Energy

Tesla’s battery genius may hold the key to a closed-loop recycling endgame

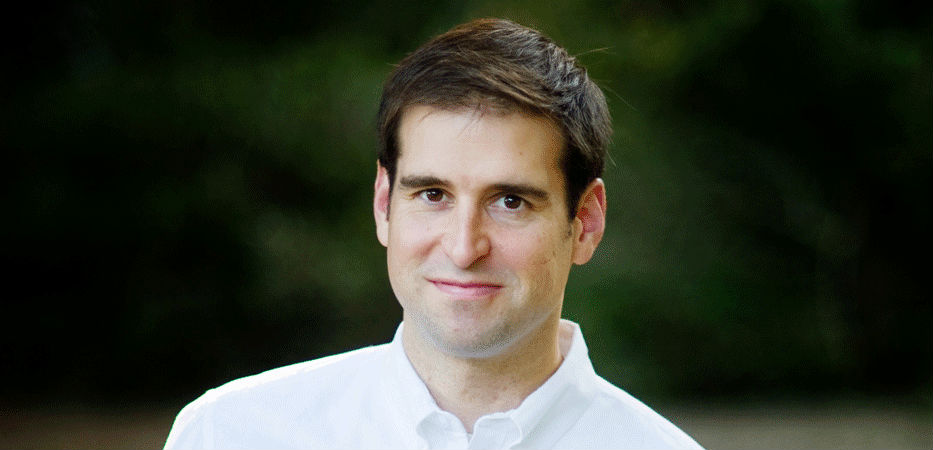

Last year, a proverbial bomb dropped on Tesla after CTO and co-founder JB Straubel announced that he was transitioning into an advisor role and stepping away from his day-to-day duties in the company. While Straubel assured investors that he was not “disappearing” from Tesla in his final earnings call, he did stay notably under the radar following his departure. But as the date for the electric car maker’s Battery Day draws closer, it appears that some pieces are slowly falling into place suggesting that JB Straubel’s company, Redwood Materials, and Tesla, may be coming together at a key junction.

To state that JB Straubel was the backbone of Tesla’s industry-leading battery tech is no understatement. Much of the company’s breakthroughs in its battery-related efforts, such as the construction of Gigafactory Nevada, would not have been possible without Straubel’s genius. In fact, so notable were his contributions to Tesla’s battery tech in the company’s early days that he was eventually considered as a co-founder of the electric car maker.

But even during his last years at Tesla, Straubel has remarked that one key aspect remains missing from the EV transition — closed-loop battery recycling. Battery electric vehicles are great in the way that they are zero-emissions, after all, but disposing of their batteries at their end-of-life presents notable challenges under closed-loop recycling is developed. “Ultimately what we want is a closed-loop, right, at the Gigafactories that reuses the same, recycled materials,” he remarked at Tesla’s 2018 Annual Shareholders Meeting.

Prior to his departure from his day-to-day duties at Tesla, reports emerged stating that Straubel had founded a stealthy battery recycling startup called Redwood Materials. Interestingly enough, Redwood centered its operations in Nevada, the same state that hosts Tesla’s biggest battery facility to date, Gigafactory 1. When reports about Redwood initially emerged in 2018, however, Straubel was quick to note that his recycling startup’s operations are “unrelated to Tesla or to the Gigafactory directly.”

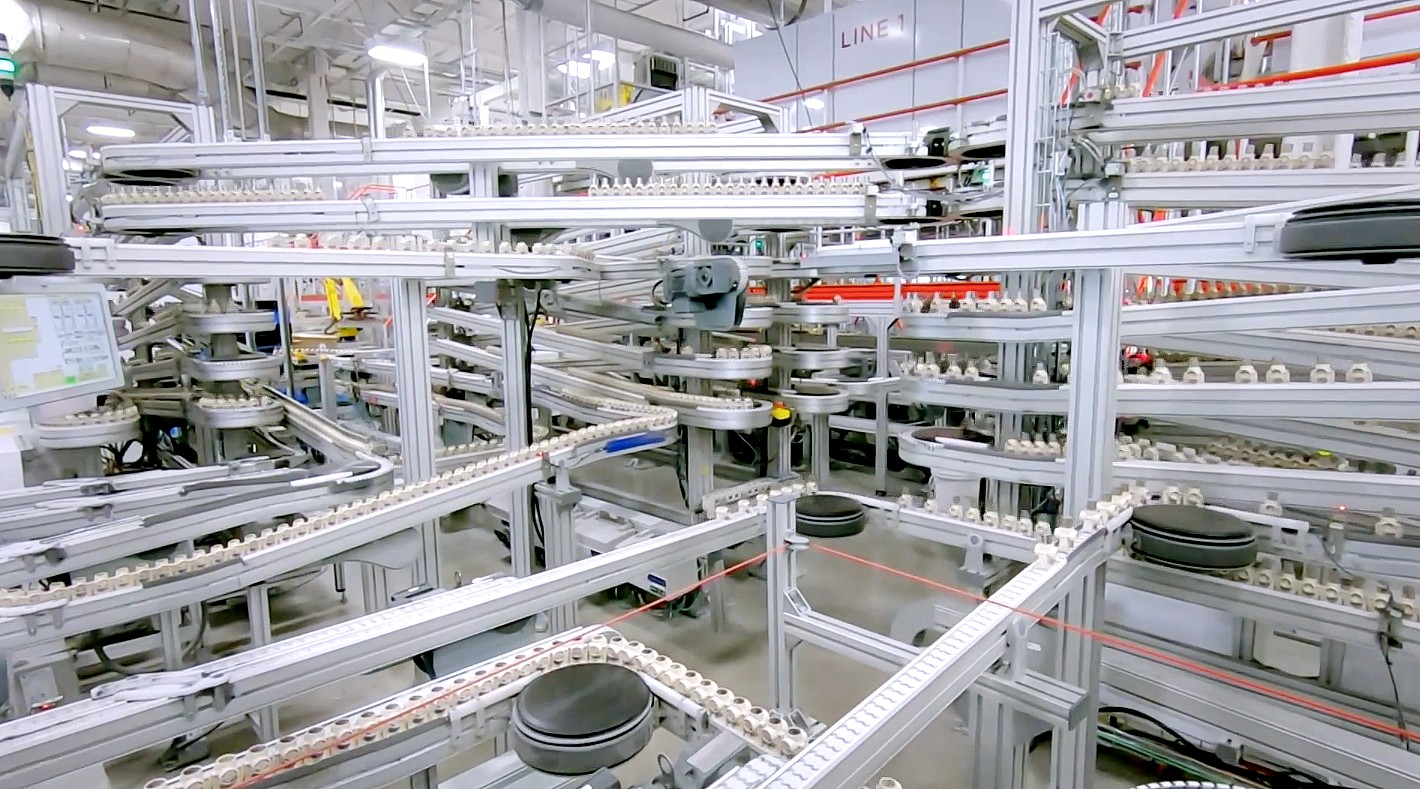

A recent report from The Wall Street Journal has now revealed some notable details that may explain some aspects of Straubel’s statement back in 2018. According to the publication, Redwood has already convinced Panasonic, Tesla’s battery partner at Gigafactory Nevada, to utilize Redwood’s technology to reclaim scrap from its operations in the facility. Panasonic reportedly started with a trial run that involved Redwood reclaiming more than 400 pounds of scrap from its Giga Nevada operations. The Japanese firm appears to have been satisfied with Redwood’s results in the trial run, as Panasonic reportedly upped its contract with the startup to 2 tons not long after.

Today, the Journal stated that all of the scrap coming from Panasonic’s side of Gigafactory Nevada’s battery production activities are being shipped to Redwood Materials for recycling. In a way, Redwood’s partnership with Panasonic seems to fit Straubel’s statement back in 2018, when he noted that his startup has no direct relation to Tesla’s operations. That being said, it is evident that Redwood’s tech is a notable step forward towards JB Straubel’s vision of a closed-loop battery recycling system.

Straubel’s plans for Redwood are ambitious, as he is looking to develop a recycling process that is so efficient that batteries coming from retired electric vehicles and energy storage units could be quickly stripped down, recycled for their core materials, and used to rebuild new batteries. With such a system in place, a closed-loop is created, and hardly any materials are lost. It’s a lofty goal, but it does hint at Straubel’s understated determination that made him such a powerful background force in Tesla.

Interestingly enough, Tesla’s new Impact Report specifically includes a section about closed-loop battery recycling. According to the electric car maker, such a setup at Gigafactory Nevada “presents a compelling solution to move energy supply away from the fossil-fuel based practice of take, make and burn, to a more circular model of recycling end-of-life batteries for reuse over and over again. From an economic perspective, we expect to recognize significant savings over the long term, as the costs associated with large-scale battery material recovery and recycling will be far lower than purchasing and transporting new materials.”

It remains to be seen if JB Straubel’s Redwood Materials and Tesla are indeed working together to recycle batteries from Gigafactory 1 and perhaps even the electric car maker’s own Roadrunner program, but despite the lack of confirmation for now, one thing is certain. One of the brightest minds in Tesla, who is arguably the genius behind the company’s battery tech and initiatives, has started a thriving company that fills in the crucial gap of battery recycling. And with such a key innovation at its doorstep, it appears out of character for Tesla to simply ignore the opportunities presented by Redwood Materials and its battery recycling technologies.

Energy

Tesla Megapack Megafactory in Texas advances with major property sale

Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet.

Tesla’s planned Megapack factory in Brookshire, Texas has taken a significant step forward, as two massive industrial buildings fully leased to the company were sold to an institutional investor.

In a press release, Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet. The properties are 100% leased to Tesla under a long-term agreement and were acquired by BGO on behalf of an institutional investor.

The two facilities, located at 100 Empire Boulevard in Brookshire, Texas, will serve as Tesla’s new Megafactory dedicated to manufacturing Megapack battery systems.

According to local filings previously reported, Tesla plans to invest nearly $200 million into the site. The investment includes approximately $44 million in facility upgrades such as electrical, utility, and HVAC improvements, along with roughly $150 million in manufacturing equipment.

Building 9, spanning roughly 1 million square feet, will function as the primary manufacturing floor where Megapacks are assembled. Building 10, covering approximately 600,000 square feet, will be dedicated to warehousing and logistics operations, supporting storage and distribution of completed battery systems.

Waller County Commissioners have approved a 10-year tax abatement agreement with Tesla, offering up to a 60% property-tax reduction if the company meets hiring and investment targets. Tesla has committed to employing at least 375 people by the end of 2026, increasing to 1,500 by the end of 2028, as noted in an Austin County News Online report.

The Brookshire Megafactory will complement Tesla’s Lathrop Megafactory in California and expand U.S. production capacity for the utility-scale energy storage unit. Megapacks are designed to support grid stabilization and renewable-energy integration, a segment that has become one of Tesla’s fastest-growing businesses.

Energy

Tesla meets Giga New York’s Buffalo job target amid political pressures

Giga New York reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease.

Tesla has surpassed its job commitments at Giga New York in Buffalo, easing pressure from lawmakers who threatened the company with fines, subsidy clawbacks, and dealership license revocations last year.

The company reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease at the state-built facility.

As per an employment report reviewed by local media, Tesla employed 2,399 full-time workers at Gigafactory New York and 1,060 additional employees across the state at the end of 2025. Part-time roles pushed the total headcount of Tesla’s New York staff above the 3,460-job target.

The gains stemmed in part from a new Long Island service center, a Buffalo warehouse, and additional showrooms in White Plains and Staten Island. Tesla also said it has invested $350 million in supercomputing infrastructure at the site and has begun manufacturing solar panels.

Empire State Development CEO Hope Knight said the agency was “very happy” with Giga New York’s progress, as noted in a WXXI report. The current lease runs through 2029, and negotiations over updated terms have included potential adjustments to job requirements and future rent payments.

Some lawmakers remain skeptical, however. Assemblymember Pat Burke questioned whether the reported job figures have been fully verified. State Sen. Patricia Fahy has also continued to sponsor legislation that would revoke Tesla’s company-owned dealership licenses in New York. John Kaehny of Reinvent Albany has argued that the project has not delivered the manufacturing impact originally promised as well.

Knight, for her part, maintained that Empire State Development has been making the best of a difficult situation.

“(Empire State Development) has tried to make the best of a very difficult situation. There hasn’t been another use that has come forward that would replace this one, and so to the extent that we’re in this place, the fact that 2,000 families at (Giga New York) are being supported through the activity of this employer. It’s the best that we can have happen,” the CEO noted.

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

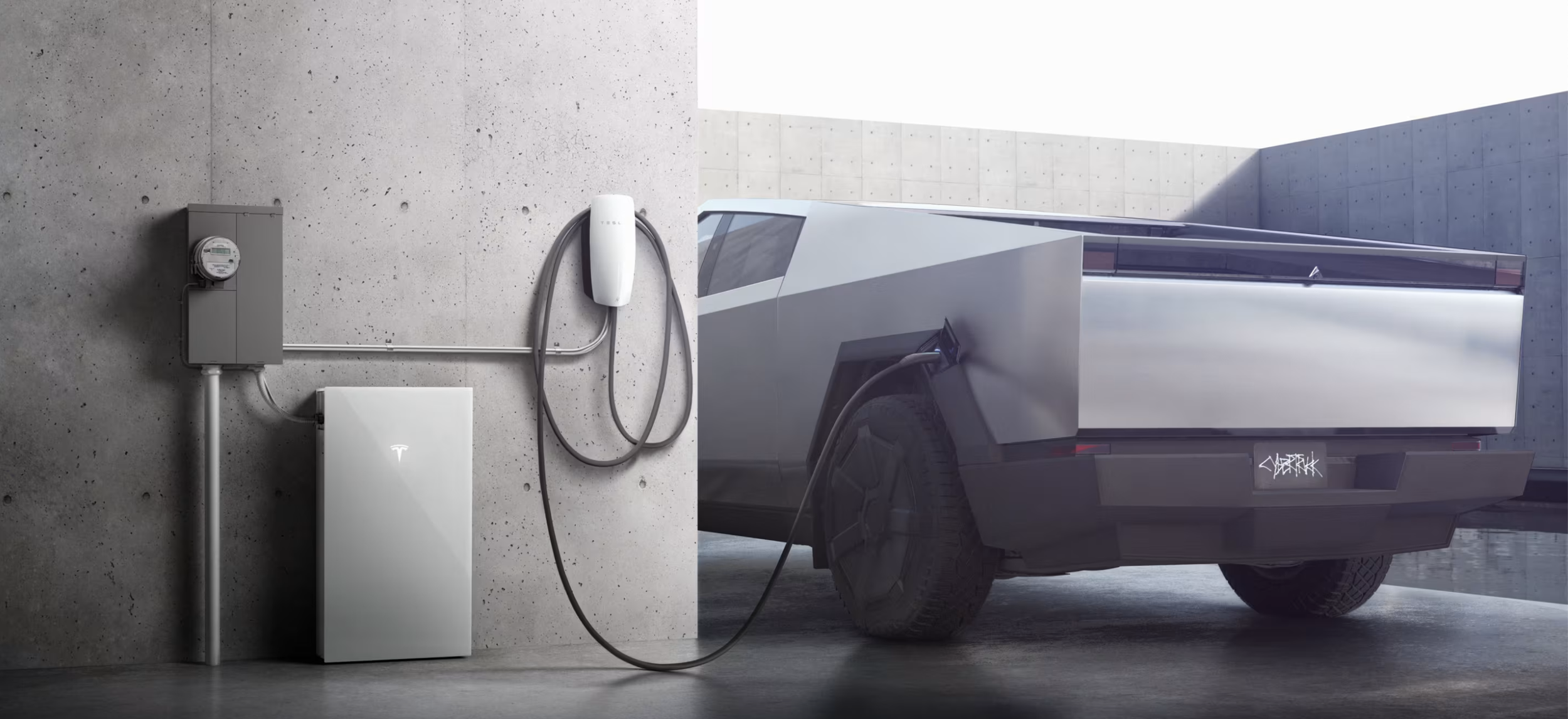

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.