News

Why The Boring Company’s $10 million dollars per mile price tag is a game changer

With The Boring Company, Elon Musk hopes to overcome the pitfalls that drive up the costs of underground rail transport construction using good old-fashioned innovation with a dash of Silicon Valley startup dust (dirt?). Currently, most U.S. local and state governments (i.e., tax payers) hand over an average of $200-$500 million dollars per mile to construct a subway system, with hundreds of millions more per mile a common occurrence and even a $1 billion dollars per mile price tag having happened a few times already. The reasons for such expense seems to be multi-faceted and stubborn: regulations, unions, and project management. So, when the Tesla CEO and Boring Company founder cited $10 million dollars as the final price of their mile-long demonstration tunnel, including internal infrastructure, lighting, comms/video, safety systems, ventilation, and tracks, he seemed to be threatening to completely upend yet another industry, this one having been at the core of transportation for nearly 200 years.

“I like trains, by the way. I really like trains a lot,” Musk assured his press audience at the company’s recent demonstration tunnel opening event. The Boring Company (TBC) began as a Twitter discussion wherein the tech mogul was venting about “soul-destroying” traffic in Los Angeles. A concept animation followed soon after (as well as hats and not-a-flamethrowers), imagining a transportation system where cars would be shuttled around at high speeds underground on electric skates. Ideas flowed, tunneling began, and the result of all those efforts went on display December 18, 2018, demo rides included. A rideable 1.14 mile tunnel had been constructed from Crenshaw Boulevard across from the Hawthorne, California headquarters of SpaceX, Musk’s private rocket company, to the 120th Street/Prairie Avenue crossroad of Hawthorne.

Around this time last year, Brian Rosenthal of the New York Times exposed several astonishing factors that added up to a $3.5 billion dollars per mile cost to construct a 3.5 mile tunnel to connect Grand Central Terminal to the Long Island Rail Road in New York City, aka the “East Side Access”. An infamous “first”, this price tag is 7 times more than the average of anywhere else in the world. A combination of trade union, construction company, and consulting firm practices, including significant staff redundancy, bred an environment ripe for cost pile-ups, and both incompetence and the lack of oversight within New York’s Metropolitan Transportation Authority (MTA) added significantly to the issue. While the specific amount of money spent made the system’s cost unique in the world, the general underlying issues were not uncommon.

New York may be an exception to the already high-cost of rail construction rule, but there’s the rub: It’s already incredibly expensive. As documented in numerous articles by Alon Levy, an independent journalist whose 2011 blog post on the topic inspired the research that eventually led to the Times piece, $100-$500 million dollars per mile is a typical cost for building railed transporation worldwide. “These are crazy numbers,” Musk exclaimed at the tunnel opening event after summarizing the multiple billions of dollars short tunneling projects cost to complete in L.A. and New York. If the building cost wasn’t enough sticker shock, it gets worse: The daily operating costs of rail systems in the U.S. exceed the amount earned.

Another metric that is used to estimate the true cost of rail construction is cost per rider. After the time and money is spent building a public rail system, it needs to be staffed and repaired, expenses which are difficult to match with revenue without a large number of riders. As cited by Alon Levy in an article Elon Musk tweeted recently, New York’s Second Avenue Subway will cost $25,000 per rider to complete 200,000 trips per day. In Los Angeles, the Purple Line will cost $45,000 per rider for 150,000 trips per day as will Boston’s Green Line Extension for 52,000 trips. Looking at rider fares, New York loses a bit less than $1 per ride taken and L.A. loses over $2 per ride.

So, how will The Boring Company “do” underground transportation system building better than the traditional, money-heavy methods? To put it simply: Be efficient.

Building a better mouse snail trap

They’ve designed their tunneling machines to bore faster and more efficiently. While the first generation machine is conventional and named Godot after the Samuel Backett play, Waiting for Godot due to the length of time it took to understand the machine’s functionality and assemble it, two other improved generations will be part of the Boring family.

The second generation machine, named “Line-Storm” after a Robert Frost love poem with the same phrase in its title that’s about overcoming hardships, is a conventional boring machine that has been highly modified. It uses a redesigned cutting head that takes in significantly more dirt and is 2 times faster than Godot.

The third generation machine, named “Prufrock”, will be a ground-up, fully designed TBC machine that’s 15 times better than the next best boring system, and that means 15 times faster than the next best machine out there, period.

Improved construction practices and project management

During construction, TBC reinforced tunnel segments as they were dug, those reinforcements being created on-site out of materials comprising 70% of the dirt dug and the remaining 30% primarily cement. This recycled material, as-you-go system enabled quick construction with cost efficiency, the demo tunnel taking 2 years almost to the day from Musk’s initial Tweet that inspired the undertaking.

Function-focused engineering

TBC’s tunnels are smaller than the typical underground rail system because they’re designed for specific types of vehicles that are smaller than traditional transports (autonomous electrics) and don’t require extra space for maintenance. This in itself reduces costs by 3-4 times.

Although The Boring Company has the advantage of being the new kid on the block whose founder has a unique background in shaking up traditional systems, there may still be a few hangups that will never quite go away. Anything involving the general public, especially public transit, will have serious bureaucracy involved. To achieve the company’s mile-long demo track feat, it had to face the extreme regulatory environment of Los Angeles. California overall has earthquakes, is a methane zone, and has oil and gas fields, all which add to a long list of rules to be followed for any construction projects to commence. “The amount of paperwork we had to go through to do this was enormous,” Musk said at TBC’s recent event.

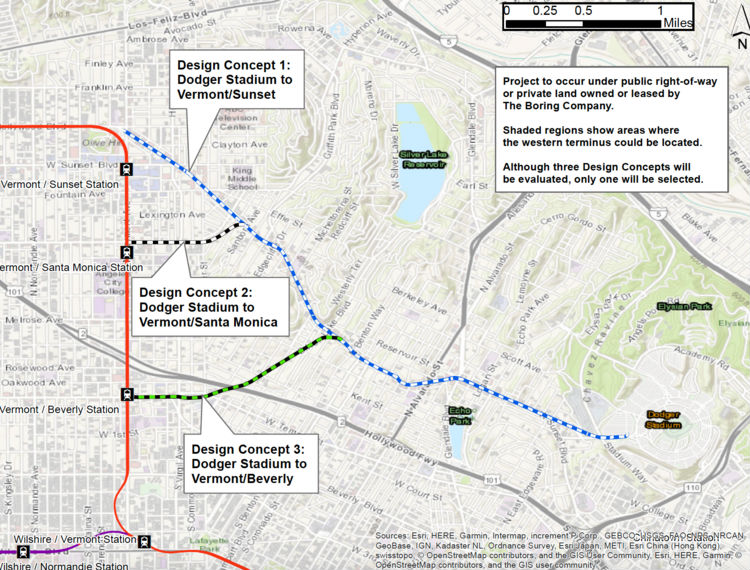

Additionally, a lawsuit filed last year by the Brentwood Residents Coalition and the Sunset Coalition objecting to the company’s Sepulveda tunnel eventually led to their abandonment of that leg of the demonstration project. The coalitions primarily alleged that TBC was skirting environmental review requirements by “chopping large projects into smaller pieces that taken individually appear to have no significant environmental impacts”, citing a conceptual map the company released showing its planned Los Angeles tunnel system. Musk hasn’t let these hurdles damage his confidence, however. While speaking with press at TBC’s opening event, he added his own spin to the Broadway mantra (and Frank Sinatra hit, “New York, New York”) about “making it” there : “If you can build a tunnel in L.A., you can build it anywhere.”

As CEO of an innovative electric car company and a commercial rocket company set on sending humans to Mars, Musk is known as an industry disruptor. Even if the cost of boring tunnels for public transportation projects rises somewhat above the $10 million per mile price demonstrated with the LA/Hawthorne tunnel, it will be still be well under the typical costs in the boring industry. It’s obvious already that a potential disruption is underway. “We have people hounding us to invest nonstop…it’s kinda ridiculous how much interest we’ve had in investing in Boring Company,” Musk stated at the tunnel unveiling. Steve Davis, president of the company, added that they receive “greater than 5 and less than 20 requests per week from different municipalities and stakeholders.”

Also in the works for the tunneling newcomers: A transport line connecting downtown Chicago to Chicago O’Hare International Airport. The company won a contract to build a transport system for the city’s fliers in June 2017, and ground breaking is planned for sometime in the next few months. The Boring Company’s calendar still includes plans for an “urban loop system” as well, an underground network of pod-type buses for pedestrians and cyclists connecting numerous points throughout city centers.

News

Tesla preps to build its most massive Supercharger yet: 400+ V4 stalls

The project will be an expansion of the current Eddie World Supercharger in Yermo, California, and will take place in several stages.

Tesla is preparing to build its most massive Supercharger yet, as it recently submitted plans for an over 400-stall Supercharging station in California, which would dwarf its massive 168-stall location in Lost Hills, California.

The project will be an expansion of the current Eddie World Supercharger in Yermo, California, and will take place in several stages.

The expansion, adjacent to the existing Eddie World Supercharger, which is currently comprised of 22 older V2 and V3 stalls limited to 150 kW, unfolds across six phases.

Construction on Phase 1 begins later this year with 72 V4 stalls. Subsequent stages will progressively add hundreds more, culminating in over 400 next-generation chargers. Site plans label expansive parking arrays across Phases 1–5 along Calico Boulevard, with Phase 6 design still to be determined.

Tesla is planning an absolutely massive Supercharger expansion in Yermo, California!!

Over the course of 6 phases, Tesla is set to add over 400 V4 stalls in a commercial development known as Eddie World 2.

The first phase, which should begin construction sometime this year,… pic.twitter.com/ks5Y5dE8lR

— MarcoRP (@MarcoRPi1) March 6, 2026

The project was first flagged by MarcoRP, a notable Tesla Supercharger watcher.

Strategically located midway on I-15 between Los Angeles and Las Vegas, the station targets heavy EV traffic on this high-demand corridor.

The surrounding 20-mile stretch already hosts over 200 high-power stalls (including 40 at 250 kW, 120 at 325 kW, and more), plus 96 in nearby Baker—yet bottlenecks persist during peak travel.

In scale, it eclipses all existing Tesla Superchargers. The current record holder, the solar- and Megapack-powered “Project Oasis” in Lost Hills, California, offers 164 stalls. Barstow’s former leader had 120. Eddie World 2 will be more than double that size, cementing Tesla’s dominance in ultra-high-capacity charging.

Tesla finishes its biggest Supercharger ever with 168 stalls

Development blends charging with convenience. Architectural drawings show integrated retail: a 10,100 square foot Cracker Barrel, a 4,300 square foot McDonald’s, a 3,800 square foot convenience store, additional restaurants, drive-thrus, outdoor dining, and lease space.

EV-centric features include pull-through bays for Cybertrucks and trailers, ensuring accessibility for larger vehicles and future Semi trucks.

News

Tesla makes latest move to remove Model S and Model X from its lineup

Tesla’s latest decisive step toward phasing out its flagship sedan and SUV was quietly removing the Model S and Model X from its U.S. referral program earlier this week.

Tesla has made its latest move that indicates the Model S and Model X are being removed from the company’s lineup, an action that was confirmed by the company earlier this quarter, that the two flagship vehicles would no longer be produced.

Tesla has ultimately started phasing out the Model S and Model X in several ways, as it recently indicated it had sold out of a paint color for the two vehicles.

Now, the company is making even more moves that show its plans for the two vehicles are being eliminated slowly but surely.

Tesla’s latest decisive step toward phasing out its flagship sedan and SUV was quietly removing the Model S and Model X from its U.S. referral program earlier this week.

The change eliminates the $1,000 referral discount previously available to new buyers of these vehicles. Existing Tesla owners purchasing a new Model S or Model X will now only receive a halved loyalty discount of $500, down from $1,000.

The updates extend beyond the two flagship vehicles. New Cybertruck buyers using a referral code on Premium AWD or Cyberbeast configurations will no longer get $1,000 off. Instead, both referrer and buyer receive three months of Full Self-Driving (Supervised).

The loyalty discount for Cybertruck purchases, excluding the new Dual Motor AWD trim level, has also been cut to $500.

NEWS: Tesla has removed the Model S and Model X from the referral program.

New owners also no longer get a $1,000 referral discount on a new Cybertruck Premium AWD or Cyberbeast. Instead, you now get 3 months of FSD (Supervised).

Additionally, Tesla has reduced the loyalty… pic.twitter.com/IgIY8Hi2WJ

— Sawyer Merritt (@SawyerMerritt) March 6, 2026

These adjustments apply only in the United States, and reflect Tesla’s broader strategy to optimize margins while boosting adoption of its autonomous driving software.

The timing is no coincidence. Tesla confirmed earlier this year that Model S and Model X production will end in the second quarter of 2026, roughly June, as the company reallocates factory capacity toward its Optimus humanoid robot and next-generation vehicles.

With annual sales of the low-volume flagships already declining (just 53,900 units in 2025), incentives are no longer needed to drive demand. Production is winding down, and Tesla expects strong remaining interest without subsidies.

Industry observers see this as the clearest sign yet of an “end-of-life” phase for the vehicles that once defined Tesla’s luxury segment. Community reactions on X range from nostalgia, “Rest in power S and X”, to frustration among long-time owners who feel perks are eroding just as the models approach discontinuation.

Some buyers are rushing orders to lock in final discounts before they vanish entirely.

Doug DeMuro names Tesla Model S the Most Important Car of the last 30 years

For Tesla, the move prioritizes efficiency: fewer discounts on outgoing models, a stronger push for FSD subscriptions, and a focus on high-margin Cybertruck trims amid surging orders.

Loyalists still have a narrow window to purchase a refreshed Plaid or Long Range model with remaining incentives, but the message is clear: Tesla’s lineup is evolving, and the era of the original flagships is drawing to a close.

News

Tesla Australia confirms six-seat Model Y L launch in 2026

Compared with the standard five-seat Model Y, the Model Y L features a longer body and extended wheelbase to accommodate an additional row of seating.

Tesla has confirmed that the larger six-seat Model Y L will launch in Australia and New Zealand in 2026.

The confirmation was shared by techAU through a media release from Tesla Australia and New Zealand.

The Model Y L expands the Model Y lineup by offering additional seating capacity for customers seeking a larger electric SUV. Compared with the standard five-seat Model Y, the Model Y L features a longer body and extended wheelbase to accommodate an additional row of seating.

The Model Y L is already being produced at Tesla’s Gigafactory Shanghai for the Chinese market, though the vehicle will be manufactured in right-hand-drive configuration for markets such as Australia and New Zealand.

Tesla Australia and New Zealand confirmed the vehicle will feature seating for six passengers.

“As shown in pictures from its launch in China, Model Y L will have a new seating configuration providing room for 6 occupants,” Tesla Australia and New Zealand said in comments shared with techAU.

Instead of a traditional seven-seat arrangement, the Model Y L uses a 2-2-2 layout. The middle row features two individual seats, allowing easier access to the third row while providing additional space for passengers.

Tesla Australia and New Zealand also confirmed that the Model Y L will be covered by the company’s updated warranty structure beginning in 2026.

“As with all new Tesla Vehicles from the start of 2026, the Model Y L will come with a 5-year unlimited km vehicle warranty and 8 years for the battery,” the company said.

The updated policy increases Tesla’s vehicle warranty from the previous four-year or 80,000-kilometer coverage.

Battery and drive unit warranties remain unchanged depending on the variant. Rear-wheel-drive models carry an eight-year or 160,000-kilometer warranty, while Long Range and Performance variants are covered for eight years or 192,000 kilometers.

Tesla has not yet announced official pricing or range figures for the Model Y L in Australia.