News

SpaceX closes out 2021 with $1.85 billion in new funding

On the eve of the last day of 2021, SEC filings show that SpaceX has secured another $337 million, bringing the total funding the company has raised this year to approximately $1.85 billion.

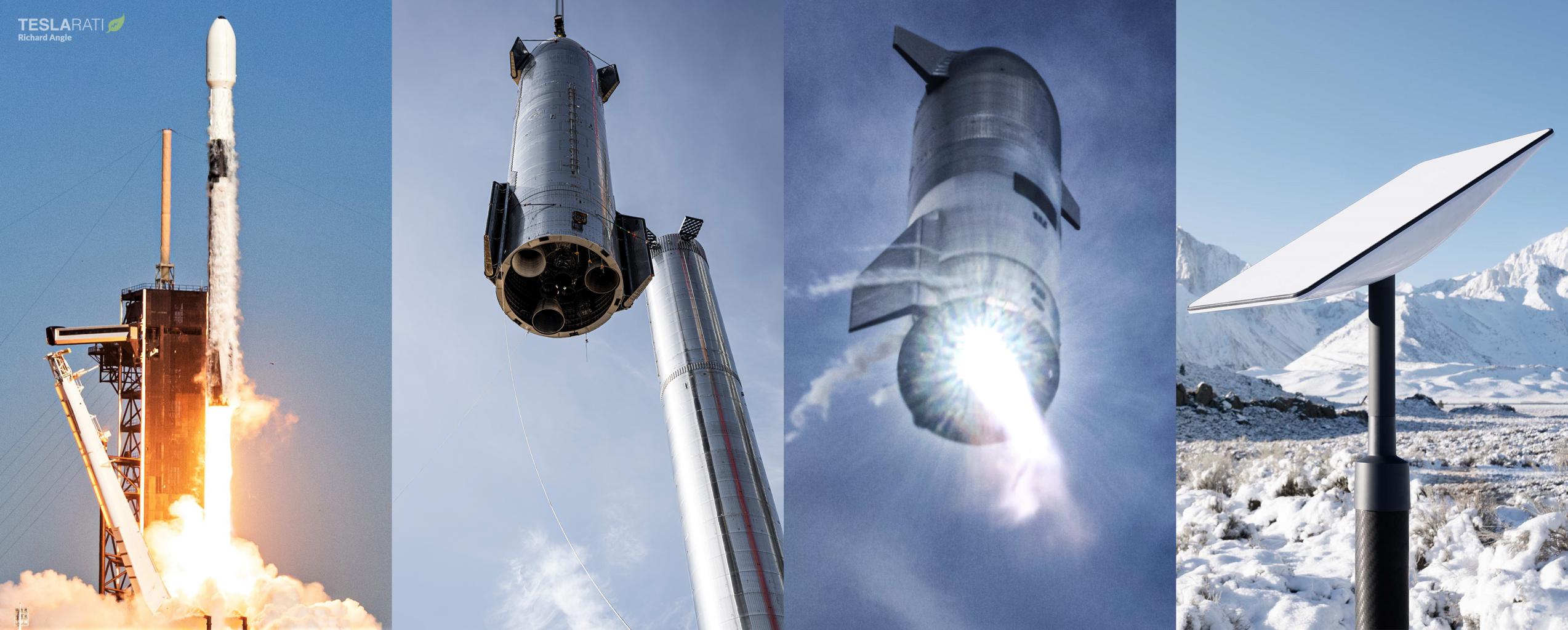

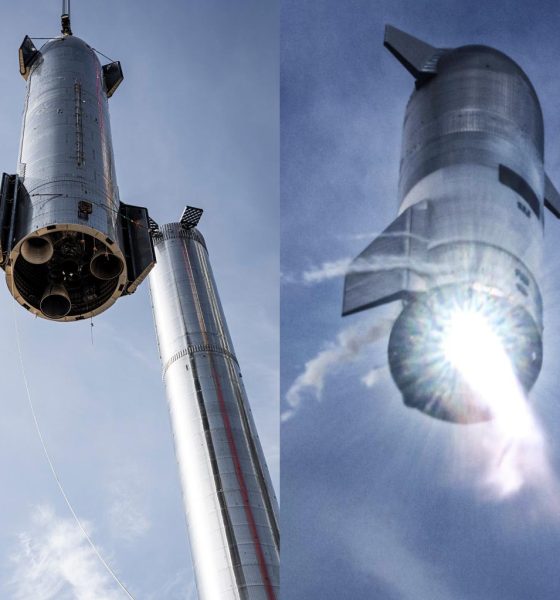

While there’s evidence that SpaceX’s Falcon and Dragon launch business is easily profitable on its own, the company has been simultaneously developing a next-generation rocket (Starship) and an unprecedentedly ambitious internet satellite constellation (Starlink) for at least the last 5-6 years. Additionally, SpaceX developed Falcon booster reusability and Falcon Heavy entirely on its own at a total cost of at least $1-2 billion. In short, rocket development is incredibly expensive, and adding a far more ambitious rocket and an immense satellite constellation into the mix has created an insatiable demand for fresh capital.

Investors have been more than eager to satisfy that demand, practically chomping at the bit to buy SpaceX equity or debt over the last six years. Since 2015, SpaceX has raised an average of more than $1B per year for the last seven years.

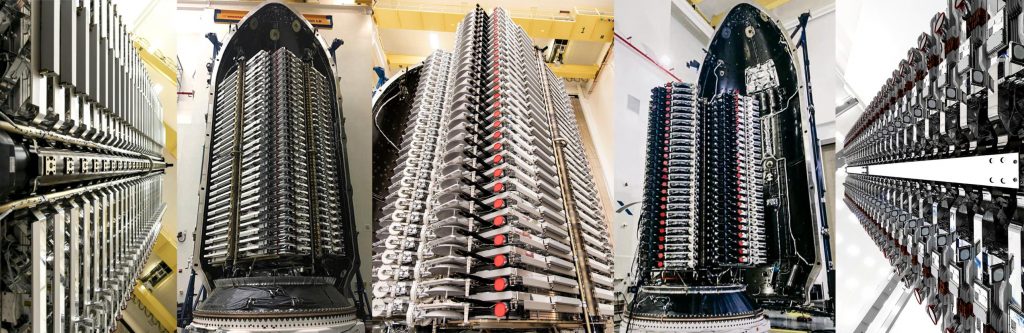

That funding has accomplished a great deal. As of the end of 2021, SpaceX has built and launched 1869 operational Starlink satellites in 25 months, more than 1750 of which are still in orbit and working. SpaceX has also built hundreds of thousands of ‘user terminals’ – dishes and WiFi routers that currently connect more than 150,000 subscribers to the internet even while the service remains in beta.

Starship, while somewhat behind its CEO’s optimistic schedules, continues to march towards its first spaceflight and orbital-velocity launch attempt – possibly in the first half of 2022. With help from its Hawthorne, CA headquarters, SpaceX’s Starbase factory continues to churn out Starship, Super Heavy booster, and test tank prototypes and appears to be ramping back up after six or so months of relative quiet. Having produced approximately 150 Raptor 1 and Raptor 1.5 engines in the last two years, Hawthorne is now focused on ramping up production of Raptor 2 – an upgraded engine variant capable of producing up to 25% more thrust while, in theory, being far cheaper to produce.

In about 12 months, SpaceX has also built – from nothing – an orbital launch site on the verge of being ready to support the first test flights of the largest, heaviest, and most powerful rocket ever built. To accommodate the massive vehicle, SpaceX has also nearly completed the largest cryogenic tank farm ever built for a launch site and partially filled at least four or five of its seven cryogenic storage tanks. Alongside that tank farm, the company has more or less completed a skyscraper-sized launch tower and outfitted it with three giant, moving arms – two of which are designed to stack Starship on Super Heavy and, maybe one day, catch ships and boosters out of mid-air.

According to a company-wide email CEO Elon Musk recently wrote but subsequently downplayed on Twitter, SpaceX’s financial health could be heavily dependent on the successful start and expansion of Raptor 2 production to enable Starship to begin launching new and much-improved Starlink V2.0 satellites. Those satellites are several times larger than V1.0 or V1.5 spacecraft, apparently making it hard or impossible for Falcon 9 to cost-effectively launch them.

On top of building and activating new factories capable of producing millions of Starlink user terminals per year, completing the first phase of orbital Starship development, ramping up Raptor 2 production, starting to build a fleet of operational Starships and Super Heavy boosters, continuing Falcon 9 Starlink V1.5 launches, and simultaneously building or completing no less than three orbital Starship launch sites in Florida and Texas, SpaceX thus also apparently needs to complete Starlink V2.0 satellite development and effectively build one or several entirely new production lines to start producing the substantially different spacecraft.

A large portion of SpaceX’s 2021 funding – especially the ~$337M raised in the last two weeks – will likely help support a portion of all those development efforts next year.

News

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

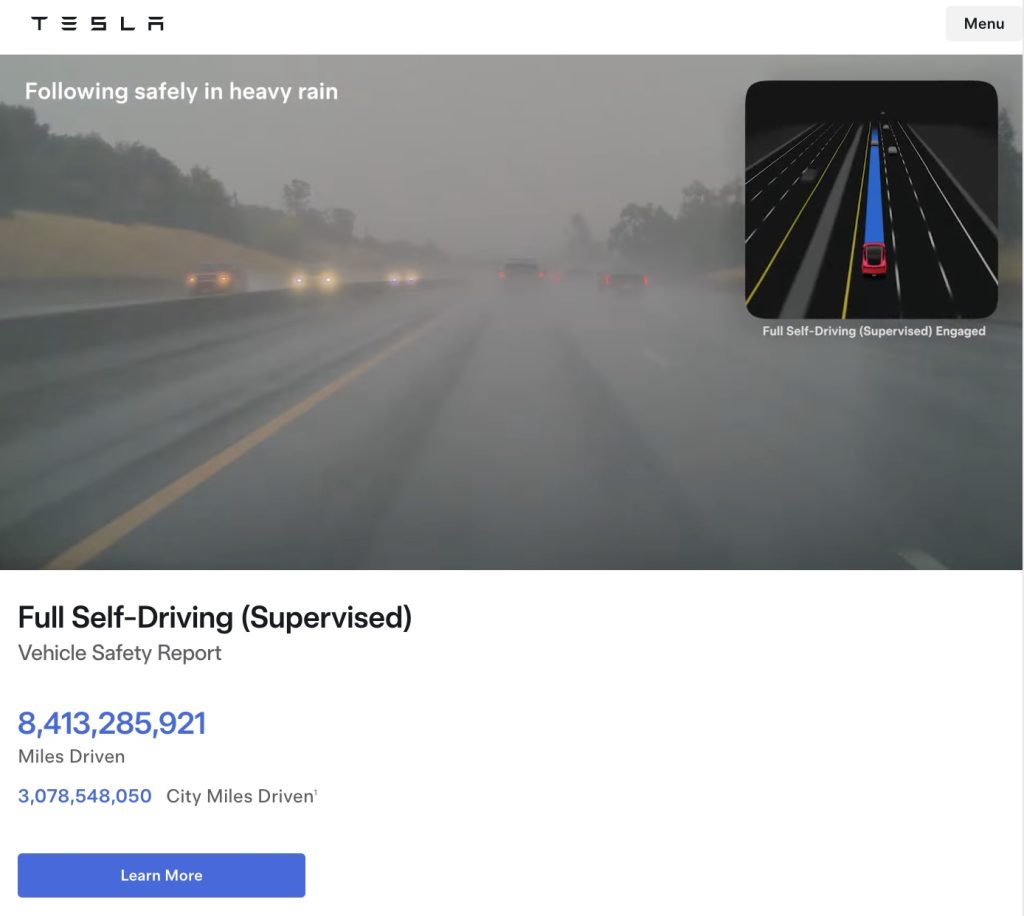

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.