News

SpaceX’s orbital Starship prototype sheds tiles, comes to life during first tests

After weeks of mostly invisible – albeit slow and steady – work at Starbase’s suborbital launch and test facilities, SpaceX has finally kicked off the first orbital Starship prototype’s first test campaign.

Almost two months ago, Starship 20 (S20) departed the factory it was built in for the first time and was rolled a few miles down a South Texas highway to Starbase’s nascent orbital launch site. There, SpaceX briefly installed Ship 20 on top of Super Heavy Booster 4 (B4) – an important first and one done with the same ship and booster pair CEO Elon Musk says could eventually support the rocket’s inaugural orbital launch attempt. Mere hours after that August 6th photo opportunity and fit test, Ship 20 was rolled back to the Starbase build site for another week of work before again returning to the launch site.

This time around, Starship S20 headed for one of two suborbital launch and test stands and ultimately spent the better part of the next six weeks sitting in place as workers swarmed around the 50m (~165 ft) tall spacecraft and upper stage to prepare it for the next steps. In theory, those steps were simple enough, beginning with the completion of two basic qualification tests – the same tests that a half-dozen prototypes preceding Ship 20 completed without issue.

Effectively SpaceX’s first Starship or Super Heavy test of any kind in more than two months, it thankfully didn’t take long for things to get interesting. Before the pad had even been cleared of the last few remaining workers, Starship S20 violently shed a good dozen or so fragile heat shield tiles. CEO Elon Musk quickly confirmed speculation that Starship S20 had effectively jetted the tiles off its nose during a brief test of high-pressure cold gas maneuvering thrusters, coincidentally around the same time as SpaceX began to pressurize the rocket for its first tests.

Going into what was believed to be Starship S20’s first ambient-temperature pressure test and cryogenic proof test, the loss of some heat shield tiles was almost universally expected. In a structure as large as Starship, even just the thermal contraction of steel at supercool temperatures (and expansion as it warms back up) could change the rocket’s diameter an inch or so, potentially causing tiles to scrape or press against each other. About the size of a dinner plate and the thickness of an average paperback book, Starship’s ceramic heat shield tiles have proven to be very fragile, with dozens routinely chipping, cracking, and shattering during and after installation on Ship 20.

One unique (and no less unproven) aspect of Starship is SpaceX’s decision to mount its heat shield directly to the thin steel propellant tanks and skin that make up the rocket’s entire airframe. SpaceX’s first stab at the problem involves studs/pins welded – by robot – directly to the exterior of Starship’s tanks and skin. By embedding small metal plates inside each cast tile, they can be easily installed by aligning the tile and pressing it against each set of three barb-like pins, which then irreversibly lock in place. Over most of Starship’s hull, SpaceX then tacks on blankets of off-the-shelf ceramic wool insulation before tiles are installed on top of that steel and blanket sandwich. Compared to the Space Shuttle and Russia’s Buran, the only other orbital spacecraft to fly with non-ablative heat shields, Starship’s thermal protection system (TPS) is incredibly simple. Of course, the challenges imposed on heat shields by mechanical stresses during launch/landing, orbital reentry, and a need for rapid reusability are anything but simple.

As such, to see tiles blown off Starship S20 by cold gas maneuvering thrusters that were simply placed too close to adjacent TPS was an unexpected route to an expected outcome. During Monday’s nine-hour test window, SpaceX appeared to partially or fully pressurize Starship S20 at ambient temperatures before aborting a cryogenic proof test either before or just after it began. While an ambient-temperature proof was the easier of the two tests on the docket, it’s still encouraging to see no obvious tile loss caused by the actual mechanical stresses involved in the test.

Most importantly, compared to losing dozens of tiles to regular mechanical or thermal stresses, fixing an issue with thruster impingement is much easier and should only require a few design tweaks to one specific Starship component. The real nail-biting moments will come during Starship S20’s seemingly imminent cryogenic proof and static fire debuts, major TPS issues during either of which could necessitate vehicle-wide design changes and cause delays.

With any luck, whatever forced SpaceX to abort Starship S20’s first cryogenic proof test can be easily rectified, opening the door for additional attempts. Two more test windows are scheduled later this week from 5pm to 11pm CDT on Tuesday and Wednesday. Rewatch today’s brief testing below.

News

Tesla Semis to get 18 new Megachargers at this PepsiCo plant

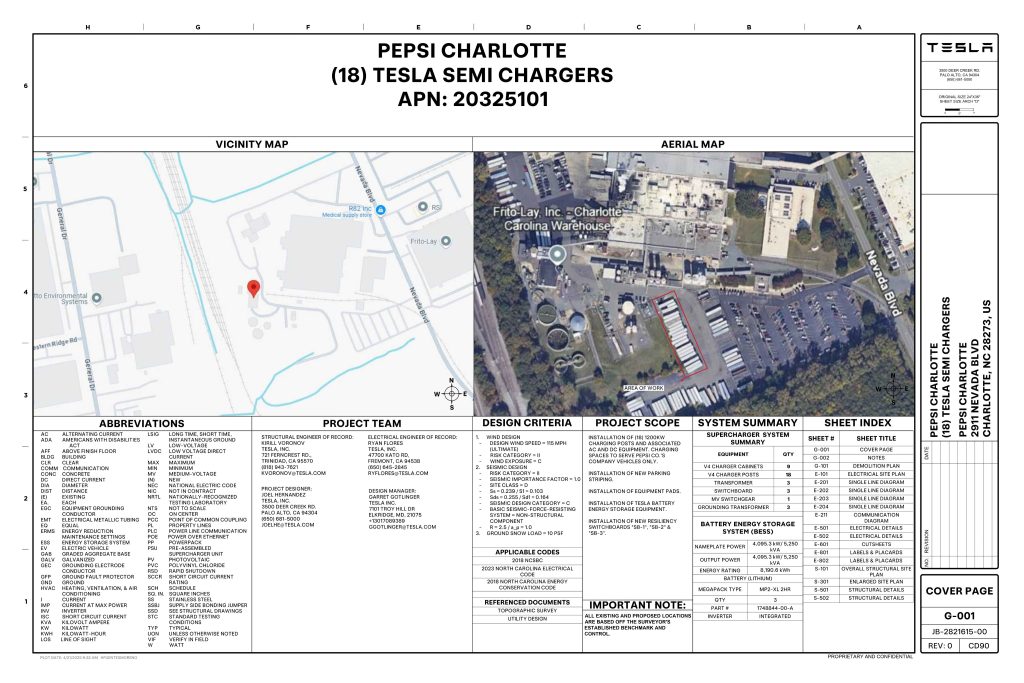

PepsiCo is set to add more Tesla Semi Megachargers, this time at a facility in North Carolina.

Tesla partner PepsiCo is set to build new Semi charging stations at one of its manufacturing sites, as revealed in new permitting plans shared this week.

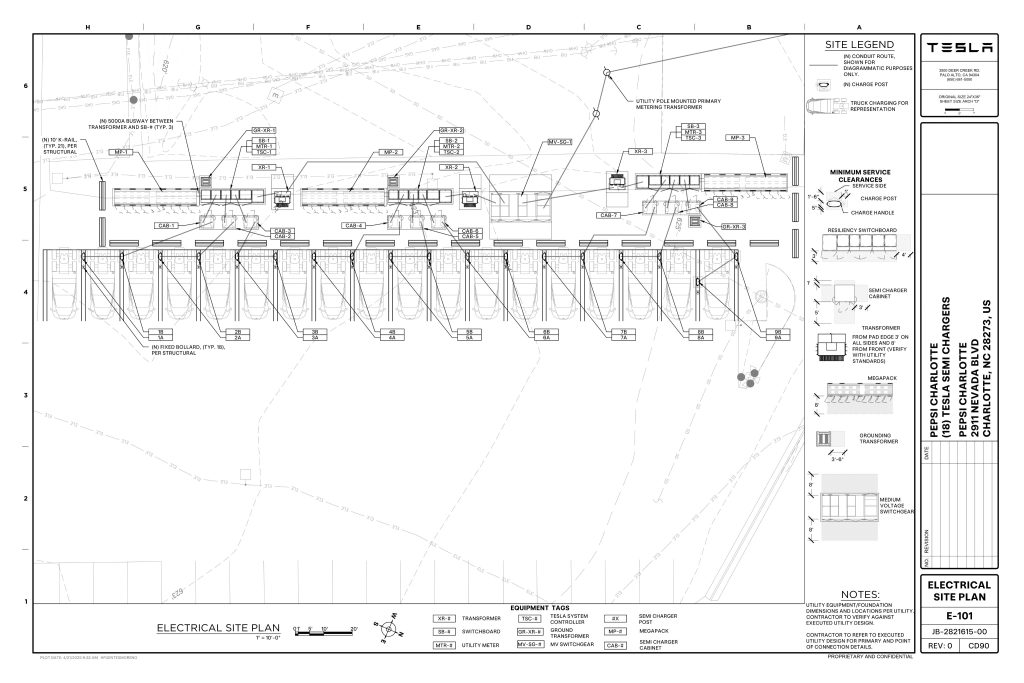

On Friday, Tesla charging station scout MarcoRP shared plans on X for 18 Semi Megacharging stalls at PepsiCo’s facility in Charlotte, North Carolina, coming as the latest update plans for the company’s increasingly electrified fleet. The stalls are set to be built side by side, along with three Tesla Megapack grid-scale battery systems.

The plans also note the faster charging speeds for the chargers, which can charge the Class 8 Semi at speeds of up to 1MW. Tesla says that the speed can charge the Semi back to roughly 70 percent in around 30 minutes.

You can see the site plans for the PepsiCo North Carolina Megacharger below.

Credit: PepsiCo (via MarcoRPi1 on X)

Credit: PepsiCo (via MarcoRPi1 on X)

READ MORE ON THE TESLA SEMI: Tesla to build Semi Megacharger station in Southern California

PepsiCo’s Tesla Semi fleet, other Megachargers, and initial tests and deliveries

PepsiCo was the first external customer to take delivery of Tesla’s Semis back in 2023, starting with just an initial order of 15. Since then, the company has continued to expand the fleet, recently taking delivery of an additional 50 units in California. The PepsiCo fleet was up to around 86 units as of last year, according to statements from Semi Senior Manager Dan Priestley.

Additionally, the company has similar Megachargers at its facilities in Modesto, Sacramento, and Fresno, California, and Tesla also submitted plans for approval to build 12 new Megacharging stalls in Los Angeles County.

Over the past couple of years, Tesla has also been delivering the electric Class 8 units to a number of other companies for pilot programs, and Priestley shared some results from PepsiCo’s initial Semi tests last year. Notably, the executive spoke with a handful of PepsiCo workers who said they really liked the Semi and wouldn’t plan on going back to diesel trucks.

The company is also nearing completion of a higher-volume Semi plant at its Gigafactory in Nevada, which is expected to eventually have an annual production capacity of 50,000 Semi units.

Tesla executive teases plan to further electrify supply chain

News

Tesla sales soar in Norway with new Model Y leading the charge

Tesla recorded a 54% year-over-year jump in new vehicle registrations in June.

Tesla is seeing strong momentum in Norway, with sales of the new Model Y helping the company maintain dominance in one of the world’s most electric vehicle-friendly markets.

Model Y upgrades and consumer preferences

According to the Norwegian Road Federation (OFV), Tesla recorded a 54% year-over-year jump in new vehicle registrations in June. The Model Y led the charge, posting a 115% increase compared to the same period last year. Tesla Norway’s growth was even more notable in May, with sales surging a whopping 213%, as noted in a CNBC report.

Christina Bu, secretary general of the Norwegian EV Association (NEVA), stated that Tesla’s strong market performance was partly due to the updated Model Y, which is really just a good car, period.

“I think it just has to do with the fact that they deliver a car which has quite a lot of value for money and is what Norwegians need. What Norwegians need, a large luggage space, all wheel drive, and a tow hitch, high ground clearance as well. In addition, quite good digital solutions which people have gotten used to, and also a charging network,” she said.

Tesla in Europe

Tesla’s success in Norway is supported by long-standing government incentives for EV adoption, including exemptions from VAT, road toll discounts, and access to bus lanes. Public and home charging infrastructure is also widely available, making the EV ownership experience in the country very convenient.

Tesla’s performance in Europe is still a mixed bag, with markets like Germany and France still seeing declines in recent months. In areas such as Norway, Spain, and Portugal, however, Tesla’s new car registrations are rising. Spain’s sales rose 61% and Portugal’s sales rose 7% last month. This suggests that regional demand may be stabilizing or rebounding in pockets of Europe.

News

Tesla to open first India experience center in Mumbai on July 15

The event is scheduled for July 15 at the Bandra Kurla Complex, a premier business district in Mumbai.

Tesla is officially entering India with the opening of its first showroom and experience center in Mumbai next week. The event is scheduled for July 15 at the Bandra Kurla Complex, a premier business district in Mumbai.

Tesla imports to India signal an early-stage market entry strategy

According to Indian customs data, Tesla has imported approximately $1 million worth of vehicles, charging equipment, and merchandise into the country between January and June. The shipments include six Model Y comprised of five standard variants valued at $32,500 each and one long-range model valued at $46,000. Several Superchargers and related accessories were also imported into the country, as noted in a Yahoo Finance report.

These vehicles are expected to serve as display models and test units as Tesla gauges interest and navigates India’s high import duties, which hover around 70% on fully built vehicles. Despite the significant tariffs in the country, Tesla has opted to begin its India expansion with imported cars.

An invitation to the Tesla India launch event has been making the rounds online. As could be seen in the document, Tesla noted that July 15 would be the launch of Tesla in India through the opening of a Tesla experience centre at Bandra Kurla Complex in Mumbai.

Tesla India’s hiring and expansion efforts are underway

Tesla has filled a number of key roles from the 30+ positions it advertised earlier this year. Recent hires include store managers, service executives, and sales staff, while ongoing recruitment is focused on supply chain engineers and vehicle operators to support the company’s Autopilot program.

Indian officials have been open about their intention to encourage Tesla to establish a manufacturing hub in the country. Tesla does seem open to the idea, at least, with reports last year hinting that Elon Musk was set to visit the country to discuss or even potentially announce a domestic project. The trip, however, was ultimately canceled.

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

Elon Musk2 days ago

Elon Musk2 days agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

Elon Musk4 days ago

Elon Musk4 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News1 week ago

News1 week agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

Elon Musk1 week ago

Elon Musk1 week agoxAI’s Memphis data center receives air permit despite community criticism

-

News2 weeks ago

News2 weeks agoXiaomi CEO congratulates Tesla on first FSD delivery: “We have to continue learning!”

-

News2 weeks ago

News2 weeks agoTesla sees explosive sales growth in UK, Spain, and Netherlands in June