Energy

Tesla patent hints at stunning colored Solar Roof tiles with zero compromises

Elon Musk recently noted on Twitter that Tesla would be prioritizing the production of its Solar Roof tiles this coming 2019. These updates were announced not long after the company invited local media from Buffalo, NY to tour Gigafactory 2, the company’s facility which is producing the unique solar shingles. As Tesla continues to prepare for the ramp of the Solar Roof tiles next year, a recent patent has been published outlining a design that would allow the company to offer colored variants of the solar shingles without compromising any functionality.

Tesla’s recent patent, titled “Uniformly and Directionally Colored Photovoltaic Modules,” was published last Thursday. In the document’s background, Tesla noted that PV modules are usually blue, dark blue, or black because these are the natural color of solar cells. Considering that homeowners have preferences in their roofing material’s color, though, there is a need for the Solar Roof tiles to have varying shades and textures. There are currently several conventional ways to colorize PV modules, such the utilization of tinted glass and/or encapsulation sheets. That said, such systems are prone to absorbing large amounts of sunlight, which results in PV power loss. The appearance of standard colored PV modules also tends to degrade over time.

“Shading, or absorption of incident sunlight, causes PV power loss, a consequential problem of existing coloring techniques. In addition, colored PV modules manufactured with these techniques, and colored glass more generally, commonly suffer from: sparkle, or glint; flop, or angle-dependent color appearance; and graininess. Note that sparkle refers to glint or localized bright spots. Flop, on the other hand, usually refers to angle-dependent color, i.e. an angular dependence of the peak reflected wavelength. The term flop, or light-dark flop, can also refer to angle-dependent brightness, i.e. an angular dependence of total reflectivity.”

- An illustration of Tesla’s patent for its colored Solar Roof tiles. [Credit: US Patent Office]

- An illustration of Tesla’s patent for its colored Solar Roof tiles. [Credit: US Patent Office]

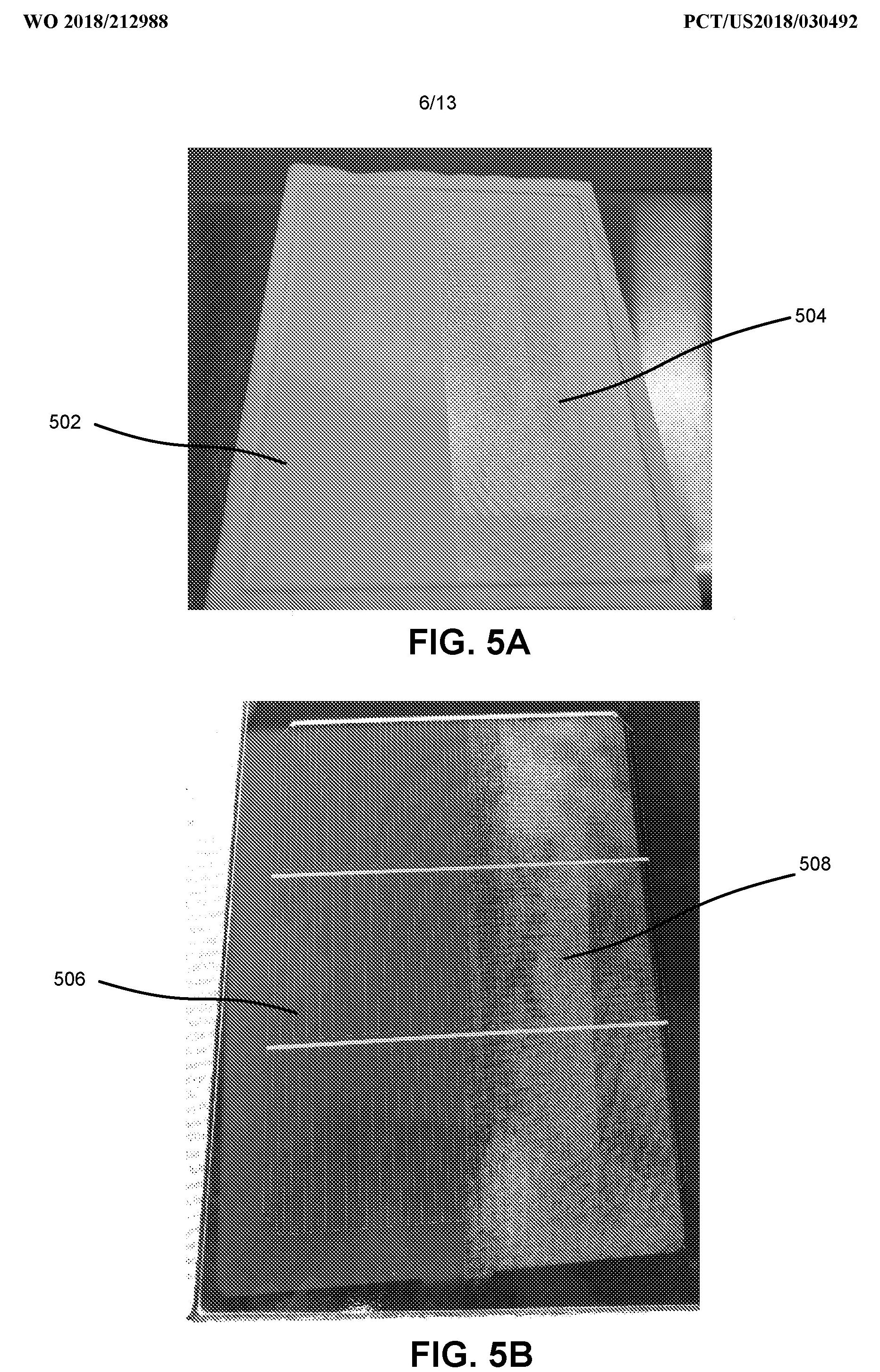

An illustration of Tesla’s patent for its colored Solar Roof tiles. [Credit: US Patent Office]

Tesla’s system for its colored Solar Roof tiles utilizes a rather clever system to avoid the drawbacks of conventional PV module coloration methods. Instead of using traditional solutions like tinted glass, Tesla’s design employs a texturized surface of a glass cover that has a color filter layer, as well as a “transparent material with a predetermined refractive index.” Following is Tesla’s description of its colored Solar Roof tiles’ design.

“Embodiments of the present invention can produce PV roof tiles with a uniform color with little light absorption. As a result, a high proportion of the incident light (of colors other than the module’s intended color) is transmitted to the PV cells. To facilitate uniform coloring of PV modules and roof tiles, the inside surface of a top glass cover can be texturized, and a transparent material with a predetermined refractive index or combination of refractive indices can be deposited on the texturized surface. Such a micro-textured or frosted glass cover can display significantly less sparkle, flop, and graininess than conventional glass covers, thus improving color uniformity and appearance. Customizable directional coloring, and intentionally controlled angle-dependent color, can provide further aesthetic options, while still performing efficiently for solar conversion. It is also possible to produce a layer of sphere-shaped metal nanoparticles on the inside surface of the glass cover.

“These nanoparticles can produce colors efficiently while absorbing little light. Another feature described herein is directional coloring of PV modules or roof tiles. The texturized surface of a glass cover can have a color filter layer covering one or more facets of the texture. This color filter can include multiple thin film layers formed using a directional thin film deposition technique, such as chemical or physical vapor deposition (CVD or PVD), e.g. sputtering. The coating layer can be deposited by coating the textured glass surface in one or more directions. Such directional coating can reduce unwanted light absorption by the color filter, while still providing a uniform color appearance to viewers at a certain viewing angle.”

Tesla opted to design the colored Solar Roof tiles with textured “micro-structured” glass, which feature surface roughness on the order of 100 nm to 10 μιη. This allows the colored Solar Roof tiles to display a uniform color with little light absorption and less sparkle, flop, and graininess than conventional colored glass. The colored shingles’ design also provides customizable directional and multi-directional coating, improving the aesthetics of the Solar Roof tiles themselves while still being optimized for solar conversion.

Following is a comparison of conventional colored PV modules (504 and 508) and Tesla’s coloration system (502 and 506), showing how the electric car maker’s micro-structured glass design addresses sparkle, or glare; flop, or angle-dependent coloring.

The Solar Roof tiles are Tesla’s flagship residential solar product. Designed to mimic the appearance of conventional roofing materials while offering all the advantages of solar panels, the Solar Roofs are an excellent way for homeowners to utilize a PV system without compromising the aesthetics of their home. The shingles were warmly received when they were unveiled back in 2016, though the production and installation of Solar Roof tiles are yet to ramp. Elon Musk explained the delay in the shingles’ production ramp during the third quarter earnings call.

“We’ll also start going into volume production of the solar tile roof next year. That’s quite a long development cycle for — because anything that’s roof has got to last 30 years. So even if you do accelerate life testing as fast as possible, there’s still a minimum amount of time required to do that. And there’s a lot of engineering that goes into how do you put on the solar tile roof with a — and not be really labor-intensive in doing so. So there’s a lot of engineering not just in the tile but in the way it’s done,” Musk said.

Back in July, Tesla CTO JB Straubel noted that the company is “aggressively” ramping its capacity to produce and deliver its residential solar products, stating that “No one should see us as stepping back from solar. In fact, it’s the opposite. It’s like with Model 3. People have come flooding in and are waiting on the product. So now we’re aggressively ramping our capacity.”

The full text of Tesla’s patent for its colored Solar Roof tiles could be accessed here.

Energy

Tesla meets Giga New York’s Buffalo job target amid political pressures

Giga New York reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease.

Tesla has surpassed its job commitments at Giga New York in Buffalo, easing pressure from lawmakers who threatened the company with fines, subsidy clawbacks, and dealership license revocations last year.

The company reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease at the state-built facility.

As per an employment report reviewed by local media, Tesla employed 2,399 full-time workers at Gigafactory New York and 1,060 additional employees across the state at the end of 2025. Part-time roles pushed the total headcount of Tesla’s New York staff above the 3,460-job target.

The gains stemmed in part from a new Long Island service center, a Buffalo warehouse, and additional showrooms in White Plains and Staten Island. Tesla also said it has invested $350 million in supercomputing infrastructure at the site and has begun manufacturing solar panels.

Empire State Development CEO Hope Knight said the agency was “very happy” with Giga New York’s progress, as noted in a WXXI report. The current lease runs through 2029, and negotiations over updated terms have included potential adjustments to job requirements and future rent payments.

Some lawmakers remain skeptical, however. Assemblymember Pat Burke questioned whether the reported job figures have been fully verified. State Sen. Patricia Fahy has also continued to sponsor legislation that would revoke Tesla’s company-owned dealership licenses in New York. John Kaehny of Reinvent Albany has argued that the project has not delivered the manufacturing impact originally promised as well.

Knight, for her part, maintained that Empire State Development has been making the best of a difficult situation.

“(Empire State Development) has tried to make the best of a very difficult situation. There hasn’t been another use that has come forward that would replace this one, and so to the extent that we’re in this place, the fact that 2,000 families at (Giga New York) are being supported through the activity of this employer. It’s the best that we can have happen,” the CEO noted.

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

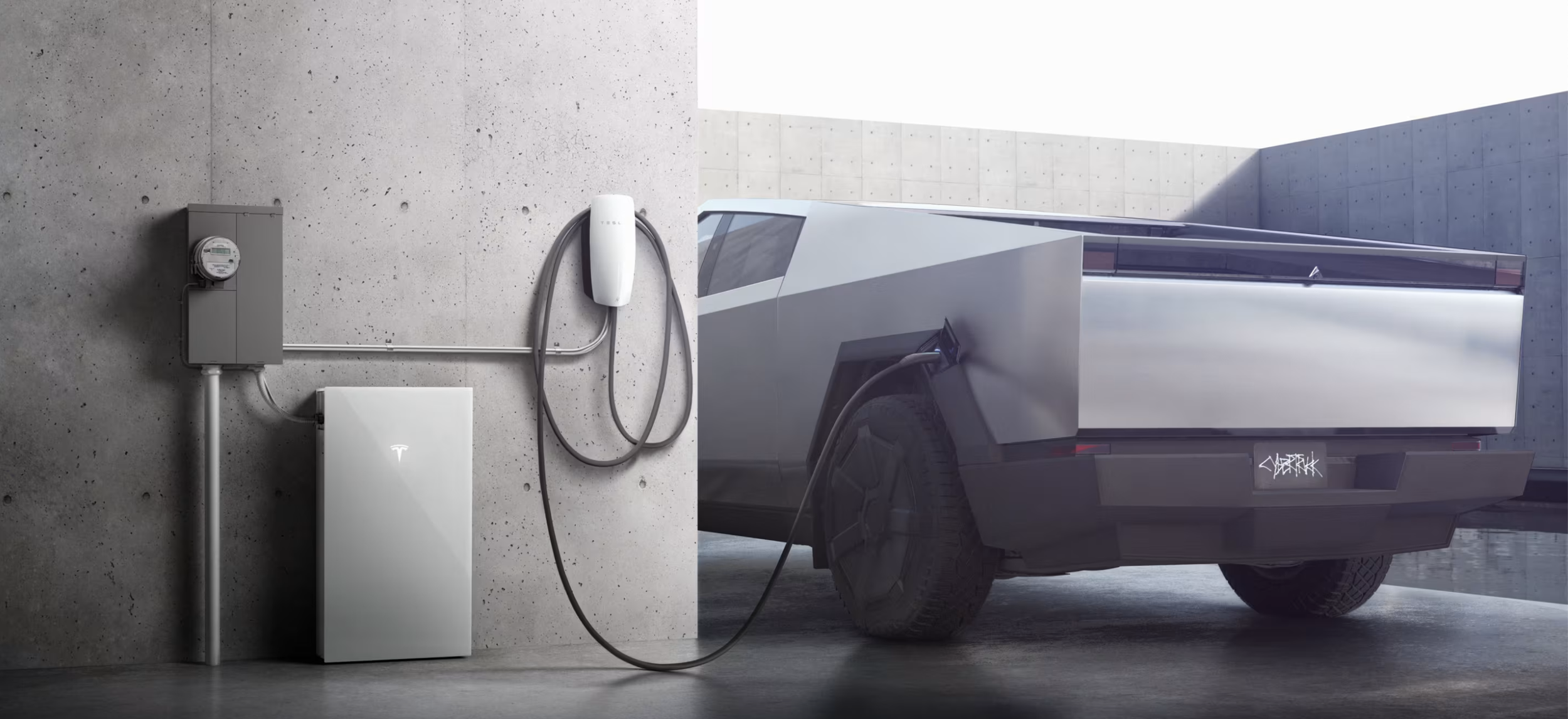

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.

Cybertruck

Tesla updates Cybertruck owners about key Powershare feature

Tesla is updating Cybertruck owners on its timeline of a massive feature that has yet to ship: Powershare with Powerwall.

Powershare is a bidirectional charging feature exclusive to Cybertruck, which allows the vehicle’s battery to act as a portable power source for homes, appliances, tools, other EVs, and more. It was announced in late 2023 as part of Tesla’s push into vehicle-to-everything energy sharing, and acting as a giant portable charger is the main advantage, as it can provide backup power during outages.

Cybertruck’s Powershare system supports both vehicle-to-load (V2L) and vehicle-to-home (V2H), making it flexible and well-rounded for a variety of applications.

However, even though the feature was promised with Cybertruck, it has yet to be shipped to vehicles. Tesla communicated with owners through email recently regarding Powershare with Powerwall, which essentially has the pickup act as an extended battery.

Powerwall discharge would be prioritized before tapping into the truck’s larger pack.

However, Tesla is still working on getting the feature out to owners, an email said:

“We’re writing to let you know that the Powershare with Powerwall feature is still in development and is now scheduled for release in mid-2026.

This new release date gives us additional time to design and test this feature, ensuring its ability to communicate and optimize energy sharing between your vehicle and many configurations and generations of Powerwall. We are also using this time to develop additional Powershare features that will help us continue to accelerate the world’s transition to sustainable energy.”

Owners have expressed some real disappointment in Tesla’s continuous delays in releasing the feature, as it was expected to be released by late 2024, but now has been pushed back several times to mid-2026, according to the email.

Foundation Series Cybertruck buyers paid extra, expecting the feature to be rolled out with their vehicle upon pickup.

Cybertruck’s Lead Engineer, Wes Morrill, even commented on the holdup:

As a Cybertruck owner who also has Powerwall, I empathize with the disappointed comments.

To their credit, the team has delivered powershare functionality to Cybertruck customers who otherwise have no backup with development of the powershare gateway. As well as those with solar…

— Wes (@wmorrill3) December 12, 2025

He said that “it turned out to be much harder than anticipated to make powershare work seamlessly with existing Powerwalls through existing wall connectors. Two grid-forming devices need to negotiate who will form and who will follow, depending on the state of charge of each, and they need to do this without a network and through multiple generations of hardware, and test and validate this process through rigorous certifications to ensure grid safety.”

It’s nice to see the transparency, but it is justified for some Cybertruck owners to feel like they’ve been bait-and-switched.