Tesla is rumored to be purchasing wireless charging company Wiferion, a Freiberg, Germany-based entity with charging and power solutions.

Wiferion describes itself as “the industry’s leading supplier of automated, wireless power supply systems.” The company has worked to provide over 100 companies with wireless charging solutions since 2015, when it initially started developing products.

BREAKING: Tesla in process of buying Wiferion – wireless charging for both Electric Vehicles and Robots pic.twitter.com/ER9ajNwe2N

— Herbert Ong (@herbertong) June 21, 2023

Wiferion entered the North American market after reaching a global licensing agreement with WiTricity last year, which unveiled its wireless charging tech using a Tesla last year.

A report from Gründerszene/Business Insider states that Wiferion is set to offload its business to Tesla International BV, a filing in the German Commercial Register indicates. “The shareholders intend to sell their shares in the company to Tesla International BV by means of a purchase agreement,” the filing said.

Tesla International BV is a wholly-owned subsidiary that operates out of the Netherlands.

The publication went on to ask two Wiferion investors if the sale was taking place, and they confirmed it but would not say what company the deal would be with.

The deal could be a work in progress toward Tesla’s wireless charging device, which it seemed to quietly unveil during the Shareholder Meeting earlier this year. Tesla showed a vehicle sitting above a wireless charging pad in a garage, seemingly hinting toward a wireless charging module that would soon be on the way.

Tesla teases mysterious “wireless” home charger on Investor Day

Tesla has used company acquisitions as a means to move certain projects forward in the past. In 2019, Tesla acquired Maxwell Technologies, only to sell it a couple of years later in 2021. It also bought Hibar Systems in late 2019.

Both of these purchases were groundbreaking moves to help Tesla develop in-house battery cells, which it produces at several of its manufacturing locations, including in California and Texas.

I’d love to hear from you! If you have any comments, concerns, or questions, please email me at joey@teslarati.com. You can also reach me on Twitter @KlenderJoey, or if you have news tips, you can email us at tips@teslarati.com.

News

EVs getting cleaner more quickly than expected in Europe: study

Battery-electric vehicles are still championing emissions reductions, and a new analysis suggests they’re doing so even more quickly than previously expected.

As Europe’s electricity mix is getting cleaner, battery-electric vehicles (BEVs) are also offering a larger climate advantage than previously expected, according to the results of a new study released this week.

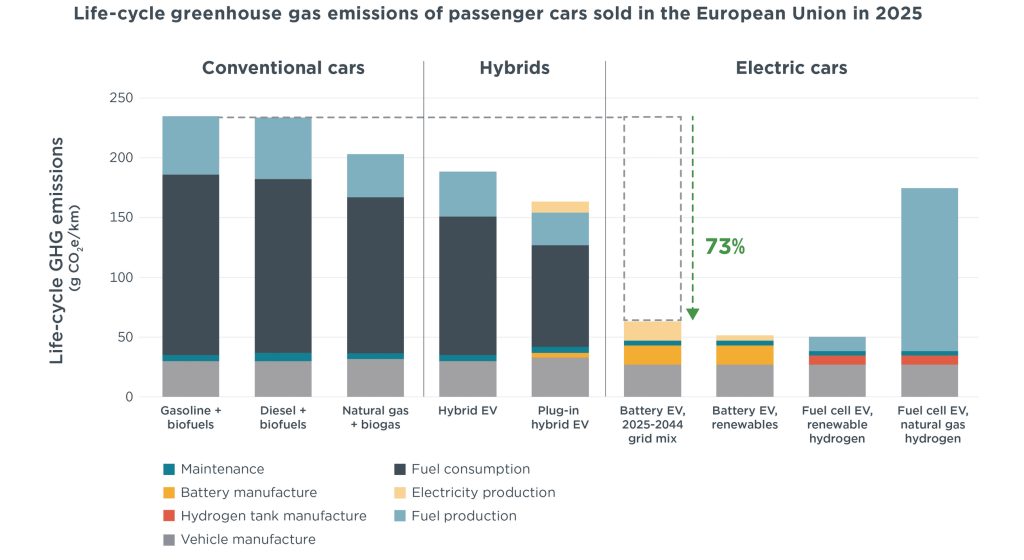

On Wednesday, the International Council on Clean Transportation (ICCT) released a study noting that BEVs sold today produce 73 percent fewer life-cycle greenhouse gas emissions than internal combustion engine (ICE) vehicles, even factoring in production. This figure also represents a 24-percent improvement upon the organization’s 2021 estimates for this year, meaning that BEVs are getting cleaner more quickly than expected as the continent’s renewable programs continue to grow.

The study was comprised of a comprehensive life-cycle analysis of all major powertrain types, and the results suggest that BEVs are the only widely available powertrain that can slash emissions levels enough to meet climate goals. By contrast, the study’s results suggest that other clean energy powertrains, such as hybrids and plugin hybrids, only have a marginal impact, if any, on reducing the overall climate impact of the transportation sector.

“Battery electric cars in Europe are getting cleaner faster than we expected and outperform all other technologies, including hybrids and plug-in hybrids,” says ICCT researcher Dr. Marta Negri. “This progress is largely due to the fast deployment of renewable electricity across the continent and the greater energy efficiency of battery electric cars.”

Credit: International Council on Clean Transportation (ICCT)

READ MORE ON ELECTRIC VEHICLES: Study reveals hybrids could have up to 4.9x lifetime emissions vs. BEVs

ICCT Senior Researcher Dr. Georg Bieker says he also hopes the analysis can help fight misinformation regarding BEV powertrains. For example, he notes that, while it’s true that manufacturing emissions for BEVs can be up to 40 percent higher than for ICE vehicles, this is quickly offset by an electric automobile after just around 17,000 km (~10,563 miles) of driving.

“We hope this study brings clarity to the public conversation, so that policymakers and industry leaders can make informed decisions,” Dr. Bieker says. “We’ve recently seen auto industry leaders misrepresenting the emissions math on hybrids. But life-cycle analysis is not a choose-your-own-adventure exercise.”

Additionally, the ICCT study covers emissions from both vehicle and battery production, recycling, fuel and electricity production, fuel consumption, and maintenance.

“Our study accounts for the most representative use cases and is grounded in real-world data,” Dr. Bieker adds. “Consumers deserve accurate, science-backed information.”

News

Tesla executive teases plan to further electrify supply chain

One of Tesla’s top executive hints at how Tesla is further electrifying its supply chain.

A high-level Tesla executive has said the company is working to further electrify its supply chain, following a successful road test with the Semi this week.

After Tesla supplier thyssenkrupp completed a successful 5,000-mile winter trial with the Semi this week, Dan Priestley, the company’s Director of Semi Engineering, noted on X that the demonstration is a part of larger efforts to electrify more of the supply chain. The executive said that the company is already working to help suppliers like thyssenkrupp implement the Semi into their operations, particularly due to its cost savings and reliability.

Following the thyssenkrupp demo, the supply chain company has also begun integrating the Semi into its fleet, and Priestley suggests that more are still to come:

Working with our suppliers and logistics partners to electrify Tesla’s supply chain. With lower cost and higher reliability, it just makes sense. thyssenkrupp pushed the truck hard over this demo and now plans to integrate Semi into their fleet.

🚨 A Tesla Semi rolling around near Gigafactory Texas

If you remember, the Drone GOAT 🐐 @JoeTegtmeyer spotted one on factory property last week!pic.twitter.com/tvchIQar1u

— TESLARATI (@Teslarati) June 10, 2025

READ MORE ON TESLA SEMI: Tesla Full Self-Driving displays impressive collision avoidance with Semi

Tesla Semi factory nears official production as trials continue to impress

Tesla’s early Semi trials received positive results from both thyssenkrup and ArcBest’s ABF Freight this week, with the latter company logging 4,494 miles during a pilot period, and averaging 321 miles per day despite a 7,200-foot climb over Donner Pass.

The company has also been constructing a factory for volume Semi production at its Gigafactory in Nevada, and in recent weeks, the plant is looking nearly complete. Semi frames have been spotted in increasing numbers outside the facility recently, suggesting that Tesla is nearing early production on site.

The company also hired more than 1,000 workers for the Semi factory in April, while the plant is eventually expected to produce as many as 50,000 Semi units annually.

Tesla reveals Semi fleet data, shows off new feature and infrastructure plans

News

Tesla Semi completes 5,000-mile winter trial with thyssenkrupp

The test covered nearly 5,000 miles in winter conditions.

thyssenkrupp Supply Chain Services has completed a three-week pilot of the Tesla Semi at one of its California logistics hubs, marking a new step in the company’s sustainability push. The test covered nearly 5,000 miles in winter conditions and focused on evaluating the electric Class 8 truck’s efficiency, transparency, and operational performance.

Tesla Semi offers efficiency gains and real-time logistics visibility

During the pilot, the Tesla Semi was used for active freight delivery, including routes over the Altamont Pass. thyssenkrupp evaluated the vehicle’s ability to reduce downtime, enhance delivery speed, and offer greater real-time supply chain visibility, the company noted in a press release.

Live diagnostics and performance monitoring allowed the logistics provider to track metrics such as speed, routes, and overall efficiency—data that supports smarter and more transparent logistics operations.

“The Tesla Semi aligns with our ongoing commitment to sustainability and operational excellence,” said Bob Denehy, Chief Commercial Officer at thyssenkrupp Supply Chain Services. “Its efficiency and diagnostic features, and low environmental impact make it a natural fit for our evolving logistics strategy.”

Pilot builds on long-term partnership with Tesla and green energy goals

A logistics partner to Tesla since 2015, thyssenkrupp Supply Chain Services was one of the first companies selected to test the Tesla Semi in a real-world setting. The trial reinforces the company’s push into renewable energy logistics and reflects its long-term goal of integrating alternative-fuel technologies across its operations.

Plans are now underway to begin adding electric Semis to its fleet as part of a wider emissions-reduction effort. The pilot is thus the latest example of how logistics providers are embracing next-generation transport technologies to meet environmental goals and enhance supply chain performance.

-

Elon Musk1 week ago

Elon Musk1 week agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

Elon Musk2 days ago

Elon Musk2 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News2 weeks ago

News2 weeks agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

News6 days ago

News6 days agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk confirms Tesla Optimus V3 already uses Grok voice AI

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI welcomes Memphis pollution results, environmental groups push back

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla’s Omead Afshar, known as Elon Musk’s right-hand man, leaves company: reports