SpaceX

SpaceX to launch replacement satellite two years after fateful Falcon 9 failure

On September 1st, 2016, SpaceX’s Falcon 9 rocket suffered a catastrophic anomaly during a static fire test, causing an explosion that completely destroyed the vehicle, the launch pad, and Spacecom’s $200M Amos-6 satellite. This ultimately triggered a months-long investigation into what CEO Elon Musk described as “the most difficult and complex failure [SpaceX has] had in 14 years.”

More than two years and 41 successful consecutive launches later, SpaceX and Israeli satellite operator Spacecom are reportedly aiming to launch Amos-6’s replacement – Amos-17 – as early as the end of May, around three months from now.

Business in Brief: Spacecom says it will launch Amos 17 satellite within four months https://t.co/nkIFd7DzHJ

— Haaretz.com (@haaretzcom) February 25, 2019

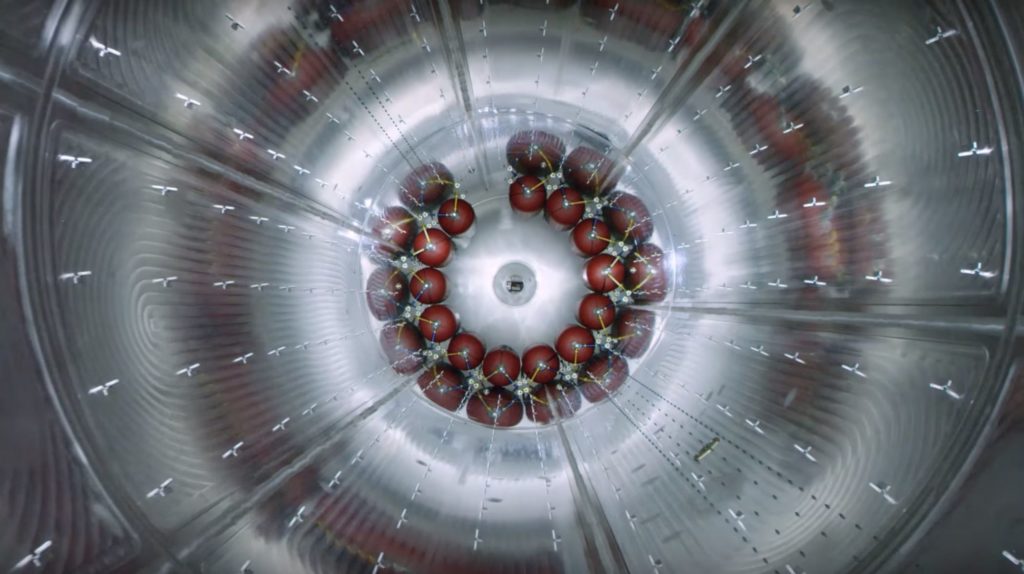

Nearly two and a half years distant, the reverberations of SpaceX’s Amos-6 Falcon 9 failure continue to reverberate loudly. Aside from demanding changes to the operational procedures used to launch Falcon 9 and forcing an extensive critical analysis of design, production, and qualification methods, SpaceX has spent countless resources pursuing an extensive redesign of the component pointed at as the primary source of the explosion that destroyed Falcon 9. Known as composite overwrapped pressure vessels (COPVs), SpaceX uses the bottles to store extremely high-pressure helium (5000+ psi, 340+ bar) to pressurize Falcon 9’s RP-1 and oxygen tanks, as well as nitrogen to power its cold-gas maneuvering thrusters.

According to a failure analysis performed by SpaceX with NASA, the USAF, the NTSB, and the FAA, it was concluded that the cause could be traced back to a complex series of events centered around those helium COPVs. Meant to be the first mission to utilize subcooled propellant and oxidizer, the extreme cold in the upper stage LOx tank caused solid oxygen to form on the outside of the COPVs located inside it. While complex, the gist was that liquid (and perhaps solid) oxygen could have formed around the outside of the COPV, potentially finding its way in between the carbon fiber wrappings, creating a buckle in the fibers, and ultimately causing fibers to break. Near the end of this process, those breaking fibers could have created a spark or breached the helium tank, instantaneously overpressurizing the upper stage and causing an explosion.

NASA’s Aerospace Safety Advisory Panel (ASAP) and NASA itself have aired concerns about those COPVs since 2016, triggering an extraordinarily comprehensive program of testing, characterization, and redesign of the COPVs SpaceX uses. They have now successfully flown on 3-4 Falcon 9 launches under the same expedited propellant loading conditions that an identical rocket will undergo in preparation for Crew Dragon launches. CEO Elon Musk spent several minutes discussing the redesigned COPVs in a May 2018 press conference and did not mince words when he described them as “by far the most advanced pressure vessel[s] ever developed by humanity.”

“The amount of testing and research that’s gone into COPV safety is gigantic. This is by far the most advanced pressure vessel ever developed by humanity. It’s nuts. And I’ve personally gone over the test design, I’ve lost count how many times. But the top engineering minds at SpaceX have agonized over this. We’ve tested the living daylights out of it. We’ve been in deep, deep discussions with NASA about this. And I think we’re in a good situation.” – SpaceX CEO Elon Musk, May 2018

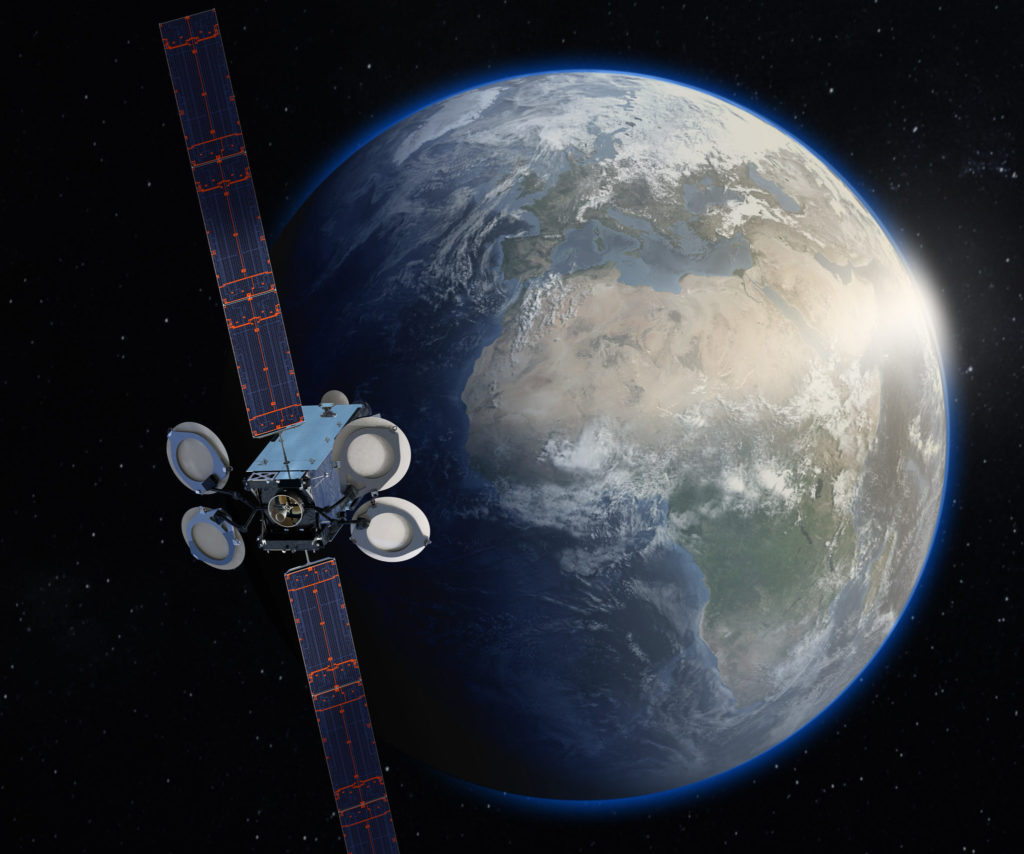

NASA and ASAP concerns have since been alleviated, culminating on February 22nd with an official announcement that NASA was ready for SpaceX to conduct the first uncrewed launch of its Crew Dragon spacecraft on March 2nd. It’s thus almost poetic that customer Spacecom chose the same week to announce a target date for the Falcon 9 launch of a satellite built to replace the destroyed Amos-6, known as Amos-17. Soon after the Amos-6 disaster, Spacecom settled on a free SpaceX launch contract for a future satellite instead of an immediate $50M payout. Procured for around $160M, SpaceX is reportedly targeting the launch of the Boeing-built satellite during the week of May 27th, likely from Launch Complex 40 (LC-40) – the same pad that suffered extensive damage during the September 2016 anomaly.

- Spacecom’s Boeing-built Amos-17 satellite. (Boeing)

- Falcon 9 shows off some of its COPVs in a tour of SpaceX’s Hawthorne factory. (SpaceX)

- An impressive view of Crew Dragon (DM-1), Falcon 9 B1051, and its upper stage. (SpaceX)

Since Amos-6, SpaceX’s record of reliability has been effectively spotless and now stands at an impressive 41 consecutive successful launches, including Falcon Heavy’s February 2018 debut. Aside from the sheer volume of launches SpaceX performed in a little over two years, the company has pushed full speed ahead towards its goal of routinely reusing Falcon 9 boosters. Less than 24 months after the first commercial reuse, SpaceX has landed Falcon 9 boosters 34 times and reused them 20 times, numbers that are only likely to grow in 2019.

Set to occur shortly after the planned launch debuts of Crew Dragon and Falcon Heavy (commercially), SpaceX will hopefully be able to place Amos-17 in a healthy orbit and thus effectively retire the Amos-6 saga before the second half of 2019.

Check out Teslarati’s newsletters for prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes!

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.

Elon Musk

SpaceX pursues 5G-level connectivity with Starlink Mobile V2 expansion

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system.

SpaceX has previewed a major upgrade to Starlink Mobile, outlining next-generation satellites that aim to deliver significantly higher capacity and full 5G-level connectivity directly to mobile phones.

The update comes as Starlink rebrands its Direct-to-Cell service to Starlink Mobile, positioning the platform as a scalable satellite-to-mobile solution that’s integrated with global telecom partners.

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system. The company also noted that the new V2 satellites are designed to provide significantly higher throughput capability compared to its current iteration.

“The next generation of Starlink Mobile satellites – V2 – will deliver full cellular coverage to places never thought possible via the highest performing satellite-to-mobile network ever built.

“Driven by custom SpaceX-designed silicon and phased array antennas, the satellites will support thousands of spatial beams and higher bandwidth capability, enabling around 20x the throughput capability as compared to a first-generation satellite,” SpaceX wrote in its official Starlink Mobile page.

Thanks to the higher bandwidth of Starlink Mobile, users should be able to stream, browse the internet, use high-speed apps, and enjoy voice services comparable to terrestrial cellular networks.

In most environments, Starlink says the upgraded system will enable full 5G cellular connectivity with a user experience similar to existing ground-based networks.

The satellites function as “cell towers in space,” using advanced phased-array antennas and laser interlinks to integrate with terrestrial infrastructure in a roaming-like architecture.

“Starlink Mobile works with existing LTE phones wherever you can see the sky. The satellites have an antenna that acts like a cellphone tower in space, the most advanced phased array antennas in the world that connect seamlessly over lasers to any point in the globe, allowing network integration similar to a standard roaming partner,” SpaceX wrote.

Starlink Mobile currently operates with approximately 650 satellites in low-Earth orbit and is active across more than 32 countries, representing over 1.7 billion people through partnerships with mobile network operators. Starlink Mobile’s current partnerships span North America, Europe, Asia, Africa, and Oceania, allowing reciprocal access across participating nations.