News

SpaceX’s Mr Steven gains upgraded arms to catch its first Falcon 9 fairings

SpaceX’s iconic Falcon 9 payload fairing recovery ship, known as Mr Steven, has been spotted in California’s Port of San Pedro having new arms installed with two cranes and a crew of SpaceX technicians. Aside from the sudden addition of dramatically different arm design, a large inflatable structure also took shape – seemingly overnight – right behind Mr Steven, the purpose of which is entirely unclear.

Incredibly, these massive new arms and their new equally large support struts and base plates have begun installation barely two weeks after Mr Steven took roost and had his old arms removed at SpaceX’s Berth 240 property. While the timeline of the arm and net upgrades – mentioned by CEO Elon Musk several weeks ago – was previously uncertain, the incredibly quick turnaround from old arm removal to new arm install suggests that SpaceX may, in fact, be aiming to have Mr Steven ready for recovery operations as early as Iridium-7, scheduled for launch on July 20th. In all likelihood, the fairing recovery vessel will be held up till the subsequent Vandenberg Air Force Base launch while a net with an area perhaps four times larger is custom-built for SpaceX.

A massive inflatable structure appeared out of nowhere at Berth 240 roughly four days after Teslarati photographer Pauline Acalin had last checked up on the facility. (Pauline Acalin)

Nevertheless, SpaceX’s speed rarely fails to surprise, and it’s entirely possible that a new, larger net was already ordered some time ago in preparation for the eventuality that Mr Steven’s first recovery mechanism was unsuccessful. Given the fact that at least two main arms and perhaps eight white, cylindrical struts have apparently been completed and are awaiting installation at Berth 240, it’s probable that the lead time on this new recovery mechanism stretches back at least several months, likely at least a month before Musk mentioned that Mr Steven would have its usable catching area grown “by a factor of [four]” in early June.

Yup, we are extending the net area by a factor of 4

— Elon Musk (@elonmusk) June 5, 2018

Closing the fairing recovery gap

With four times the net available to catch wayward Falcon 9 payload fairings, SpaceX may be able to finally close the gap between Mr Steven and the successful and routine recovery and reuse of the second of three main Falcon 9 (and Heavy) components. At roughly 10% of the total cost (not price) of a single-booster Falcon 9, the considerable effort being put into the recovery of carbon-composite payload fairings is in a way motivated more by manufacturing bottlenecks than by the money it will save SpaceX (somewhat less than $3m per half).

- Taken on Friday, these two photos show the new arm mounting brackets, installed on Mr Steven the week of July 2nd. (Pauline Acalin)

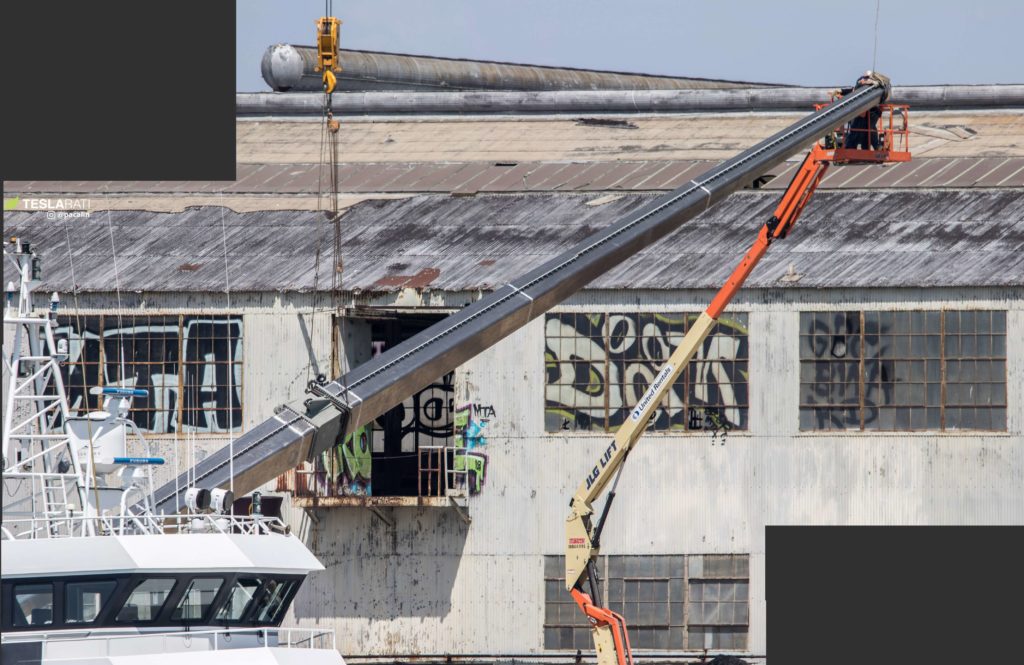

- Scarcely 48 hours later, an entirely new pear-shaped arm and two huge, circular struts were successfully installed, presumably the first of four sets. (Pauline Acalin)

- (Pauline Acalin)

SpaceX’s team of composite technicians and engineers will need to reliably fabricate as many as ~50 payload fairing halves in 2018, effectively one half each week

By recovering payload fairings before they touch the ocean surface, the company may – in one fell swoop – be able to dramatically reduce the operational expenditure required to sustain the annual production of dozens of Falcon fairings, each of which requires an inescapable and tediously slow stint in a massive autoclave, only a few of which can be squeeze into the company’s Hawthorne factory. As an example, SpaceX’s team of roughly 150 dedicated composite technicians and engineers will need to reliably fabricate as many as ~50 payload fairing halves – nearly a full half each week – to sustain SpaceX’s anticipated 2018 manifest of 24-28 launches, excluding three Cargo Dragon resupply missions that don’t need fairings.

While both Crew and Cargo Dragon spacecraft and trunks contain a large proportion of carbon fiber-composite structures, every composite Falcon 9 interstage that rolled off of the assembly line since February 2018 is part of a Block 5 booster and is thus expected to support a bare minimum of several missions on its own, functionally multiplying the useful output of any given production line even while the amount of work (and thus work-hours) is reduced. While Falcon 9 boosters – making up roughly 70% of the cost of the entire rocket – have been successfully upgraded to support several reuses each, SpaceX still has to produce a new payload fairing and upper stage for each launch. A spectacular Block 4 farewell earlier this month – complete with a recoverable booster expended to make way for Block 5 – simply served to emphasize the company’s desire to mitigate the expandability of both (currently) unreusable segments of Falcon 9.

- Meanwhile, the purpose of this massive inflatable ring is almost entirely unclear, as it would appear to be redundant with the initial installation of Mr Steven’s new recovery mechanism. (Pauline Acalin)

- Arm installation will presumably continue over the course of the week, hopefully reaching completion in time to recovery Iridium-7’s payload fairing. (Pauline Acalin)

If Mr Steven can recover even a small fraction – say 25% – of SpaceX payload fairings launched annually, the exact same level of effort (and thus capital) could support 25% more launches annually or reduce the work hours spent on fairing production by 25%. As it happens, SpaceX’s next-generation rocket (BFR) happens to be built (theoretically) almost entirely out of carbon-composites, from the propellant tanks to the spaceship’s delta wing.

Originally meant to focus on the wholly unexpected appearance of a giant inflatable structure at Berth 240, SpaceX’s breakneck pace of action abruptly recentered it on the equally unexpected installation of one the vessel’s first upgraded arms, meant to support a net that could be as much as four times larger than its predecessor. That symbolism on its own is a worthy representation of some of the best aspects of SpaceX’s world-class team of engineers and technicians, acting as a slightly more on-topic corollary to the equally rapid design, prototyping, fabrication, and testing of ad-hoc ‘submarines’ intended to help a number of Thai children currently trapped in a cave near the country’s border with Myanmar/Burma.

Mr Steven shows off the first of four new arms as a mysterious inflatable ring patiently sits astern. (Pauline Acalin)

Follow us for live updates, peeks behind the scenes, and photos from Teslarati’s East and West Coast photographers.

Teslarati – Instagram – Twitter

Tom Cross – Twitter

Pauline Acalin – Twitter

Eric Ralph – Twitter

News

Tesla Sweden strikers see tax issues over IF Metall union error

To address the issue, IF Metall is encouraging Tesla strikers to return the refunded tax amounts to the union.

A tax correction is set to return two years of income tax payments to Tesla strikers in Sweden, after authorities determined that conflict compensation during a labor dispute should not have been taxed.

The issue is caused by a decision by IF Metall to treat strike compensation for Tesla workers as taxable income during the ongoing labor dispute with Tesla Sweden. That approach has now been reversed following guidance from the Swedish Tax Agency.

Strike compensation is typically tax-free under Sweden’s Income Tax Act, as noted in a report from Dagens Arbete (DA). However, two years ago, IF Metall’s board decided to classify payments to Tesla strikers as taxable.

“We did it to secure SGI, unemployment insurance and public pension. Those were the risks we saw when the strike had already dragged on,” Kent Bursjöö, financial manager at IF Metall, stated.

According to Bursjöö, the union wanted to ensure that members continued to register earned income with the tax agency, protecting benefits tied to income history. At the end of January, however, the Swedish Tax Agency informed the union that compensation during a labor dispute must be tax-free.

“Of course, we knew that it could be tax-free. But we clearly didn’t know that it couldn’t be taxable,” Bursjöö said.

Following discussions with auditors and tax authorities, IF Metall began correcting the payments. As a result, two years of paid income tax will now be credited back to the affected strikers’ tax accounts. The union will also recover previously paid employer contributions.

However, the correction creates secondary effects. Since the payments will now be treated as tax-free, pension contributions tied to those earnings will be withdrawn, potentially affecting state pension accrual and income-based benefits such as parental or sickness benefits.

To address this, IF Metall is encouraging members to return the refunded tax amounts to the union. In exchange, the union plans to pay 18.5% into occupational pensions on their behalf. “Otherwise, it will be a form of overcompensation when they get the tax paid back,” Bursjöö said.

That being said, the IF Metall officer acknowledged that the union’s legal ability to reclaim the funds from its improperly paid Tesla Sweden strikers is limited. “The legal possibilities are probably limited, from what we can see. But we assume that most people see the value of securing their pension,” Bursjöö said.

News

Tesla sues California DMV over Autopilot and FSD advertising ruling

The complaint seeks to remove the agency’s conclusion that Tesla falsely promoted the capabilities of Autopilot and Full Self-Driving.

Tesla has filed a lawsuit against the California Department of Motor Vehicles (DMV) in an effort to overturn a prior ruling that found the automaker engaged in false advertising related to its driver-assistance systems.

The complaint seeks to remove the agency’s conclusion that Tesla misled customers about the capabilities of Autopilot and Full Self-Driving.

Tesla’s legal action follows a decision by California’s Office of Administrative Hearings (OAH), which concluded that Tesla’s earlier marketing of “Autopilot” and “Full Self-Driving” violated state law, as noted in a CNBC report.

While the DMV opted not to suspend Tesla’s license after determining the company had updated its marketing language for its advanced driver-assistance systems, Tesla is asking the court to go further and reverse the agency’s conclusion.

In its Feb. 13 complaint, Tesla’s attorneys argued that the DMV “wrongfully and baselessly” labeled the company a “false advertiser” for its Autopilot and FSD systems. The filing argued that regulators failed to demonstrate that consumers were actually misled about the capabilities of Tesla’s systems.

According to Tesla’s complaint, the DMV “never proved consumers in the state had been confused about whether its cars were safe to drive without a human at the wheel.”

Tesla’s legal team further stated: “It was impossible to buy a Tesla equipped with either Autopilot or Full Self-Driving Capability, or to use any of their associated features, without seeing clear and repeated statements that they do not make the vehicle autonomous.”

Tesla now promotes its driver-assistance system as “Full Self-Driving (Supervised),” a name that overemphasizes the need for active driver attention.

Tesla’s autonomous driving program is a pivotal part of the company’s future, with CEO Elon Musk stating that self-driving technology will truly be the solution that will push Tesla into its full potential. The company is currently operating a Robotaxi pilot in Austin and the Bay Area, and the company recently announced that it has produced the first Cybercab from Giga Texas’ production line.

News

Tesla is making two big upgrades to the Model 3, coding shows

According to coding found in the European and Chinese configurators, Tesla is planning to make two big upgrades: Black Headliner offerings and a new 16-inch QHD display, similar to that on the Model Y Performance.

Tesla is making two big upgrades to the Model 3, one of which is widely requested by owners and fans, and another that it has already started to make on some trim levels of other models within the lineup.

The changes appear to be taking effect in the European and Chinese markets, but these are expected to come to the United States based on what Tesla has done with the Model Y.

According to coding found in the European and Chinese configurators, Tesla is planning to make two big upgrades: Black Headliner offerings and a new 16-inch QHD display, similar to that on the Model Y Performance.

These changes in the coding were spotted by X user BERKANT, who shared the findings on the social media platform this morning:

🚨 Model 3 changes spotted in Tesla backend

• New interior code: IN3PB (Interior 3 Premium Black)

• Linked to Alcantara-style black headliner

• Mapped to 2026 Model 3 Performance and Premium VINs• EPC now shows: “Display_16_QHD”

• Multiple 2026 builds marked with… pic.twitter.com/OkDM5EdbTu— BERKANT (@Tesla_NL_TR) February 23, 2026

It appears these new upgrades will roll out with the Model 3 Performance and Tesla’s Premium trim levels of the all-electric sedan.

The changes are welcome. Tesla fans have been requesting that its Model 3 and Model Y offerings receive a black headliner, as even with the black interior options, the headliner is grey.

Tesla recently upgraded Model Y vehicles to this black headliner option, even in the United States, so it seems as if the Model 3 will get the same treatment as it appears to be getting in the Eastern hemisphere.

Tesla has been basically accentuating the Model 3 and Model Y with small upgrades that owners have been wanting, and it has been a focal point of the company’s future plans as it phases out other vehicles like the Model S and Model X.

Additionally, Tesla offered an excellent 0.99% APR last week on the Model 3, hoping to push more units out the door to support a strong Q1 delivery figure at the beginning of April.