News

SpaceX’s Mr Steven gains upgraded arms to catch its first Falcon 9 fairings

SpaceX’s iconic Falcon 9 payload fairing recovery ship, known as Mr Steven, has been spotted in California’s Port of San Pedro having new arms installed with two cranes and a crew of SpaceX technicians. Aside from the sudden addition of dramatically different arm design, a large inflatable structure also took shape – seemingly overnight – right behind Mr Steven, the purpose of which is entirely unclear.

Incredibly, these massive new arms and their new equally large support struts and base plates have begun installation barely two weeks after Mr Steven took roost and had his old arms removed at SpaceX’s Berth 240 property. While the timeline of the arm and net upgrades – mentioned by CEO Elon Musk several weeks ago – was previously uncertain, the incredibly quick turnaround from old arm removal to new arm install suggests that SpaceX may, in fact, be aiming to have Mr Steven ready for recovery operations as early as Iridium-7, scheduled for launch on July 20th. In all likelihood, the fairing recovery vessel will be held up till the subsequent Vandenberg Air Force Base launch while a net with an area perhaps four times larger is custom-built for SpaceX.

A massive inflatable structure appeared out of nowhere at Berth 240 roughly four days after Teslarati photographer Pauline Acalin had last checked up on the facility. (Pauline Acalin)

Nevertheless, SpaceX’s speed rarely fails to surprise, and it’s entirely possible that a new, larger net was already ordered some time ago in preparation for the eventuality that Mr Steven’s first recovery mechanism was unsuccessful. Given the fact that at least two main arms and perhaps eight white, cylindrical struts have apparently been completed and are awaiting installation at Berth 240, it’s probable that the lead time on this new recovery mechanism stretches back at least several months, likely at least a month before Musk mentioned that Mr Steven would have its usable catching area grown “by a factor of [four]” in early June.

Yup, we are extending the net area by a factor of 4

— Elon Musk (@elonmusk) June 5, 2018

Closing the fairing recovery gap

With four times the net available to catch wayward Falcon 9 payload fairings, SpaceX may be able to finally close the gap between Mr Steven and the successful and routine recovery and reuse of the second of three main Falcon 9 (and Heavy) components. At roughly 10% of the total cost (not price) of a single-booster Falcon 9, the considerable effort being put into the recovery of carbon-composite payload fairings is in a way motivated more by manufacturing bottlenecks than by the money it will save SpaceX (somewhat less than $3m per half).

- Taken on Friday, these two photos show the new arm mounting brackets, installed on Mr Steven the week of July 2nd. (Pauline Acalin)

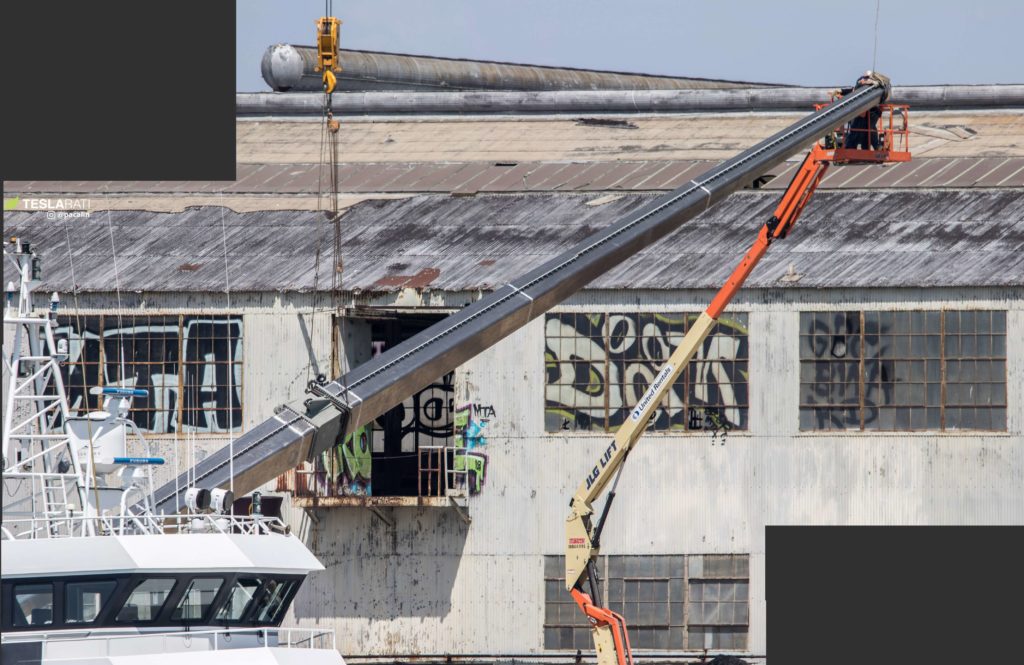

- Scarcely 48 hours later, an entirely new pear-shaped arm and two huge, circular struts were successfully installed, presumably the first of four sets. (Pauline Acalin)

- (Pauline Acalin)

SpaceX’s team of composite technicians and engineers will need to reliably fabricate as many as ~50 payload fairing halves in 2018, effectively one half each week

By recovering payload fairings before they touch the ocean surface, the company may – in one fell swoop – be able to dramatically reduce the operational expenditure required to sustain the annual production of dozens of Falcon fairings, each of which requires an inescapable and tediously slow stint in a massive autoclave, only a few of which can be squeeze into the company’s Hawthorne factory. As an example, SpaceX’s team of roughly 150 dedicated composite technicians and engineers will need to reliably fabricate as many as ~50 payload fairing halves – nearly a full half each week – to sustain SpaceX’s anticipated 2018 manifest of 24-28 launches, excluding three Cargo Dragon resupply missions that don’t need fairings.

While both Crew and Cargo Dragon spacecraft and trunks contain a large proportion of carbon fiber-composite structures, every composite Falcon 9 interstage that rolled off of the assembly line since February 2018 is part of a Block 5 booster and is thus expected to support a bare minimum of several missions on its own, functionally multiplying the useful output of any given production line even while the amount of work (and thus work-hours) is reduced. While Falcon 9 boosters – making up roughly 70% of the cost of the entire rocket – have been successfully upgraded to support several reuses each, SpaceX still has to produce a new payload fairing and upper stage for each launch. A spectacular Block 4 farewell earlier this month – complete with a recoverable booster expended to make way for Block 5 – simply served to emphasize the company’s desire to mitigate the expandability of both (currently) unreusable segments of Falcon 9.

- Meanwhile, the purpose of this massive inflatable ring is almost entirely unclear, as it would appear to be redundant with the initial installation of Mr Steven’s new recovery mechanism. (Pauline Acalin)

- Arm installation will presumably continue over the course of the week, hopefully reaching completion in time to recovery Iridium-7’s payload fairing. (Pauline Acalin)

If Mr Steven can recover even a small fraction – say 25% – of SpaceX payload fairings launched annually, the exact same level of effort (and thus capital) could support 25% more launches annually or reduce the work hours spent on fairing production by 25%. As it happens, SpaceX’s next-generation rocket (BFR) happens to be built (theoretically) almost entirely out of carbon-composites, from the propellant tanks to the spaceship’s delta wing.

Originally meant to focus on the wholly unexpected appearance of a giant inflatable structure at Berth 240, SpaceX’s breakneck pace of action abruptly recentered it on the equally unexpected installation of one the vessel’s first upgraded arms, meant to support a net that could be as much as four times larger than its predecessor. That symbolism on its own is a worthy representation of some of the best aspects of SpaceX’s world-class team of engineers and technicians, acting as a slightly more on-topic corollary to the equally rapid design, prototyping, fabrication, and testing of ad-hoc ‘submarines’ intended to help a number of Thai children currently trapped in a cave near the country’s border with Myanmar/Burma.

Mr Steven shows off the first of four new arms as a mysterious inflatable ring patiently sits astern. (Pauline Acalin)

Follow us for live updates, peeks behind the scenes, and photos from Teslarati’s East and West Coast photographers.

Teslarati – Instagram – Twitter

Tom Cross – Twitter

Pauline Acalin – Twitter

Eric Ralph – Twitter

Elon Musk

Tesla Full Self-Driving pricing strategy eliminates one recurring complaint

Tesla’s new Full Self-Driving pricing strategy will eliminate one recurring complaint that many owners have had in the past: FSD transfers.

In the past, if a Tesla owner purchased the Full Self-Driving suite outright, the company did not allow them to transfer the purchase to a new vehicle, essentially requiring them to buy it all over again, which could obviously get pretty pricey.

This was until Q3 2023, when Tesla allowed a one-time amnesty to transfer Full Self-Driving to a new vehicle, and then again last year.

Tesla is now allowing it to happen again ahead of the February 14th deadline.

The program has given people the opportunity to upgrade to new vehicles with newer Hardware and AI versions, especially those with Hardware 3 who wish to transfer to AI4, without feeling the drastic cost impact of having to buy the $8,000 suite outright on several occasions.

Now, that issue will never be presented again.

Last night, Tesla CEO Elon Musk announced on X that the Full Self-Driving suite would only be available in a subscription platform, which is the other purchase option it currently offers for FSD use, priced at just $99 per month.

Tesla is shifting FSD to a subscription-only model, confirms Elon Musk

Having it available in a subscription-only platform boasts several advantages, including the potential for a tiered system that would potentially offer less expensive options, a pay-per-mile platform, and even coupling the program with other benefits, like Supercharging and vehicle protection programs.

While none of that is confirmed and is purely speculative, the one thing that does appear to be a major advantage is that this will completely eliminate any questions about transferring the Full Self-Driving suite to a new vehicle. This has been a particular point of contention for owners, and it is now completely eliminated, as everyone, apart from those who have purchased the suite on their current vehicle.

Now, everyone will pay month-to-month, and it could make things much easier for those who want to try the suite, justifying it from a financial perspective.

The important thing to note is that Tesla would benefit from a higher take rate, as more drivers using it would result in more data, which would help the company reach its recently-revealed 10 billion-mile threshold to reach an Unsupervised level. It does not cost Tesla anything to run FSD, only to develop it. If it could slice the price significantly, more people would buy it, and more data would be made available.

News

Tesla Model 3 and Model Y dominates U.S. EV market in 2025

The figures were detailed in Kelley Blue Book’s Q4 2025 U.S. Electric Vehicle Sales Report.

Tesla’s Model 3 and Model Y continued to overwhelmingly dominate the United States’ electric vehicle market in 2025. New sales data showed that Tesla’s two mass market cars maintained a commanding segment share, with the Model 3 posting year-to-date growth and the Model Y remaining resilient despite factory shutdowns tied to its refresh.

The figures were detailed in Kelley Blue Book’s Q4 2025 U.S. Electric Vehicle Sales Report.

Model 3 and Model Y are still dominant

According to the report, Tesla delivered an estimated 192,440 Model 3 sedans in the United States in 2025, representing a 1.3% year-to-date increase compared to 2024. The Model 3 alone accounted for 15.9% of all U.S. EV sales, making it one of the highest-volume electric vehicles in the country.

The Model Y was even more dominant. U.S. deliveries of the all-electric crossover reached 357,528 units in 2025, a 4.0% year-to-date decline from the prior year. It should be noted, however, that the drop came during a year that included production shutdowns at Tesla’s Fremont Factory and Gigafactory Texas as the company transitioned to the new Model Y. Even with those disruptions, the Model Y captured an overwhelming 39.5% share of the market, far surpassing any single competitor.

Combined, the Model 3 and Model Y represented more than half of all EVs sold in the United States during 2025, highlighting Tesla’s iron grip on the country’s mass-market EV segment.

Tesla’s challenges in 2025

Tesla’s sustained performance came amid a year of elevated public and political controversy surrounding Elon Musk, whose political activities in the first half of the year ended up fueling a narrative that the CEO’s actions are damaging the automaker’s consumer appeal. However, U.S. sales data suggest that demand for Tesla’s core vehicles has remained remarkably resilient.

Based on Kelley Blue Book’s Q4 2025 U.S. Electric Vehicle Sales Report, Tesla’s most expensive offerings such as the Tesla Cybertruck, Model S, and Model X, all saw steep declines in 2025. This suggests that mainstream EV buyers might have had a price issue with Tesla’s more expensive offerings, not an Elon Musk issue.

Ultimately, despite broader EV market softness, with total U.S. EV sales slipping about 2% year-to-date, Tesla still accounted for 58.9% of all EV deliveries in 2025, according to the report. This means that out of every ten EVs sold in the United States in 2025, more than half of them were Teslas.

News

Tesla Model 3 and Model Y earn Euro NCAP Best in Class safety awards

“The company’s best-selling Model Y proved the gold standard for small SUVs,” Euro NCAP noted.

Tesla won dual categories in the Euro NCAP Best in Class awards, with the Model 3 being named the safest Large Family Car and the Model Y being recognized as the safest Small SUV.

The feat was highlighted by Tesla Europe & Middle East in a post on its official account on social media platform X.

Model 3 and Model Y lead their respective segments

As per a press release from the Euro NCAP, the organization’s Best in Class designation is based on a weighted assessment of four key areas: Adult Occupant, Child Occupant, Vulnerable Road User, and Safety Assist. Only vehicles that achieved a 5-star Euro NCAP rating and were evaluated with standard safety equipment are eligible for the award.

Euro NCAP noted that the updated Tesla Model 3 performed particularly well in Child Occupant protection, while its Safety Assist score reflected Tesla’s ongoing improvements to driver-assistance systems. The Model Y similarly stood out in Child Occupant protection and Safety Assist, reinforcing Tesla’s dual-category win.

“The company’s best-selling Model Y proved the gold standard for small SUVs,” Euro NCAP noted.

Euro NCAP leadership shares insights

Euro NCAP Secretary General Dr. Michiel van Ratingen said the organization’s Best in Class awards are designed to help consumers identify the safest vehicles over the past year.

Van Ratingen noted that 2025 was Euro NCAP’s busiest year to date, with more vehicles tested than ever before, amid a growing variety of electric cars and increasingly sophisticated safety systems. While the Mercedes-Benz CLA ultimately earned the title of Best Performer of 2025, he emphasized that Tesla finished only fractionally behind in the overall rankings.

“It was a close-run competition,” van Ratingen said. “Tesla was only fractionally behind, and new entrants like firefly and Leapmotor show how global competition continues to grow, which can only be a good thing for consumers who value safety as much as style, practicality, driving performance, and running costs from their next car.”