News

SpaceX’s next Falcon Heavy launch may feature record-breaking center core landing

Thanks to a temporary reopening of the US federal government, SpaceX was finally able to continue the process of filing FCC and FAA paperwork needed to acquire permits for upcoming launches, including Falcon Heavy.

One such filing related to the first operational Falcon Heavy launch has revealed a fairly impressive statistic: comprised of three first stage boosters, SpaceX indicated that Falcon Heavy’s center core will attempt to land on drone ship Of Course I Still Love You (OCISLY) nearly 1000 km (600 mi) away from its launch site, easily smashing the record for the greatest distance traveled by a Falcon booster in flight.

Of Course I Still Love You will be positioned a record ~965km downrange. That's nearly 300km further that the previous greatest distance of 681km, set during the Eutelsat-117WB mission in June 2016. (The landing was a failure, with the booster running out of LOX!) https://t.co/RECKjMtd37

— Gav Cornwell (@SpaceOffshore) January 28, 2019

The same FCC filings also revealed a No Earlier Than (NET) launch date: March 7, 2019. Originally targeted for mid to late February, the complexity and logistical challenges of building, shipping, testing, and delivering two side boosters, a center core, one upper stage, and a payload fairing from SpaceX’s California factory to its Texas test facilities and Florida launch pad unsurprisingly took a small toll on the launch’s aspirational schedule. Nevertheless, if the launch data actually holds to March 7th, SpaceX will not have missed the mark by much considering that this Falcon Heavy – based on new and more powerful Block 5 boosters – is likely a significant departure from the Block 2/Block 3 hardware that has flight heritage from the triple-booster rocket’s Feb. 2018 launch debut.

Just shy of a year after Falcon Heavy’s launch debut, it appears that the rocket’s second and third launches were pushed back by a fundamental lack of production capacity. In other words, SpaceX’s Hawthorne rocket factory simply had to focus on more critical priorities in the 6-9 months that followed the demo mission. At nearly the same time as Falcon Heavy was lifting off for the first time, SpaceX’s world-class production crew was in the midst of manufacturing the first upgraded Falcon 9 Block 5 booster (B1046) and wrapped up final checkouts just 10 days after Heavy’s Feb. 6 launch debut, sending the pathfinder rocket to McGregor, Texas for the first static fire of a Block 5 booster.

In the meantime, SpaceX’s decision to intentionally expend otherwise recoverable reused Falcon boosters after their second launches meant that the company’s fleet of flightworthy rockets was rapidly approaching zero, a move CEO Elon Musk specifically indicated was meant to make room for Block 5, the future (and final form) of the Falcon family. SpaceX’s busy 2018 launch manifest and multiple critical missions for the US government were thus balanced on the success, reliability, and rapid production of a serious number of Merlin engines, boosters, and upper stages. This included B1051 – the first explicitly crew-rated Falcon 9 – and B1054, the first SpaceX rocket rated to launch high-value US military (specifically Air Force) satellites. However, SpaceX also needed to produce a cadre of Falcon 9 boosters capable of easy reuse to support the dozen or so other commercial launches on the manifest.

- Falcon 9 B1046 is processed in Port of LA shortly after its third successful launch and landing, December 2018. (Pauline Acalin)

- Falcon 9 B1047 is pictured here beneath an upper stage and satellite Es’hail-2 prior to its second launch. (Tom Cross)

- Falcon 9 B1048 returned to Port of Los Angeles aboard drone ship Just Read The Instructions after its first launch. July 27. (Pauline Acalin)

- Falcon 9 B1049 returned to Port of Los Angeles after its second successful launch and landing in four months. (Pauline Acalin)

- Falcon 9 B1050 is seen here just after liftoff. GPS III SV01’s Falcon 9 will feature no grid fins or landing legs. ☹ (Tom Cross)

- Falcon 9 B1051 and Crew Dragon vertical at Pad 39A. (SpaceX)

That gamble ultimately paid off, with Block 5 performing admirably and supporting a reasonable – if not record-breaking – rate of reuse. SpaceX successfully launched B1054 for the USAF, completed B1051 (now at Pad 39A awaiting NASA’s go-ahead), and built enough reusable Block 5 boosters to support nine additional commercial missions in 2018. In hindsight, barring an assumption of a truly miraculous and unprecedented Falcon booster production rate, Falcon Heavy’s next launches were almost guaranteed to occur no fewer than 6-12 months after the rocket’s launch debut – SpaceX’s entire launch business depended on building 5+ unrelated Falcon 9 boosters, while Falcon Heavy customers Arabsat and the USAF were unlikely to be swayed to launch on flight-proven hardware so early into Block 5’s career.

https://twitter.com/_TomCross_/status/1048483536917823488

All cylinders firing

Once Falcon 9 B1054 departed SpaceX’s Hawthorne factory (see above) in early October, it appears that the company’s production team pivoted directly to integrating and shipping the next three (or more) Falcon Heavy boosters back to back for the rocket’s second and third launches. The first new side booster departed the factory in mid-November, followed by a second side booster in early December and a (presumed but highly likely) center core at the turn of 2019. Both side boosters have been static-fired in Texas and are now at SpaceX’s Florida facilities, while the center core either just completed its Texas static fire testing or is already on its way East.

- SpaceX’s Falcon Heavy Block 5 side booster is pictured here in Texas in November 2018. (Teslarati/Aero Photo)

- The second (and third) flight of Falcon Heavy is even closer to reality as a new side booster heads to Florida after finishing static fire tests in Texas. (Reddit /u/e32revelry)

- SpaceX Facebook group member Joshua Murrah captured the second Falcon Heavy side booster to arrive in Florida in the last month. (Joshua Murrah, 01/17/19)

- The next Falcon Heavy’s first side booster delivery was caught by several onlookers around December 21. (Instagram)

- A booster – likely the next Falcon Heavy center core – was vertical at McGregor’s S1 static fire stand. (Instagram /u/tcryguy)

- A booster – either Falcon Heavy’s next center core or a new Falcon 9 – was vertical at SpaceX’s McGregor, TX test facilities on Jan 28. (Instagram /u/n75sd)

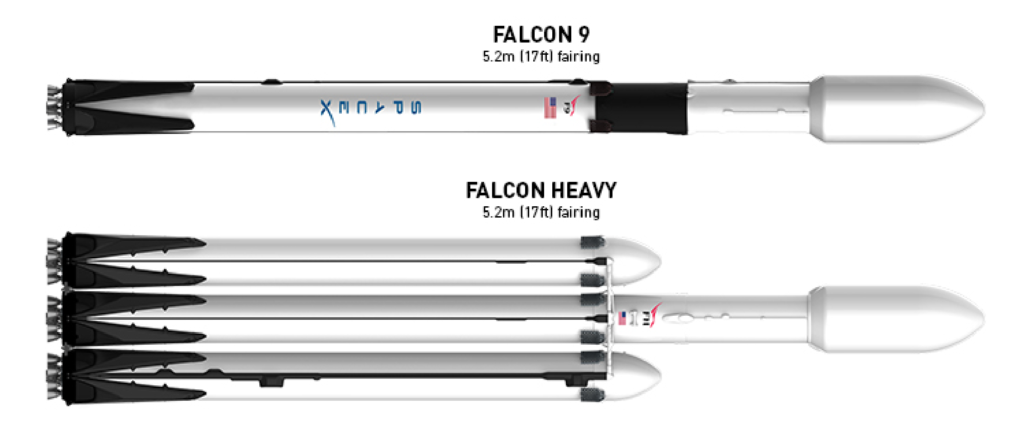

- A diagram from a recent SpaceX document offers an idea of what Falcon Heavy Block 5 will look like. (SpaceX)

Once the center core and upper stage make their way to SpaceX’s Kennedy Space Center Pad 39A, the company’s technicians and engineers will be able to integrate the second Falcon Heavy to have ever existed in preparation for a critical static fire test. That could occur as early as February, although the launch debut of Crew Dragon (DM-1) – now NET March from Pad 39A after a relentless string of slips – will likely take precedence over Falcon Heavy and could thus directly interfere with its launch, as the launch pad and transporter/erector (T/E) has to undergo at least a few days of modifications to switch between Falcon 9 and Heavy.

Regardless, the next two Falcon Heavy launches will be well worth the wait. SpaceX’s FCC filings indicate that the center core may travel nearly 1000 km (600 mi) East of Pad 39A to land on drone ship OCISLY after launch, smashing the previous record attempt – during the June 2016 launch of Eutelsat 117WB – of ~700 km (430 mi). That Falcon 9 booster – albeit a less-powerful Block 2 variant – was unsuccessful in its landing attempt, running out of oxidizer seconds before landing. Falcon Heavy’s debut center core also happened to suffer a wholly different but no less fatal anomaly during landing, causing it to miss the drone ship and slam into the Atlantic Ocean at almost half the speed of sound (300 mph/480 km/h).

Looks like early liquid oxygen depletion caused engine shutdown just above the deck pic.twitter.com/Sa6uCkpknY

— Elon Musk (@elonmusk) June 17, 2016

Known for their rocket performance estimates, NASASpaceflight forum user “Orbiter” first pointed out the impressive distance – gathered by mapping coordinates included in SpaceX’s Jan. 28th FCC filing – and estimated that the Falcon Heavy center booster flying a trajectory as implied could be traveling as fast as ~3.5 km/s (2.2 mi/s) at main engine cut-off (MECO), the point at which the booster separates from the upper stage and fairing. This would be a nearly unprecedented velocity for any Falcon booster, let alone a booster with plans to land after launch. Falcon 9 MECO typically occurs at velocities between 1.5 and 2.5 km/s for recoverable missions, while even the recent expendable GPS III launch saw F9 S1’s engines cut off around 2.7 km/s.

Whether that MECO velocity estimate is correct, Falcon Heavy’s NET March launch of the ~6000 kg (13,300 lb) Arabsat 6A satellite is likely to be an exceptionally hot reentry and recovery for the center core, while the rocket’s duo of side boosters will attempt a repeat of the debut mission’s spectacular double-landing at LZ-1.

News

These Tesla, X, and xAI engineers were just poached by OpenAI

The news is the latest in an ongoing feud between Elon Musk and the Sam Altman-run firm OpenAI.

OpenAI, the xAI competitor for which Elon Musk previously served as a boardmember and helped to co-found, has reportedly poached high-level engineers from Tesla, along with others from xAI, X, and still others.

On Tuesday, Wired reported that OpenAI hired four high-level engineers from Tesla, xAI, and X, as seen in an internal Slack message sent by co-founder Greg Brockman. The engineers include Tesla Vice President of Software Engineering David Lau, X and xAI’s head of infrastructure engineering Uday Ruddarraju, and fellow xAI infrastructure engineer Mike Dalton. The hiring spree also included Angela Fan, an AI researcher from Meta.

“We’re excited to welcome these new members to our scaling team,” said Hannah Wong, an OpenAI spokesperson. “Our approach is to continue building and bringing together world-class infrastructure, research, and product teams to accelerate our mission and deliver the benefits of AI to hundreds of millions of people.”

Lau has been in his position as Tesla’s VP of Software Engineering since 2017, after previously working for the company’s firmware, platforms, and system integration divisions.

“It has become incredibly clear to me that accelerating progress towards safe, well-aligned artificial general intelligence is the most rewarding mission I could imagine for the next chapter of my career,” Lau said in a statement to Wired.

🚨Optimistic projections point to xAI possibly attaining profitability by 2027, according to Bloomberg's sources.

If accurate, this would be quite a feat for xAI. OpenAI, its biggest rival, is still looking at 2029 as the year it could become cash flow positive.💰 https://t.co/pE5Z9daez8

— TESLARATI (@Teslarati) June 18, 2025

READ MORE ON OPENAI: Elon Musk’s OpenAI lawsuit clears hurdle as trial looms

At xAI, Ruddarraju and Dalton both played a large role in developing the Colossus supercomputer, which is comprised of over 200,000 GPUs. One of the major ongoing projects at OpenAI is the company’s Stargate program,

“Infrastructure is where research meets reality, and OpenAI has already demonstrated this successfully,” Ruddarraju told Wired in another statement. “Stargate, in particular, is an infrastructure moonshot that perfectly matches the ambitious, systems-level challenges I love taking on.”

Elon Musk is currently in the process of suing OpenAI for shifting toward a for-profit model, as well as for accepting an investment of billions of dollars from Microsoft. OpenAI retaliated with a counterlawsuit, in which it alleges that Musk is interfering with the company’s business and engaging in unfair competition practices.

Elon Musk confirms Grok 4 launch on July 9 with livestream event

News

SpaceX share sale expected to back $400 billion valuation

The new SpaceX valuation would represent yet another record-high as far as privately-held companies in the U.S. go.

A new report this week suggests that Elon Musk-led rocket company SpaceX is considering an insider share sale that would value the company at $400 billion.

SpaceX is set to launch a primary fundraising round and sell a small number of new shares to investors, according to the report from Bloomberg, which cited people familiar with the matter who asked to remain anonymous due to the information not yet being public. Additionally, the company would sell shares from employees and early investors in a follow-up round, while the primary round would determine the price for the secondary round.

The valuation would represent the largest in history from a privately-owned company in the U.S., surpassing SpaceX’s previous record of $350 billion after a share buyback in December. Rivaling company valuations include ByteDance, the parent company of TikTok, as well as OpenAI.

Bloomberg went on to say that a SpaceX representative didn’t respond to a request for comment at the time of publishing. The publication also notes that the details of such a deal could still change, especially depending on interest from the insider sellers and share buyers.

Axiom’s Ax-4 astronauts arriving to the ISS! https://t.co/WQtTODaYfj

— TESLARATI (@Teslarati) June 26, 2025

READ MORE ON SPACEX: SpaceX to decommission Dragon spacecraft in response to Pres. Trump war of words with Elon Musk

SpaceX’s valuation comes from a few different key factors, especially including the continued expansion of the company’s Starlink satellite internet company. According to the report, Starlink accounts for over half of the company’s yearly revenue. Meanwhile, the company produced its 10 millionth Starlink kit last month.

The company also continues to develop its Starship reusable rocket program, despite the company experiencing an explosion of the rocket on the test stand in Texas last month.

The company has also launched payloads for a number of companies and government contracts. In recent weeks, SpaceX launched Axiom’s Ax-4 mission, sending four astronauts to the International Space Station (ISS) for a 14-day stay to work on around 60 scientific experiments. The mission was launched using the SpaceX Falcon 9 rocket and a new Crew Dragon capsule, while the research is expected to span a range of fields including biology, material and physical sciences, and demonstrations of specialized technology.

News

Tesla Giga Texas continues to pile up with Cybercab castings

Tesla sure is gathering a lot of Cybercab components around the Giga Texas complex.

Tesla may be extremely tight-lipped about the new affordable models that it was expected to start producing in the first half of the year, but the company sure is gathering a lot of Cybercab castings around the Giga Texas complex. This is, at least, as per recent images taken of the facility.

Cybercab castings galore

As per longtime drone operator Joe Tegtmeyer, who has been chronicling the developments around the Giga Texas complex for several years now, the electric vehicle maker seems to be gathering hundreds of Cybercab castings around the factory.

Based on observations from industry watchers, the drone operator appears to have captured images of about 180 front and 180 rear Cybercab castings in his recent photos.

Considering the number of castings that were spotted around Giga Texas, it would appear that Tesla may indeed be preparing for the vehicle’s start of trial production sometime later this year. Interestingly enough, large numbers of Cybercab castings have been spotted around the Giga Texas complex in the past few months.

Cybercab production

The Cybercab is expected to be Tesla’s first vehicle that will adopt the company’s “unboxed” process. As per Tesla’s previous update letters, volume production of the Cybercab should start in 2026. So far, prototypes of the Cybercab have been spotted testing around Giga Texas, and expectations are high that the vehicle’s initial trial production should start this year.

With the start of Tesla’s dedicated Robotaxi service around Austin, it might only be a matter of time before the Cybercab starts being tested on public roads as well. When this happens, it would be very difficult to deny the fact that Tesla really does have a safe, working autonomous driving system, and it has the perfect vehicle for it, too.

-

Elon Musk1 week ago

Elon Musk1 week agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News2 weeks ago

News2 weeks agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

Elon Musk1 day ago

Elon Musk1 day agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News2 weeks ago

News2 weeks agoWatch the first true Tesla Robotaxi intervention by safety monitor

-

News5 days ago

News5 days agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI welcomes Memphis pollution results, environmental groups push back

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk confirms Tesla Optimus V3 already uses Grok voice AI