News

Panasonic deepens ties with Tesla and bets big on Auto Tech

The following post was originally published on EVANNEX

As the inevitability of a major disruption in the auto industry becomes clearer, we’ve been reading (and writing) a lot about the companies that seem likely to lose out – Big Oil, incumbent automakers, some parts suppliers. But who will be the winners? Battery-makers obviously, but also providers of “auto tech.” This term includes the electronics that make electric powertrains go – motor controllers, inverters, chargers and the like – as well as self-driving hardware and software, and customer-facing components such as touchscreens, head-up displays and infotainment systems.

Tech companies are infiltrating the automotive space, making acquisitions and alliances to position themselves for profits under the new order. Last year, GM paid a billion bucks for Cruise Automation and invested half a billion in Lyft. Intel is putting its recent acquisition, Mobileye, to work in a partnership with BMW to build self-driving vehicles. Google is working with Fiat Chrysler on self-driving cars and providing display systems for Volvo. Israeli startup Otonomo is competing with Google and Apple to sell user data to Daimler and other automakers.

No company is better placed to thrive in the electric, automated future than Panasonic, which is steadily redirecting its focus from consumer electronics to auto tech. In February, Panasonic named Tom Gebhardt Chairman and CEO of its North American operations. Gebhardt’s former post was leading the company’s Automotive Systems subsidiary.

“Our business has evolved… from purely a consumer business to a B2B business,” Gebhardt recently told Business Insider. “There’s a number of reasons for that: The commoditization of consumer products [and] the unfavorability in some of the cost models led us to look for better values in in-vehicle technologies.”

Gebhardt said Panasonic is devoting more resources to digital cockpits and vehicle entertainment systems as self-driving vehicles get closer to reality. “If the scenario says the car drives itself, it’s similar to sitting in an airplane seat, because you’re no longer actively driving,” he said. “We see that as an evolution of the space that has infinite possibilities for us.”

Panasonic offered several glimpses of those possibilities at CES in January. Fiat Chrysler’s semi-autonomous Portal concept car featured a Panasonic touchscreen with facial and voice recognition. Panasonic also revealed a new system with a head-up display and augmented reality that’s designed to replace the traditional instrument cluster and many of the car’s physical controls. Some speculated that it was a preview of Model 3’s user interface. A few days later, Panasonic CEO Kazuhiro Tsuga said in an interview, “We are deeply interested in Tesla’s self-driving system. We are hoping to expand our collaboration by jointly developing devices for that, such as sensors.”

Meanwhile, Panasonic’s collaboration with Tesla on batteries gives it a large stake in the potential profits as electrification gathers momentum. Panasonic is one of the largest battery manufacturers in the world, and it plans to invest $1.6 billion in Tesla’s Gigafactory. And looking back, in 2007 Panasonic began working with Tesla on the Roadster and has established a strong track record supporting Tesla over the past decade — even investing $30 million with Tesla at a critical juncture (in 2010) in order to develop lithium-ion battery cells for its forthcoming Model S sedan.

A lot has changed since those early days. Nevertheless, global electric vehicle sales are still hovering around 1% of the market. That said, there are many reasons to expect a breakout soon. Orders for Tesla’s upcoming Model 3 keep growing, and legacy automakers from VW to BMW to Ford are responding with plans for new electric models.

“The future is definitely electric, no question in my mind,” Gebhardt said. “What is the future timeline? Is it 10 years, 15 years, 40 years? It’s just a matter of what the adoption hits at the scale that makes this a slam dunk… We’re pretty bullish on the fact that this is a space that will continue to grow and there’s value there.”

Gebhardt conceded that EV adoption is slow in the US, a trend that may continue now that the federal government has shifted from supporting electrification to trying to revive the elderly fossil fuel industries. However, he characterizes this as “a short-term problem,” and points out that it’s a very different scene in China, the world’s largest car market. “If they adopt in a big way, that changes the balance of where electric is today versus where it will be going.”

Panasonic’s increasing investment in auto tech is already paying off, according to Nikkei Asian Review. At a recent financial briefing, President Kazuhiro Tsuga said the company is expecting an increase in net profit in fiscal year 2017, its first gain in two years, largely because of strong growth in EV batteries and other auto tech-related products. “We are confident we can achieve increases both in sales and profit for the year through March 2018 and later years,” he said.

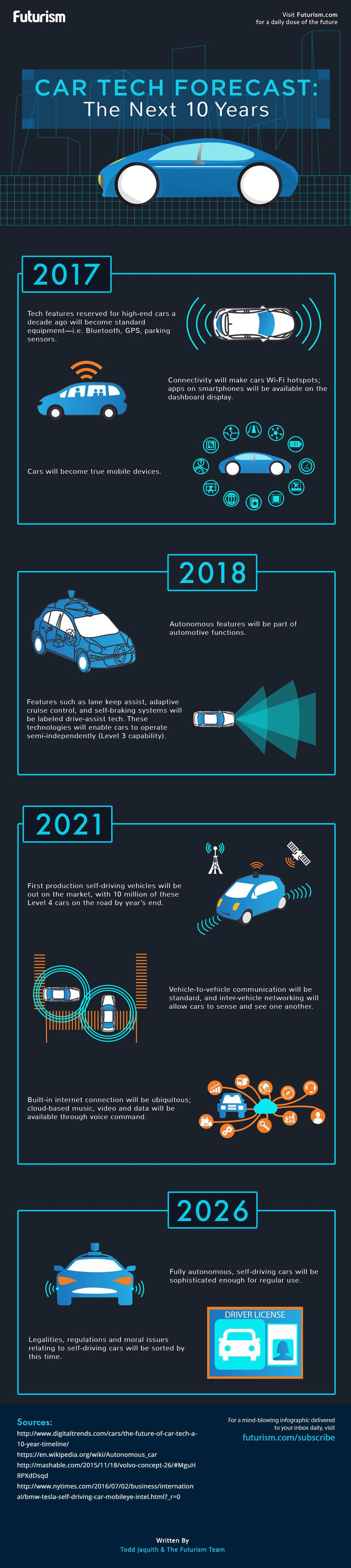

Infographic

What auto tech opportunities are coming in the next decade? Check out this infographic for a few possibilities…

Sources: Business Insider, Nikkei Asian Review / Infographic: Futurism

News

Tesla wins another award critics will absolutely despise

Tesla earned an overall score of 49 percent, up 6 percentage points from the previous year, widening its lead over second-place Ford (45 percent, up 2 points) to a commanding 4-percentage-point gap. The company also excelled in the Fossil Free & Environment category with a 50 percent score, reflecting strong progress in reducing emissions and decarbonizing operations.

Tesla just won another award that critics will absolutely despise, as it has been recognized once again as the company with the most sustainable supply chain.

Tesla has once again proven its critics wrong, securing the number one spot on the 2026 Lead the Charge Auto Supply Chain Leaderboard for the second consecutive year, Lead the Charge rankings show.

NEWS: Tesla ranked 1st on supply chain sustainability in the 2026 Lead the Charge auto/EV supply chain scorecard.

“@Tesla remains the top performing automaker of the Leaderboard for the second year running, and increased its overall score by 6 percentage points, while Ford only… pic.twitter.com/nAgGOIrGFS

— Sawyer Merritt (@SawyerMerritt) March 4, 2026

This independent ranking, produced by a coalition of environmental, human rights, and investor groups including the Sierra Club, Transport & Environment, and others, evaluates 18 major automakers on their efforts to build equitable, sustainable, and fossil-free supply chains for electric vehicles.

Tesla earned an overall score of 49 percent, up 6 percentage points from the previous year, widening its lead over second-place Ford (45 percent, up 2 points) to a commanding 4-percentage-point gap. The company also excelled in the Fossil Free & Environment category with a 50 percent score, reflecting strong progress in reducing emissions and decarbonizing operations.

Perhaps the most impressive achievement came in the batteries subsection, where Tesla posted a massive +20-point jump to reach 51 percent, becoming the first automaker ever to surpass 50 percent in this critical area.

Tesla achieved this milestone through transparency, fully disclosing Scope 3 emissions breakdowns for battery cell production and key materials like lithium, nickel, cobalt, and graphite.

The company also requires suppliers to conduct due diligence aligned with OECD guidelines on responsible sourcing, which it has mentioned in past Impact Reports.

While Tesla leads comfortably in climate and environmental performance, it scores 48 percent in human rights and responsible sourcing, slightly behind Ford’s 49 percent.

The company made notable gains in workers’ rights remedies, but has room to improve on issues like Indigenous Peoples’ rights.

Overall, the leaderboard highlights that a core group of leaders, Tesla, Ford, Volvo, Mercedes, and Volkswagen, are advancing twice as fast as their peers, proving that cleaner, more ethical EV supply chains are not just possible but already underway.

For Tesla detractors who claim EVs aren’t truly green or that the company cuts corners, this recognition from sustainability-focused NGOs delivers a powerful rebuttal.

Tesla’s vertical integration, direct supplier contracts, low-carbon material agreements (like its North American aluminum deal with emissions under 2kg CO₂e per kg), and raw materials reporting continue to set the industry standard.

As the world races toward electrification, Tesla isn’t just building cars; it’s building a more responsible future.

News

Tesla Full Self-Driving likely to expand to yet another Asian country

“We are aiming for implementation in 2026. [We are] doing everything in our power [to achieve this],” Richi Hashimoto, president of Tesla’s Japanese subsidiary, said.

Tesla Full Self-Driving is likely to expand to yet another Asian country, as one country seems primed for the suite to head to it for the first time.

The launch of Full Self-Driving in yet another country this year would be a major breakthrough for Tesla as it continues to expand the driver-assistance program across the world. Bureaucratic red tape has held up a lot of its efforts, but things are looking up in some regions.

Tesla is poised to transform Japan’s roads with Full Self-Driving (FSD) technology by 2026.

Richi Hashimoto, president of Tesla’s Japanese subsidiary, announced the ambitious timeline, building on successful employee test drives that began in 2025 and earned positive media reviews. Test drives, initially limited to the Model 3 since August 2025, expanded to the Model Y on March 5.

Once regulators approve, Over-the-Air (OTA) software updates could activate FSD across roughly 40,000 Teslas already on Japanese roads. Japan’s orderly traffic and strict safety culture make it an ideal testing ground for autonomous driving.

Hashimoto said:

“We are aiming for implementation in 2026. [We are] doing everything in our power [to achieve this].”

The push aligns with Hashimoto’s leadership, which has been credited for Tesla’s sales turnaround.

In 2025, Tesla delivered a record 10,600 vehicles in Japan — a nearly 90% jump from the prior year and the first time exceeding 10,000 units annually.

BREAKING 🇯🇵 FSD IS LIKELY LAUNCHING IN JAPAN IN 2026 🚨

Richi Hashimoto, President of Tesla’s Japanese subsidiary, stated: “We are aiming for implementation in 2026” and added that they are “doing everything in our power” to achieve this 🔥

Test drives in Japan began in August… pic.twitter.com/jkkrJLszXN

— Ming (@tslaming) March 5, 2026

The strategy shifted from online-only sales to adding 29 physical showrooms in high-traffic malls, plus staff training and attractive financing offers launched in January 2026. Tesla also plans to expand its Supercharger network to over 1,000 points by 2027, boosting accessibility.

This Japanese momentum reflects Tesla’s broader international expansion. In Europe, Giga Berlin produced more than 200,000 vehicles in 2025 despite a temporary halt, supplying over 30 markets with plans for sequential production growth in 2026 and battery cell manufacturing by 2027.

While regional EV sales faced headwinds, the factory remains a cornerstone for Model Y deliveries across the continent.

In Asia, Giga Shanghai continues to be recognized as Tesla’s powerhouse. China, the company’s largest market, saw January 2026 deliveries from the plant rise 9 percent year-over-year to 69,129 units, with affordable new models expected later this year.

FSD advancements, already progressing in the U.S. and South Korea, are slated for Europe and further Asian rollout, complementing plans to expand Cybercab and Optimus to new markets as well.

With OTA-enabled autonomy on the horizon and retail strategies paying dividends, Tesla is strengthening its footprint from Tokyo showrooms to Berlin assembly lines and Shanghai exports. As Hashimoto continues to push Tesla forward in Japan, the company’s global vision for sustainable, self-driving mobility gains traction across Europe and Asia.

News

Tesla ships out update that brings massive change to two big features

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

Tesla has shipped out an update for its vehicles that was caused specifically by a California lawsuit that threatened the company’s ability to sell cars because of how it named its driver assistance suite.

Tesla shipped out Software Update 2026.2.9 starting last week; we received it already, and it only brings a few minor changes, mostly related to how things are referenced.

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

The following changes came to Tesla vehicles in the update:

- Navigate on Autopilot has now been renamed to Navigate on Autosteer

- FSD Computer has been renamed to AI Computer

Tesla faced a 30-day sales suspension in California after the state’s Department of Motor Vehicles stated the company had to come into compliance regarding the marketing of its automated driving features.

The agency confirmed on February 18 that it had taken a “corrective action” to resolve the issue. That corrective action was renaming certain parts of its ADAS.

Tesla discontinued its standalone Autopilot offering in January and ramped up the marketing of Full Self-Driving Supervised. Tesla had said on X that the issue with naming “was a ‘consumer protection’ order about the use of the term ‘Autopilot’ in a case where not one single customer came forward to say there’s a problem.”

This was a “consumer protection” order about the use of the term “Autopilot” in a case where not one single customer came forward to say there’s a problem.

Sales in California will continue uninterrupted.

— Tesla North America (@tesla_na) December 17, 2025

It is now compliant with the wishes of the California DMV, and we’re all dealing with it now.

This was the first primary dispute over the terminology of Full Self-Driving, but it has undergone some scrutiny at the federal level, as some government officials have claimed the suite has “deceptive” names. Previous Transportation Secretary Pete Buttigieg was one of those federal-level employees who had an issue with the names “Autopilot” and “Full Self-Driving.”

Tesla sued the California DMV over the ruling last week.