SpaceX has confirmed that the two large propellant tanks now present at its Boca Chica, Texas facilities will likely to be the last major ground tanks needed to enable the first test flights of the upper stage of its next-gen BFR rocket, known as the Big Falcon Spaceship (BFS).

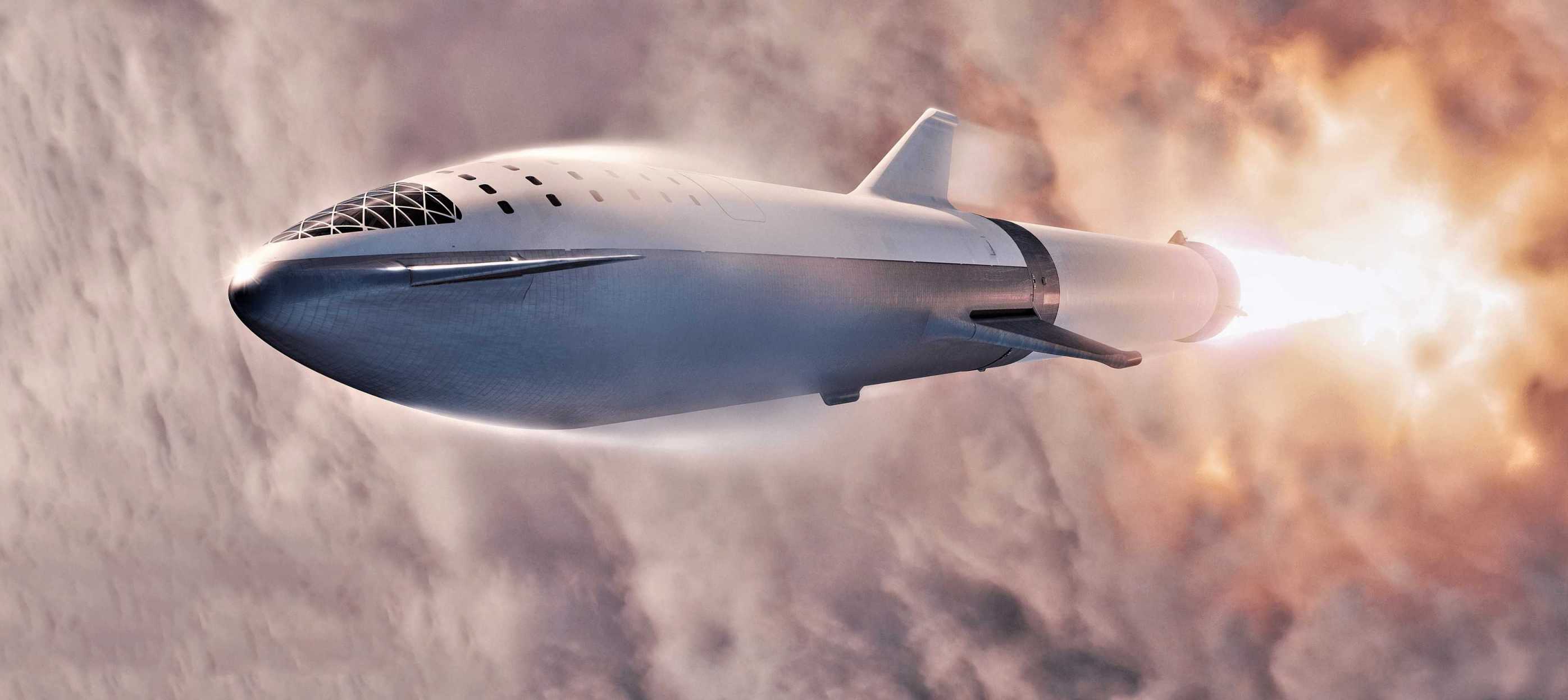

Expected to begin as soon as late 2019, SpaceX executives have recently reiterated plans for a campaign of hop tests for the first full-scale spaceship prototype, in which the ship will follow in the footsteps of its Falcon 9-based Grasshopper and F9R predecessors.

https://twitter.com/krgv_mike/status/1055748966619537408

In a comment provided to a number of local outlets, SpaceX Communications Specialist Sean Pitt stated this about the recent arrival of a second large propellant storage tank at the company’s prospective South Texas test and launch facilities.

“The ongoing construction of our launch pad in South Texas is proceeding well. SpaceX has now received the final major ground system tank needed to support initial test flights of the Big Falcon Spaceship.” – Sean Pitt, SpaceX

While there may have been some slight uncertainty before, this official statement confirms beyond the shadow of a doubt that SpaceX is actively and rapidly preparing its South Texas property for a future of BFR-related tests, spaceship hops, and perhaps even launches.

Same dance, different hops

Unlike Falcon 9’s Grasshopper and F9R reusability development programs, SpaceX’s BFS hop test campaign is likely going to be much more aggressive in order to gather real flight-test data on new technologies ranging from unfamiliar aerodynamic control surfaces (wings & fins vs. grid fins), all-composite propellant tanks (Falcon uses aluminum-lithium), a 9m-diameter vehicle versus Falcon’s 3.7m, a massive tiled heat-shield likely to require new forms of thermal protection, and entirely new regimes of flight (falling like a skydiver rather than Falcon 9’s javelin-style attitude) – to name just a handful.

To fully prove out or at least demonstrate those new technologies, BFS hop testing is likely to be better described as “flight testing”, whereby the spaceship launches vertically but focused primarily on regimes where horizontal velocity is far more important than vertical velocity.

“But by ‘hopper test,’ I mean it’ll go up several miles and then come down. The ship will – the ship is capable of a single stage to orbit if you fully load the tanks. So we’ll do flights of increasing complexity. We really want to test the heat shield material. So I think we’ll fly out, turn around, accelerate back real hard and come in hot to test the heat shield because we want to have a highly reusable heat shield that’s capable of absorbing the heat from interplanetary entry velocities, which is really tricky.” – CEO Elon Musk, October 2017

Focusing on the important things (for fully-reusable rockets)

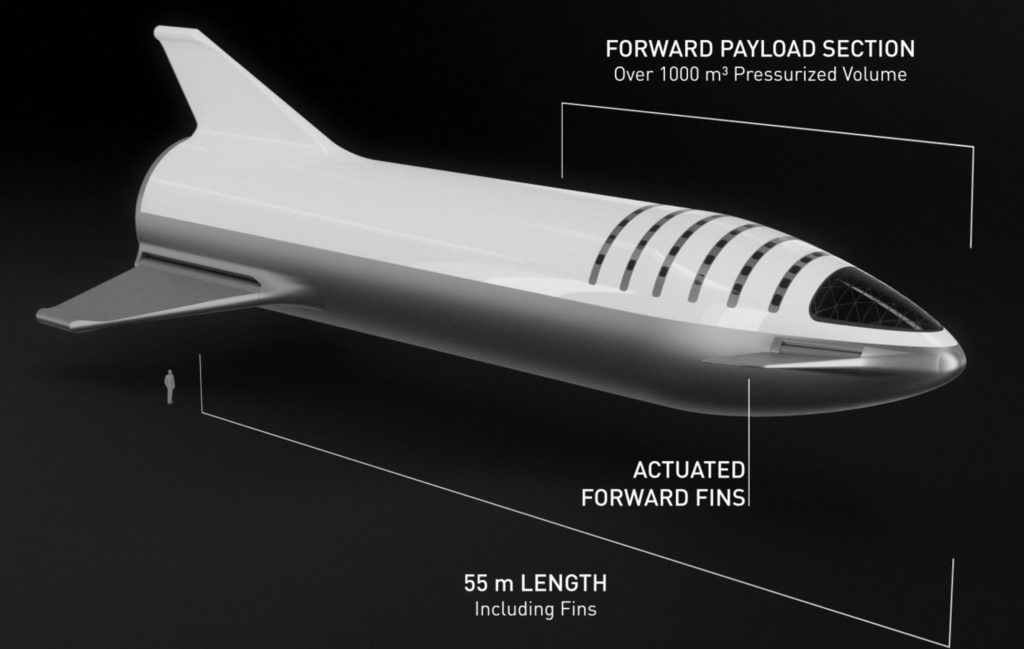

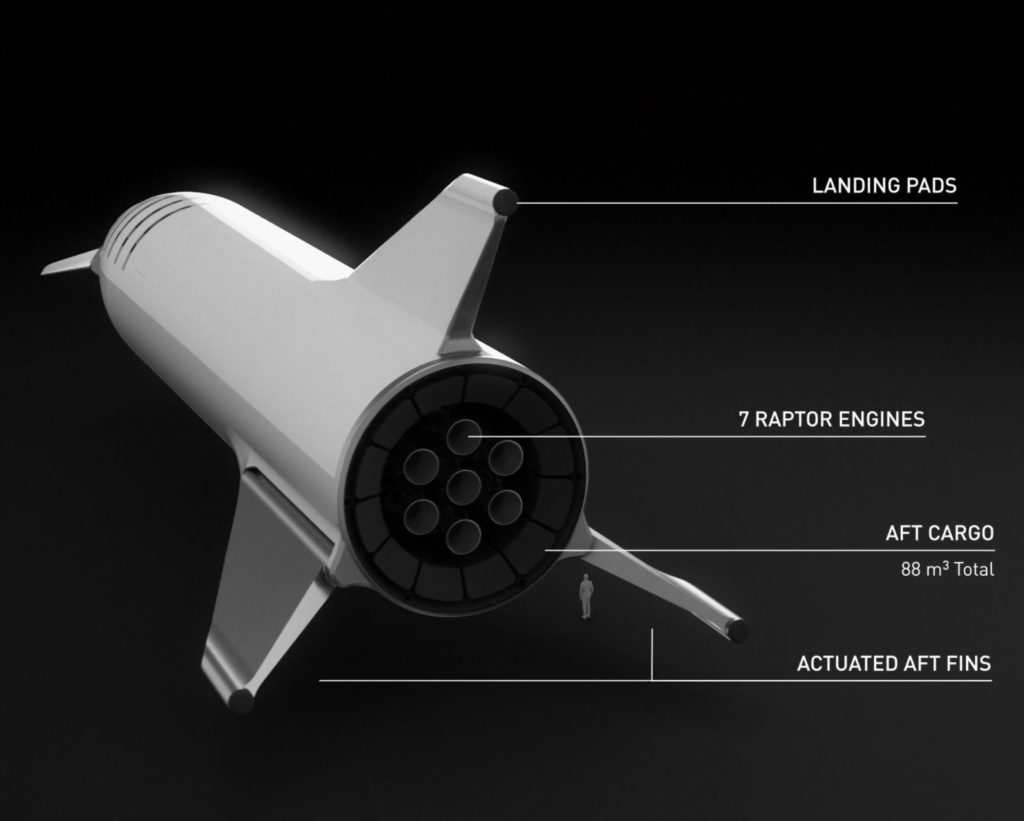

SpaceX does has significant familiarity with the general style of testing expected to be used to prove out its next-gen spaceship, a major department from anything the company has yet built or flown. Updated in September 2018 by CEO Elon Musk, the craft’s most recent design iteration is reportedly quite close to being finalized. That near-final design prominently features a trio of new aft fins (two able to actuate as control surfaces), two forward canards, and an updated layout of seven Raptor engines.

Critically, SpaceX has decided to commonize BFR’s main propulsion, choosing to skip the performance benefits of a vacuum-optimized Raptor variant for the simplicity and expediency of exclusively using sea level Raptors on both the booster and spaceship. This decision is ultimately strategic and well-placed: rather than concerning early-stage development with the inclusion of a second major branch of onboard propulsion, the company’s engineers and technicians can place their focus almost entirely on a one-size-fits-all version of BFR with plenty of room for upgrades down the road.

- BFS seen standing vertically on the pads of its tripod fins. (SpaceX)

- (SpaceX)

- A better view. (SpaceX)

- BFR’s booster and spaceship separate a few minutes after launch. (SpaceX)

With a rocket as large as BFR and a sea level engine already as efficient as Raptor, the performance downgrade wrought by the initial removal of Raptor Vacuum (RVac) is scarcely more than a theoretical diversion. The specific performance numbers remain to be seen but will likely be greater than 100 metric tons (~220,000 lbs) to low Earth orbit (LEO). Past a certain point, however, the actual performance to LEO and beyond is almost irrelevant, at least from a perspective of individual launches. The paradigm SpaceX is clearly already interrogating is one where the cost of individual launches is so low relative to today’s expendable launch pricing ($5,000-20,000/kg to LEO) that it will almost be anachronistic to design or work with a single-launch-limit in mind, a limit that is just shy of a natural law in the spaceflight industries of today.

Because SpaceX has already demonstrated expertise in vertically launching, landing, and generally controlling large rockets, the main challenges faced with BFR are more operational than purely technical. To be clear, the technical challenges are still immense, but successfully solving those challenges by no means guarantees that the aircraft-like operational efficiency needed for BFR to succeed can or will be fully realized.

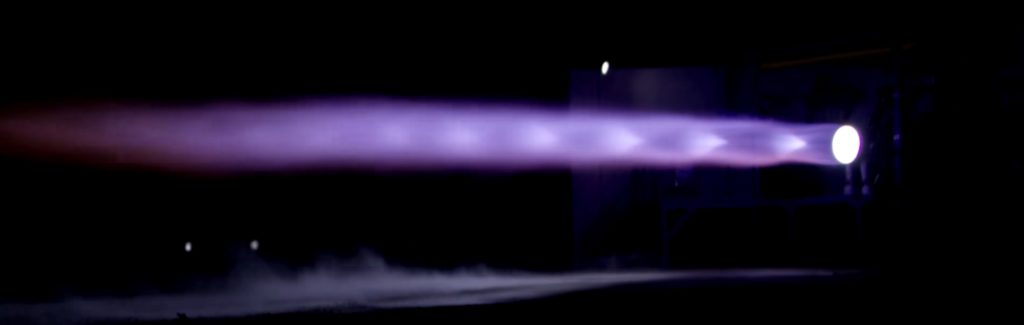

- A gif of Raptor throttling over the course of a 90+ second static-fire test in McGregor, Texas. (SpaceX)

- SpaceX’s subscale Raptor engine has completed more than 1200 seconds of testing in less than two years. (SpaceX)

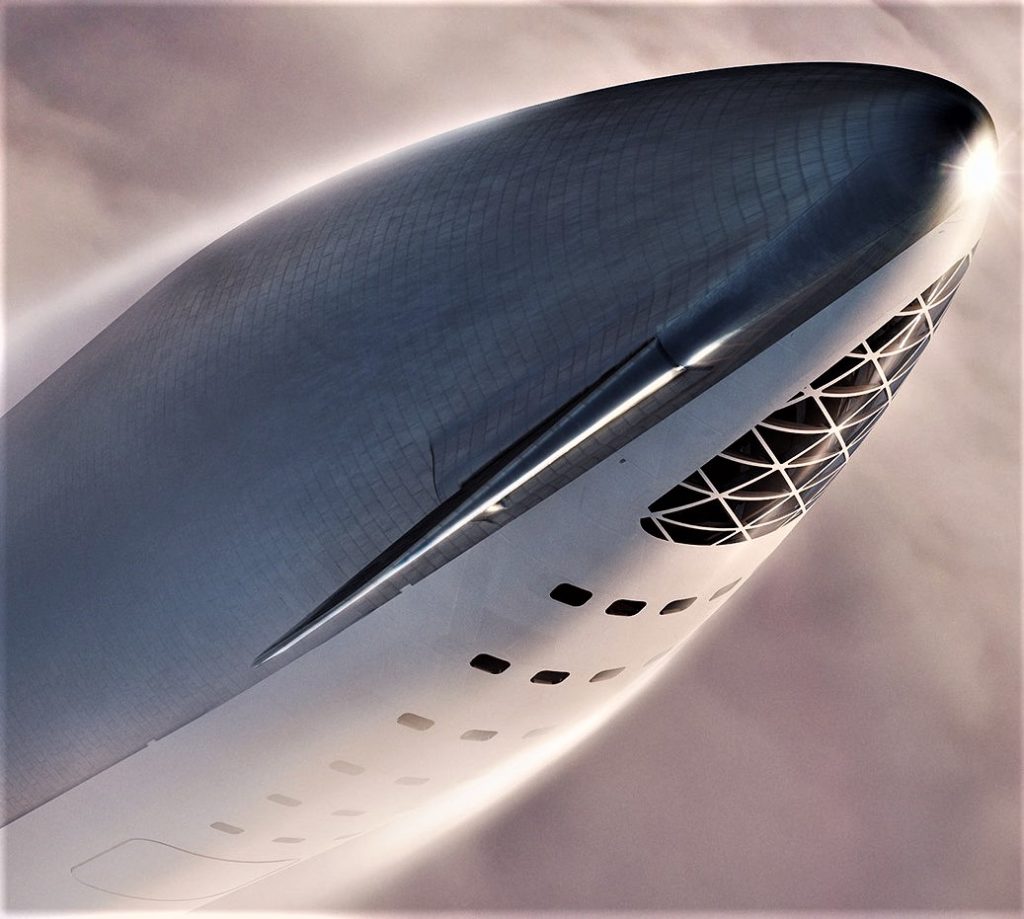

- A closeup of BFS’ nose section, featuring impressively varied tile-sizes, joining methods, and extremely precise curves on the interface between canard wings and the hull. (SpaceX)

In 2016, Musk pegged SpaceX’s cost goals for a BFR-style fully-reusable rocket at less than $1M per launch for booster and spaceship maintenance alone, or $3.3M per launch with amortization (paying for the debt/investment incurred to fund BFR’s development) and propellant estimates included. To realize those ambitious costs, SpaceX will effectively have to beat the expendable but similarly-sized Saturn V’s per-launch costs (~$700M) by a factor of 100 to 200 – more than two orders of magnitude – and SpaceX’s own Falcon 9 and Heavy launch costs (~$55M to $130M) by 20-50X.

To even approach those targets, SpaceX will need to learn how to launch Falcon and BFR near-autonomously with near-total and refurbishment-free reusability, while also developing and demonstrating orbital refueling capabilities that do not currently exist and rapidly maturing large-scale composite tankage and structures. None of those things require Raptor Vacuum.

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!

Elon Musk

Tesla investors will be shocked by Jim Cramer’s latest assessment

Jim Cramer is now speaking positively about Tesla, especially in terms of its Robotaxi performance and its perception as a company.

Tesla investors will be shocked by analyst Jim Cramer’s latest assessment of the company.

When it comes to Tesla analysts, many of them are consistent. The bulls usually stay the bulls, and the bears usually stay the bears. The notable analysts on each side are Dan Ives and Adam Jonas for the bulls, and Gordon Johnson for the bears.

Jim Cramer is one analyst who does not necessarily fit this mold. Cramer, who hosts CNBC’s Mad Money, has switched his opinion on Tesla stock (NASDAQ: TSLA) many times.

He has been bullish, like he was when he said the stock was a “sleeping giant” two years ago, and he has been bearish, like he was when he said there was “nothing magnificent” about the company just a few months ago.

Now, he is back to being a bull.

Cramer’s comments were related to two key points: how NVIDIA CEO Jensen Huang describes Tesla after working closely with the Company through their transactions, and how it is not a car company, as well as the recent launch of the Robotaxi fleet.

Jensen Huang’s Tesla Narrative

Cramer says that the narrative on quarterly and annual deliveries is overblown, and those who continue to worry about Tesla’s performance on that metric are misled.

“It’s not a car company,” he said.

He went on to say that people like Huang speak highly of Tesla, and that should be enough to deter any true skepticism:

“I believe what Musk says cause Musk is working with Jensen and Jensen’s telling me what’s happening on the other side is pretty amazing.”

Tesla self-driving development gets huge compliment from NVIDIA CEO

Robotaxi Launch

Many media outlets are being extremely negative regarding the early rollout of Tesla’s Robotaxi platform in Austin, Texas.

There have been a handful of small issues, but nothing significant. Cramer says that humans make mistakes in vehicles too, yet, when Tesla’s test phase of the Robotaxi does it, it’s front page news and needs to be magnified.

He said:

“Look, I mean, drivers make mistakes all the time. Why should we hold Tesla to a standard where there can be no mistakes?”

It’s refreshing to hear Cramer speak logically about the Robotaxi fleet, as Tesla has taken every measure to ensure there are no mishaps. There are safety monitors in the passenger seat, and the area of travel is limited, confined to a small number of people.

Tesla is still improving and hopes to remove teleoperators and safety monitors slowly, as CEO Elon Musk said more freedom could be granted within one or two months.

News

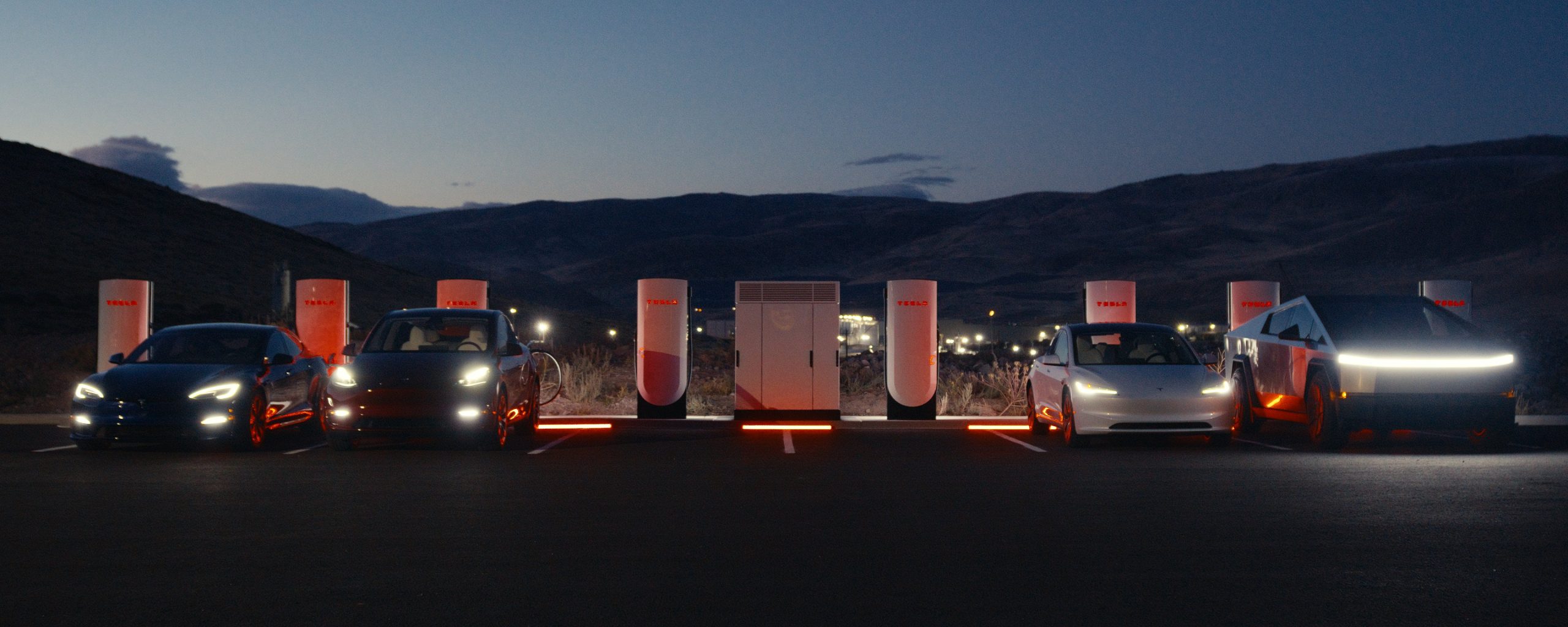

Tesla launches ultra-fast V4 Superchargers in China for the first time

Tesla has V4 Superchargers rolling out in China for the first time.

Tesla already has nearly 12,000 Supercharger piles across mainland China. However, the company just initiated the rollout of the ultra-fast V4 Superchargers in China for the first time, bringing its quick-charging piles to the country for the first time since their launch last year.

The first batch of V4 Superchargers is now officially up and running in China, the company announced in a post on Chinese social media outlet Weibo today.

The company said in the post:

“The first batch of Tesla V4 Superchargers are online. Covering more service areas, high-speed charging is more convenient, and six-layer powerful protection such as rain and waterproof makes charging very safe. Simultaneously open to non-Tesla vehicles, and other brands of vehicles can also be charged. There are more than 70,000 Tesla Superchargers worldwide. The charging network layout covers 100% of the provincial capitals and municipalities in mainland China. More V4 Superchargers will be put into use across the country. Optimize the charging experience and improve energy replenishment efficiency. Tesla will accompany you to the mountains, rivers, lakes, and seas with pure electricity!”

The first V4 Superchargers Tesla installed in China are available in four cities across the country: Shanghai, Zhejiang, Gansu, and Chongqing.

Credit: Tesla China

Tesla has over 70,000 Superchargers worldwide. It is the most expansive and robust EV charging network in the world. It’s the main reason why so many companies have chosen to adopt Tesla’s charging connector in North America and Europe.

In China, some EVs can use Tesla Superchargers as well.

The V4 Supercharger is capable of charging vehicles at speeds of up to 325kW for vehicles in North America. This equates to over 1,000 miles per hour of charging.

Elon Musk

Elon Musk hints at when Tesla could reduce Safety Monitors from Robotaxi

Tesla could be reducing Safety Monitors from Robotaxi within ‘a month or two,’ CEO Elon Musk says.

Elon Musk hinted at when Tesla could begin reducing Safety Monitors from its Robotaxis. Safety Monitors are Tesla employees who sit in the front passenger seat during the driverless rides, and are there to ensure safety for occupants during the earliest rides.

Tesla launched its Robotaxi fleet in Austin last Sunday, and after eight days, videos and reviews from those who have ridden in the driverless vehicles have shown that the suite is safe, accurate, and well coordinated. However, there have been a few hiccups, but nothing that has put anyone’s safety in danger.

A vast majority — close to all of the rides — at least according to those who have ridden in the Robotaxi, have been performed without any real need for human intervention. We reported on what was the first intervention last week, as a Safety Monitor had to step in and stop the vehicle in a strange interaction with a UPS truck.

Watch the first true Tesla Robotaxi intervention by safety monitor

The Tesla and UPS delivery truck were going for the same street parking space, and the Tesla began to turn into it. The UPS driver parallel parked into the spot, which was much smaller than his truck. It seemed to be more of an instance of human error instead of the Robotaxi making the wrong move. This is something that the driverless cars will have to deal with because humans are aggressive and sometimes make moves they should not.

The Safety Monitors have not been too active in the vehicles. After all, we’ve only seen that single instance of an intervention. There was also an issue with the sun, when the Tesla braked abnormally due to the glare, but this was an instance where the car handled the scenario and proceeded normally.

With the Robotaxi fleet operating impressively, some are wondering when Tesla will begin scaling back both the Safety Monitors and Teleoperators that it is using to ensure safety with these early rides.

CEO Elon Musk answered the inquiry by stating, “As soon as we feel it is safe to do so. Probably within a month or two.”

As soon as we feel it is safe to do so.

Probably within a month or two. We continue to improve the Tesla AI with each mile driven.

— Elon Musk (@elonmusk) June 30, 2025

Musk’s response seems to confirm that there will be fewer Teleoperators and Safety Monitors in the coming months, but there will still be some within the fleet to ensure safety. Eventually, that number will get to zero.

Reaching a point where Tesla’s Robotaxi is driverless will be another significant milestone for the company and its path to fully autonomous ride-sharing.

Eventually, Tesla will roll out these capabilities to consumer-owned vehicles, offering them a path to generate revenue as their car operates autonomously and completes rides.

For now, Tesla is focusing on perfecting the area of Austin where it is currently offering driverless rides for just $4.20 to a small group of people.

-

News5 days ago

News5 days agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

News2 weeks ago

News2 weeks agoTesla confirms massive hardware change for autonomy improvement

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk slams Bloomberg’s shocking xAI cash burn claims

-

News2 weeks ago

News2 weeks agoTesla China roars back with highest vehicle registrations this Q2 so far

-

News2 weeks ago

News2 weeks agoTesla features used to flunk 16-year-old’s driver license test

-

News2 weeks ago

News2 weeks agoTexas lawmakers urge Tesla to delay Austin robotaxi launch to September

-

News2 weeks ago

News2 weeks agoTesla dominates Cars.com’s Made in America Index with clean sweep

-

News2 weeks ago

News2 weeks agoTesla’s Grok integration will be more realistic with this cool feature