News

Tesla’s software fixes, the NHTSA’s status quo, and an impending need for updated recall terminologies

It is no secret that Tesla is a popular topic, so much so that the coverage around the company is immense. Couple this with CEO Elon Musk’s rockstar persona and you get a company whose vehicles are looked at under a microscope constantly. It might feel unfair for some, but it’s just the way it is. Tesla — by simply being Tesla — is newsworthy.

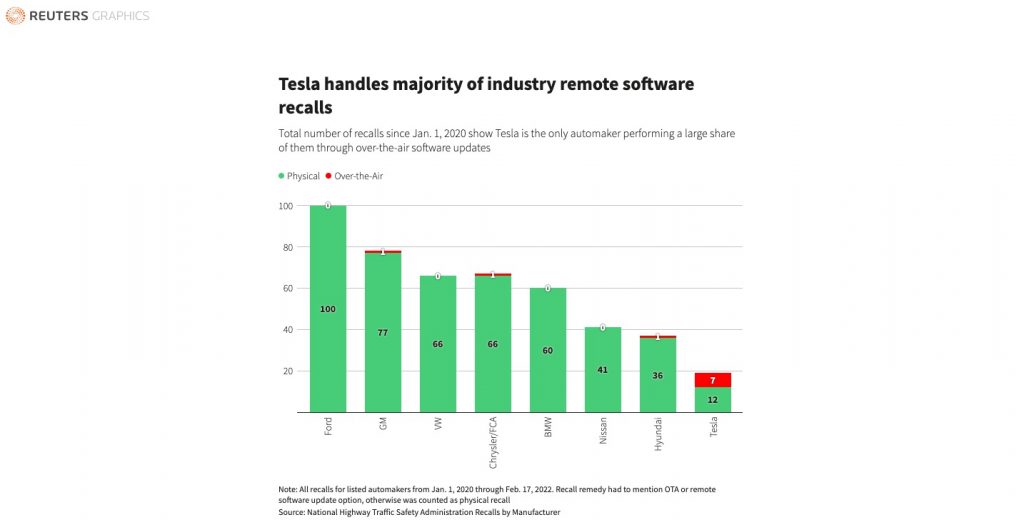

Tesla’s newsworthiness is a double-edged sword. A look at the coverage for the company’s vehicle recalls from the NHTSA would prove this point. So notable is Tesla’s news coverage that a mainstream newsreader would likely get the impression that Teslas get recalls frequently. The opposite is true. As evidenced by Reuters in the graphic below, data from January 1, 2020, through February 17, 2022, shows that Tesla actually recalls its vehicles less frequently than some of the market’s leading automakers. Tesla is also the only carmaker performing a large share of its vehicle recalls through over-the-air software updates.

Tesla currently handles the majority of the industry’s remote software recalls, but it would soon not be the only one. New electric vehicle makers have used the idea of software updates as a means to promote their EVs’ capabilities. Rivian has performed OTA updates to its R1 vehicles, and those cars are only starting customer deliveries. Lucid is the same with its Air sedan, with the company rolling out features like Automatic Emergency Braking, Cross-Traffic Protection, Lane Departure Protection, Traffic Drive-Off Alert, and other features earlier this month through a software update. Ford has been rolling out updates called “Power-Ups” to the Mustang Mach-E as well.

Considering that software-based fixes are only bound to get more widespread over the coming years, one must then ask the question: Should software-based over-the-air fixes be dubbed and classified with the same terminologies as physical recalls, which typically involve the replacement of vehicle hardware?

A Vastly Different “Recall” Experience

Any car owner has likely experienced a recall for their vehicle at some point in their driving life. And more likely than not, one’s experience is probably not that pleasant. I certainly count myself among drivers who look at vehicle recalls with trepidation. My current vehicle, a Japanese-made van, was part of a minor fuel pump recall a couple of years ago, and even addressing that took a whole day out of my weekend. The dealer was overwhelmed with the number of cars it was fixing that day, and tempers among owners were flaring by the hour — all for a simple fuel pump replacement. I’ve been told that my experiences with vehicle recalls are not that unique.

In comparison, a software-based fix, such as the disabling of FSD Beta’s “rolling stops” feature, only required affected vehicles to be connected to the internet. There was no dealer visit, no forms to fill out, and no staff to argue with. The car was connected to the internet, a software fix was implemented, and the issue was resolved. One can argue that Tesla’s software fix to disable FSD Beta’s “rolling stops” feature was safety-related, and that’s true. But one could also argue that at least from a driver’s point of view, the experience related to software and hardware-based recalls is vastly different.

The Status Quo

Despite the different experiences involved when software and hardware-based vehicle recalls are addressed, it appears that the National Highway Traffic Safety Administration (NHTSA) will, at least for now, keep the status quo. Teslarati reached out to the NHTSA to inquire if it was considering the adoption of updated terminologies for cars whose fixes are completed through OTA software updates, but the agency suggested that this would likely not be the case, at least for now. According to the NHTSA, vehicle manufacturers must initiate a recall for any repair that remedies a safety risk, regardless of whether the issue is fixed by software update or by hardware replacement.

“The National Highway Traffic Safety Administration is committed to ensuring the highest safety standards on the nation’s roadways. NHTSA is empowered with robust tools and authorities to protect the public, to investigate potential safety issues, and to compel recalls when it finds evidence of noncompliance or an unreasonable risk to safety. Manufacturers are required to initiate a recall for any repair, including a software update, that remedies an unreasonable risk to safety. NHTSA recalls can include any required repair, which includes a software update, to remedy a potential safety risk. Manufacturers are also required to submit any communications to owners, dealers, and others about any software updates that address a defect, whether it is safety-related or not,” the NHTSA stated.

Product recall specialist and associate professor at the Indiana University Kelley School of Business Professor George Ball told Teslarati that while the NHTSA’s use of similar terminologies for software and hardware-based recalls is “definitely an example of regulators and industry moving at a different pace on technology,” the agency’s hesitation in adopting new terminologies for OTA fixes is understandable. Professor Ball further explained that using terms such as “soft recall” to refer to software-based vehicle fixes might imply a reduced level of risk, and this is something that the NHTSA would likely be unwilling to do.

“I believe NHTSA would resist ‘soft recall’ terminology because it implies a reduced level of customer hazard and allows the firm to be under less scrutiny by the press and public for quality corrections. While some updates are minor, some of the Tesla software upgrades are actually quite serious, and if not done, can allow a harmful defect to persist,” the recall specialist said.

But while the NHTSA’s stance on recall terminologies is completely understandable, one cannot deny the fact that the issues covered by vehicle recalls have a very wide range of risks. Take Tesla’s recall for 817,143 vehicles, which was announced earlier this month, for example. The recall was initiated since a software error may prevent a warning chime from activating even if drivers do not have their seat belts on. From a layman’s perspective, this recall seems grave as it affects over 800,000 Teslas on the road today. However, the issue was simply addressed through firmware release 2021.43.101.1 and later, which included a remedy for the seat belt chime error.

Compare this with General Motors’ recall last year of 400,000 pickup trucks in the US. Granted, it only affected about half as many vehicles as Tesla’s seat belt chime recall, but its hardware-based nature suggested that the risk presented by the issue was great. The recall covered certain 2015 and 2016 Chevrolet and GMC Sierra 1500, 2500, and 3500 trucks, and it involved a faulty airbag inflator that may rupture without warning. To fix the issue, owners of the affected trucks were required to head to a dealer so that they could get their airbag modules replaced. Since parts were in short supply last year, however, owners were notified with a letter to inform them when their trucks’ replacement parts were available.

What Can Be Done

While the NHTSA will likely continue to maintain the status quo with its recall terminologies for the foreseeable future, Professor Ball told Teslarati that the agency can actually implement some adjustments now that can make distinguishing safety fixes and issues clearer. This would likely be extremely important in the near future as more connected cars are rolled out and software updates become the norm.

“If I were to provide advice to the NHTSA, I would recommend that they get out ahead of this issue before every car maker starts updating cars like Tesla. One way to do it is to require the automaker to send all auto updates to NHTSA when pushed out, and to classify updates as ‘minor’ or ‘major.’ Any major update that impacts customer safety would be classified as a recall. Automakers won’t like this, but it will help keep the safety fixes transparent for all, especially consumers. By sending all updates to NHSTA, the agency could assign qualified people to audit the classifications assigned by the manufacturer, to ensure they are making good decisions there.

“I think any language that de-emphasizes the importance of a safety recall is not likely to be supported by NHTSA, and it doesn’t likely help customer safety. A clear distinction needs to be made between minor updates and major updates that influence safety. Those major updates should be classified as a recall, and NHTSA needs to get their arms around these updates and keep on top of them soon, or they will fall way behind the industry,” the recall specialist said.

Recalls can affect the perception of a company to the public. Software fixes should be one of the factors that are considered an edge for automakers like Tesla, not the other way around. Gary Black, Managing Partner of The Future Fund LLC, explained this from the point of view of a Tesla investor. “Since every NHTSA recall so far has been quickly solvable via Tesla OTA updates, ‘recalls’ are noise to most investors. Tesla’s huge software edge highlights one of the key advantages of owning Tesla over every other EV manufacturer,” the Wall Street veteran told Teslarati.

OTA updates, including those related to vehicle safety, are coming. With automakers like Ford joining the group of carmakers embracing OTA updates, software-based fixes are inevitable. Ultimately, I am inclined to agree with the recall specialist. By refusing to adapt to the advent of software-based vehicle fixes, the NHTSA may risk being left behind by the automotive industry. And that’s a scenario that I believe no automaker — or government agency for that matter — would prefer.

Don’t hesitate to contact us with news tips. Just send a message to simon@teslarati.com to give us a heads up.

News

Tesla Full Self-Driving v14.2.2.5 might be the most confusing release ever

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

Tesla Full Self-Driving v14.2.2.5 hit my car back on Valentine’s Day, February 14, and since I’ve had it, it has become, in my opinion, the most confusing release I’ve ever had.

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

It has been about three weeks of driving on v14.2.2.5; I’ve used it for nearly every mile traveled since it hit my car. I’ve taken short trips of 10 minutes or less, I’ve taken medium trips of an hour or less, and I’ve taken longer trips that are over 100 miles per leg and are over two hours of driving time one way.

These are my thoughts on it thus far:

Speed Profiles Are a Mixed Bag

Speed Profiles are something Tesla seems to tinker with quite frequently, and each version tends to show a drastic difference in how each one behaves compared to the previous version.

I do a vast majority of my FSD travel using Standard and Hurry modes, although in bad weather, I will scale it back to Chill, and when it’s a congested city on a weekend or during rush hour, I’ll throw it into Mad Max so it takes what it needs.

Early on, Speed Profiles really felt great. This is one of those really subjective parts of the FSD where someone might think one mode travels too quickly, whereas another person might see the identical performance as too slow or just right.

To me, I would like to see more consistency from release to release on them, but overall, things are pretty good. There are no real complaints on my end, as I had with previous releases.

In a past release, Mad Max traveled under the speed limit quite frequently, and I only had that experience because Hurry was acting the same way. I’ve had no instances of that with v14.2.2.5.

Strange Turn Signal Behavior

This is the first Full Self-Driving version where I’ve had so many weird things happen with the turn signals.

Two things come to mind: Using a turn signal on a sharp turn, and ignoring the navigation while putting the wrong turn signal on. I’ve encountered both things on v14.2.2.5.

On my way to the Supercharger, I take a road that has one semi-sharp right-hand turn with a driveway entrance right at the beginning of the turn.

Only recently, with the introduction of v14.2.2.5, have I had FSD put on the right turn signal when going around this turn. It’s obviously a minor issue, but it still happens, and it’s not standard practice:

How can we get Full Self-Driving to stop these turn signals?

There’s no need to use one here; the straight path is a driveway, not a public road. The right turn signal here is unnecessary pic.twitter.com/7uLDHnqCfv

— TESLARATI (@Teslarati) February 28, 2026

When sharing this on X, I had Tesla fans (the ones who refuse to acknowledge that the company can make mistakes) tell me that it’s a “valid” behavior that would be taught to anyone who has been “professionally trained” to drive.

Apparently, if you complain about this turn signal, you are also claiming you know more than Tesla engineers…okay.

Nobody in their right mind has ever gone around a sharp turn when driving their car and put on a signal when continuing on the same road. You would put a left turn signal on to indicate you were turning into that driveway if that’s what your intention was.

Like I said, it’s a totally minor issue. However, it’s not really needed, and nor is it normal. If I were in the car with someone who was taking a simple turn on a road they were traveling, and they signaled because the turn was sharp, I’d be scratching my head.

I’ve also had three separate instances of the car completely ignoring the navigation and putting on a signal that is opposite to what the routing says. Really quite strange.

Parking Performance is Still Underwhelming

Parking has been a complaint of mine with FSD for a long time, so much so that it is pretty rare that I allow the vehicle to park itself. More often than not, it is because I want to pick a spot that is relatively isolated.

However, in the times I allow it to pull into a spot, it still does some pretty head-scratching things.

Recently, it tried to back into a spot that was ~60% covered in plowed snow. The snow was piled about six feet high in a Target parking lot.

A few days later, it tried backing into a spot where someone failed the universal litmus test of returning their shopping cart. Both choices were baffling and required me to manually move the car to a different portion of the lot.

I used Autopark on both occasions, and it did a great job of getting into the spot. I notice that the parking performance when I manually choose the spot is much better than when the car does the entire parking process, meaning choosing the spot and parking in it.

It’s Doing Things (For Me) It’s Never Done Before

Two things that FSD has never done before, at least for me, are slow down in School Zones and avoid deer. The first is something I usually take over manually, and the second I surprisingly have not had to deal with yet.

I had my Tesla slow down at a school zone yesterday for the first time, traveling at 20 MPH and not 15 MPH as the sign suggested, but at the speed of other cars in the School Zone. This was impressive and the first time I experienced it.

I would like to see this more consistently, and I think School Zones should be one of those areas where, no matter what, FSD will only travel the speed limit.

Last night, FSD v14.2.2.5 recognized a deer in a roadside field and slowed down for it:

🚨 Cruising home on a rainy, foggy evening and my Tesla on Full Self-Driving begins to slow down suddenly

FSD just wanted Mr. Deer to make it home to his deer family ❤️ pic.twitter.com/cAeqVDgXo5

— TESLARATI (@Teslarati) March 4, 2026

Navigation Still SUCKS

Navigation will be a complaint until Tesla proves it can fix it. For now, it’s just terrible.

It still has not figured out how to leave my neighborhood. I give it the opportunity to prove me wrong each time I leave my house, and it just can’t do it.

It always tries to go out of the primary entrance/exit of the neighborhood when the route needs to take me left, even though that exit is a right turn only. I always leave a voice prompt for Tesla about it.

It still picks incredibly baffling routes for simple navigation. It’s the one thing I still really want Tesla to fix.

Investor's Corner

Tesla gets tip of the hat from major Wall Street firm on self-driving prowess

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet,” BoA wrote.

Tesla received a tip of the hat from major Wall Street firm Bank of America on Wednesday, as it reinitiated coverage on Tesla shares with a bullish stance that comes with a ‘Buy’ rating and a $460 price target.

In a new note that marks a sharp reversal from its neutral position earlier in 2025, the bank declared Tesla’s Full Self-Driving (FSD) technology the “leading consumer autonomy solution.”

Analysts highlighted Tesla’s camera-only architecture, known as Tesla Vision, as a strategic masterstroke. While technically more challenging than the multi-sensor setups favored by rivals, the vision-based approach is dramatically cheaper to produce and maintain.

This cost edge, combined with Tesla’s rapidly expanding real-world data engine, positions the company to scale robotaxis far more profitably than competitors, BofA argues in the new note:

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet.”

The bank now attributes roughly 52% of Tesla’s total valuation to its Robotaxi ambitions. It also flagged meaningful upside from the Optimus humanoid robot program and the fast-growing energy storage business, suggesting the auto segment’s recent headwinds, including expired incentives, are being eclipsed by these higher-margin opportunities.

Tesla’s own data underscores exactly why Wall Street is waking up to FSD’s potential. According to Tesla’s official safety reporting page, the FSD Supervised fleet has now surpassed 8.4 billion cumulative miles driven.

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

That total ballooned from just 6 million miles in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and a staggering 4.25 billion in 2025 alone. In the first 50 days of 2026, owners added another 1 billion miles — averaging more than 20 million miles per day.

This avalanche of real-world, camera-captured footage, much of it on complex city streets, gives Tesla an unmatched training dataset. Every mile feeds its neural networks, accelerating improvement cycles that lidar-dependent rivals simply cannot match at scale.

Tesla owners themselves will tell you the suite gets better with every release, bringing new features and improvements to its self-driving project.

The $460 target implies roughly 15 percent upside from recent trading levels around $400. While regulatory and safety hurdles remain, BofA’s endorsement signals growing institutional conviction that Tesla’s data advantage is not hype; it’s a tangible moat already delivering billions of miles of proof.

News

Tesla to discuss expansion of Samsung AI6 production plans: report

Tesla has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla is reportedly discussing an expansion of its next-generation AI chip supply deal with Samsung Electronics.

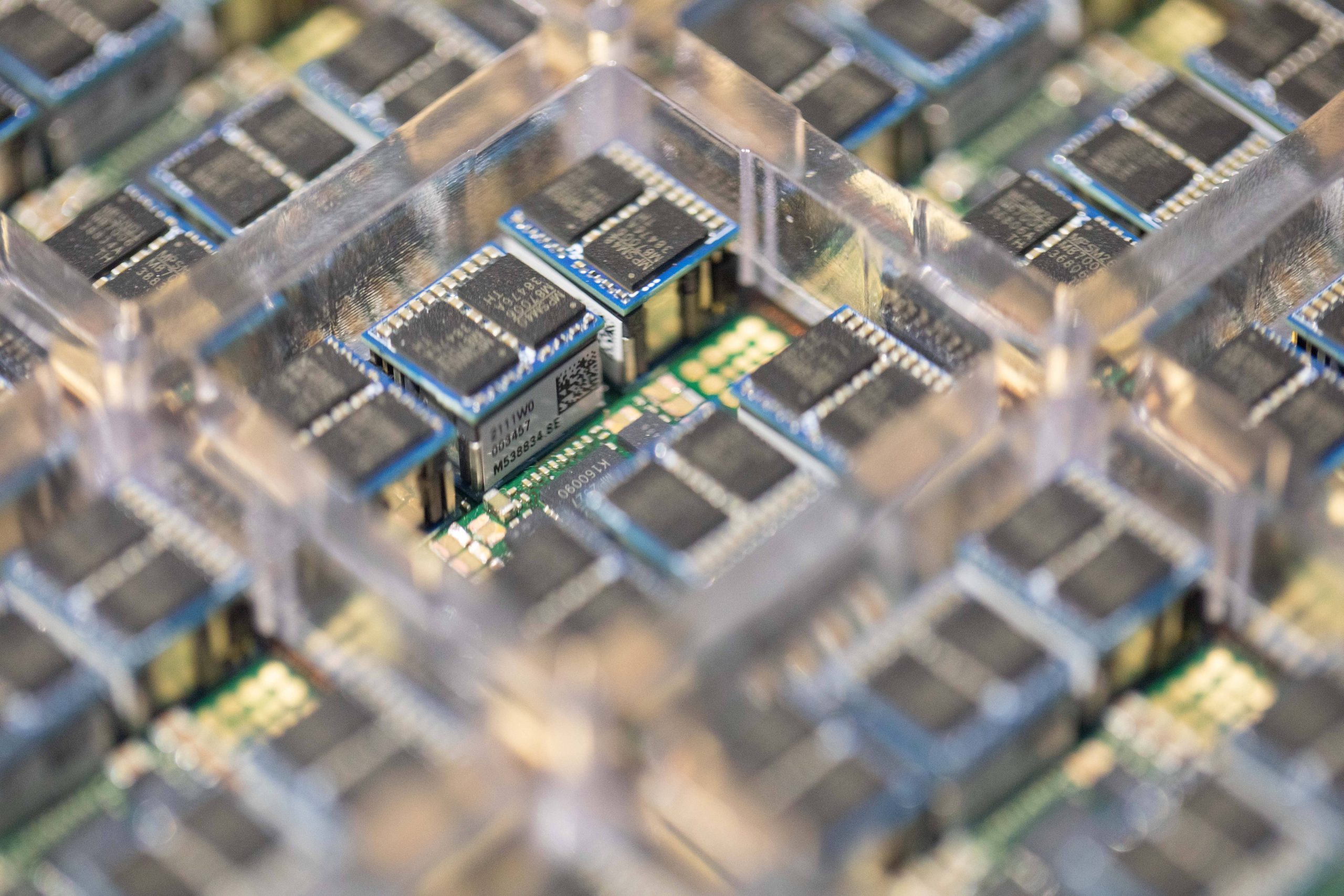

As per a report from Korean industry outlet The Elec, Tesla purchasing executives are reportedly scheduled to meet Samsung officials this week to negotiate additional production volume for the company’s upcoming AI6 chip.

Industry sources cited in the report stated that Tesla is pushing to increase the production volume of its AI6 chip, which will be manufactured using Samsung’s 2-nanometer process.

Tesla previously signed a long-term foundry agreement with Samsung covering AI6 production through December 31, 2033. The deal was reportedly valued at about 22.8 trillion won (roughly $16–17 billion).

Under the existing agreement, Tesla secured approximately 16,000 wafers per month from the facility. The company has reportedly requested an additional 24,000 wafers per month, which would bring total production capacity to around 40,000 wafers if finalized.

Tesla purchasing executives are expected to discuss detailed supply terms during their visit to Samsung this week.

The AI6 chip is expected to support several Tesla technologies. Industry sources stated that the chip could be used for the company’s Full Self-Driving system, the Optimus humanoid robot, and Tesla’s internal AI data centers.

The report also indicated that AI6 clusters could replace the role previously planned for Tesla’s Dojo AI supercomputer. Instead of a single system, multiple AI6 chips would be combined into server-level clusters.

Tesla’s semiconductor collaboration with Samsung dates back several years. Samsung participated in the design of Tesla’s HW3 (AI3) chip and manufactured it using a 14-nanometer process. The HW4 chip currently used in Tesla vehicles was also produced by Samsung using a 5-nanometer node.

Tesla previously planned to split production of its AI5 chip between Samsung and TSMC. However, the company reportedly chose Samsung as the primary partner for the newer AI6 chip.