News

Opinion: The Tesla Cybertruck accelerated the Ford F-150 Lightning’s release, like it or not

During the Ford F-150 Lightning’s unveiling, the veteran automaker proudly presented a vehicle that has the potential to carry the company well into the age of electric cars. But inasmuch as the F-150 Lightning is impressive and worthy of its flagship EV status, Ford may have a competitor and unlikely ally to thank for its release. This competitor is the steel beast from Silicon Valley, the Tesla Cybertruck.

A different landscape

It should be noted that just a few years ago, the EV landscape was much different for Ford and its fellow veteran automakers. In 2019, it appeared that the electric pickup market was destined to be yet another niche segment populated by expensive EVs that were out of reach for the conventional buyer. Back then, the Rivian R1T seemed to be the electric pickup truck to beat, after it debuted in late 2018 and impressed the car community with its novel features.

Inasmuch as Rivian captured the attention of EV enthusiasts, legacy auto, at least from the perspective of a layman, seemed to be quite uninterested in the battery-electric truck market. This was one of the reasons why Ford inspired a ton of headlines in January 2019 when then-president of global markets and now-CEO Jim Farley announced that the F-Seres was getting electrified. “We’re going to be electrifying the F-Series — battery electric and hybrid,” he said.

It was a shock to the United States’ automotive industry, with longtime industry observer and Autoline This Week host John McElroy highlighting the gravity of Farley’s statement. “When he says ‘battery-electric,’ what I’m taking that to mean is a battery electric vehicle. Pure electric. They’ve said they would have a hybrid plug-in version of the F-150. But this is different than what they’ve talked about in the past,” McElroy said.

A noncommittal stance

But while Ford’s announcement showed that it could talk the talk, the company didn’t necessarily walk the walk. Even after Ford showed off the capabilities of the electric F-150 by having the vehicle pull a freight train loaded with other F-150s, the company proved very elusive about its plans for the vehicle. Speaking to Yahoo Finance’s The First Trade following the electric F-150’s 1-million-pound demonstration, Ford Chief Product Development Officer Hau Thai-Tang was asked about the upcoming vehicle’s release.

The Ford executive’s answers about the all-electric truck were very reserved. When pressed further, the executive simply remarked that the battery-electric F-150 was “still a couple of years out,” though he did highlight that the F-150 Hybrid would be released first.

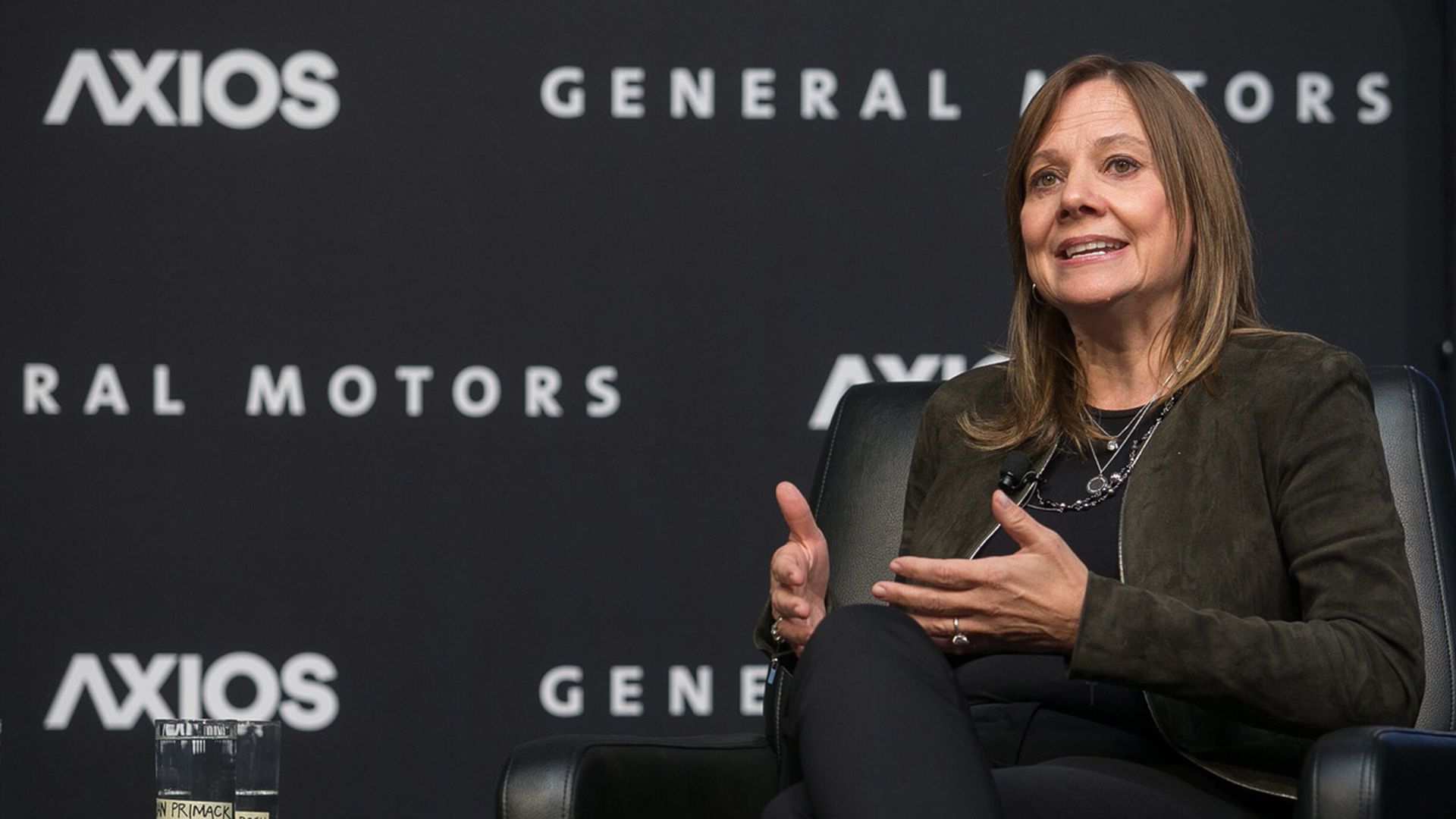

This noncommittal stance was prevalent for much of 2019. Ford’s longtime rival, General Motors, also announced then that it had a program for an all-electric pickup truck. During a quarterly earnings call, GM CEO Mary Barra stated that the company intends to “create an all-electric future that includes a complete range of EVs, including full-size pickups. She also noted that details about GM’s battery-electric pickup would be shared “when competitively appropriate.”

A watershed moment

But something happened at the end of 2019. In November 2019, Tesla took the wraps off its all-electric pickup truck. It was a vehicle that Elon Musk has been mentioning for years, and in the months leading up to its unveiling, the CEO had been setting the public’s expectations. Musk noted that the Cybertruck would probably be polarizing, and he even stated that if it were to flop, Tesla would simply make a more conventional pickup truck. The Cybertruck proved to be everything that Musk said it was, and more. With its angular design and unpainted steel body, the Cybertruck was unlike any vehicle on the road, and it barely looked like a pickup truck.

Its appearance, together with the Armor Glass demonstration that ended with the Cybertruck’s driver’s side windows getting cracked, resulted in the futuristic vehicle becoming a meme overnight. Tesla fans learned to love it, and critics made sure to point out how strange and ugly it looked. But amidst all the memes about the Cybertruck’s looks and its failed Armor Glass demonstration lay something notable—Tesla’s all-electric pickup truck had some serious specs.

While the Cybertruck’s looks were amusing to critics, its specs were very real, and most of all, it was cheap for the features that it offers. Starting at less than $40,000 and capable of towing 14,000 pounds, it was a threat to the status quo, especially as it could become attractive to businesses and people who value low operating costs and a rapid return of investment. After all, Tesla may be known for its delays, but the company never overpromises on its vehicles’ capabilities.

An accelerated shift

Something seemed to change after the Cybertruck was unveiled. Just months after the Cybertruck’s launch, GM revealed its Ultium batteries, which was announced together with a number of new all-electric models. By October 2020, GMC launched the Hummer EV, a gargantuan all-electric pickup truck designed for serious off-roading. GM may never admit it, but signs pointed to the Hummer EV’s development being rushed. The automaker unveiled the vehicle with a CGI video and a prototype that barely moved.

This was very different from the strategy of Tesla and Rivian, of course, both of whom unveiled fully-working trucks. Tesla even had the Cybertruck take attendees for a test ride for several hours following its unveiling. GM Chief Engineer Al Oppenheiser admitted as such in a statement to EV publication Green Car Reports. Oppenheiser revealed that the Hummer EV was only 18 months into its development cycle when it was unveiled, which was a very short time for a legacy automaker.

“Interestingly enough, we don’t have a vehicle yet. We’re building our first test vehicle as we speak; the vehicle you see in the video is our display vehicle,” he said. GM, of course, eventually started demonstrating the Hummer EV’s capabilities in real-life settings later on. But by then, it was practically evident that the automaker was moving as fast as it could to enter the all-electric pickup truck market with a competitive edge.

Ford seemed to have accelerated its battery-electric truck program as well, and now the Ford F-150 Lightning is here. And unlike the Hummer EV, it seems to be ready to go. The Rouge facility seems ready to produce the vehicle, though the ongoing chip shortage is still looming in the background. There’s also the issue of securing enough batteries for the vehicle, considering that the F-150 is expected to demand equally large battery packs to hit its targeted 300 miles of range.

Overall, it appears that the rush is now on to produce the first mainstream electric pickup truck. And so far, it appears that the battle will be waged by the Ford F-150 Lightning and the Tesla Cybertruck, considering their comparable starting prices. But while the F-150 Lightning loses out in key features such as range and towing capacity, it does have the pedigree and reputation of a tried and tested pickup brand and a design that is as conventional as it is comfortable. And that, ultimately, could be a trump card for the electric revolution as a whole.

The battle is on for America’s most popular automotive segment.

Don’t hesitate to contact us for news tips. Just send a message to tips@teslarati.com to give us a heads up.

News

Tesla workers push back against Giga Berlin unionization

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

Tesla workers pushed back against unionization efforts at Gigafactory Berlin, and over the past few years, there has been a dramatic decrease in interest to unionize at the German plant.

Gigafactory Berlin Plant Manager André Thierig announced on Wednesday that IG Metall, the European union group, saw its share reduce from 40 to 31 percent in 2026 as employees eligible to vote on the issue. Instead, the Giga Berlin team, known as Giga United, received the most votes with more than 40 percent.

BREAKING! 🚨

IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026!

This is a clear message by theGiga Berlin team towards an independent co-determination!

The list called Giga…

— André Thierig (@AndrThie) March 4, 2026

Thierig gave specific details in a post on X:

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

There were over 10,700 total employees who were eligible to vote, with 87 percent of them turning out to cast what they wanted. There were three key outcomes: Giga United, IG Metall, and other notable groups, with the most popular being the Polish Initiative.

The 37-seat council remains dominated by non-unionized representatives, preserving Giga Berlin as Germany’s only major auto plant without a collective bargaining agreement.

Thierig and Tesla framed the outcome as employee support for an “independent, flexible, and unbureaucratic” future, enabling acceleration on projects like potential expansions or new models. IG Metall expressed disappointment, accusing management of intimidation tactics and an “unfair” campaign.

The first election of this nature happened back in 2022. In 2024, IG Metall emerged as the largest single faction with 39.4 percent, but non-union lists coalesced for a majority.

But this year was different. There was some extra tension at Giga Berlin this year, as just two weeks ago, an IG Metall rep was accused by Tesla of secretly recording a council meeting. The group countersued for defamation.

Tesla Giga Berlin plant manager faces defamation probe after IG Metall union complaint

This result from the 2026 vote reinforced Tesla’s model of direct employee-management alignment over traditional German union structures, amid ongoing debates about working conditions. IG Metall views it as a setback but continues advocacy. Tesla sees it as validation of its approach in a competitive EV market.

This outcome may influence future labor dynamics at Giga Berlin, including any revival of expansion plans or product lines, which Musk has talked about recently.

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.

News

Tesla Full Self-Driving v14.2.2.5 might be the most confusing release ever

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

Tesla Full Self-Driving v14.2.2.5 hit my car back on Valentine’s Day, February 14, and since I’ve had it, it has become, in my opinion, the most confusing release I’ve ever had.

With each Full Self-Driving release, I am realistic. I know some things are going to get better, and I know some things will regress slightly. However, these instances of improvements are relatively mild, as are the regressions. Yet, this version has shown me that it contains extremes of both.

It has been about three weeks of driving on v14.2.2.5; I’ve used it for nearly every mile traveled since it hit my car. I’ve taken short trips of 10 minutes or less, I’ve taken medium trips of an hour or less, and I’ve taken longer trips that are over 100 miles per leg and are over two hours of driving time one way.

These are my thoughts on it thus far:

Speed Profiles Are a Mixed Bag

Speed Profiles are something Tesla seems to tinker with quite frequently, and each version tends to show a drastic difference in how each one behaves compared to the previous version.

I do a vast majority of my FSD travel using Standard and Hurry modes, although in bad weather, I will scale it back to Chill, and when it’s a congested city on a weekend or during rush hour, I’ll throw it into Mad Max so it takes what it needs.

Early on, Speed Profiles really felt great. This is one of those really subjective parts of the FSD where someone might think one mode travels too quickly, whereas another person might see the identical performance as too slow or just right.

To me, I would like to see more consistency from release to release on them, but overall, things are pretty good. There are no real complaints on my end, as I had with previous releases.

In a past release, Mad Max traveled under the speed limit quite frequently, and I only had that experience because Hurry was acting the same way. I’ve had no instances of that with v14.2.2.5.

Strange Turn Signal Behavior

This is the first Full Self-Driving version where I’ve had so many weird things happen with the turn signals.

Two things come to mind: Using a turn signal on a sharp turn, and ignoring the navigation while putting the wrong turn signal on. I’ve encountered both things on v14.2.2.5.

On my way to the Supercharger, I take a road that has one semi-sharp right-hand turn with a driveway entrance right at the beginning of the turn.

Only recently, with the introduction of v14.2.2.5, have I had FSD put on the right turn signal when going around this turn. It’s obviously a minor issue, but it still happens, and it’s not standard practice:

How can we get Full Self-Driving to stop these turn signals?

There’s no need to use one here; the straight path is a driveway, not a public road. The right turn signal here is unnecessary pic.twitter.com/7uLDHnqCfv

— TESLARATI (@Teslarati) February 28, 2026

When sharing this on X, I had Tesla fans (the ones who refuse to acknowledge that the company can make mistakes) tell me that it’s a “valid” behavior that would be taught to anyone who has been “professionally trained” to drive.

Apparently, if you complain about this turn signal, you are also claiming you know more than Tesla engineers…okay.

Nobody in their right mind has ever gone around a sharp turn when driving their car and put on a signal when continuing on the same road. You would put a left turn signal on to indicate you were turning into that driveway if that’s what your intention was.

Like I said, it’s a totally minor issue. However, it’s not really needed, and nor is it normal. If I were in the car with someone who was taking a simple turn on a road they were traveling, and they signaled because the turn was sharp, I’d be scratching my head.

I’ve also had three separate instances of the car completely ignoring the navigation and putting on a signal that is opposite to what the routing says. Really quite strange.

Parking Performance is Still Underwhelming

Parking has been a complaint of mine with FSD for a long time, so much so that it is pretty rare that I allow the vehicle to park itself. More often than not, it is because I want to pick a spot that is relatively isolated.

However, in the times I allow it to pull into a spot, it still does some pretty head-scratching things.

Recently, it tried to back into a spot that was ~60% covered in plowed snow. The snow was piled about six feet high in a Target parking lot.

A few days later, it tried backing into a spot where someone failed the universal litmus test of returning their shopping cart. Both choices were baffling and required me to manually move the car to a different portion of the lot.

I used Autopark on both occasions, and it did a great job of getting into the spot. I notice that the parking performance when I manually choose the spot is much better than when the car does the entire parking process, meaning choosing the spot and parking in it.

It’s Doing Things (For Me) It’s Never Done Before

Two things that FSD has never done before, at least for me, are slow down in School Zones and avoid deer. The first is something I usually take over manually, and the second I surprisingly have not had to deal with yet.

I had my Tesla slow down at a school zone yesterday for the first time, traveling at 20 MPH and not 15 MPH as the sign suggested, but at the speed of other cars in the School Zone. This was impressive and the first time I experienced it.

I would like to see this more consistently, and I think School Zones should be one of those areas where, no matter what, FSD will only travel the speed limit.

Last night, FSD v14.2.2.5 recognized a deer in a roadside field and slowed down for it:

🚨 Cruising home on a rainy, foggy evening and my Tesla on Full Self-Driving begins to slow down suddenly

FSD just wanted Mr. Deer to make it home to his deer family ❤️ pic.twitter.com/cAeqVDgXo5

— TESLARATI (@Teslarati) March 4, 2026

Navigation Still SUCKS

Navigation will be a complaint until Tesla proves it can fix it. For now, it’s just terrible.

It still has not figured out how to leave my neighborhood. I give it the opportunity to prove me wrong each time I leave my house, and it just can’t do it.

It always tries to go out of the primary entrance/exit of the neighborhood when the route needs to take me left, even though that exit is a right turn only. I always leave a voice prompt for Tesla about it.

It still picks incredibly baffling routes for simple navigation. It’s the one thing I still really want Tesla to fix.