News

Tesla is designing an electric pump system that makes its drive units even better

Amidst Tesla’s continued efforts to usher in an era of mobility optimized for the convenience and safety of car owners, the electric car maker is exploring new ways to improve its vehicles’ systems. Recently published patent applications, for one, indicate that Tesla is working on better damage monitoring features, as well as safer seats that are capable of classifying a car’s occupants. Apart from these, Tesla is also looking into improving its vehicles’ electric pump system, which could ultimately result in better cooling and diagnostics.

The patent application, published on January 3, 2019 and titled “Electric Pump System and Method,” explores improvements that could be implemented on traditional pump systems used in automobiles. As noted by Tesla, traditional oil pumps, particularly those that are used for EV components such as the drive unit, do not have the capability to monitor oil condition. As a result, oil that is used to lubricate an electric car’s drive unit need to be changed on a regular basis (albeit very infrequently).

In the discussion section of its patent application, Tesla pointed out that traditional oil pumps are unable to accurately determine temperature, since temperature sensors are usually located outside of a conventional pump system. Apart from this, the electric car maker notes that conventional oil pumps are also large and unwieldy due to attachment mechanisms comprised of different parts. With these points for improvement in mind, Tesla has pointed out that there is a need for an “improved oil pump — in particular an electric pump system — designed to work in conjunction with an electric motor.”

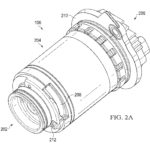

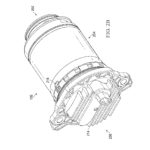

- (Photo: US Patent Office)

- (Photo: US Patent Office)

Illustrations from Tesla’s recently published patent application for an electric pump system. (Photo: US Patent Office)

Tesla’s patent describes an electric pump system that “presents methods and structures that help overcome the difficulties of operating a cooling and lubrication system, in particular, managing the transfer of heat and assessment of fluid temperature in electric pump systems.” The Silicon Valley-based carmaker describes its electric pump system design as follows.

“There is provided an apparatus that includes an electronic control unit, a mechanical pump, and a motor having a first side and a second side, the motor including: a stator, a rotor including a hollow shaft, and a housing around the stator and rotor, wherein the electronic control unit is connected to the first side of the motor, wherein the mechanical pump is connected to the second side of the motor, wherein the hollow shaft defines a shaft inlet and a shaft outlet, wherein the mechanical pump defines a first fluid passageway from a first pump inlet to the shaft inlet, wherein the housing defines an internal motor cavity, wherein the shaft outlet is in fluid communication with the internal motor cavity, wherein the mechanical pump defines a second fluid passageway from a second pump inlet to a pump outlet, and wherein the motor housing and mechanical pump define a third fluid passageway from the internal motor cavity to the pump outlet via a third pump inlet.”

“In some embodiments the apparatus according to the above-described aspect of the present disclosure or any other aspects thereof, a number of optional operations and features may be employed. One optional feature is the electronic control unit further including a thermistor to measure a temperature of a fluid exiting the shaft outlet. Another optional feature is wherein the housing defines a bypass inlet in fluid communication with the internal motor cavity. Another optional feature is at least a portion of the second fluid passageway and the third fluid passageway is common. Another optional feature is the mechanical pump is a gerotor. Another optional feature is the electronic control unit includes a microcontroller controlling the mechanical pump. Another optional feature is the electronic control unit includes cooling ribs.”

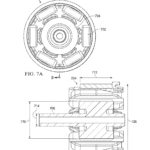

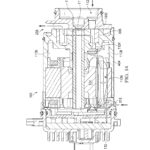

- (Photo: US Patent Office)

- (Photo: US Patent Office)

Illustrations from Tesla’s recently published patent application for an electric pump system. (Photo: US Patent Office)

With such a design, the fluid temperature inside the electric pump system could be used to control and optimize the lubrication system of a vehicle, thereby improving the efficiency of an electric drive unit. Depending on the temperature of the oil in the system, the electric pump could react accordingly, even warning the vehicle’s computers that something is wrong. The readings from the electric pump system can be used to monitor the health of a vehicle’s drive unit as well. Tesla explains this process in the following discussion.

“The fluid temperature may be controlled to achieve certain lubrication properties. For example, hotter oil has lower viscosity which reduces drag and hydraulic power to pump the fluid, which can increase efficiency. If the oil becomes too hot, however, it will not provide sufficient cooling. The fluid temperature reading feature of the oil pump can monitor the general health and performance of the fluid in the electric drive unit system. For example, if the oil is too hot, the oil pump may alert the car computer that something is wrong, for oil that is too hot can damage or/and reduce the life of some components on the drive unit.”

“Stated another way, the temperature of fluid may be used to monitor the health and performance of the drive unit. The ECU may capture other information besides the temperature, such as pump speed, pump current composition, oil pressure, or other information. The information captured by the ECU may then be fed into a proprietary algorithm that monitors oil pump and overall drive unit health. The algorithm may provide an indication of service, such as when oil must be replaced or when the drive train needs to be serviced.”

What is particularly notable is that these improvements could result in enhancements to Tesla’s drive units, which are already among the best in the industry. The Model 3’s drive unit, for one, has been lauded by veteran teardown experts such as Sandy Munro as industry-leading. In a recent appearance at Autoline TV, for one, Munro noted that Tesla’s drive units are practically a class above its competitors.

Tesla’s constant efforts to improve its vehicles are highlighted by the patent applications from the company that have been published over the past months. Among these include an automatic tire inflation system that hints at off-road capabilities for the company’s vehicles, a system that allows Tesla to address panel gaps during vehicle assembly, a way to produce colored solar roof tiles, and even a model that utilizes electric cars as a way to improve vehicle positioning, to name a few.

The full text of Tesla’s recently published patent application could be read here.

Cybertruck

Tesla set to activate long-awaited Cybertruck feature

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, as the company has officially added the feature to its list of features by trim on its website.

Tesla is set to activate a long-awaited Cybertruck feature, and no matter when you bought your all-electric pickup, it has the hardware capable of achieving what it is designed to do.

Tesla simply has to flip the switch, and it plans to do so in the near future.

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, according to Not a Tesla App, as the company has officially added the feature to its list of features by trim on its website.

Tesla rolls out Active Road Noise Reduction for new Model S and Model X

The ANC feature suddenly appeared on the spec sheet for the Premium All-Wheel-Drive and Cyberbeast trims, which are the two configurations that have been delivered since November 2023.

However, those trims have both had the ANC disabled, and although they are found in the Model S and Model X, and are active in those vehicles, Tesla is planning to activate them.

In Tesla’s Service Toolbox, it wrote:

“ANC software is not enabled on Cybertruck even though the hardware is installed.”

Tesla has utilized an ANC system in the Model S and Model X since 2021. The system uses microphones embedded in the front seat headrests to detect low-frequency road noise entering the cabin. It then generates anti-noise through phase-inverted sound waves to cancel out or reduce that noise, creating quieter zones, particularly around the vehicle’s front occupants.

The Model S and Model X utilize six microphones to achieve this noise cancellation, while the Cybertruck has just four.

Tesla Cybertruck Dual Motor AWD estimated delivery slips to early fall 2026

As previously mentioned, this will be activated through a software update, as the hardware is already available within Cybertruck and can simply be activated at Tesla’s leisure.

The delays in activating the system are likely due to Tesla Cybertruck’s unique design, which is unlike anything before. In the Model S and Model X, Tesla did not have to do too much, but the Cybertruck has heavier all-terrain tires and potentially issues from the aluminum castings that make up the vehicle’s chassis, which are probably presenting some challenges.

Unfortunately, this feature will not be available on the new Dual Motor All-Wheel-Drive configuration, which was released last week.

News

Tesla Model S and X customization options begin to thin as their closure nears

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

Tesla Model S and Model X customization options are beginning to thin for the first time as the closure of the two “sentimental” vehicles nears.

We are officially seeing the first options disappear as Tesla begins to work toward ending production of the two cars and the options that are available to those vehicles specifically.

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

🚨 Tesla Model S and Model X availability is thinning, as Tesla has officially shown that the Lunar Silver color option on both vehicles is officially sold out

To be fair, Frost Blue is still available so no need to freak out pic.twitter.com/YnwsDbsFOv

— TESLARATI (@Teslarati) February 25, 2026

Tesla is making way for the Optimus humanoid robot project at the Fremont Factory, where the Model S and Model X are produced. The two cars are low-volume models and do not contribute more than a few percent to Tesla’s yearly delivery figures.

With CEO Elon Musk confirming that the Model S and Model X would officially be phased out at the end of the quarter, some of the options are being thinned out.

This is an expected move considering Tesla’s plans for the two vehicles, as it will make for an easier process of transitioning that portion of the Fremont plant to cater to Optimus manufacturing. Additionally, this is likely one of the least popular colors, and Tesla is choosing to only keep around what it is seeing routine demand for.

During the Q4 Earnings Call in January, Musk confirmed the end of the Model S and Model X:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Fremont will now build one million Optimus units per year as production is ramped.

News

Tesla Cybertruck Dual Motor AWD estimated delivery slips to early fall 2026

Tesla has also added a note on the Cybertruck design page stating that the vehicle’s price will increase after February 28.

Tesla’s estimated delivery window for new Cybertruck Dual Motor All-Wheel Drive (AWD) orders in the United States has shifted to September–October 2026. This suggests that the vehicle’s sub-$60,000 variant is now effectively sold out until then.

The updated timeline was highlighted in a post on X by Tesla watcher Sawyer Merritt, who noted that the estimated delivery window had moved from June 2026 to September-October 2026, “presumably due to strong demand.”

The Dual Motor AWD currently starts at $59,990 before incentives. Tesla has also added a note on the Cybertruck design page stating that the vehicle’s price will increase after February 28.

If demand remains steady, the combination of a later delivery window and a pending price increase suggests Tesla is seeing sustained interest in the newly-introduced Cybertruck configuration. This was highlighted by Elon Musk on X, when he noted that the Cybertruck Dual Motor AWD’s introductory price will only be available for a limited time.

When the Cybertruck was first unveiled in November 2019, Tesla listed the Dual Motor AWD variant at $49,990. Adjusted for inflation, that figure equates to roughly $63,000 in 2026 dollars, based on cumulative U.S. inflation since 2019.

That context makes a potential post-February price in the $64,000 to $65,000 range less surprising, especially as material, labor, and manufacturing costs have shifted significantly over the past several years.

While Tesla has not announced a specific new MSRP, the updated delivery timeline and pricing note together suggest that the Cybertruck Dual Motor AWD could very well be the variant that takes the all-electric full-sized pickup truck to more widespread adoption.