News

SpaceX tests Falcon 9 Block 5’s landing leg retraction and preps for first reuse

In the two months since SpaceX first debuted its Falcon 9 Block 5 rocket upgrade with a successful May 2018 launch and landing, the company has forged ahead with final Block 4 or older launch and two additional launches and recoveries of brand new Block 5 boosters, growing the fleet of flight-proven and thus flight-worthy rocket boosters to three.

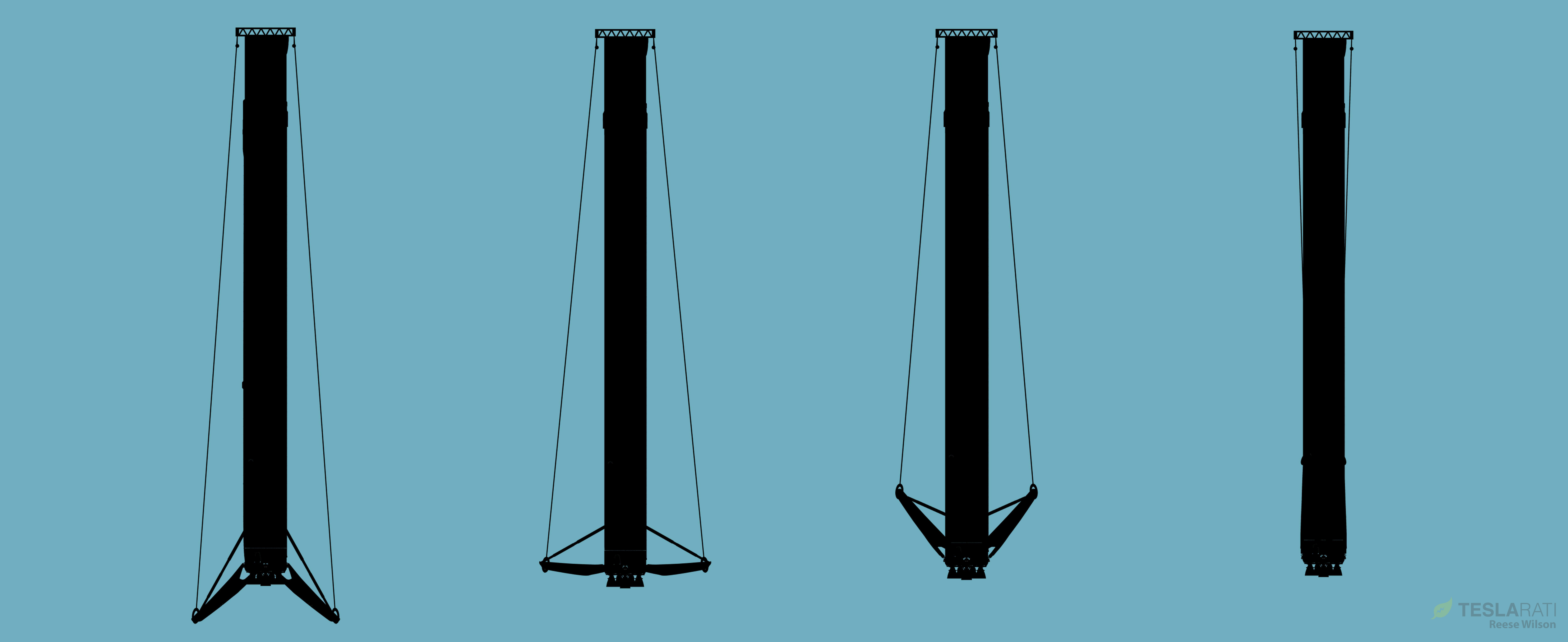

Given the dramatic changes implemented in Block 5 and the pathfinder nature of these new boosters, SpaceX has spent much of the following time conducting tests and extensive analyses to verify new designs and new technology, ranging from teardowns to tests of specific components like landing legs on a recently-recovered East Coast booster.

Most prominently on that to-do list was a deep-dive teardown of inaugural Block 5 booster B1046, which was apparently completed within the last week or so – as evidenced by the sooty booster’s appearance at SpaceX’s Cape Canaveral Launch Complex 40 (LC-40) around July 24th. The purpose of that teardown was to give most of Falcon 9’s many thousands of individual and critical components a thorough examination, particularly those parts most impacted and worn by launch, reentry, and landing. That most likely includes B1046’s black octaweb and interstage thermal protection, its nine upgraded Merlin 1D engines, the “dance floor” heatshield at the rocket’s base, and landing legs, among myriad other smaller aspects.

More recently (July 27 and 28), SpaceX technicians attempted and completed the first retraction of a Block 5 booster landing leg (B1047 in Port Canaveral, Florida), compared with the current practice of removing both the landing legs and booms before rotating the recovered rocket horizontal and transporting it to a nearby refurbishment facility. Briefly discussed by CEO Elon Musk, Block 5 includes a number of landing leg optimizations, intended to improve robustness, increase reliability, and significantly ease reuse.

“So essentially deploying the landing gear and stowing the landing gear is now a very easy thing to do [on Block 5 boosters], whereas previously it required several hours to re-stow the landing gear. Which can now be done with an actuator, pretty easily.”

Given the fact that it took a full day to prepare for the retraction of the first leg and that the task appears to be accomplished with a fairly complex and manual lifting mechanism requiring several workers to function, it’s possible that the retraction and leg hardware described by Musk is still undergoing some form of testing or production optimization before being added to flight hardware. Nevertheless, photographer and journalist Ken Kremer observed the retraction sequence from start to finish (movement-wise) and pegged it at around 40 minutes total to go from fully deployed to fully stowed.

4 shot sequence:1st time ever #Falcon9 landing leg retracted from recovered @SpaceX 1ststage booster-using cables & pulleys pulling left leg from cap apparatus on top, flush to side, techs assist.took 40min 7/27. #Block5 #Telstar19V launch.Cred:@ken_kremer https://t.co/G4fyocB13Q pic.twitter.com/RPbgT8LdKf

— Ken Kremer🇺🇦🇩🇪🇺🇸🚀🧪 (@ken_kremer) July 27, 2018

In all fairness, truly rapid and near-automatic leg retraction would only be of value to SpaceX once the company needs to refly Falcon 9 with less than a week or two between launches, at which point spending a day or two carefully removing or stowing landing legs outweighs the cost of adding highly specific hardware useless during flight (and thus stealing mass that could otherwise be fuel for a gentler booster recovery or a higher payload orbit).

Keeping as much of that leg retraction hardware on the ground as possible thus makes a lot of sense in today’s launch industry, where SpaceX simply has no material need for near-automatic, internally-actuated leg retraction on Falcon 9 (only necessary for extremely rapid turnaround). Still, if the company hopes to achieve Musk’s 24-hour booster turnaround challenge by the end of 2019, SpaceX technicians and engineers will need to have a solution in place to retract Falcon 9’s landing legs as quickly as practically possible – every minute will count for such a rapid reuse.

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet (including fairing catcher Mr Steven) check out our brand new LaunchPad and LandingZone newsletters!

Elon Musk

Starlink restrictions are hitting Russian battlefield comms: report

The restrictions have reportedly disrupted Moscow’s drone coordination and frontline communications.

SpaceX’s decision to disable unauthorized Starlink terminals in Ukraine is now being felt on the battlefield, with Ukrainian commanders reporting that Russian troops have struggled to maintain assault operations without access to the satellite network.

The restrictions have reportedly disrupted Moscow’s drone coordination and frontline communications.

Lt. Denis Yaroslavsky, who commands a special reconnaissance unit, stated that Russian assault activity noticeably declined for several days after the shutdown. “For three to four days after the shutdown, they really reduced the assault operations,” Yaroslavsky said.

Russian units had allegedly obtained Starlink terminals through black market channels and mounted them on drones and weapons systems, despite service terms prohibiting offensive military use. Once those terminals were blocked, commanders on the Ukrainian side reported improved battlefield ratios, as noted in a New York Post report.

A Ukrainian unit commander stated that casualty imbalances widened after the cutoff. “On any given day, depending on your scale of analysis, my sector was already achieving 20:1 (casuality rate) before the shutdown, and we are an elite unit. Regular units have no problem going 5:1 or 8:1. With Starlink down, 13:1 (casualty rate) for a regular unit is easy,” the unit commander said.

The restrictions come as Russia faces heavy challenges across multiple fronts. A late January report from the Center for Strategic and International Studies estimated that more than 1.2 million Russian troops have been killed, wounded, or gone missing since February 2022.

The Washington-based Institute for the Study of War also noted that activity from Russia’s Rubikon drone unit declined after Feb. 1, suggesting communications constraints from Starlink’s restrictions may be limiting operations. “I’m sure the Russians have (alternative options), but it takes time to maximize their implementation and this (would take) at least four to six months,” Yaroslavsky noted.

Elon Musk

Tesla Korea hiring AI Chip Engineers amid push for high-volume AI chips

Tesla Korea stated that it is seeking “talented individuals to join in developing the world’s highest-level mass-produced AI chips.”

In a recent post on X, Tesla Korea announced that it is hiring AI Chip Design Engineers as part of a project aimed at developing what the company describes as the world’s highest-volume AI chips. CEO Elon Musk later amplified the initiative.

Tesla Korea stated that it is seeking “talented individuals to join in developing the world’s highest-level mass-produced AI chips.”

“This project aims to develop AI chip architecture that will achieve the highest production volume in the world in the future,” Tesla Korea wrote in its post on X.

As per Tesla Korea, those who wish to apply for the AI Chip Design Engineer post should email Ai_Chips@Tesla.com and include “the three most challenging technical problems you have solved.”

Elon Musk echoed the hiring push in a separate post. “If you’re in Korea and want to work on chip design, fabrication or AI software, join Tesla!” he wrote.

The recruitment effort in South Korea comes as Tesla accelerates development of its in-house AI chips, which power its Full Self-Driving (FSD) system, Optimus humanoid robot, and data center training infrastructure.

Tesla has been steadily expanding its silicon development teams globally. In recent months, the company has posted roles in Austin and Palo Alto for silicon module process engineers across lithography, etching, and other chip fabrication disciplines, as noted in a Benzinga report.

Tesla Korea’s hiring efforts align with the company’s long-term goal of designing and producing AI chips at massive scale. Musk has previously stated that Tesla’s future AI chips could become the highest-volume AI processors in the world.

The move also comes amid Tesla’s broader expansion into AI initiatives. The company recently committed about $2 billion into xAI as part of a Series E funding round, reinforcing its focus on artificial intelligence across vehicles, robotics, and compute infrastructure.

Elon Musk

SpaceX and xAI tapped by Pentagon for autonomous drone contest

The six-month competition was launched in January and is said to carry a $100 million award.

SpaceX and its AI subsidiary xAI are reportedly competing in a new Pentagon prize challenge focused on autonomous drone swarming technology, as per a report from Bloomberg News.

The six-month competition was launched in January and is said to carry a $100 million award.

Bloomberg reported that SpaceX and xAI are among a select group invited to participate in the Defense Department’s effort to develop advanced drone swarming capabilities. The goal is reportedly to create systems that can translate voice commands into digital instructions and manage fleets of autonomous drones.

Neither SpaceX, xAI, nor the Pentagon’s Defense Innovation Unit has commented on the report, and Reuters said it could not independently verify the details.

The development follows SpaceX’s recent acquisition of xAI, which pushed the valuation of the combined companies to an impressive $1.25 trillion. The reported competition comes as SpaceX prepares for a potential initial public offering later this year.

The Pentagon has been moving to speed up drone deployment and expand domestic manufacturing capacity, while also seeking tools to counter unauthorized drone activity around airports and major public events. Large-scale gatherings scheduled this year, including the FIFA World Cup and America250 celebrations, have heightened focus on aerial security.

The reported challenge aligns with broader Defense Department investments in artificial intelligence. Last year, OpenAI, Google, Anthropic, and xAI secured Pentagon contracts worth up to $200 million each to advance AI capabilities across defense applications.

Elon Musk previously joined AI and robotics researchers in signing a 2015 open letter calling for a ban on offensive autonomous weapons. In recent years, however, Musk has spoken on X about the strengths of drone technologies in combat situations.