News

Tesla Supercharger V3 details: 250 kW, no charge splitting, twice as fast

Tesla launched its newest V3 Supercharger at an official unveiling event in Fremont, California, Wednesday night.

As we first reported, V3 Superchargers will be able to charge twice as fast the current generation Supercharger with a maximum power output of 250 kW or 1,000 miles per hour. Additionally, Tesla owners using V3 Superchargers will no longer need to split power with neighboring vehicles, thereby substantially increasing the charge rate and reducing the overall amount of charging time by nearly half.

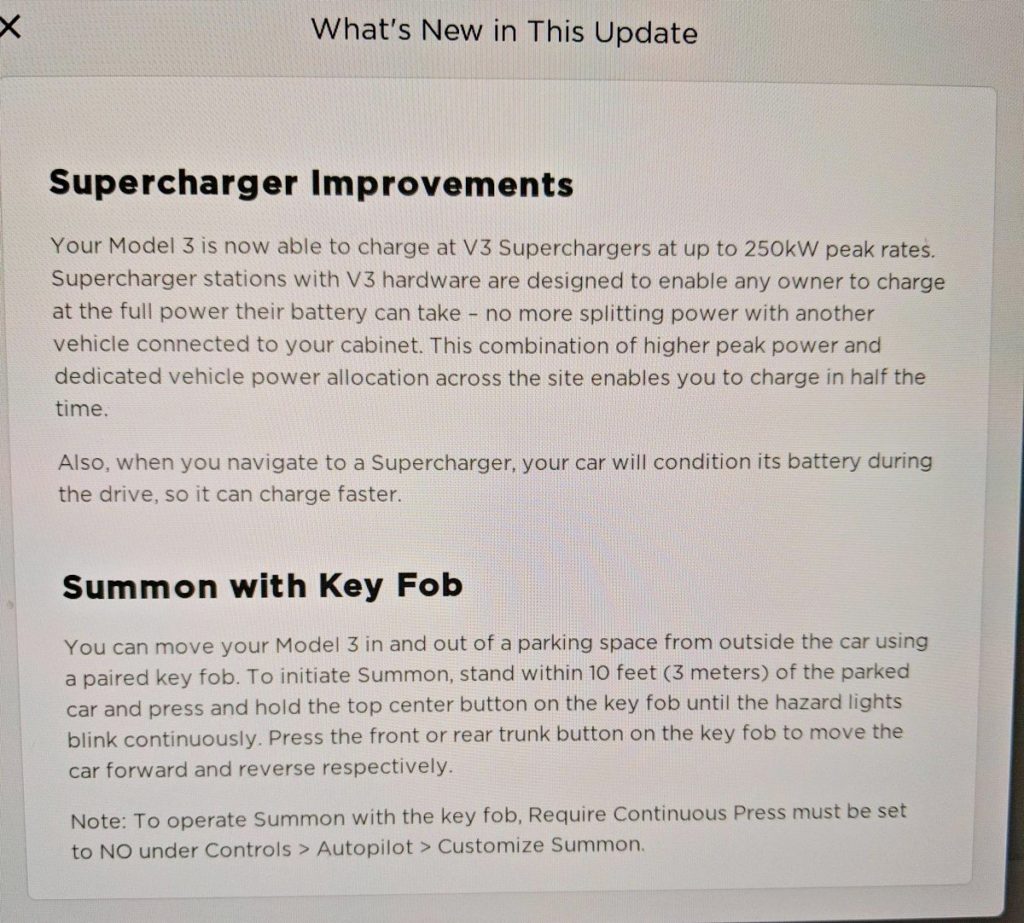

Supercharger V3 details first surfaced Wednesday evening in Release Notes for a new over-the-air firmware update that went out to Model 3 owners, first captured by Erik @teslainventory on Twitter.

Tesla began to roll out the over-the-air firmware update to a small group of Model 3 owners that were invited to attend the official Supercharger V3 unveiling. Attendees are members of Tesla’s “Early Access Program” who will be one of the first to use Tesla’s next-generation Supercharger.

The firmware update went out ahead of the event to prepare these vehicles to accept the higher power output from Tesla’s newest ultra-fast chargers.

“Your Model 3 is now able to charge at V3 Superchargers at up to 250 kW peak rates. Supercharger stations with V3 hardware are designed to enable

Of note is the final sentence in the section for “Supercharger Improvements”, which indicates that the firmware update will allow a vehicle to condition its batteries before arriving at a V3 Supercharger station. “Also, when you navigate to a Supercharger, your call will condition its battery during the drive, so it can charge faster,” reads the release note.

Preconditioning a battery isn’t something new for Tesla vehicles, especially for P100D owners looking to ‘Bring it on!‘ with Ludicrous Mode. Being able to optimize the temperature of the battery cells allows them to be in a state that can operate at higher current and thereby charge at the higher 250 kW power.

At the moment, our understanding is that only Model 3, which utilizes a newer generation 2170 cell compared to the older 18650 form factor cell found in Model S and Model X, will be able to V3 Supercharge at full potential.

Be sure to check back as we will update the story with full details and specifications for Tesla Supercharger V3.

Update: Tesla published details for V3 Supercharging in a company blog post (included below). A video of the fast charging speed can be seen in their video.

Introducing V3 Supercharging

Tesla has more than 12,000 Superchargers across North America, Europe, and Asia and our network continues to grow daily: more than 99% of the U.S. population is covered by the network, and we anticipate similar coverage in Europe by the end of 2019. Recently, we passed 90% population coverage in China and are growing that number quickly. However, in order to drive continued electric vehicle adoption and further accelerate the world’s transition to sustainable energy, charging needs to be even faster, and the number of vehicles able to charge at a location in a day needs to be significantly higher. Today, we’re unveiling V3 Supercharging, the next step in the growth of Tesla’s Supercharger network. V3, which is born from our experience building the world’s largest grid-connected batteries, enables our vehicles to charge faster than any other electric vehicle on the market today.

Faster Charging, No More Power Sharing

V3 is a completely new architecture for Supercharging. A new 1MW power cabinet with a similar design to our utility-scale products supports peak rates of up to 250kW per car. At this rate, a Model 3 Long Range operating at peak efficiency can recover up to 75 miles of charge in 5 minutes and charge at rates of up to 1,000 miles per hour. Combined with other improvements we’re announcing today, V3 Supercharging will ultimately cut the amount of time customers spend charging by an average of 50%, as modeled on our fleet data.

Supercharger stations with V3’s new power electronics are designed to enable any owner to charge at the full power their battery can take – no more splitting power with a vehicle in the stall next to you. With these significant technical improvements, we anticipate the typical charging time at a V3 Supercharger will drop to around 15 minutes.

On-Route Battery Warmup

New Supercharging infrastructure isn’t the only way we are improving our customers’ charging experience. Beginning this week, Tesla is rolling out a new feature called On-Route Battery Warmup. Now, whenever you navigate to a Supercharger station, your vehicle will intelligently heat the battery to ensure you arrive at the optimal temperature to charge, reducing average charge times for owners by 25%.

This combination of higher peak power with V3, dedicated vehicle power allocation across Supercharger sites, and On-Route Battery Warmup

With Model 3 now shipping globally in high volumes and Model Y on the way, V3 Supercharging enables us to deliver the fastest production charging experience at an unprecedented scale compared to other electric vehicle manufacturers. By increasing the number of vehicles we’re able to charge at each Supercharger in a day, the investment we’re making in our network will go significantly further with every V3 station deployed. Paired with other savings, these efficiencies will translate to an increased pace of investment for Superchargers moving forward, with a continued focus on getting to 100% ownership coverage across all regions we operate. With thousands of new Superchargers coming online in 2019, the launch of V3, and other changes we’re making to improve throughput, the Supercharger network will be able to serve more than 2x more vehicles per day at the end of 2019 compared with today – easily keeping pace with our 2019 fleet growth.

Beginning today, we’re opening the first public beta site in the Bay Area, which will incrementally be made available to owners in Tesla’s Early Access Program. We’re launching V3 Supercharging for Model 3, our highest volume vehicle, and we’ll continue to expand access as we review and assess the results of millions of charging events. We will increase Model S and X charging speeds via software updates in the coming months. V3 Supercharging will roll out to the wider fleet in an over the air firmware update to all owners in Q2 as more V3 Superchargers come online. Our first non-beta V3 Supercharger site will break ground next month, with North American sites ramping in Q2 and Q3 before coming to Europe and Asia-Pacific in Q4.

Elon Musk

Celebrating SpaceX’s Falcon Heavy Tesla Roadster launch, seven years later (Op-Ed)

Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

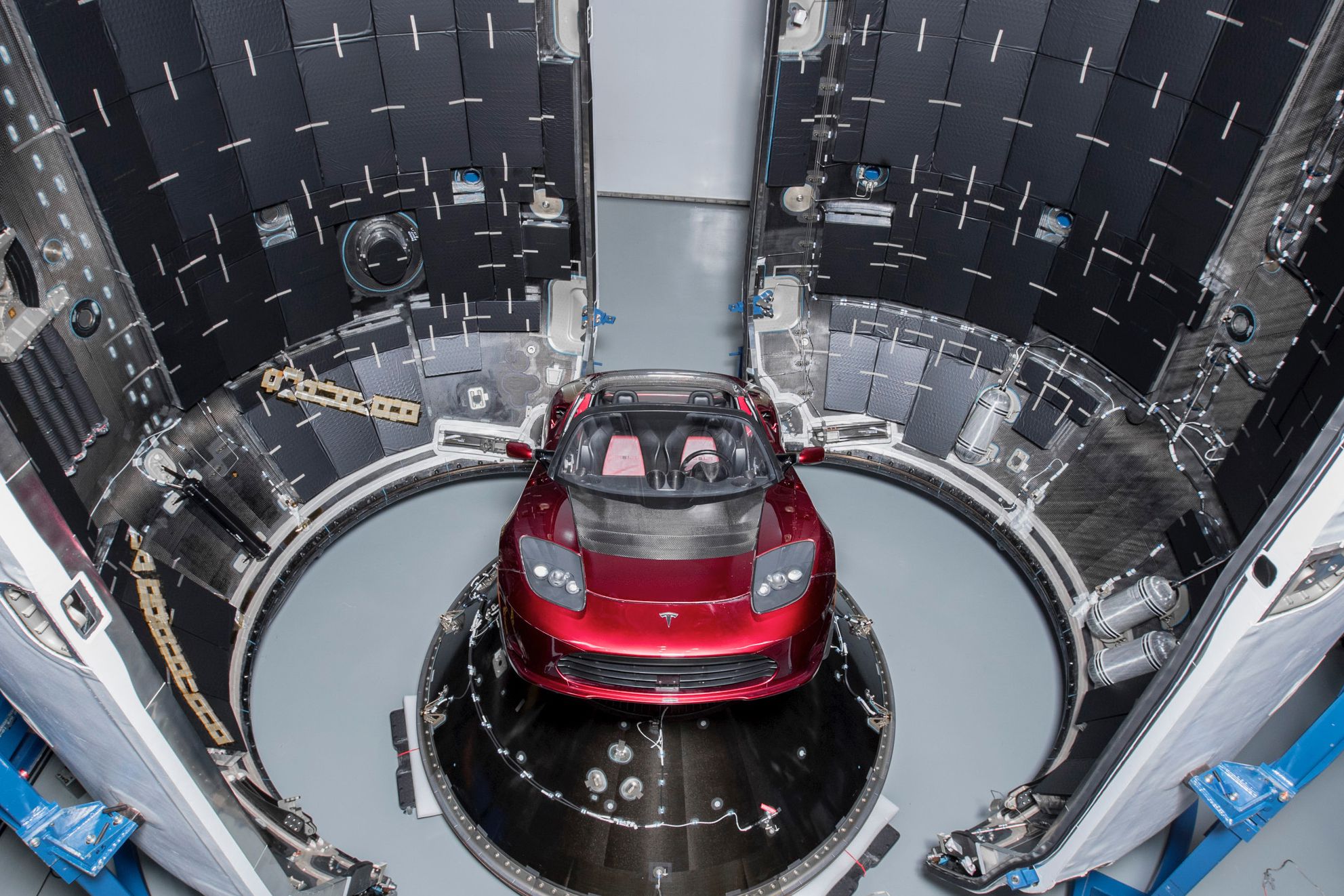

When Falcon Heavy lifted off in February 2018 with Elon Musk’s personal Tesla Roadster as its payload, SpaceX was at a much different place. So was Tesla. It was unclear whether Falcon Heavy was feasible at all, and Tesla was in the depths of Model 3 production hell.

At the time, Tesla’s market capitalization hovered around $55–60 billion, an amount critics argued was already grossly overvalued. SpaceX, on the other hand, was an aggressive private launch provider known for taking risks that traditional aerospace companies avoided.

The Roadster launch was bold by design. Falcon Heavy’s maiden mission carried no paying payload, no government satellite, just a car drifting past Earth with David Bowie playing in the background. To many, it looked like a stunt. For Elon Musk and the SpaceX team, it was a bold statement: there should be some things in the world that simply inspire people.

Inspire it did, and seven years later, SpaceX and Tesla’s results speak for themselves.

Today, Tesla is the world’s most valuable automaker, with a market capitalization of roughly $1.54 trillion. The Model Y has become the best-selling car in the world by volume for three consecutive years, a scenario that would have sounded insane in 2018. Tesla has also pushed autonomy to a point where its vehicles can navigate complex real-world environments using vision alone.

And then there is Optimus. What began as a literal man in a suit has evolved into a humanoid robot program that Musk now describes as potential Von Neumann machines: systems capable of building civilizations beyond Earth. Whether that vision takes decades or less, one thing is evident: Tesla is no longer just a car company. It is positioning itself at the intersection of AI, robotics, and manufacturing.

SpaceX’s trajectory has been just as dramatic.

The Falcon 9 has become the undisputed workhorse of the global launch industry, having completed more than 600 missions to date. Of those, SpaceX has successfully landed a Falcon booster more than 560 times. The Falcon 9 flies more often than all other active launch vehicles combined, routinely lifting off multiple times per week.

Falcon 9 has ferried astronauts to and from the International Space Station via Crew Dragon, restored U.S. human spaceflight capability, and even stepped in to safely return NASA astronauts Butch Wilmore and Suni Williams when circumstances demanded it.

Starlink, once a controversial idea, now dominates the satellite communications industry, providing broadband connectivity across the globe and reshaping how space-based networks are deployed. SpaceX itself, following its merger with xAI, is now valued at roughly $1.25 trillion and is widely expected to pursue what could become the largest IPO in history.

And then there is Starship, Elon Musk’s fully reusable launch system designed not just to reach orbit, but to make humans multiplanetary. In 2018, the idea was still aspirational. Today, it is under active development, flight-tested in public view, and central to NASA’s future lunar plans.

In hindsight, Falcon Heavy’s maiden flight with Elon Musk’s personal Tesla Roadster was never really about a car in space. It was a signal that SpaceX and Tesla were willing to think bigger, move faster, and accept risks others wouldn’t.

The Roadster is still out there, orbiting the Sun. Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

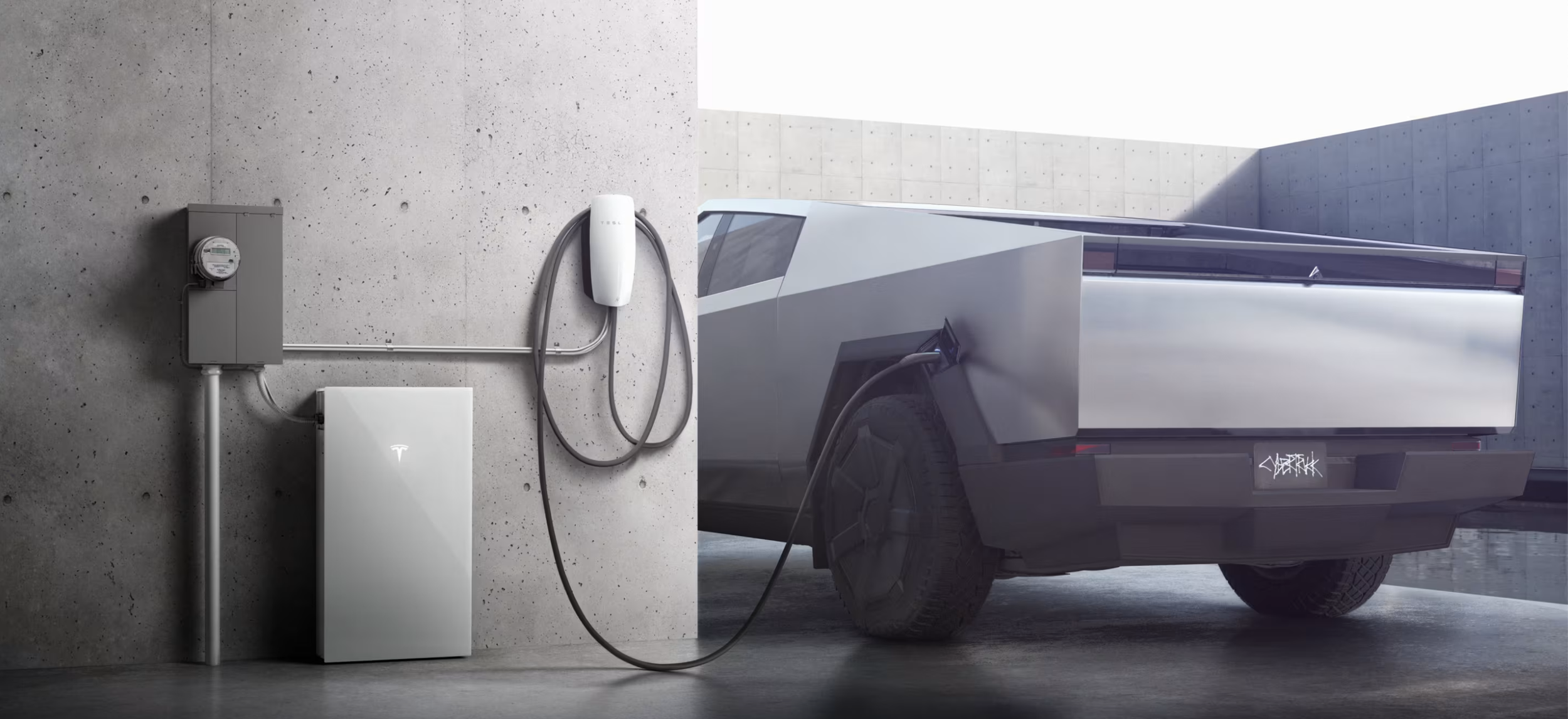

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.

News

Samsung nears Tesla AI chip ramp with early approval at TX factory

This marks a key step towards the tech giant’s production of Tesla’s next-generation AI5 chips in the United States.

Samsung has received temporary approval to begin limited operations at its semiconductor plant in Taylor, Texas.

This marks a key step towards the tech giant’s production of Tesla’s next-generation AI5 chips in the United States.

Samsung clears early operations hurdle

As noted in a report from Korea JoongAng Daily, Samsung Electronics has secured temporary certificates of occupancy (TCOs) for a portion of its semiconductor facility in Taylor. This should allow the facility to start operations ahead of full completion later this year.

City officials confirmed that approximately 88,000 square feet of Samsung’s Fab 1 building has received temporary approval, with additional areas expected to follow. The overall timeline for permitting the remaining sections has not yet been finalized.

Samsung’s Taylor facility is expected to manufacture Tesla’s AI5 chips once mass production begins in the second half of the year. The facility is also expected to produce Tesla’s upcoming AI6 chips.

Tesla CEO Elon Musk recently stated that the design for AI5 is nearly complete, and the development of AI6 is already underway. Musk has previously outlined an aggressive roadmap targeting nine-month design cycles for successive generations of its AI chips.

Samsung’s U.S. expansion

Construction at the Taylor site remains on schedule. Reports indicate Samsung plans to begin testing extreme ultraviolet (EUV) lithography equipment next month, a critical step for producing advanced 2-nanometer semiconductors.

Samsung is expected to complete 6 million square feet of floor space at the site by the end of this year, with an additional 1 million square feet planned by 2028. The full campus spans more than 1,200 acres.

Beyond Tesla, Samsung Foundry is also pursuing additional U.S. customers as demand for AI and high-performance computing chips accelerates. Company executives have stated that Samsung is looking to achieve more than 130% growth in 2-nanometer chip orders this year.

One of Samsung’s biggest rivals, TSMC, is also looking to expand its footprint in the United States, with reports suggesting that the company is considering expanding its Arizona facility to as many as 11 total plants. TSMC is also expected to produce Tesla’s AI5 chips.