of its AI5 chip between Samsung and TSMC. However, the company reportedly chose Samsung as the primary partner for the newer AI6 chip.